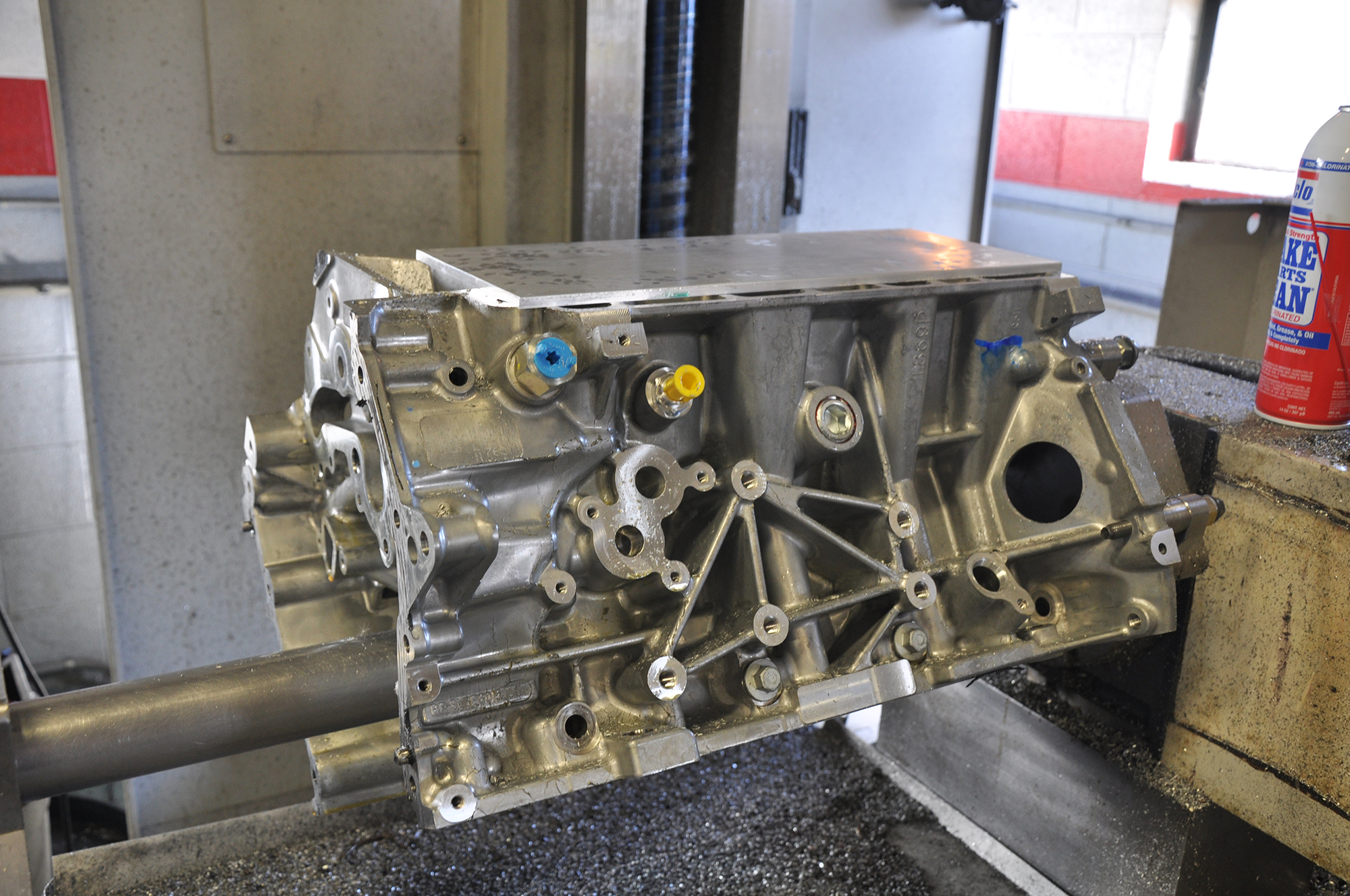

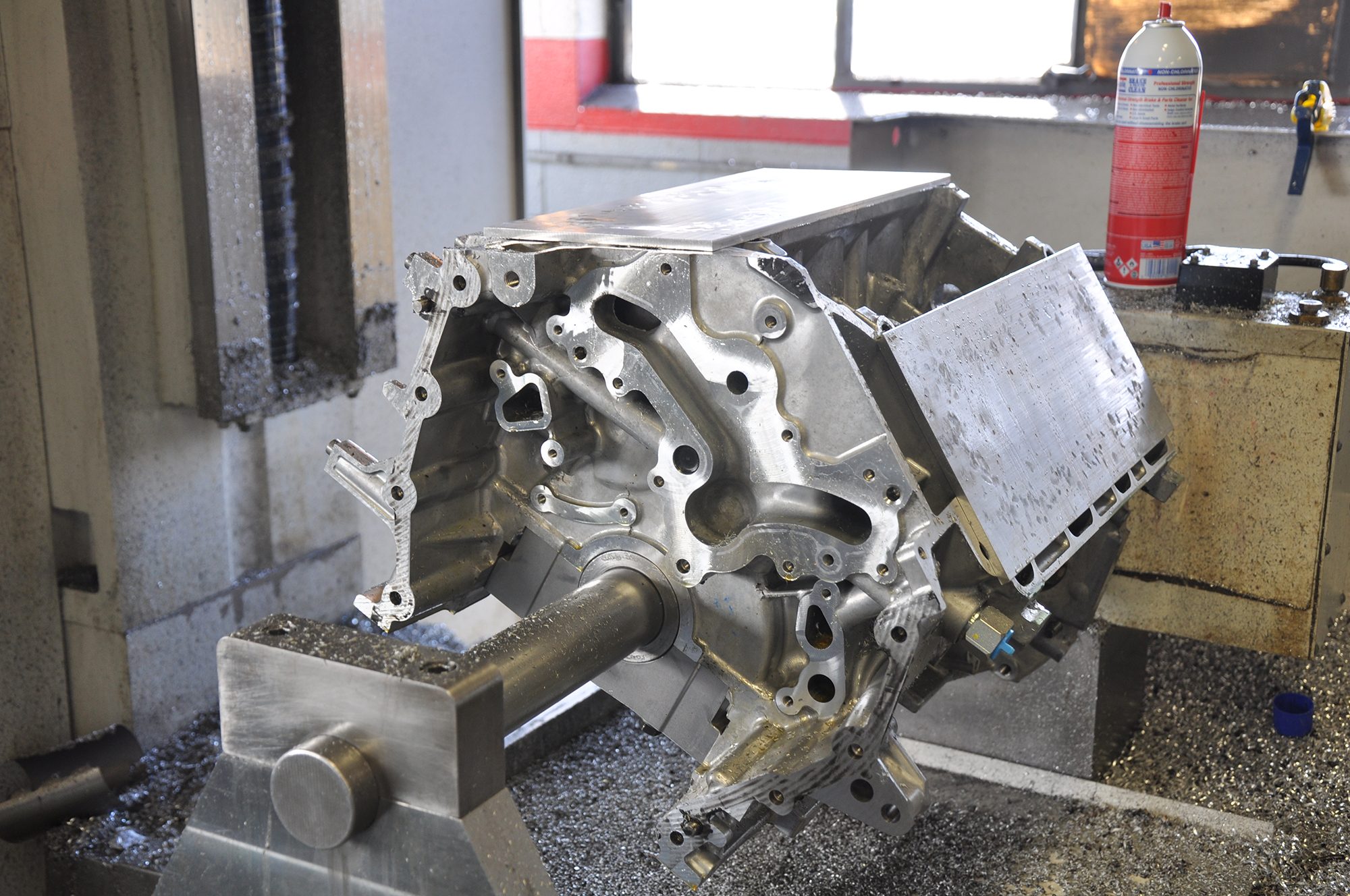

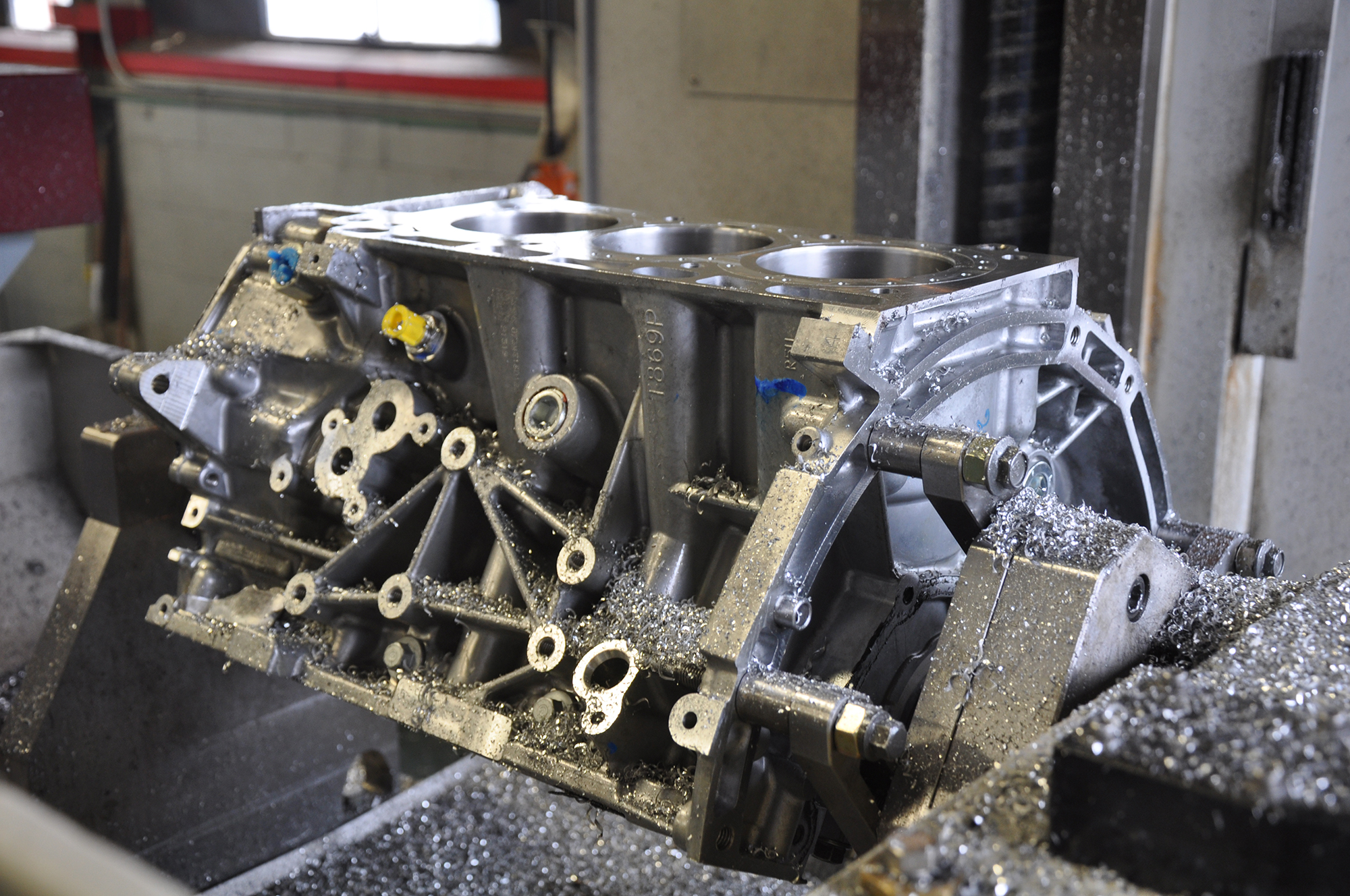

The first deck is in! After the press fit is complete, we will rotate the block to the other side. At that time, we will cut the block for a shelf and add the second deck brace.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Livernois Motorsports Powerstorm 3.5L Race Series Engine Build!

- Thread starter Livernois Motorsports

- Start date

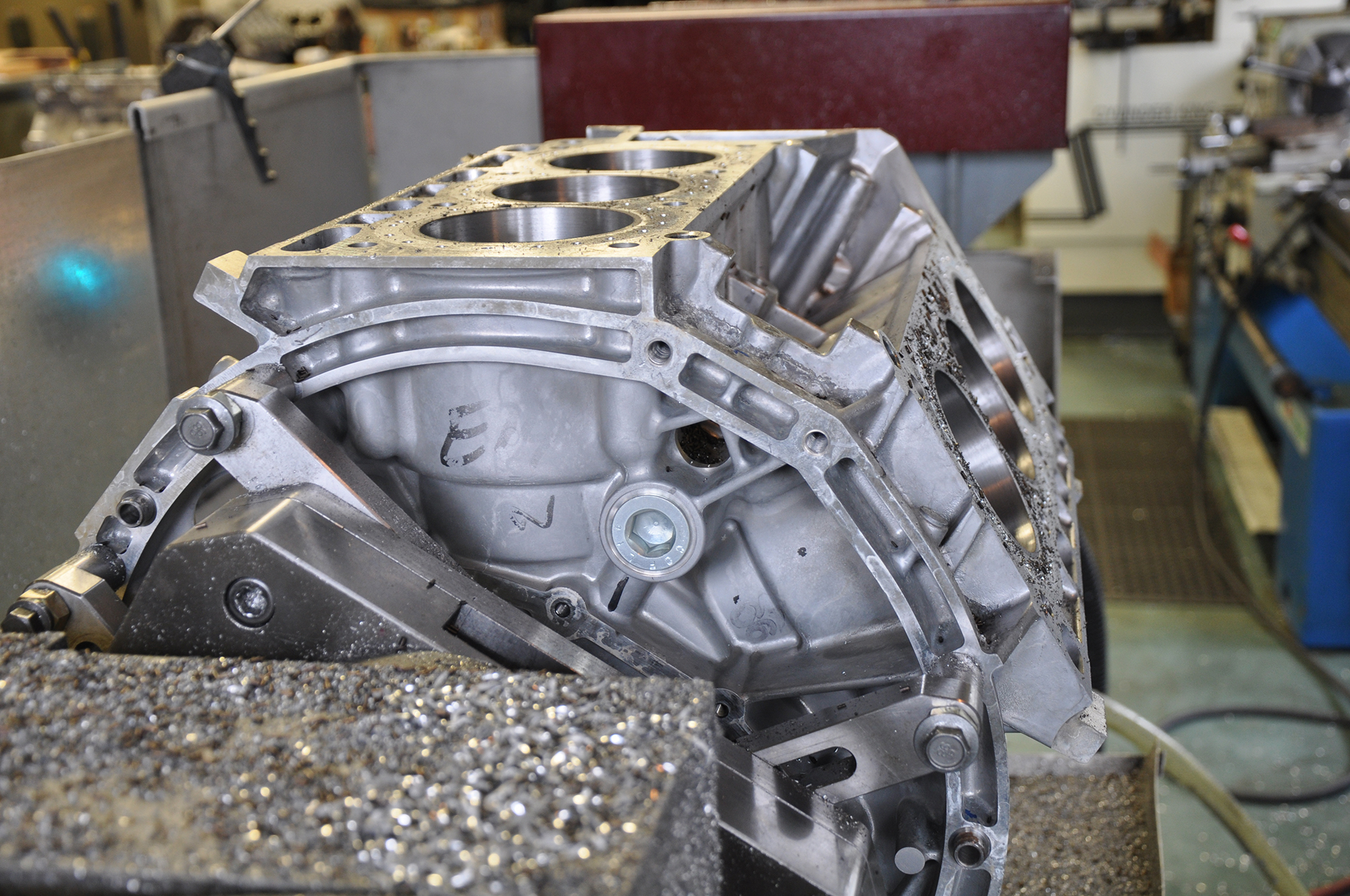

Deck number 2 is in with a little help from some Permatex high temp sleeve retainer to stay locked in place for the cutting phases.

