Bored and tired of watching 55mph winds blowing trees down all day, I figured I'd finally take a crack at the STB issue I have had ever since I finished up adding FRPP's 2.9 Whipple kit. This wasn't something I've lost sleep over as the car was fine without it. I just don't like stopping at a perceived dead end when I know there is always another way.

That said, I pondered finding another STB for raw material (if necessary) and found that Shleppy American was selling take-off units for $15 plus shipping. I've had the extra bar for half a year now as well as the original bar laying around for a year or so. So I started yesterday afternoon by laying both out on some horses.

So I stood there and stared at them brainstorming as to the best way to come up with one bar that would clear everything, not be compromised, and not look like ass. Cut in the middle...cut each end...splice here...or there...then I knew. After taking some quick measurements, I saw that I could simply cut the end bracket off the driver side, tweak the bar and bracket, then re-weld. The bar would not have as much surface area at the point of fusion when welded to the bracket (it gets effectively shorter when bent more than it already was) but I had an idea there too.

Anyhoo, I picked one of the two and plugged in my cheap ass Dremel, armed with a little zip cutting wheel. The idea was to cut the factory welds off and free the STB of the bracket on the driver side.

Big brother stopped by for cleanup duty...

To better illustrate the geometry issue the Whipple CAI kit causes with the factory POS brace, I removed the two inner strut tower nuts from their respective studs (on each strut) and laid the bar into place. With the bracket fitting on the passenger side, this is what the driver side looked like...

The bar is simply not contoured correctly, necessitating tweakage. The bracket needs to be reworked as well so that it can be more upright.

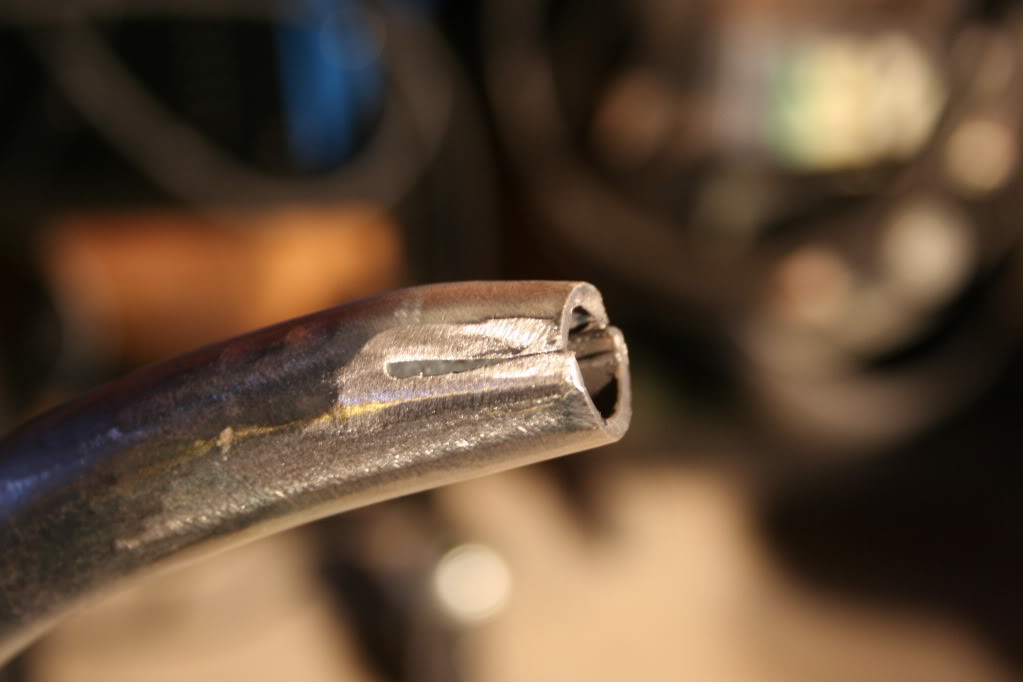

I clamped the bracket to a steel table, made two parallel slices (one on each side of the 'raised' portion where the bar used to be welded to) and started blacksmithing. I reshaped the bar using a number of techniques, taking my time to check fitment on the car with each bend. I found that I needed to narrow down the last inch or so of the bar in order to get the fit I wanted which I accomplished by cutting a slice through the end of the bar, flattening, then re-welding.