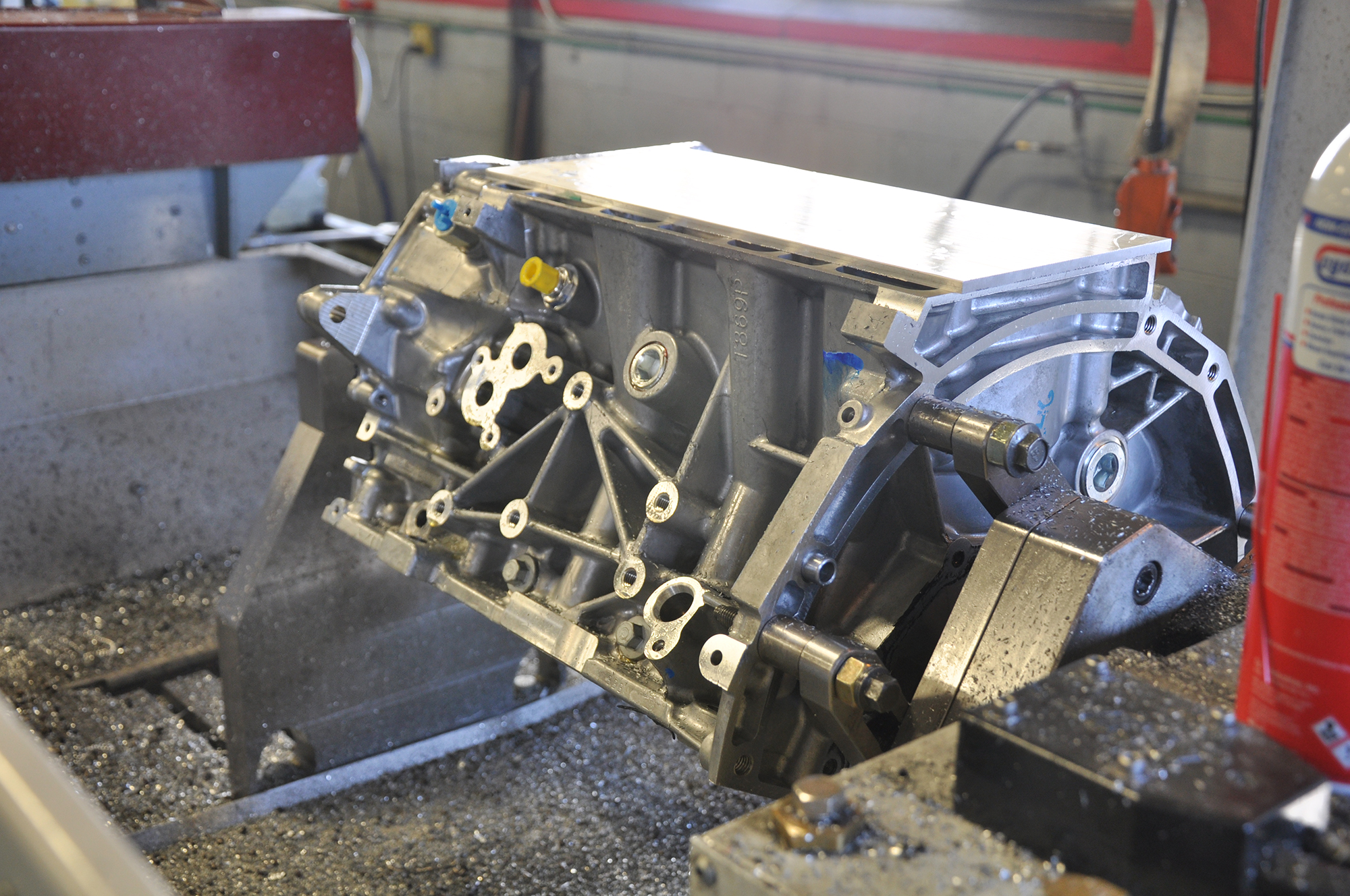

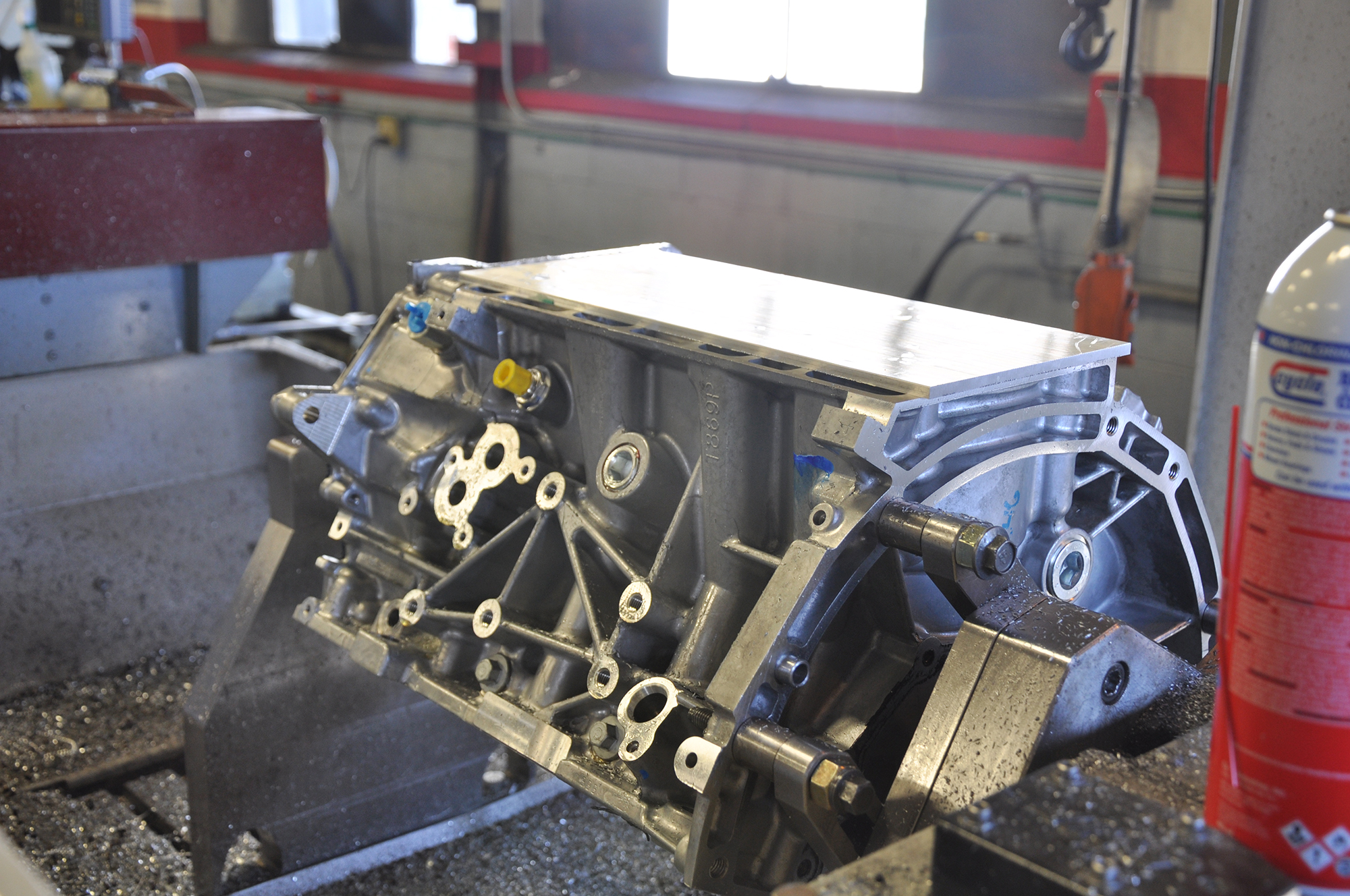

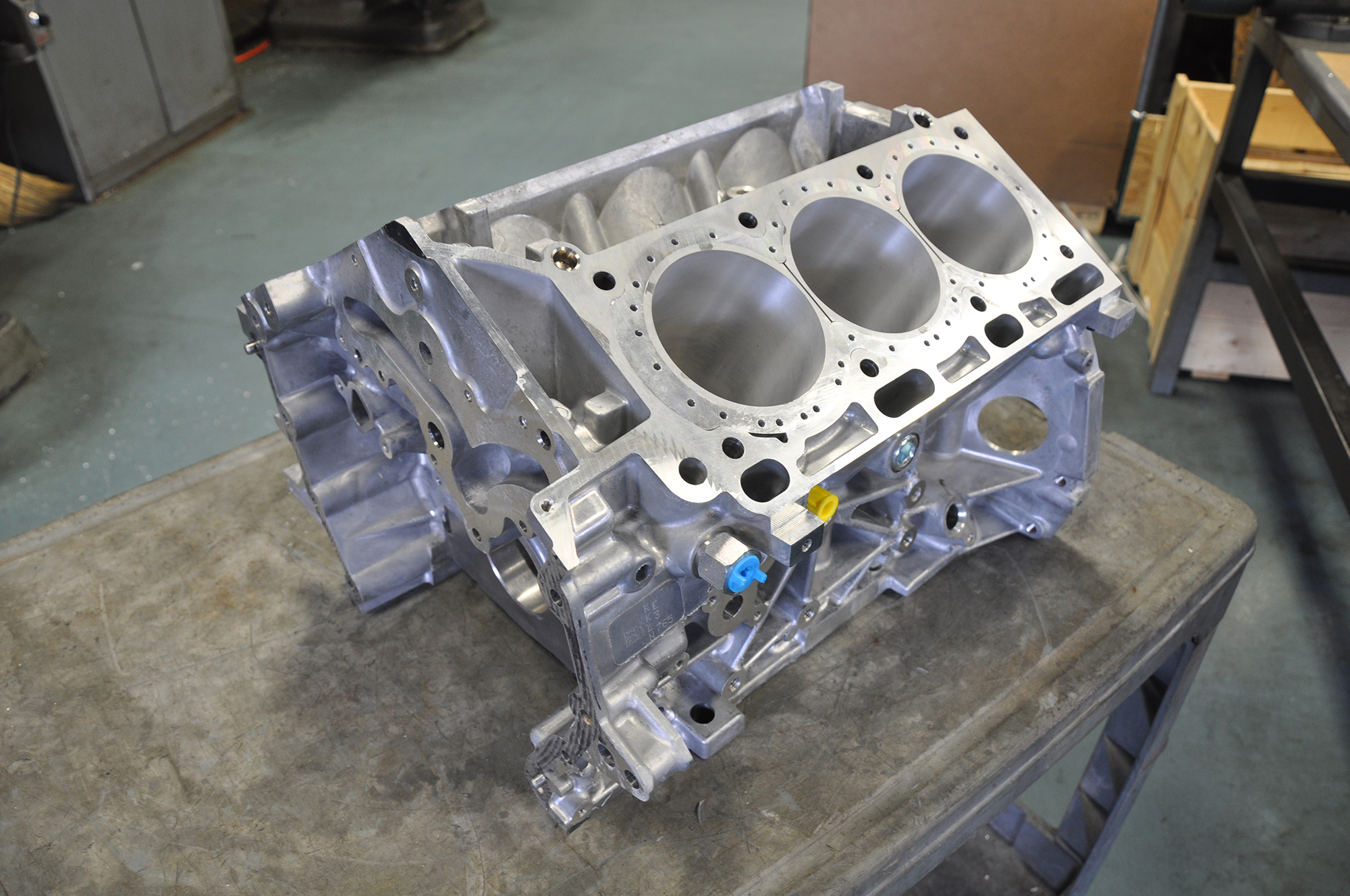

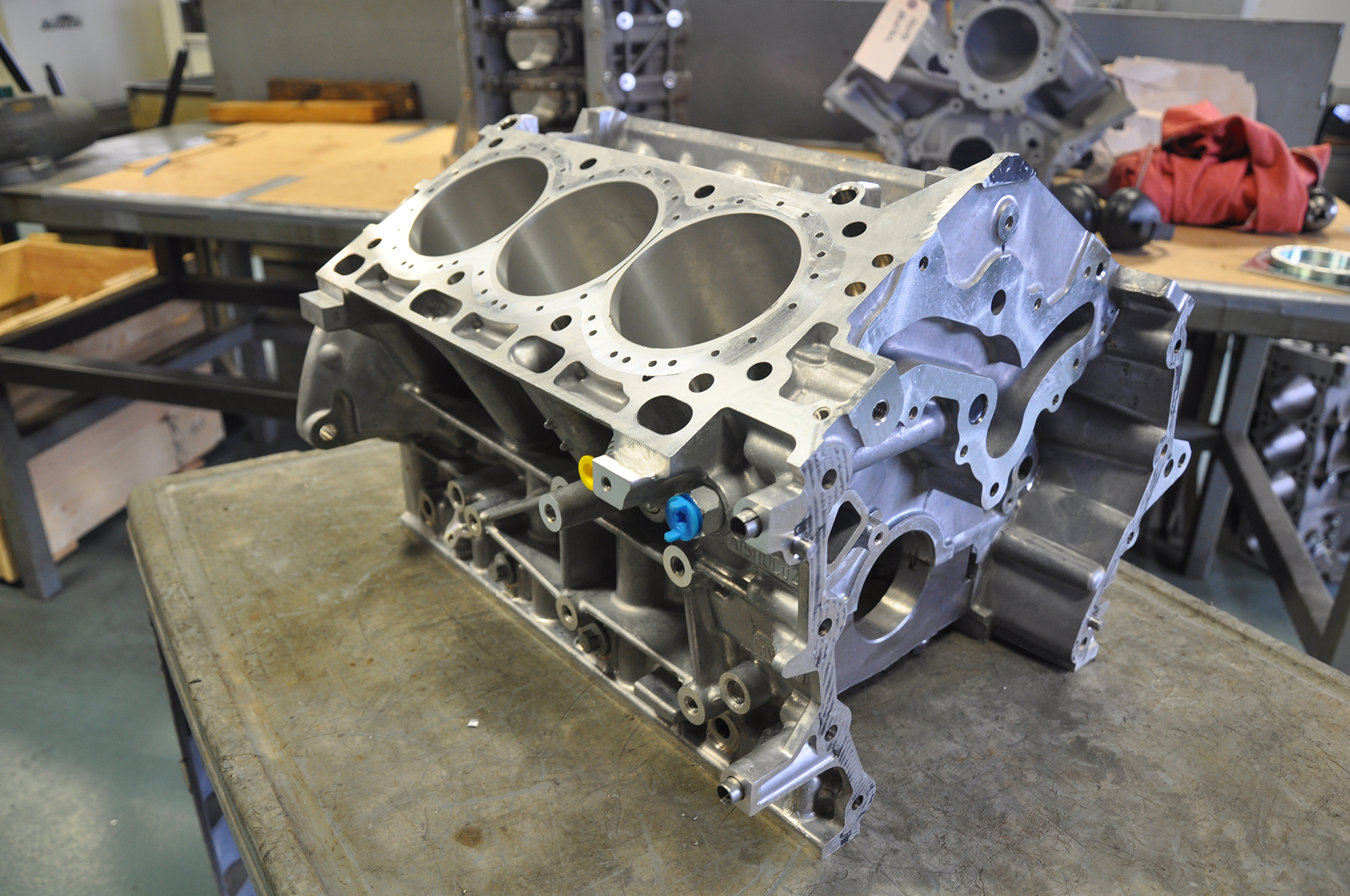

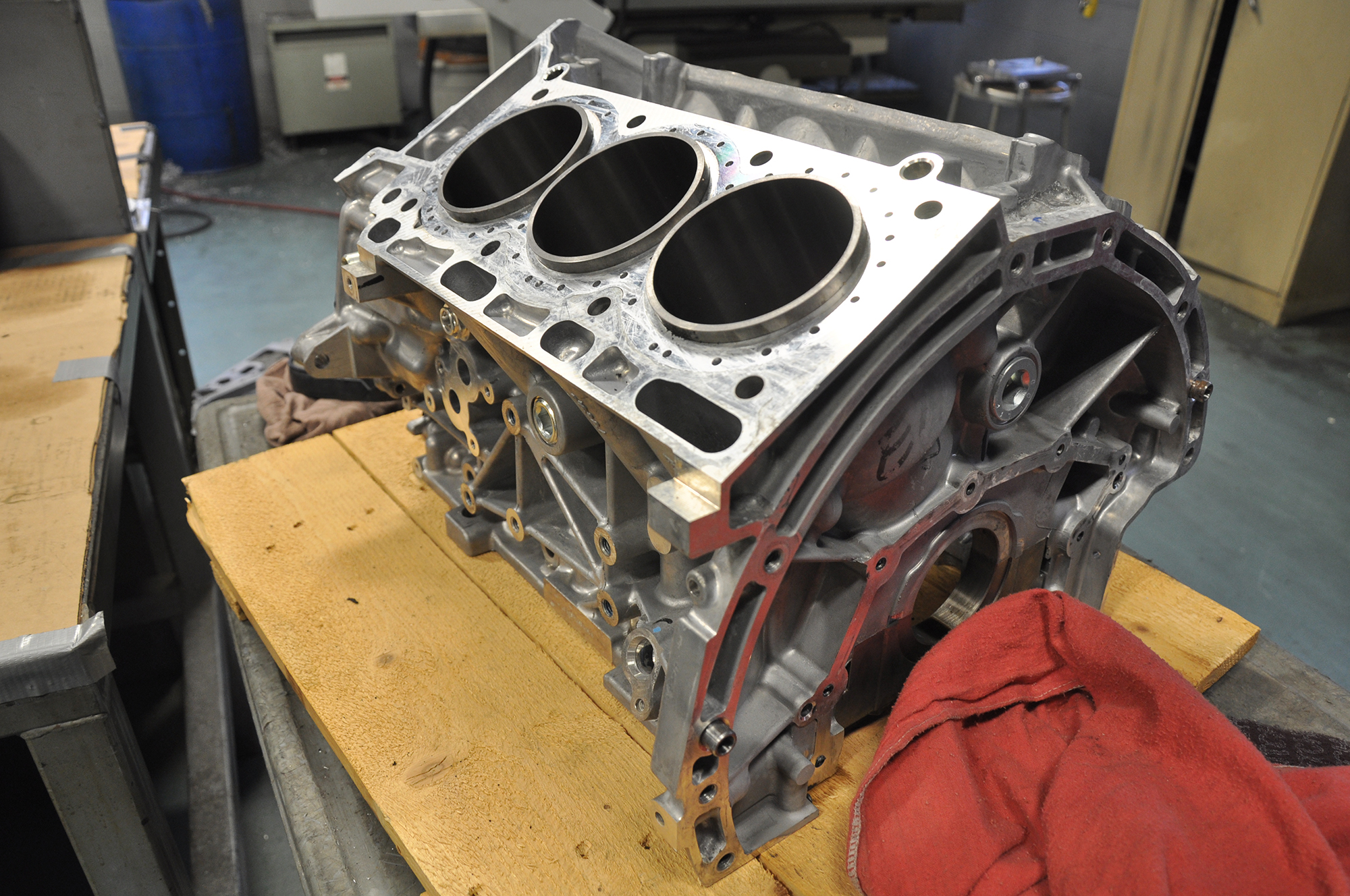

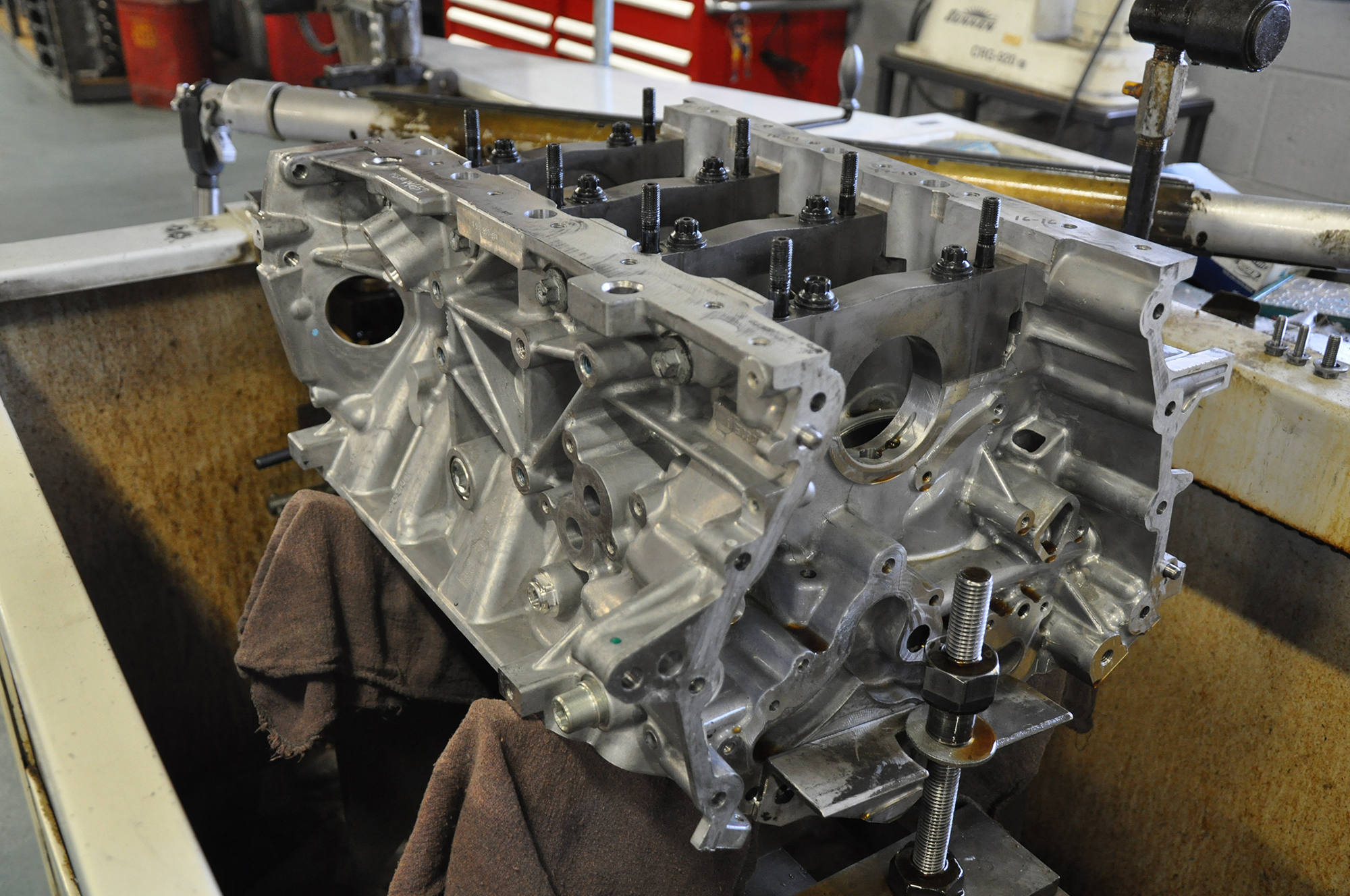

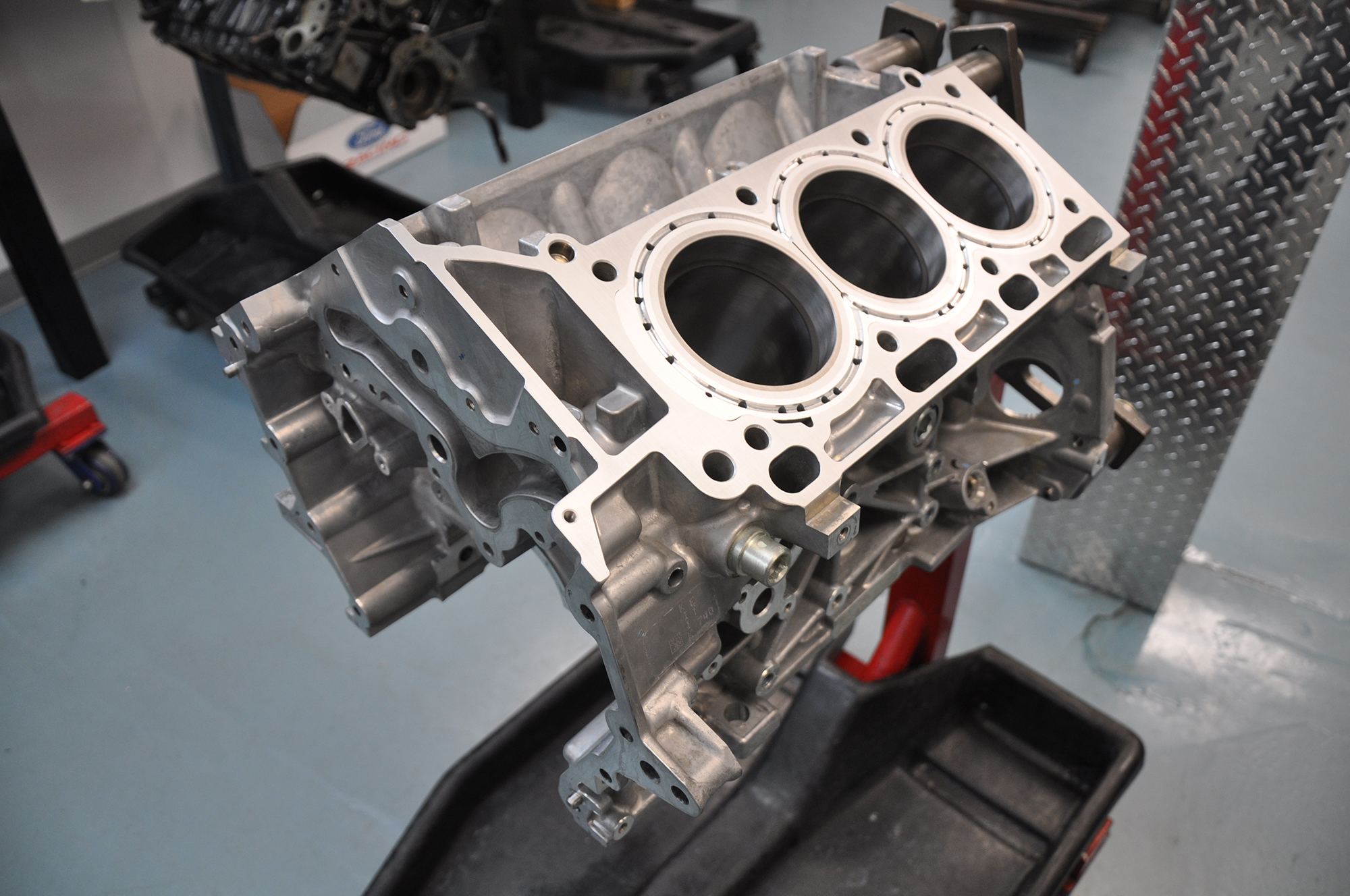

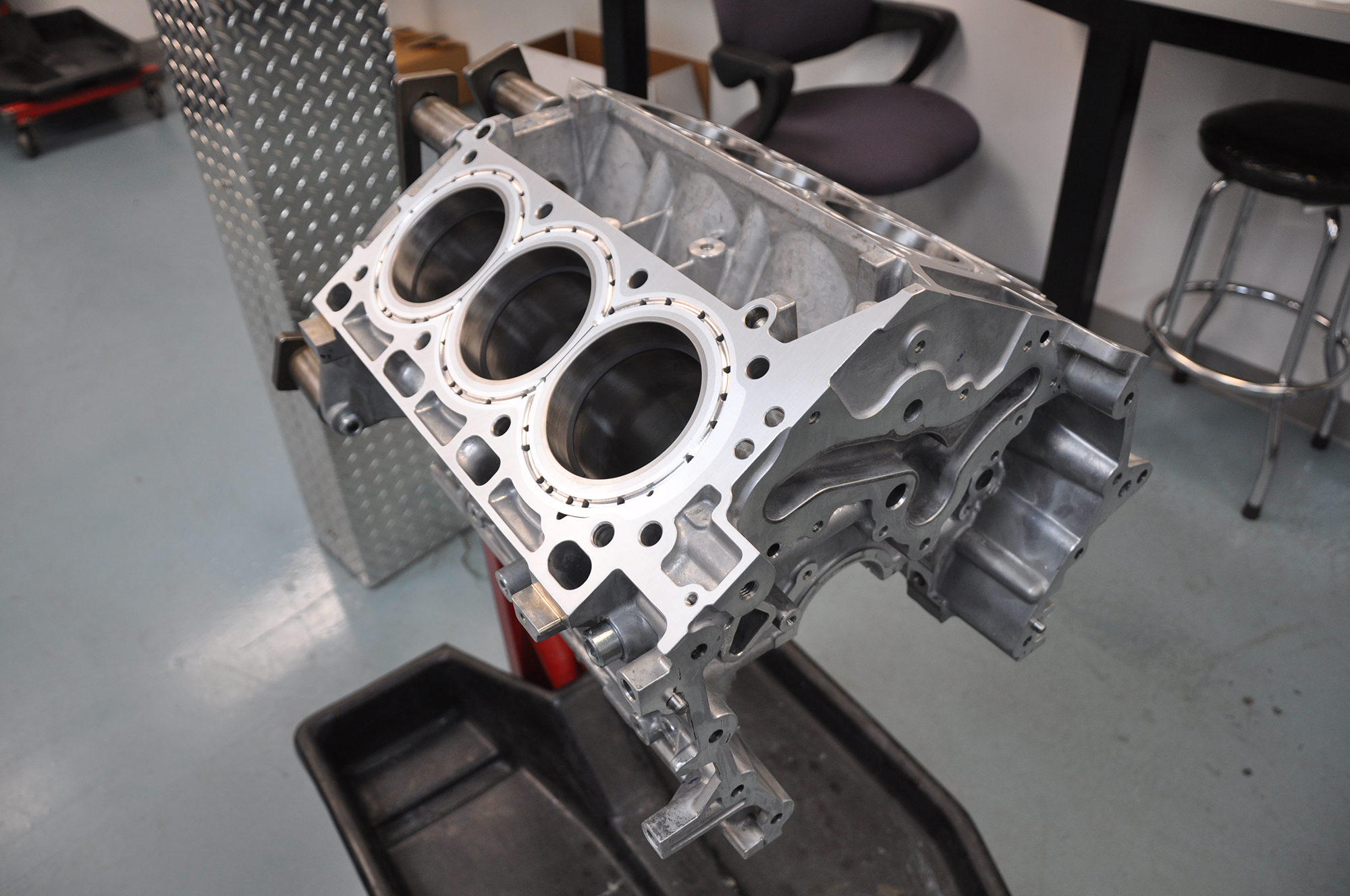

Both deck braces are in. We're calling it a night and will be back tomorrow morning to cut and deck the block.

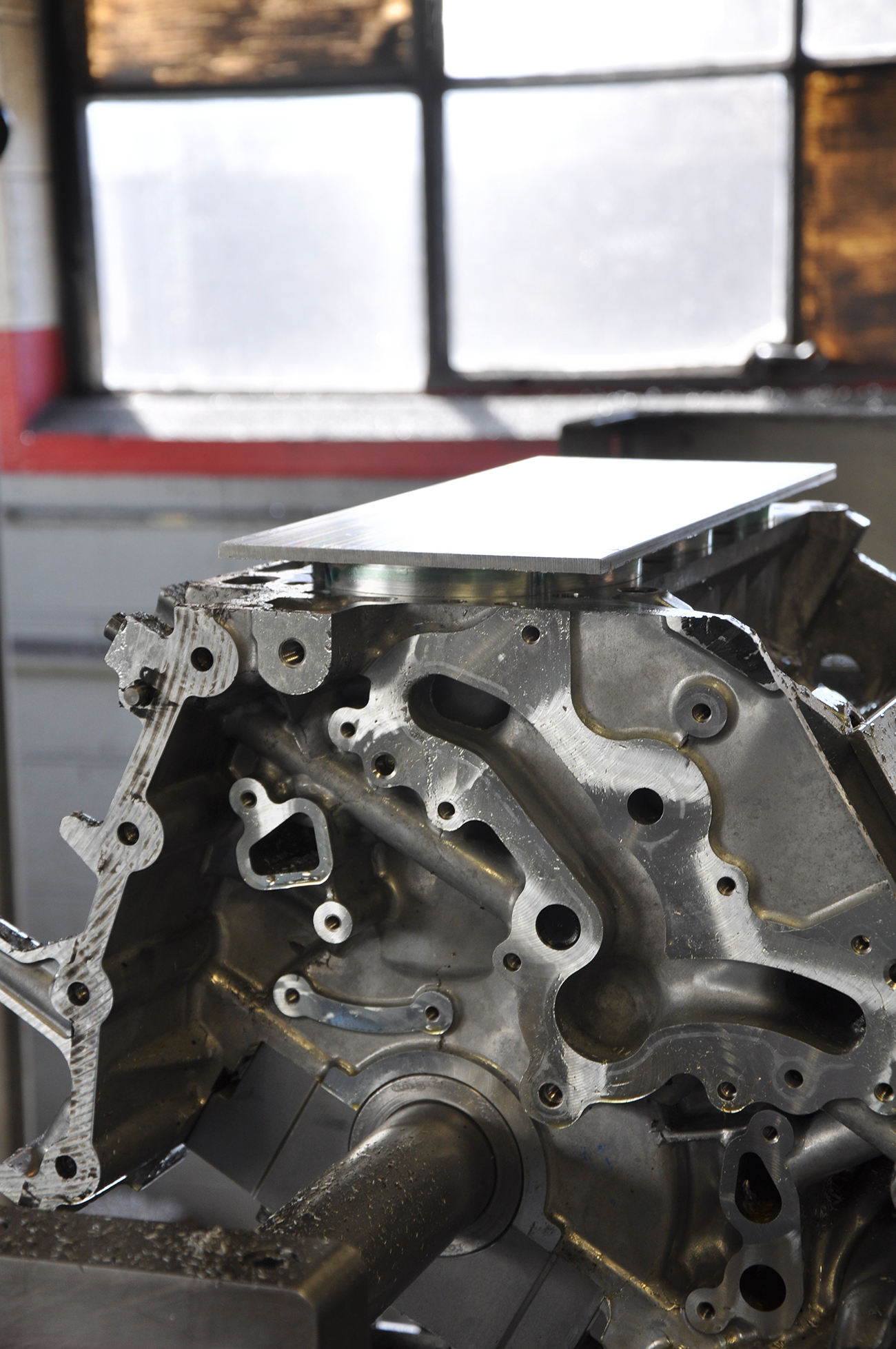

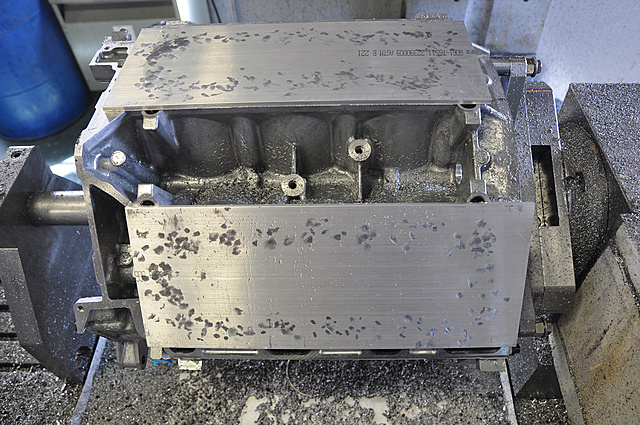

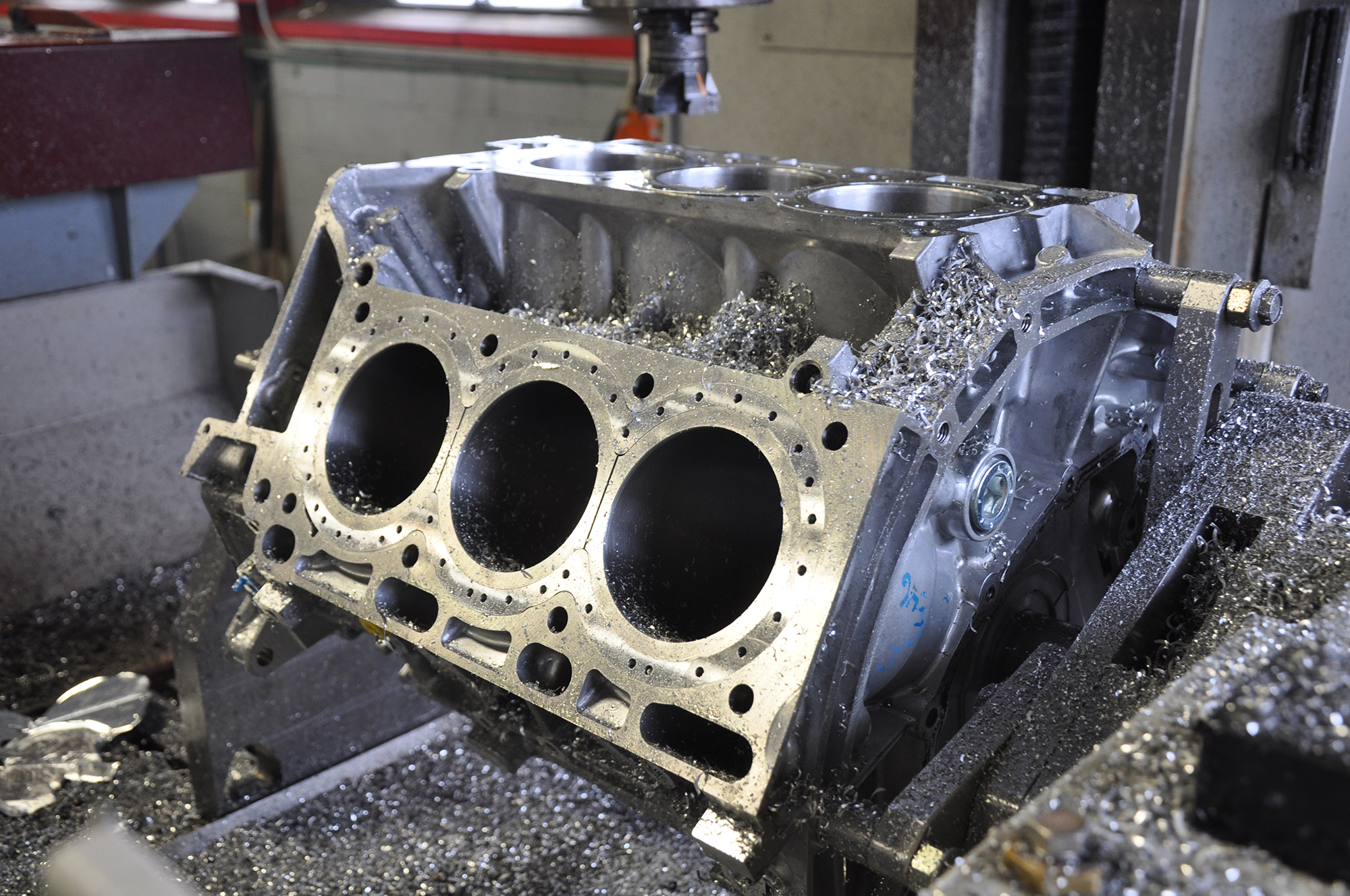

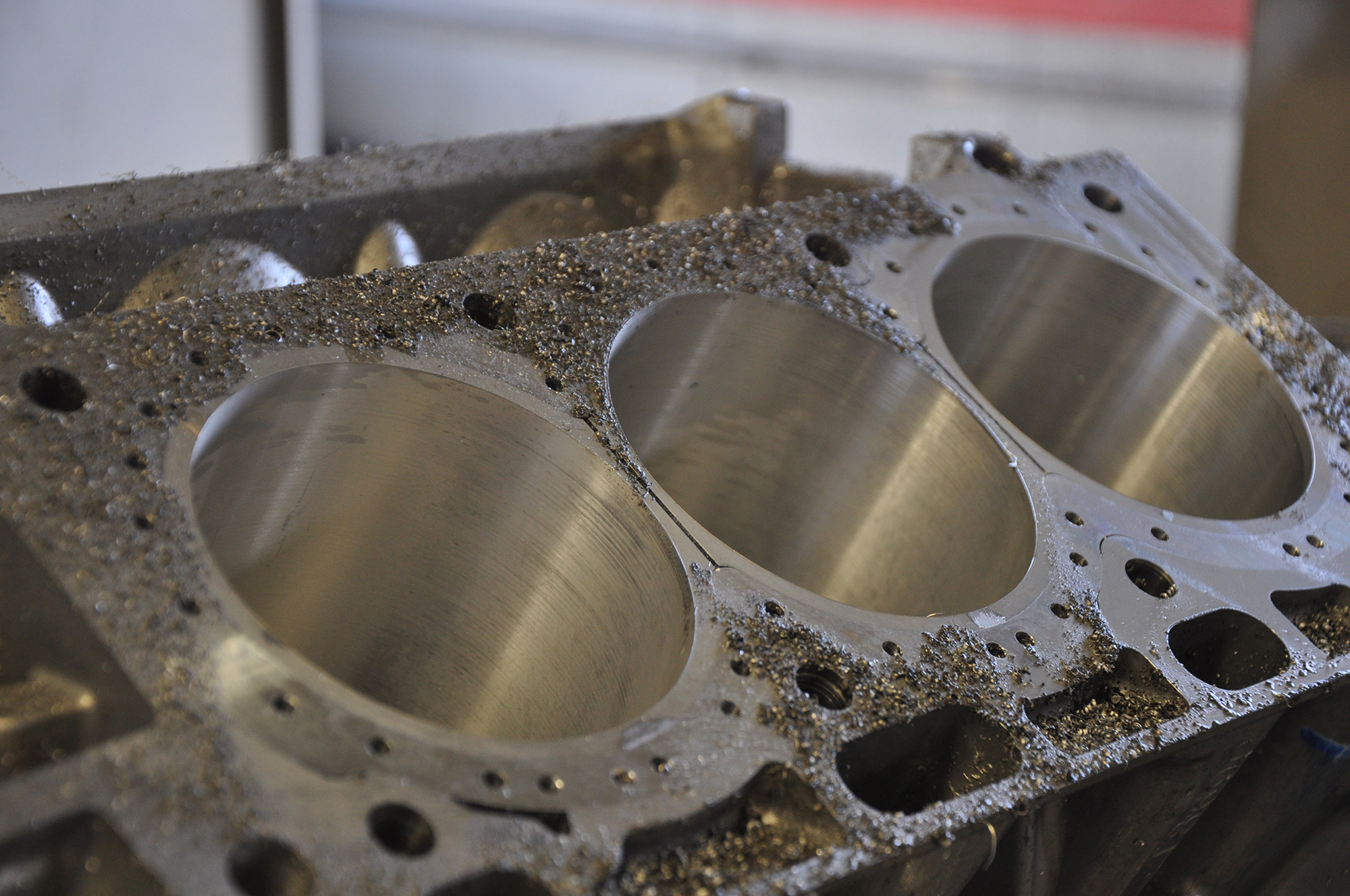

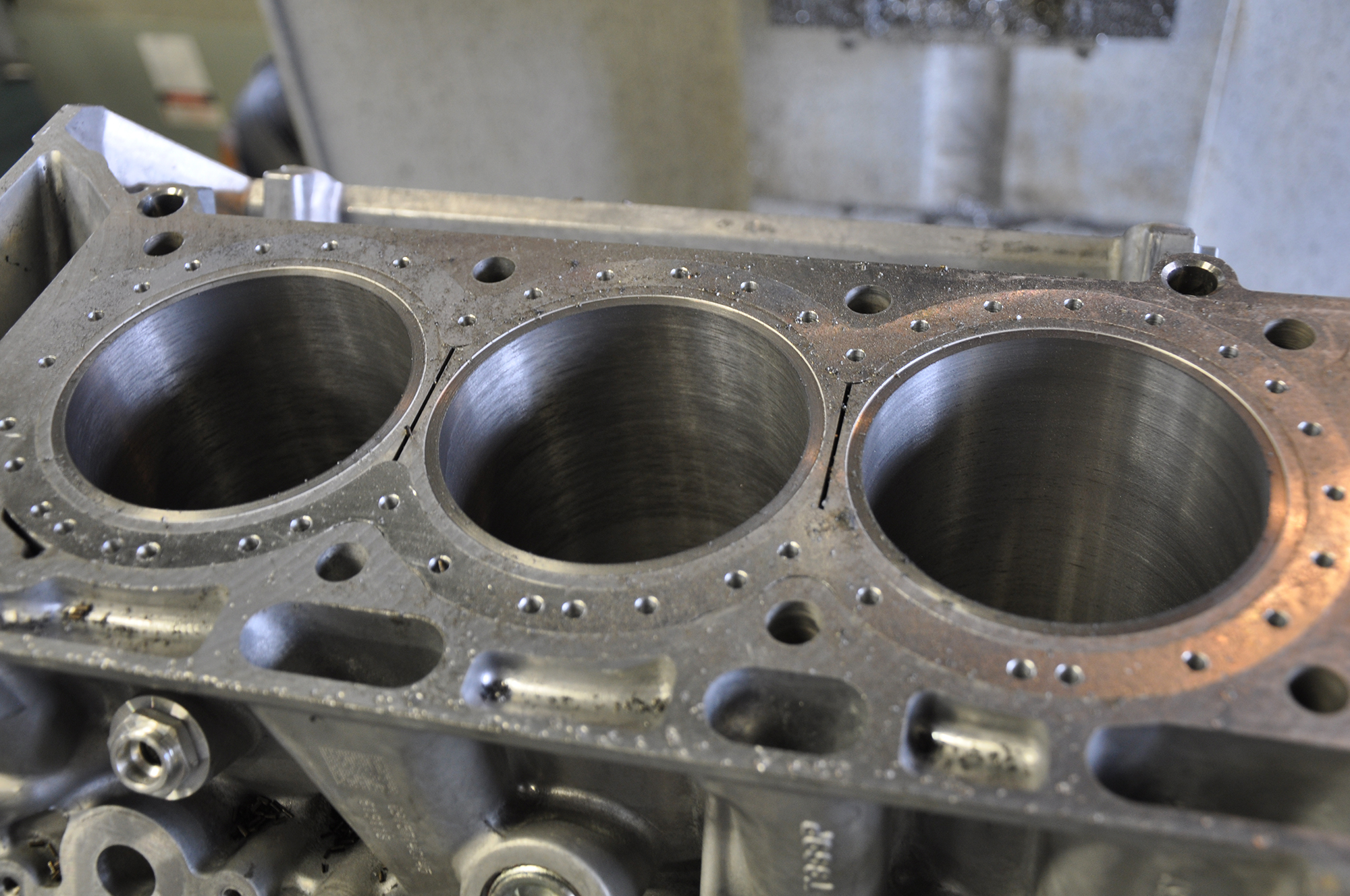

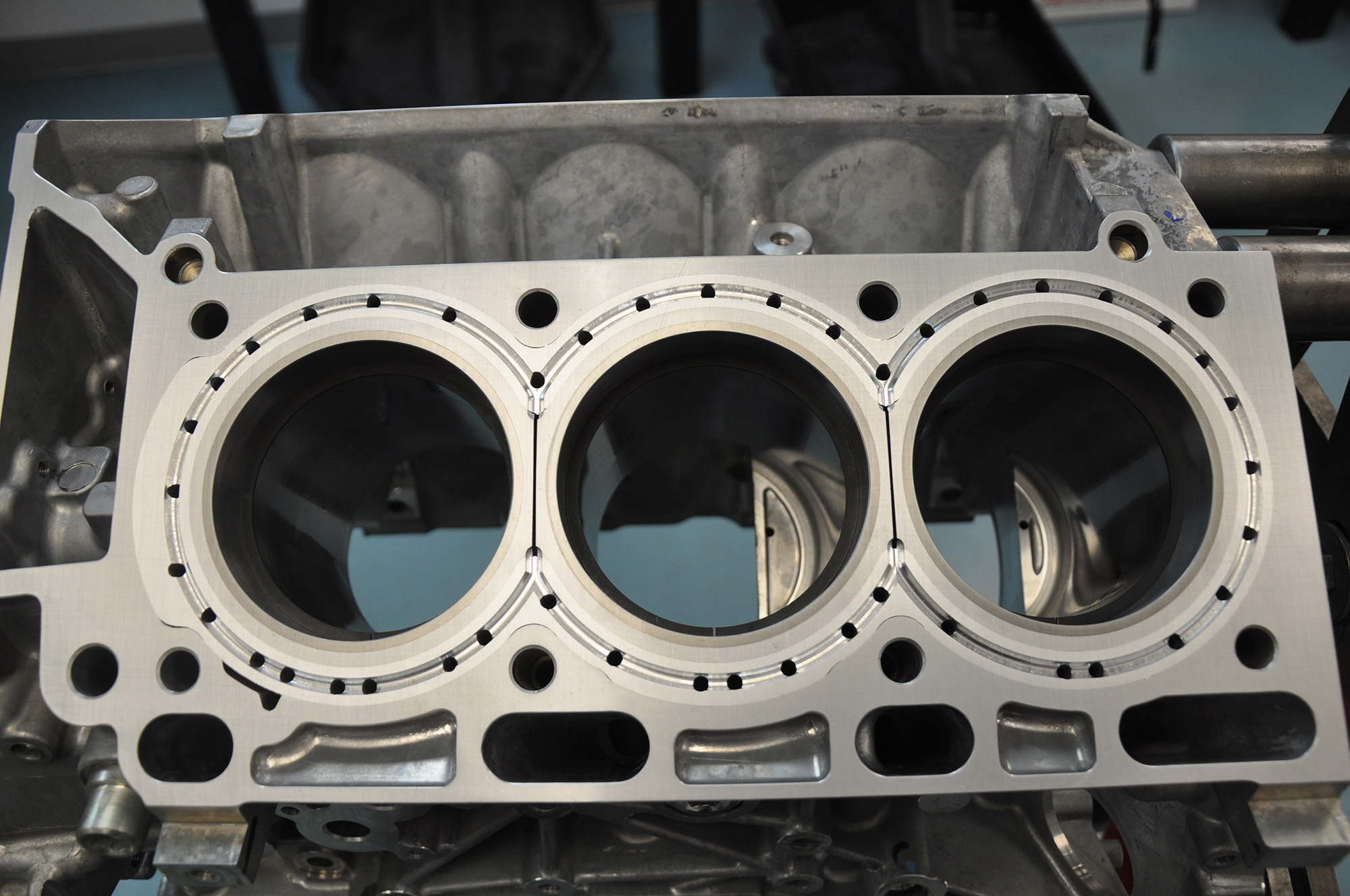

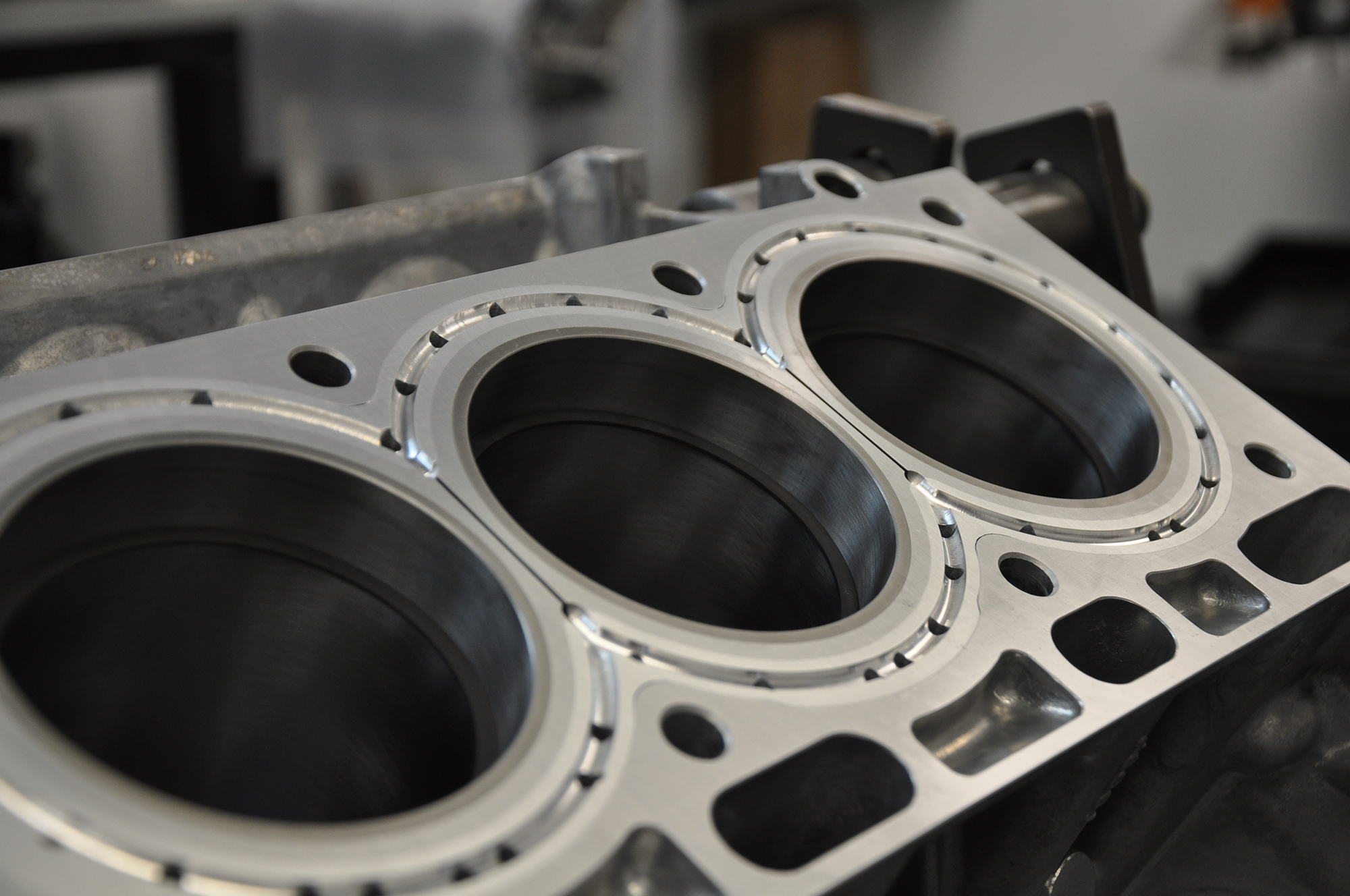

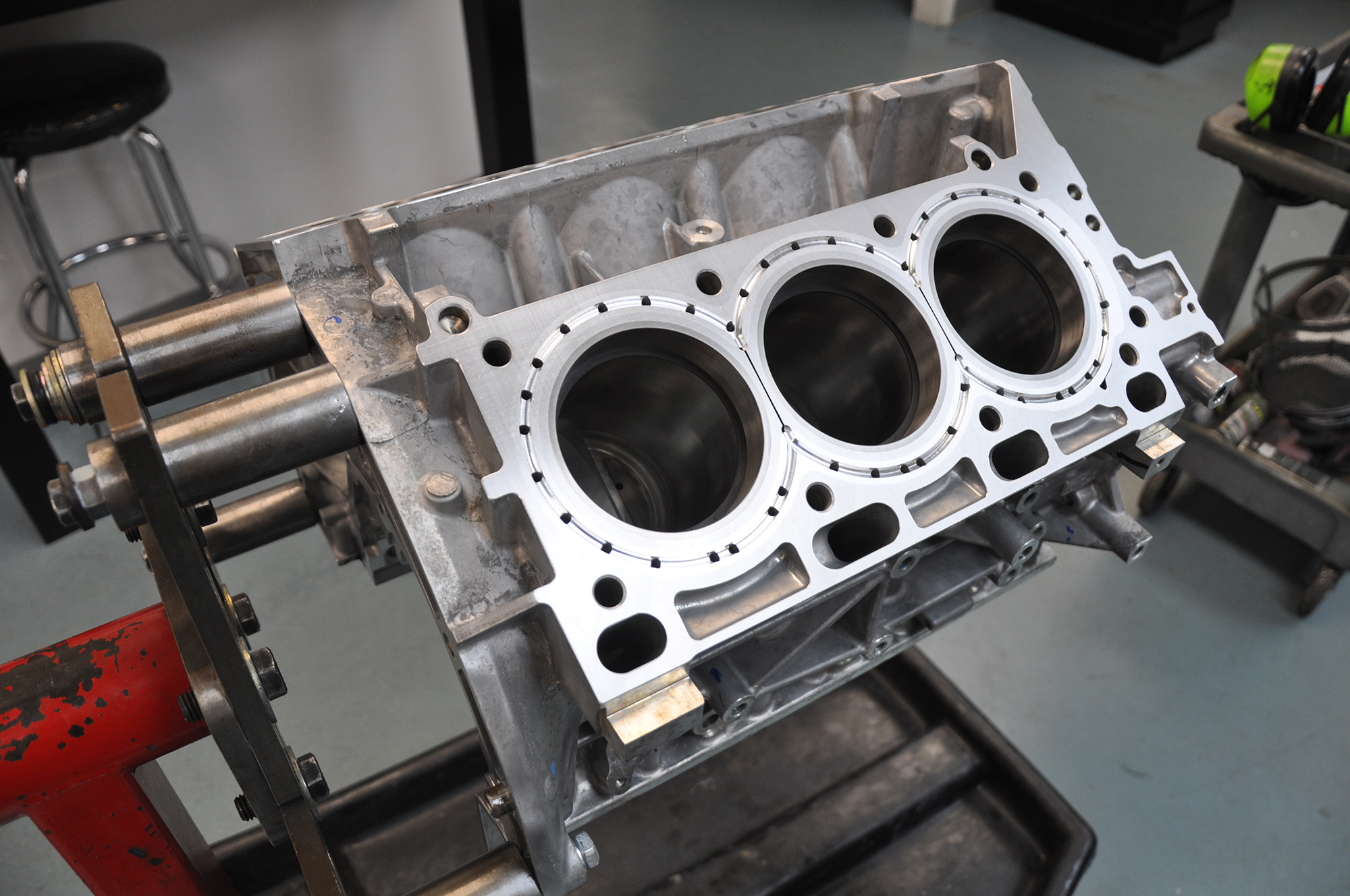

Another early morning in the machining area. The first deck brace has been shaved away to reveal the cylinders. Next, we have to cut the deck flat to ensure a level field for the head gasket and head.

Second side is cut! A few shavings but looks great. We will have to clean it up a bit before we start measuring and cutting for the sleeves.

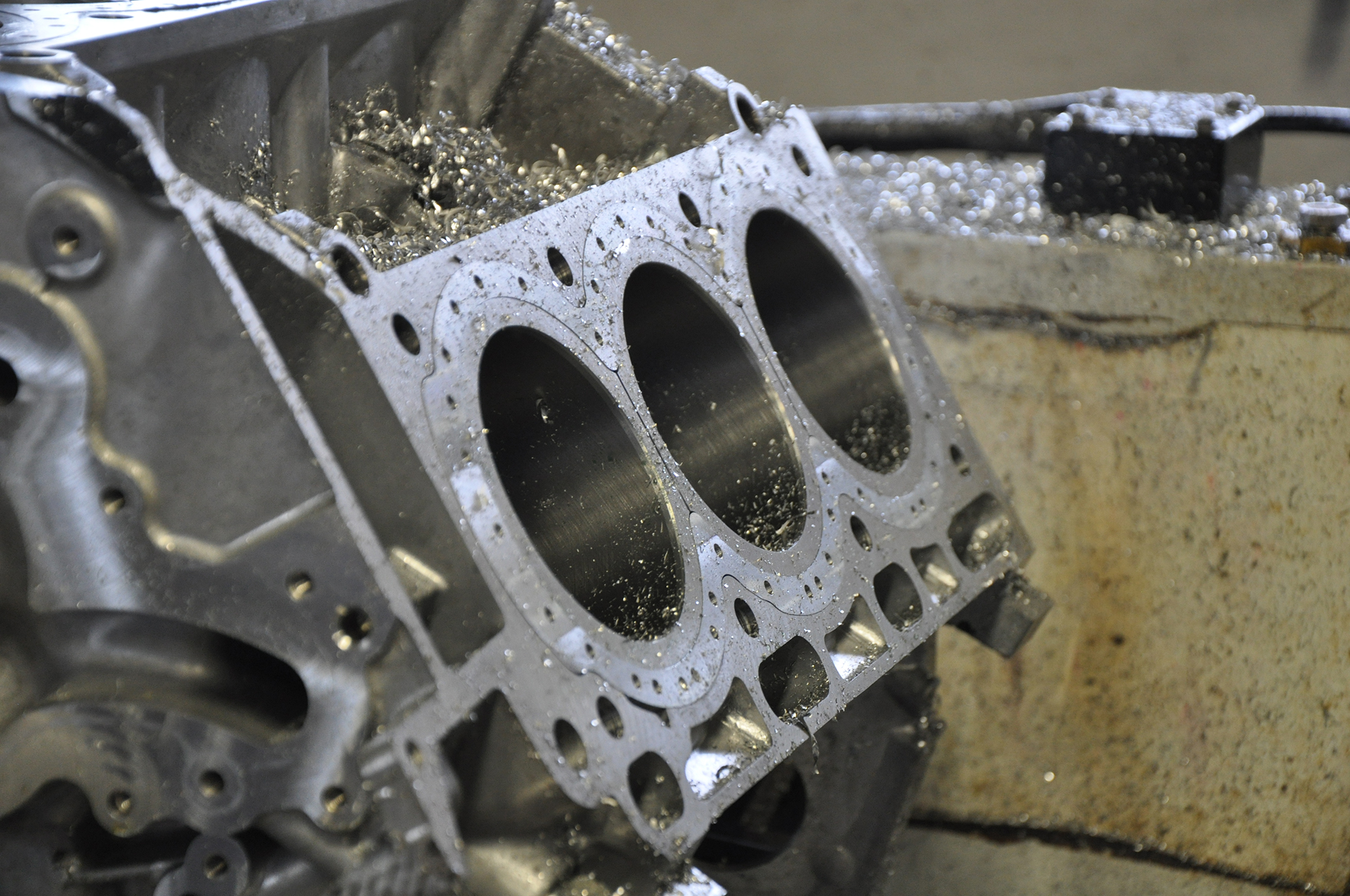

A couple measurements of the sleeves that will be going into the block before we start cutting. We measure before the cutting to find the exact bore size to get the correct sleeve to block interference. This will provide the exact fit we need!

I love fresh machine work.

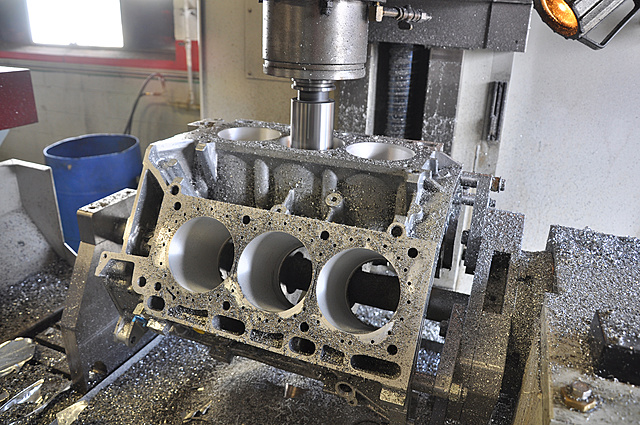

Next step, start shaving away to make room for the new sleeves!

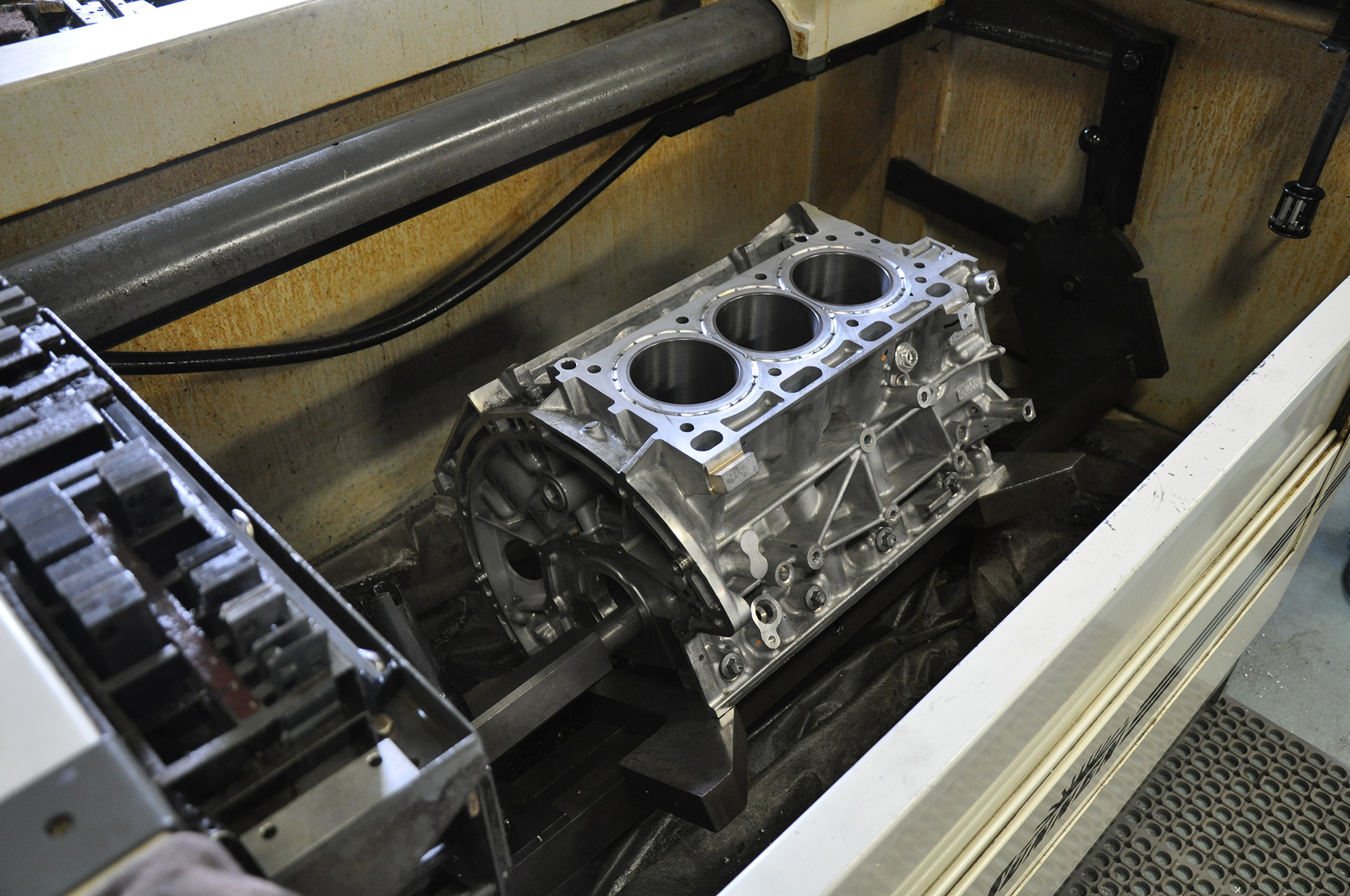

Block is out of cutting and getting cleaned up. We will be going through a few steps to get the freshly cut walls ready for the new sleeves before they are pressed in this afternoon. So far, it looks great! We can't wait for this project to come together.

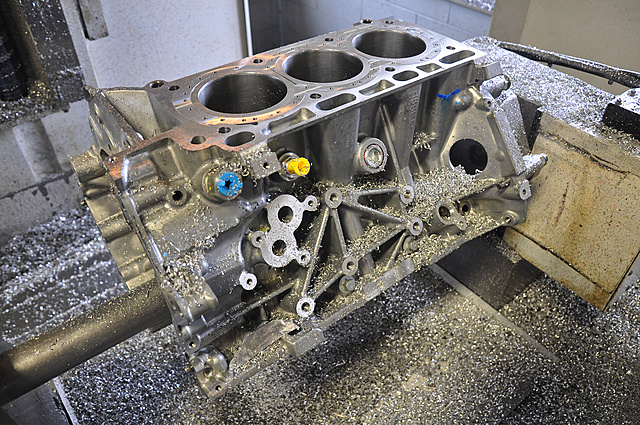

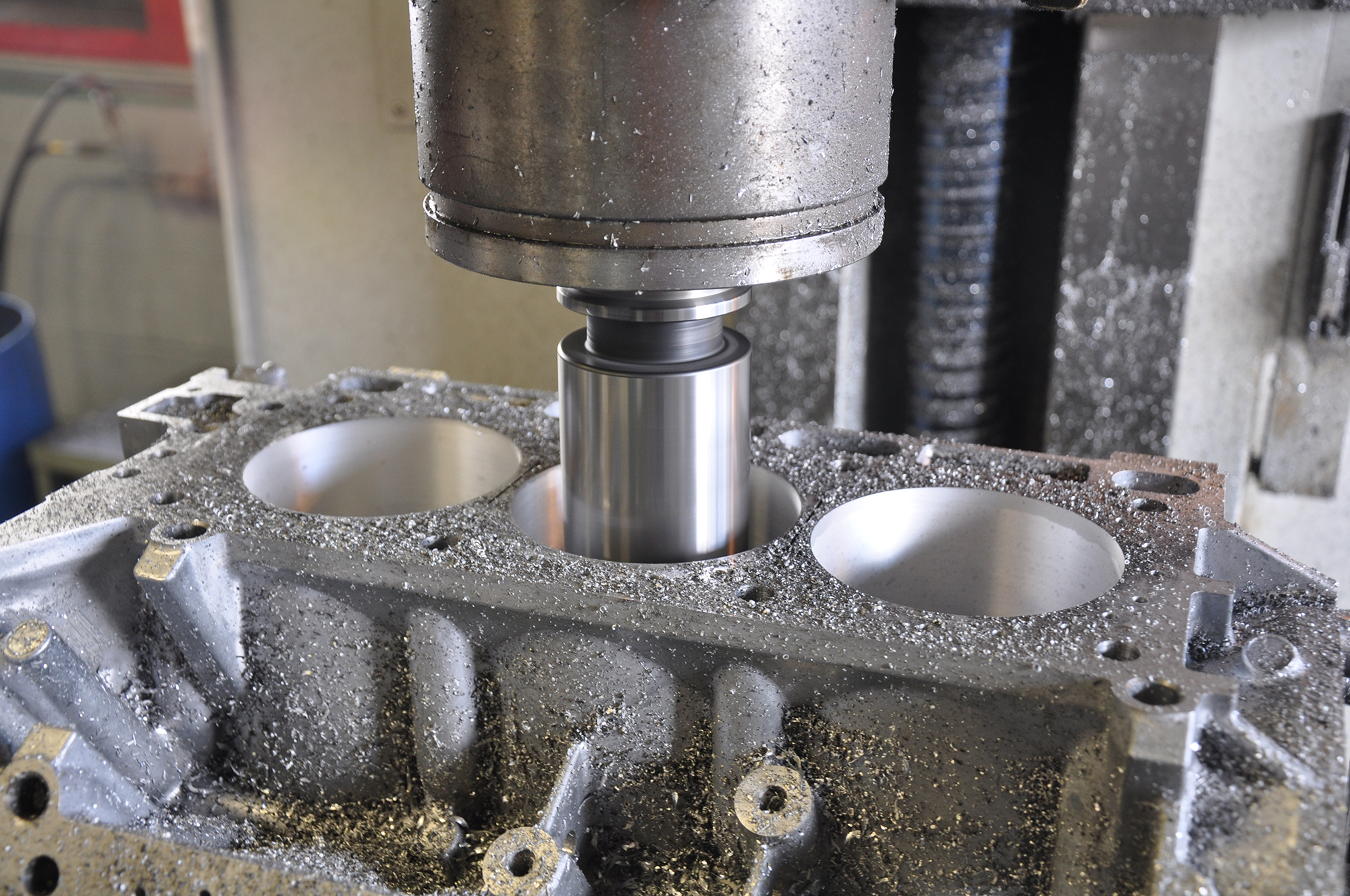

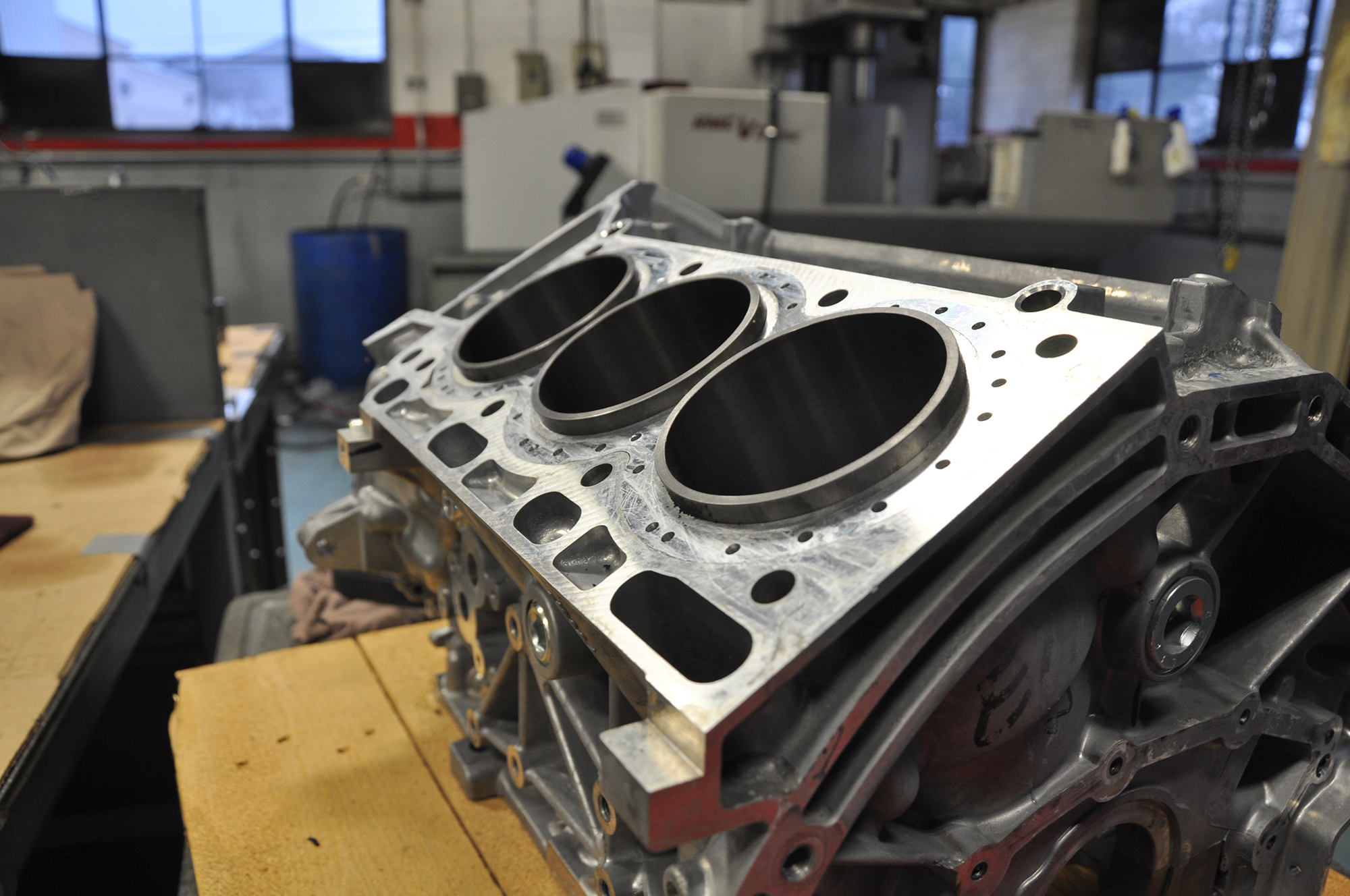

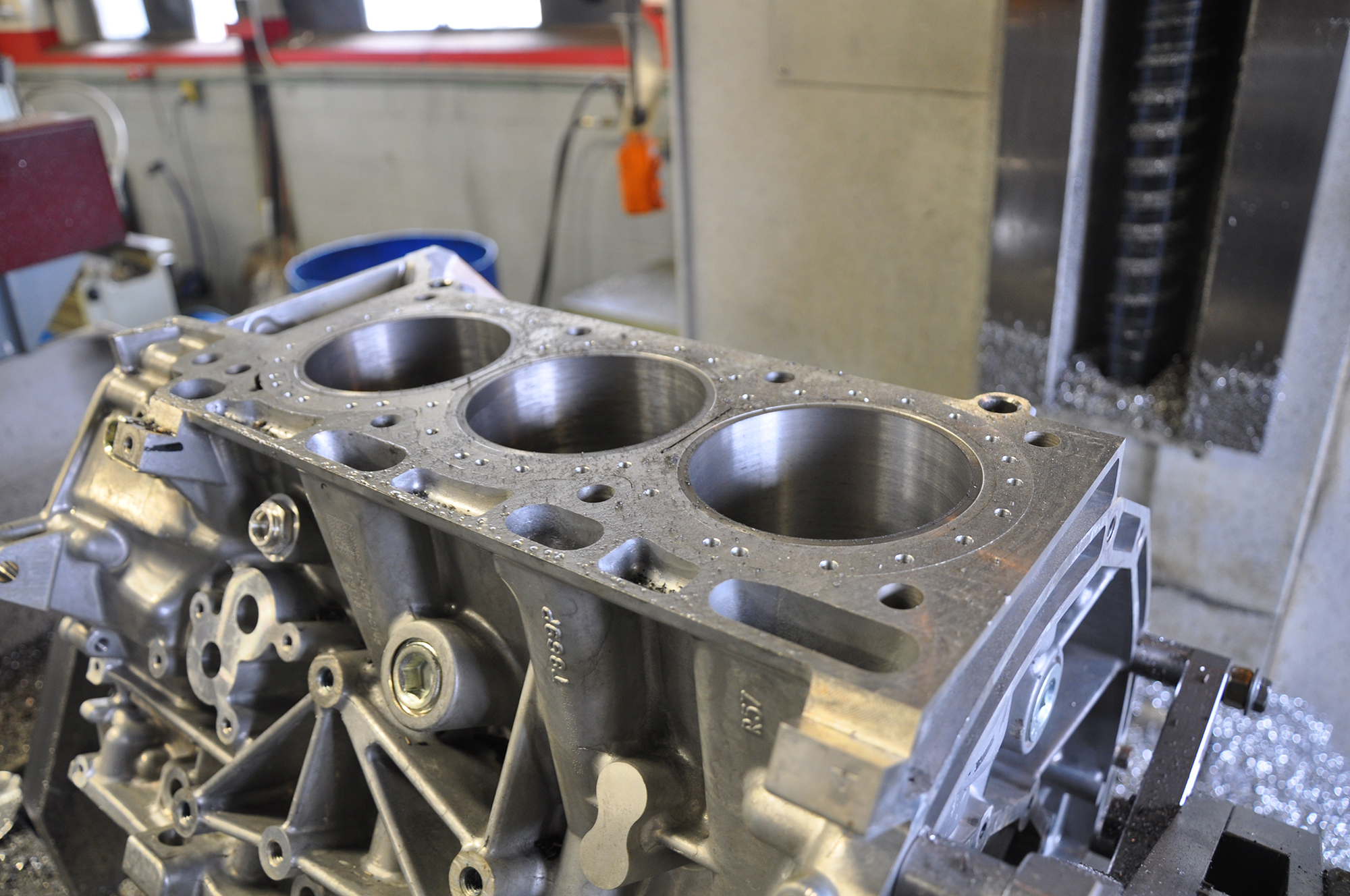

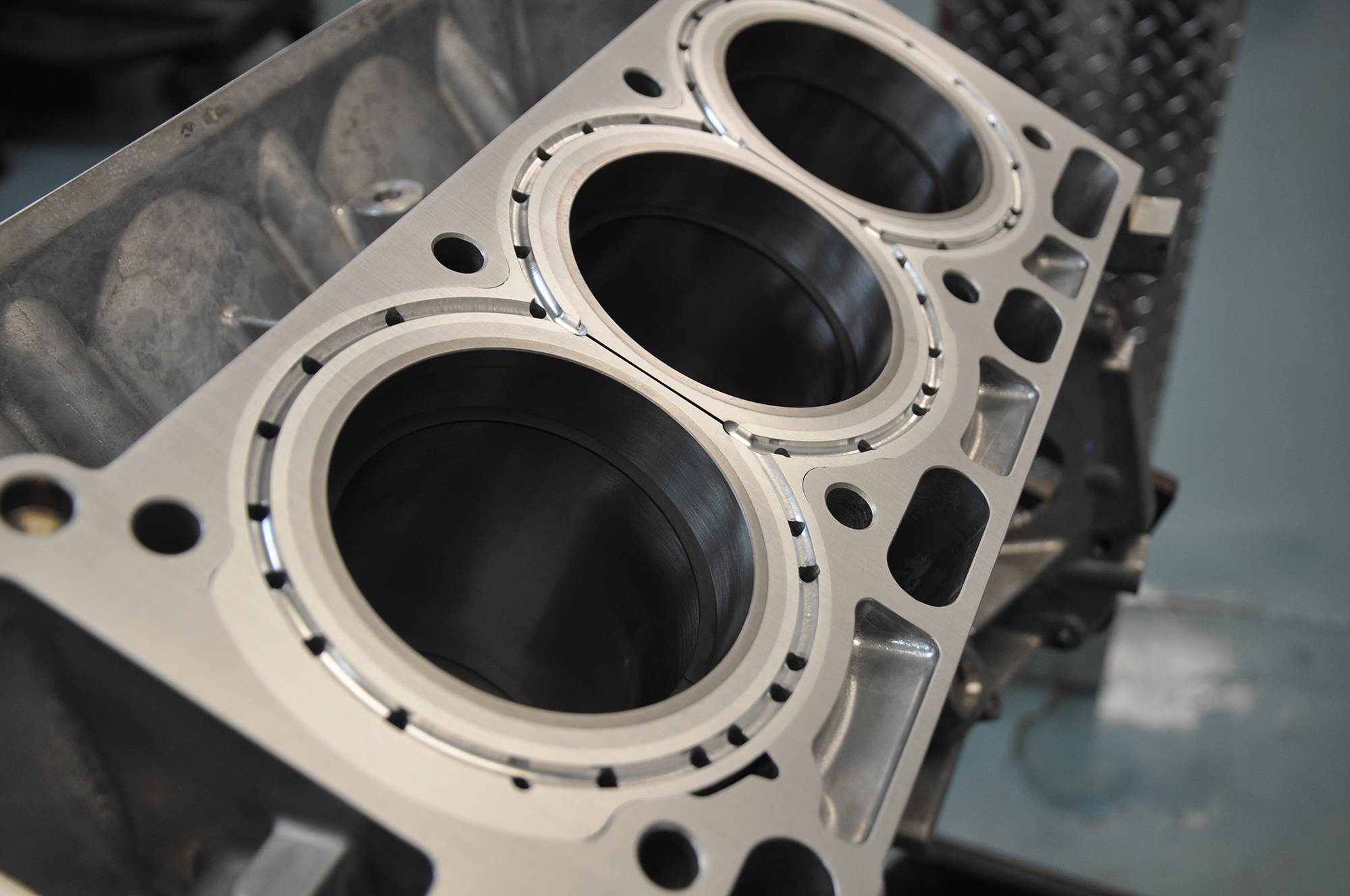

After some persuasion the sleeves are in! We will be going back to the CNC machines to cut the lip off to make sure the deck is perfectly flat.

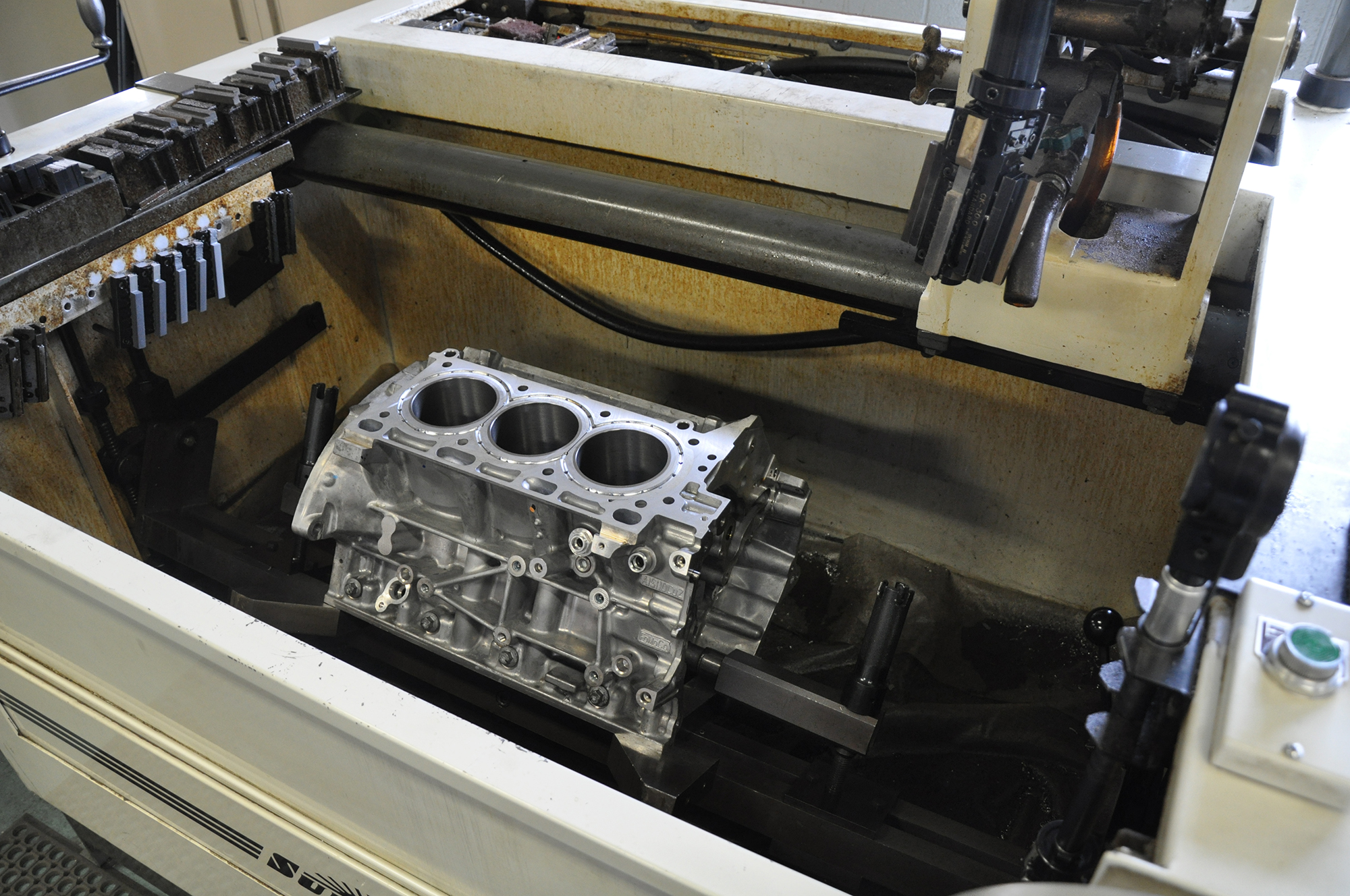

We're back to the CNC machines this morning to deck of the extra bit of sleeve sticking from the top of the block. We want to ensure a flush fit between the deck, gasket, and head for a perfect fit.

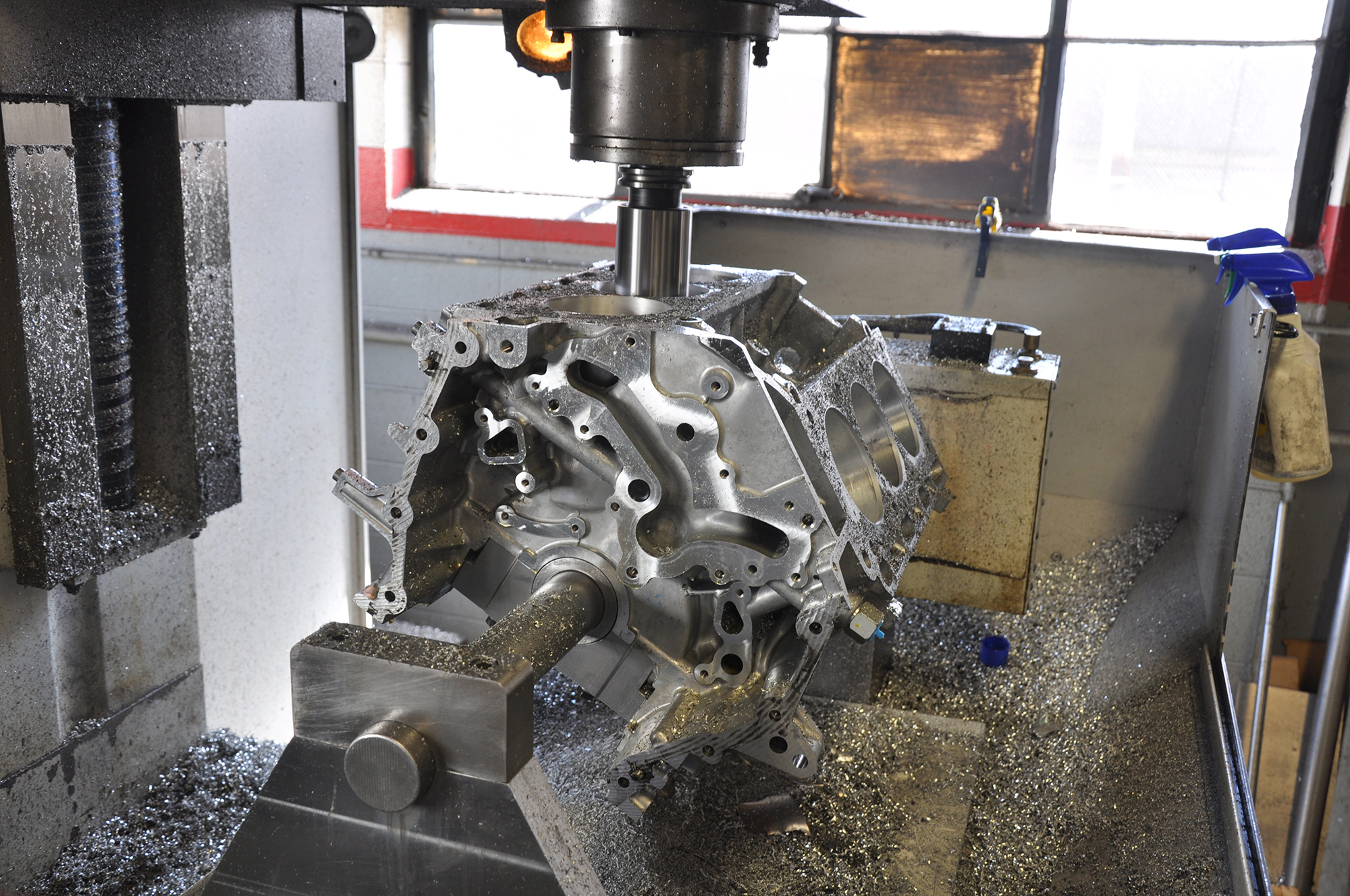

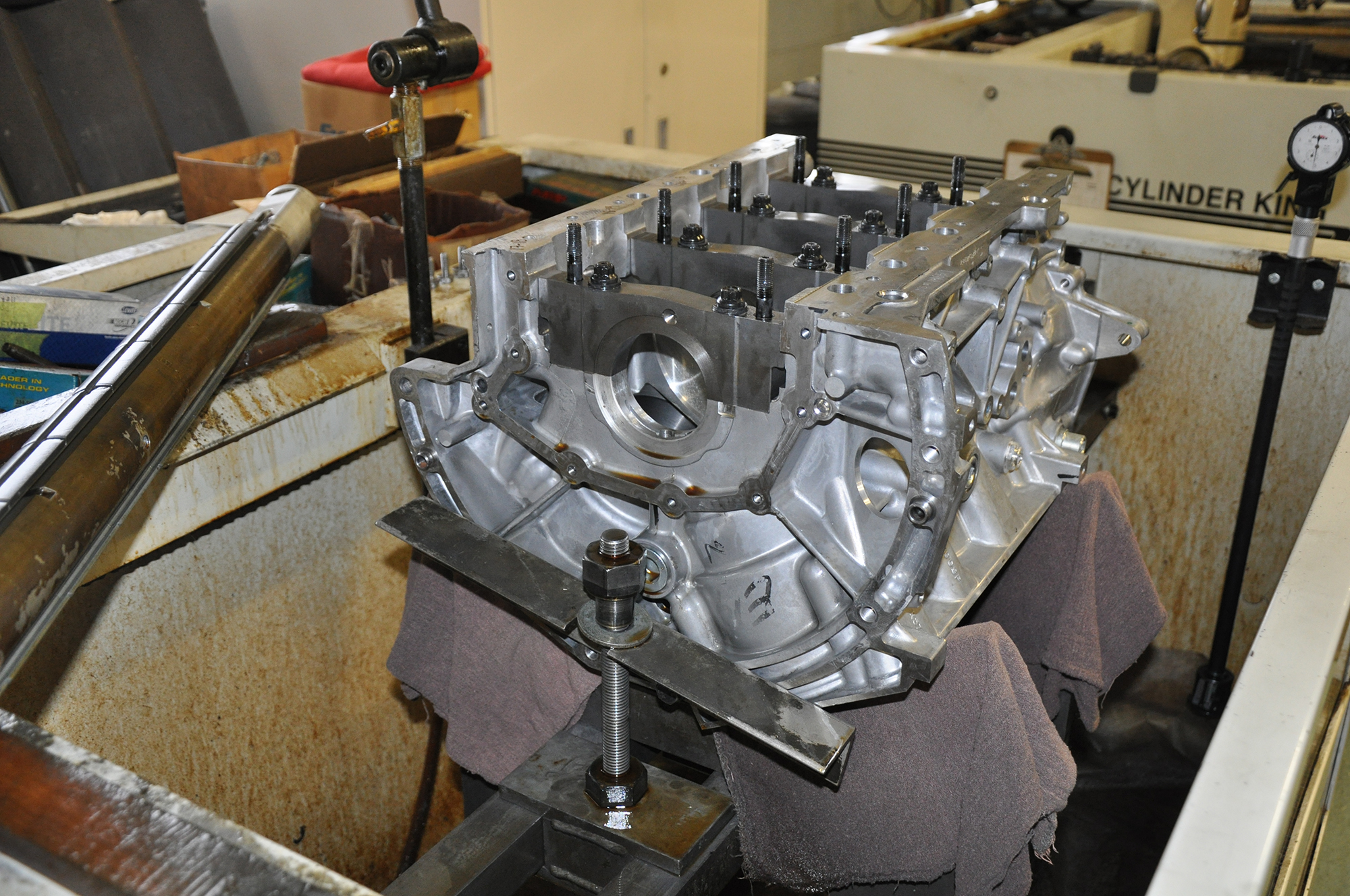

Next step in the process, line honing the block.

Here, we set the main bearing clearing by lightly shaving down the metals to fit perfectly. We also ensure that the bearing crush clearance.

Here, we set the main bearing clearing by lightly shaving down the metals to fit perfectly. We also ensure that the bearing crush clearance.

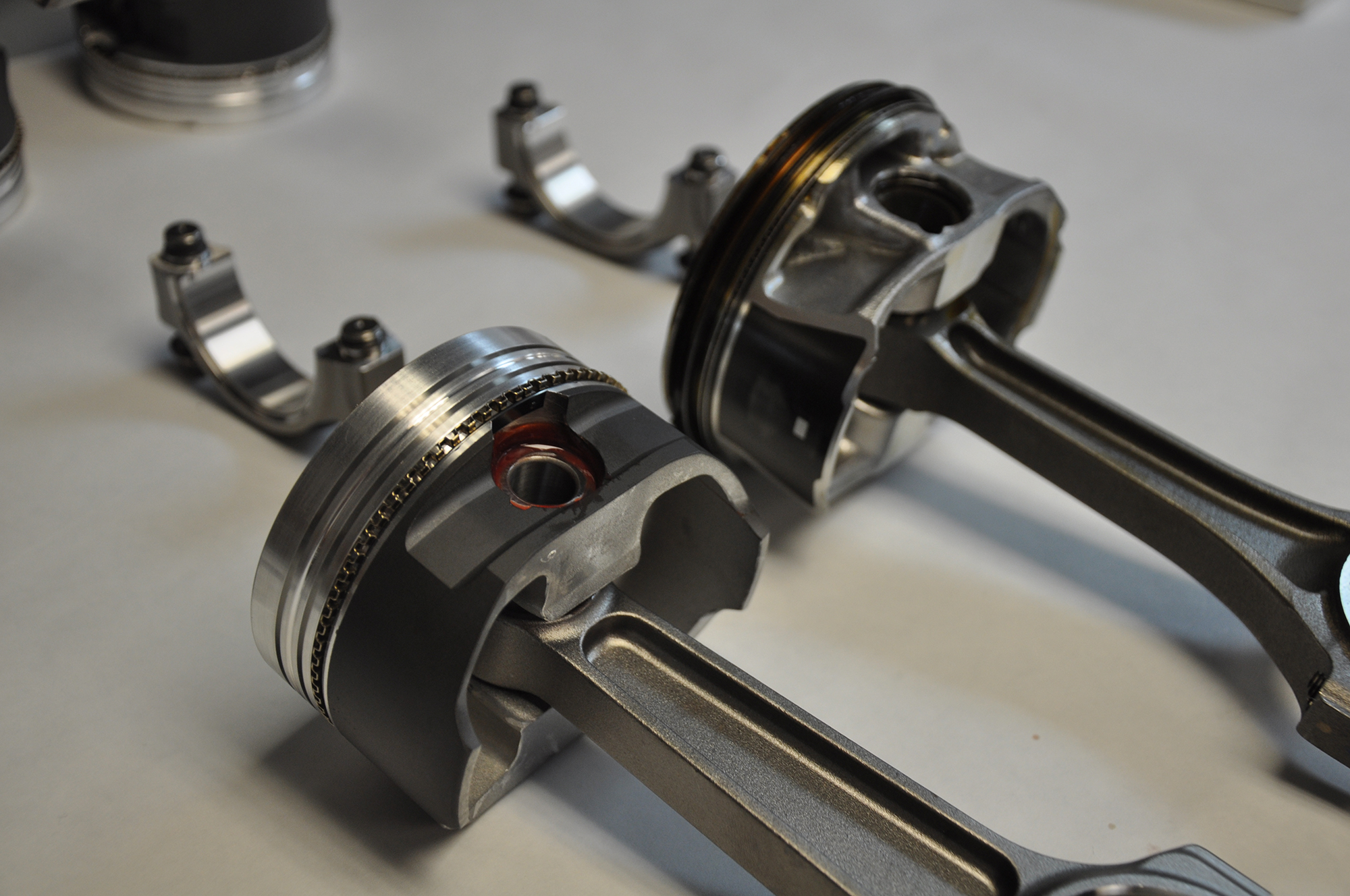

Were taking a break from the machine work to get familiar with the Powerstorm pistons and rods vs. the stock pistons and rods.

As you can see, there are many differences between the two. Thickness, design, and material are a few of the things you can spot. What's not in plain sight, the years of R&D that has gone into developing the Powerstorm pistons and rods.

Rods

Pistons

The stock example we are using shows normal wear and carbon build up.

As you can see, there are many differences between the two. Thickness, design, and material are a few of the things you can spot. What's not in plain sight, the years of R&D that has gone into developing the Powerstorm pistons and rods.

Rods

- Material Differences (Our connecting rods are made of vacuum degassed 4340, as opposed to the much weaker powdered metal stock rods)

- Design Differences (Our connecting rods are designed with significant increases in cross sectional thickness. The beam design, bore design, cap arrangement and pin end all are substantially stronger than the stock design)

- Rod Bolts (Much higher quality ARP2000 rod bolts are used in our connecting rods)

Pistons

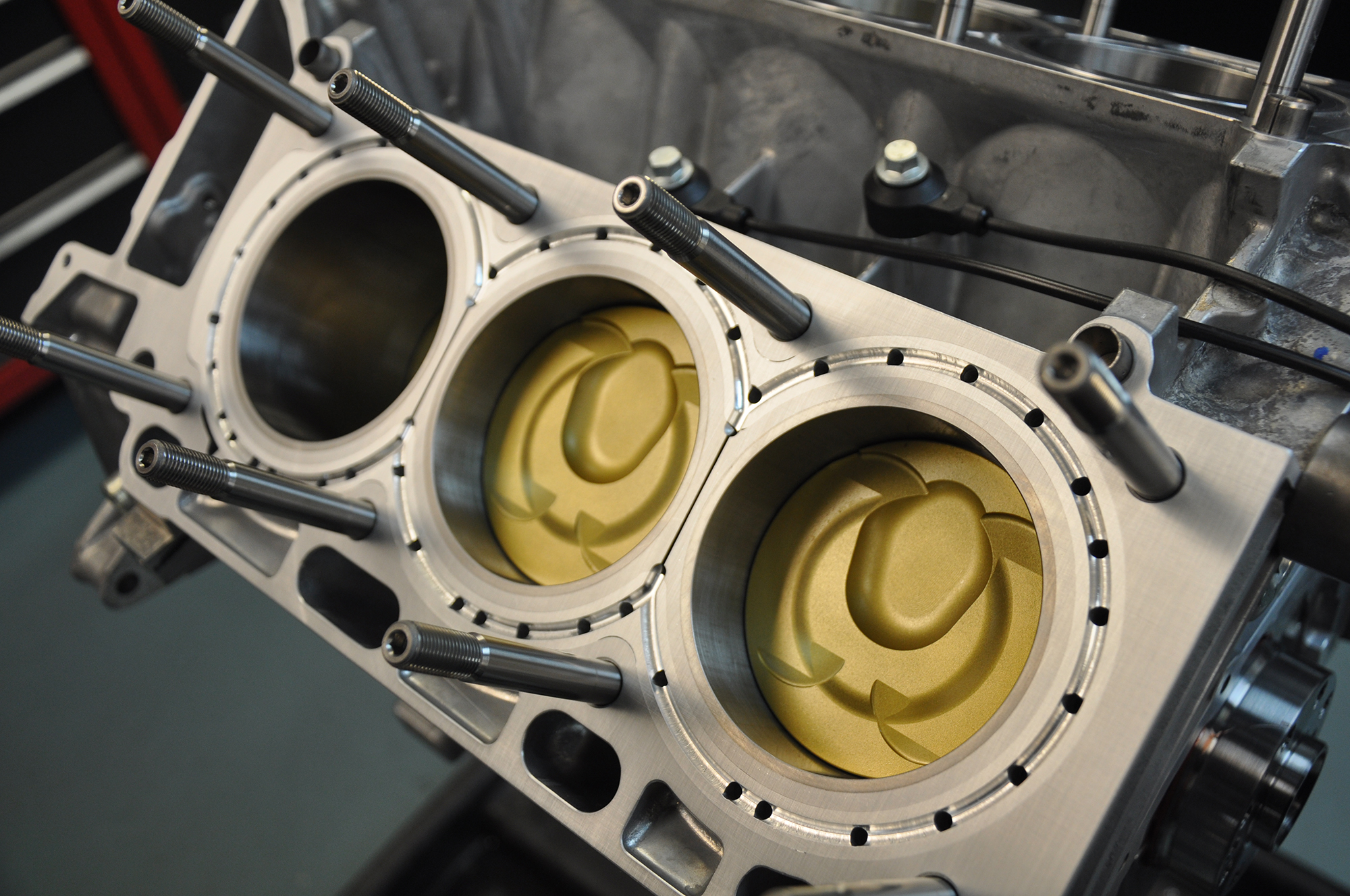

- Material Differences (Our pistons are made from 2618 aluminum alloy, much stronger, and considerably more durable under boosted applications than the stock piston material)

- Design Differences (Our pistons are designed from scratch using our own exclusive forging, with thicker skirts, crowns, strutting, ringlands and more. Features include better pin oiling, improved ringland supports, and more)

- Wristpins (Much higher quality material wristpin material, and increased wall thickness)

The stock example we are using shows normal wear and carbon build up.

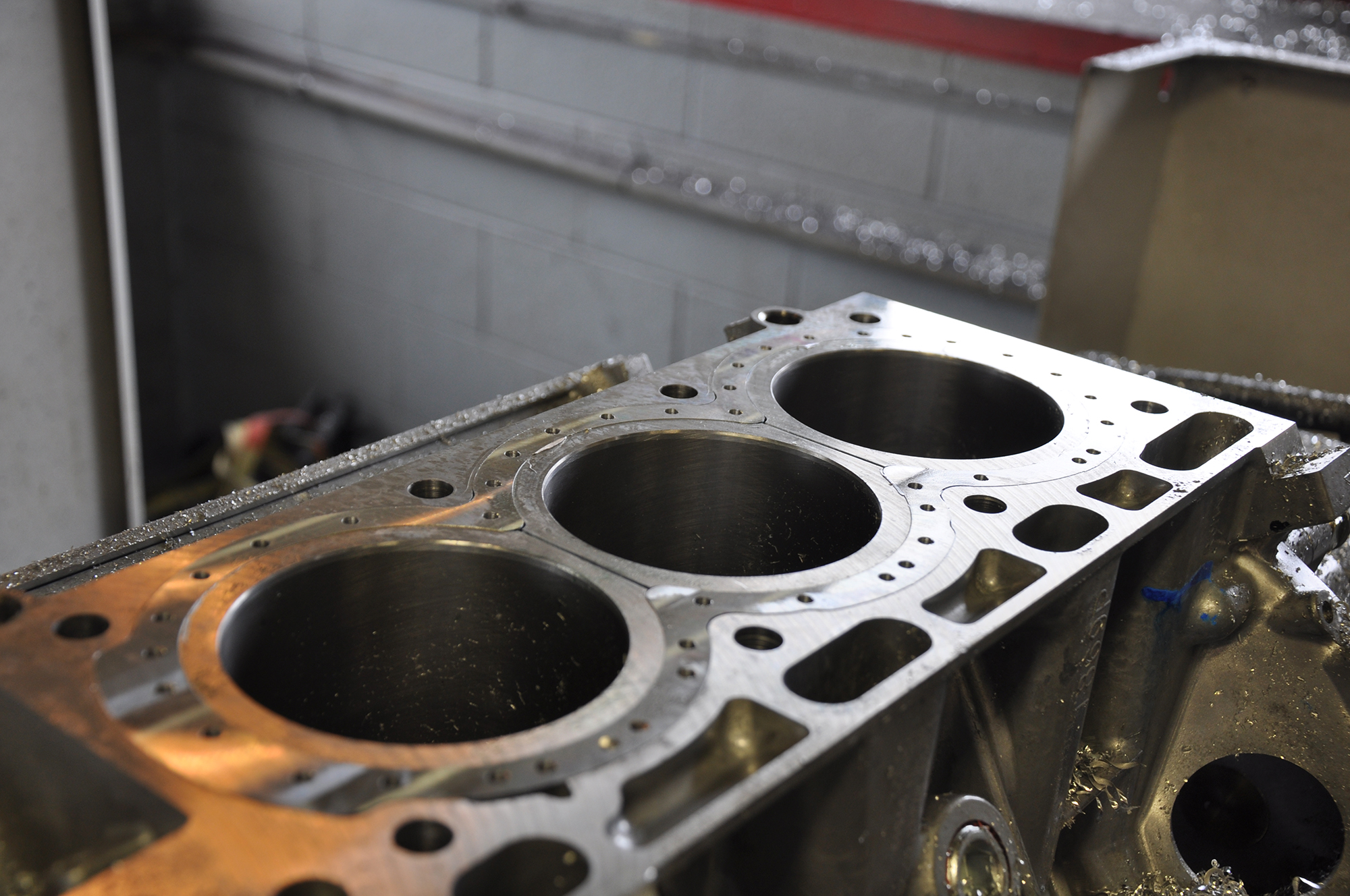

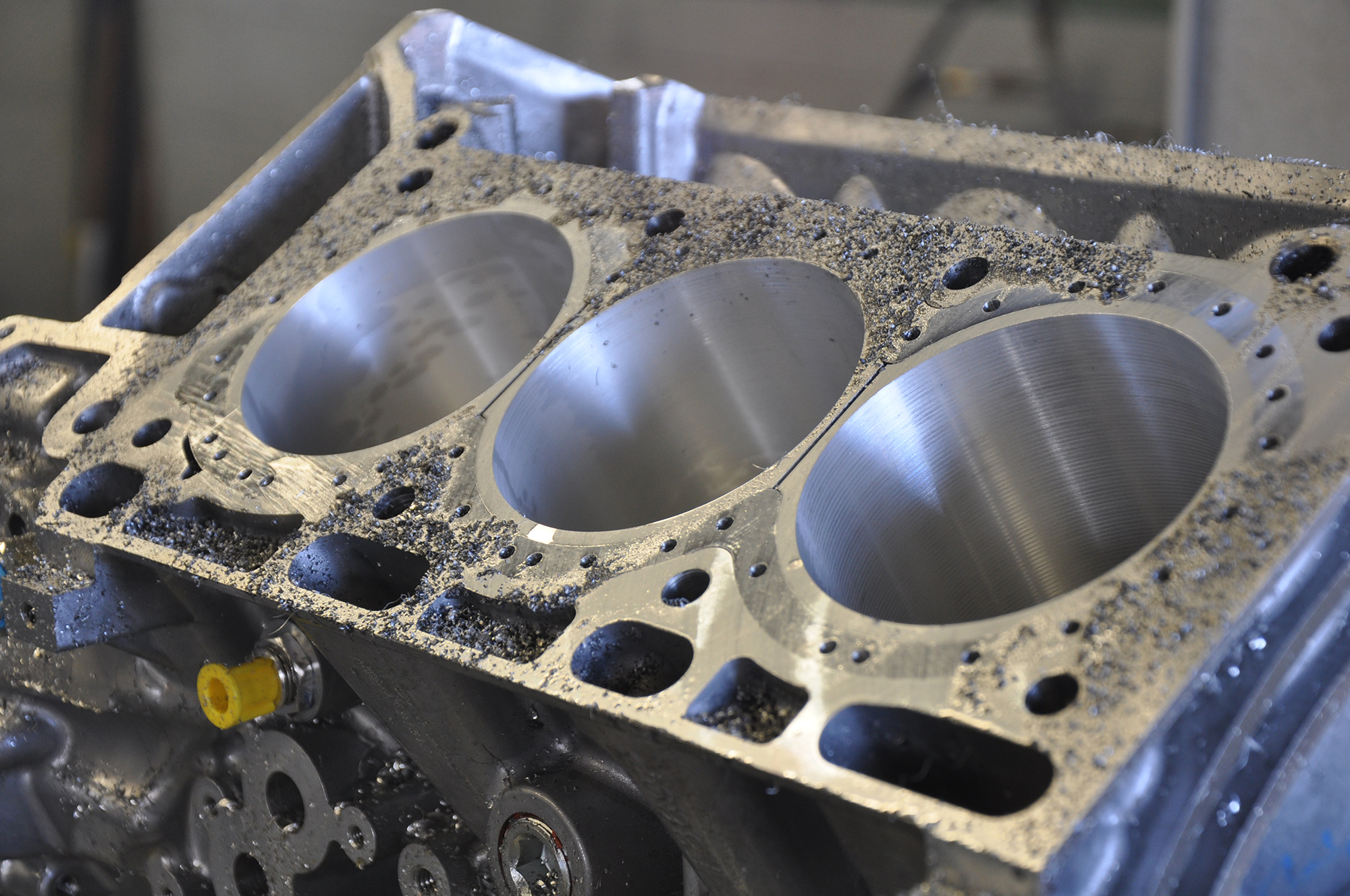

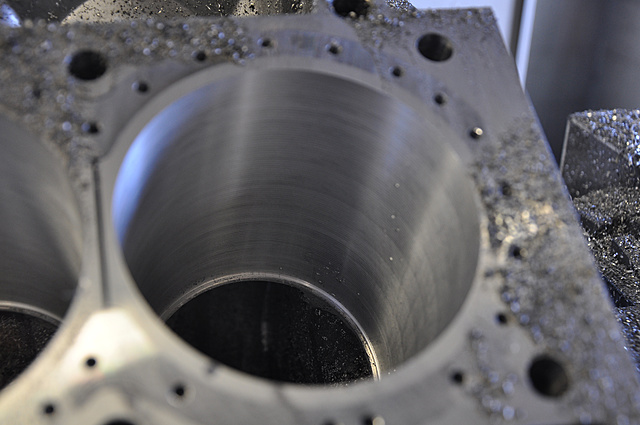

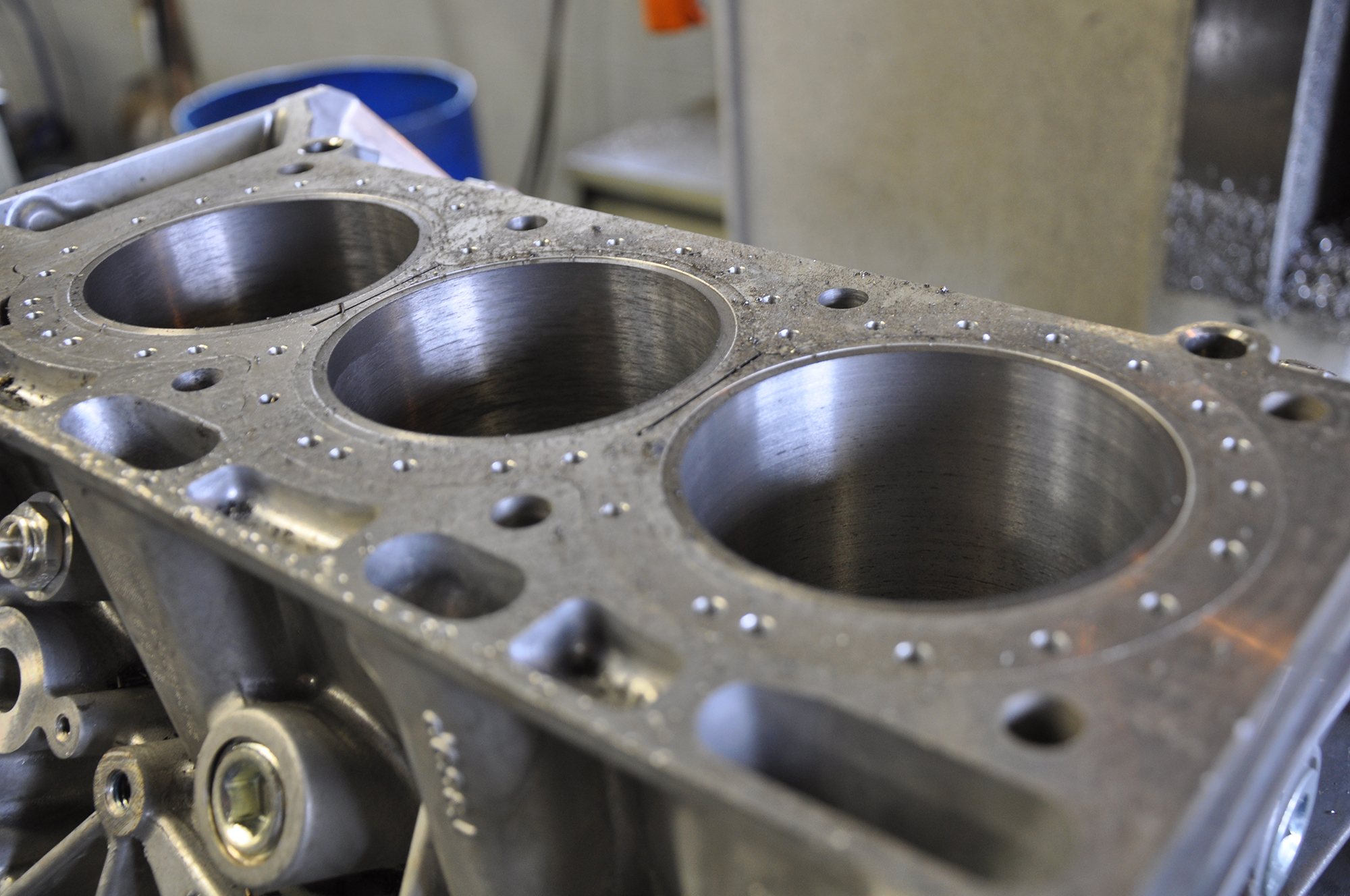

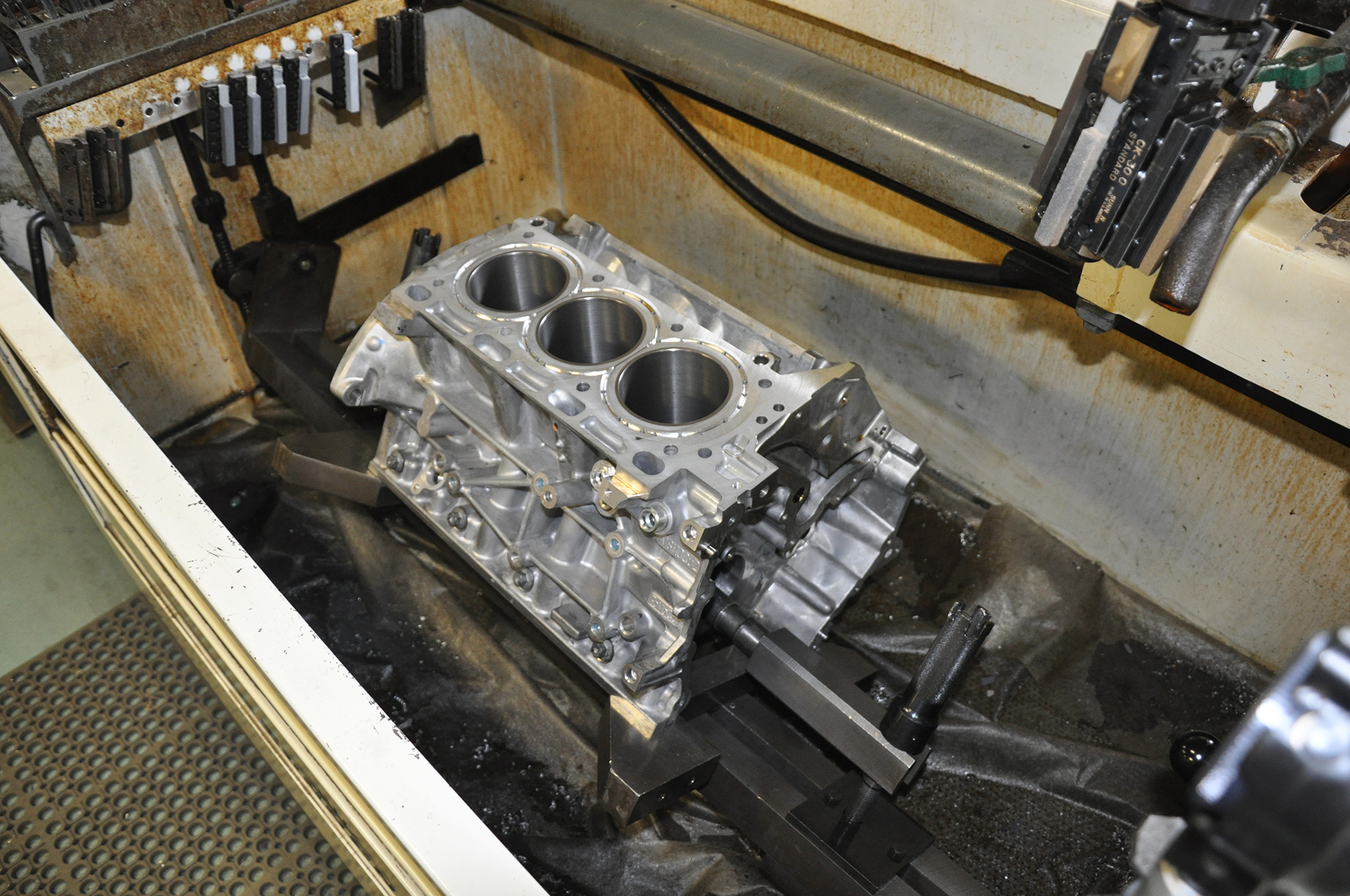

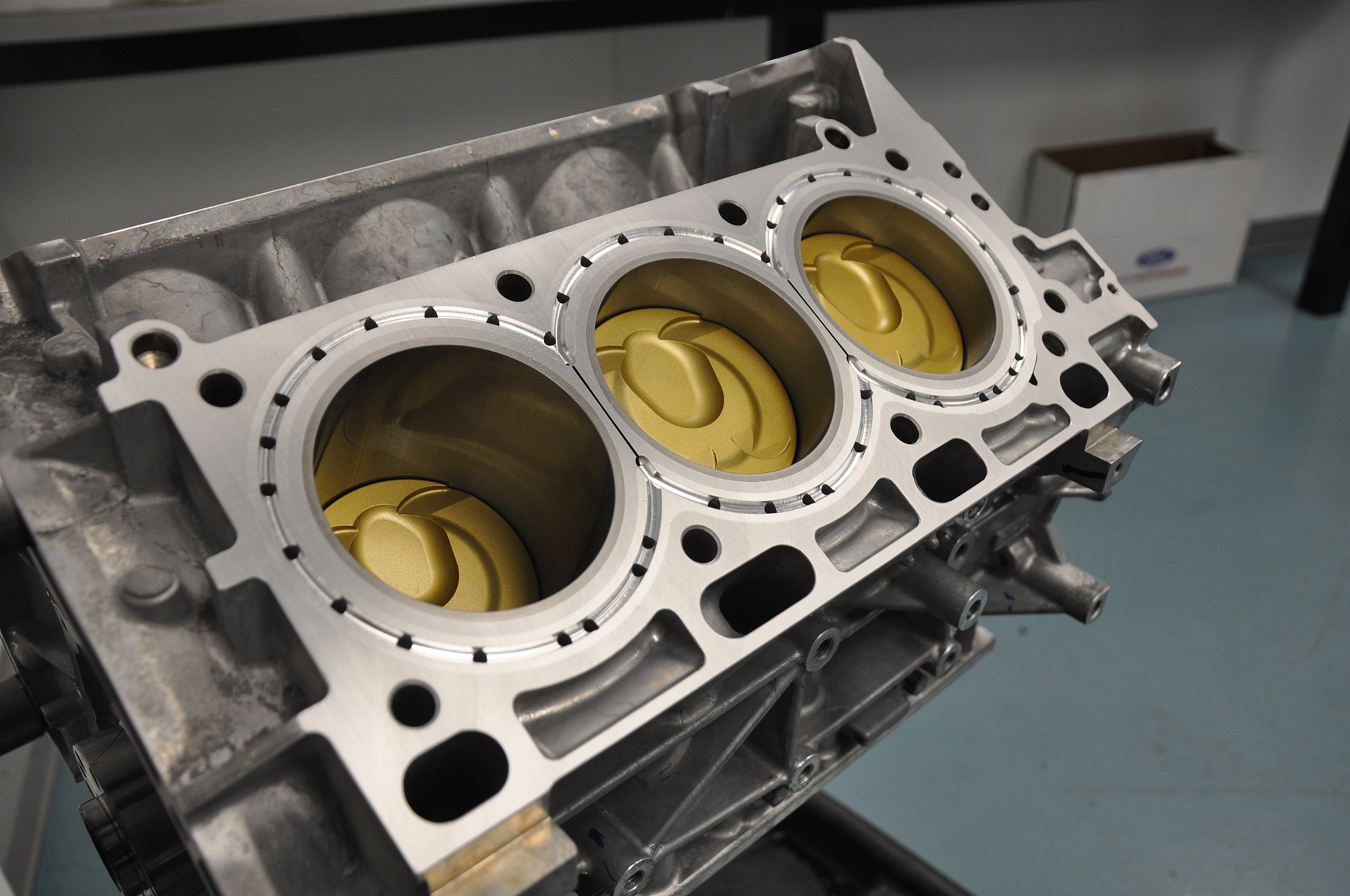

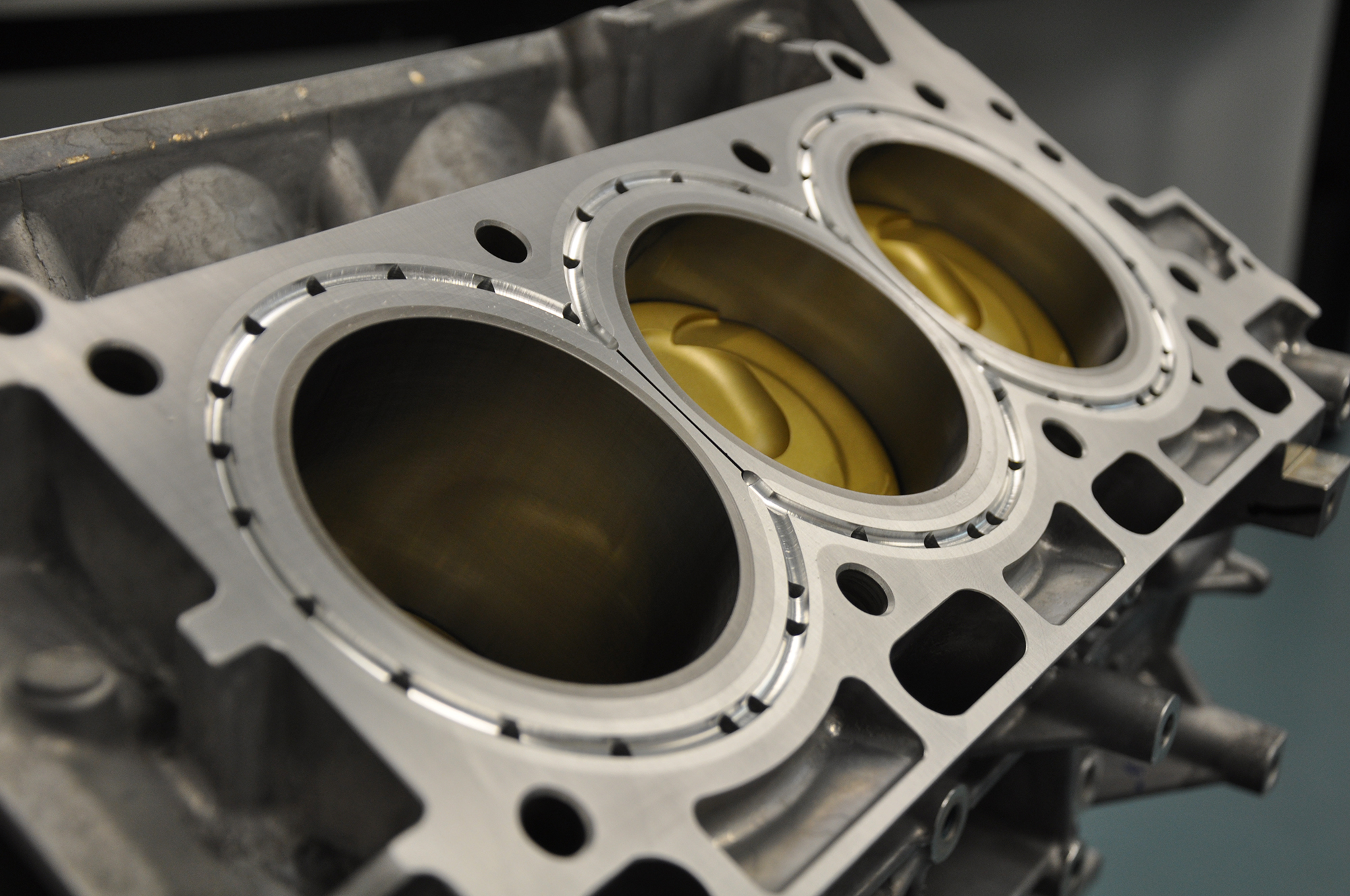

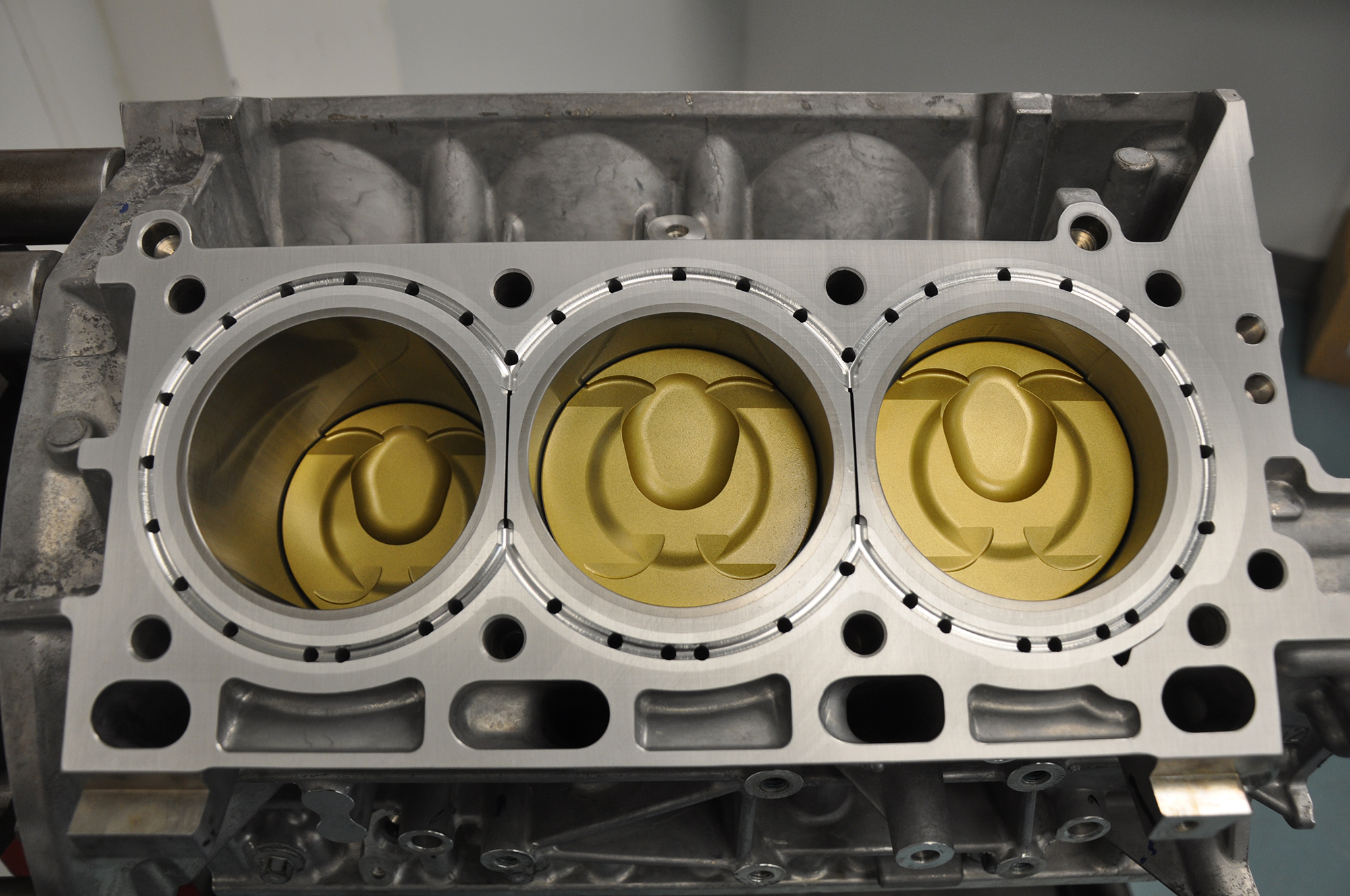

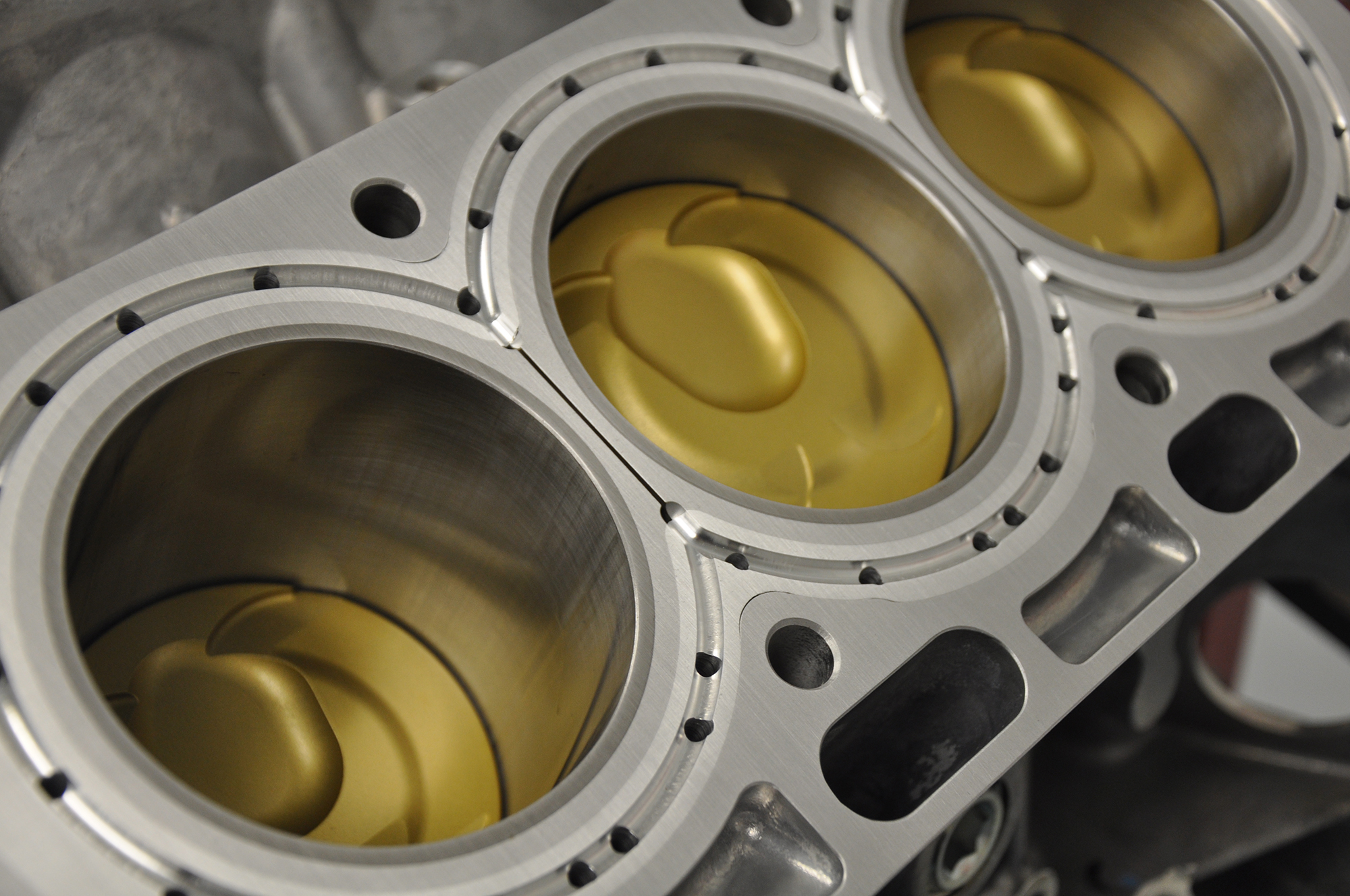

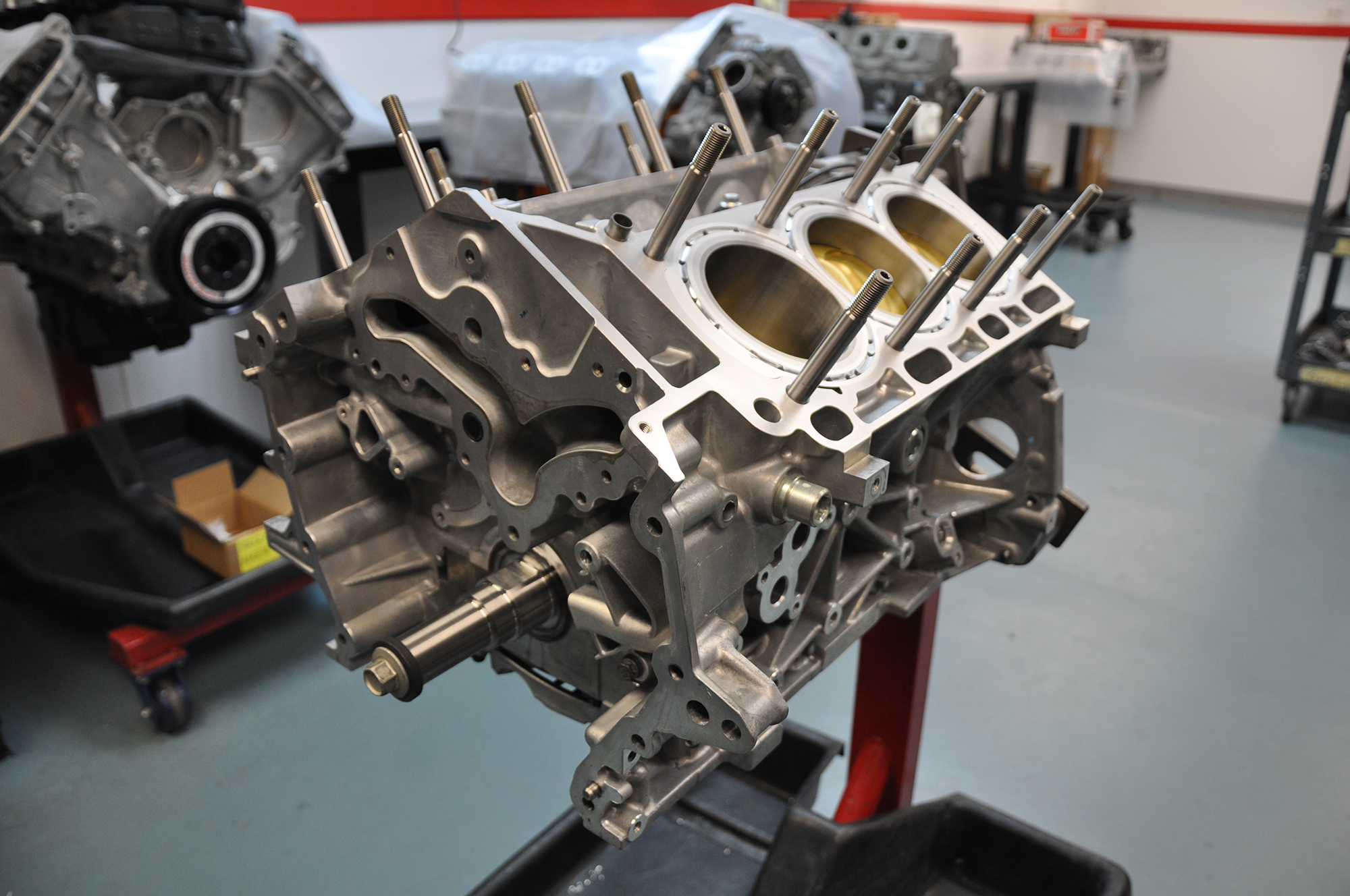

Off to the cylinder honing machine to finish the cylinder wall wit the new sleeves in. Here we bore for the piston to wall clearance and finish for the rings.