I took my time welding with some mild steel filler in conjunction with Thoriated Tungsten in my TIG torch and then hit it with a sanding disc. You'd never know...

With fit-up mostly complete, I disconnected the battery on the car (as well as the PCM) and laid everything in place and tacked the assembly together.

If you look closely at the next shot you can see one of the vertical slices I cut into the bracket so that I could bend it upward. I just wanted to tack at this point then remove everything and weld it up completely up on the table.

A clear shot that allows you to see how I had to rework the chromoly tubing to fit around the CAI ducting.

I spent quite a bit of time welding everything back up. It took a while using a TIG torch (my MIG would have been faster) but I wanted to minimize the heat into the bar near the bend I made. I then laid the welded up piece into place - it fit well.

I now have ~3/8" clearance between the STB and the intake tube. I primed it up this afternoon, painted it tonight, and will have it in place tomorrow.

Not a total waste of time but I will admit, this was a time consuming pain in the ass. I wanted to get away from stationary table welding with a TIG torch and this project allowed me to at least practice some out of position welding as well as trying to work the Tungsten into some tight spots. It was good practice. I'll follow up with some installed shots when the paint cures.

Tob

That said, I pondered finding another STB for raw material (if necessary) and found that Shleppy American was selling take-off units for $15 plus shipping. I've had the extra bar for half a year now as well as the original bar laying around for a year or so. So I started yesterday afternoon by laying both out on some horses.

So I stood there and stared at them brainstorming as to the best way to come up with one bar that would clear everything, not be compromised, and not look like ass. Cut in the middle...cut each end...splice here...or there...then I knew. After taking some quick measurements, I saw that I could simply cut the end bracket off the driver side, tweak the bar and bracket, then re-weld. The bar would not have as much surface area at the point of fusion when welded to the bracket (it gets effectively shorter when bent more than it already was) but I had an idea there too.

Anyhoo, I picked one of the two and plugged in my cheap ass Dremel, armed with a little zip cutting wheel. The idea was to cut the factory welds off and free the STB of the bracket on the driver side.

Big brother stopped by for cleanup duty...

To better illustrate the geometry issue the Whipple CAI kit causes with the factory POS brace, I removed the two inner strut tower nuts from their respective studs (on each strut) and laid the bar into place. With the bracket fitting on the passenger side, this is what the driver side looked like...

The bar is simply not contoured correctly, necessitating tweakage. The bracket needs to be reworked as well so that it can be more upright.

I clamped the bracket to a steel table, made two parallel slices (one on each side of the 'raised' portion where the bar used to be welded to) and started blacksmithing. I reshaped the bar using a number of techniques, taking my time to check fitment on the car with each bend. I found that I needed to narrow down the last inch or so of the bar in order to get the fit I wanted which I accomplished by cutting a slice through the end of the bar, flattening, then re-welding.

I took my time welding with some mild steel filler in conjunction with Thoriated Tungsten in my TIG torch and then hit it with a sanding disc. You'd never know...

With fit-up mostly complete, I disconnected the battery on the car (as well as the PCM) and laid everything in place and tacked the assembly together.

If you look closely at the next shot you can see one of the vertical slices I cut into the bracket so that I could bend it upward. I just wanted to tack at this point then remove everything and weld it up completely up on the table.

A clear shot that allows you to see how I had to rework the chromoly tubing to fit around the CAI ducting.

I spent quite a bit of time welding everything back up. It took a while using a TIG torch (my MIG would have been faster) but I wanted to minimize the heat into the bar near the bend I made. I then laid the welded up piece into place - it fit well.

I now have ~3/8" clearance between the STB and the intake tube. I primed it up this afternoon, painted it tonight, and will have it in place tomorrow.

Not a total waste of time but I will admit, this was a time consuming pain in the ass. I wanted to get away from stationary table welding with a TIG torch and this project allowed me to at least practice some out of position welding as well as trying to work the Tungsten into some tight spots. It was good practice. I'll follow up with some installed shots when the paint cures.

Tob

Last edited: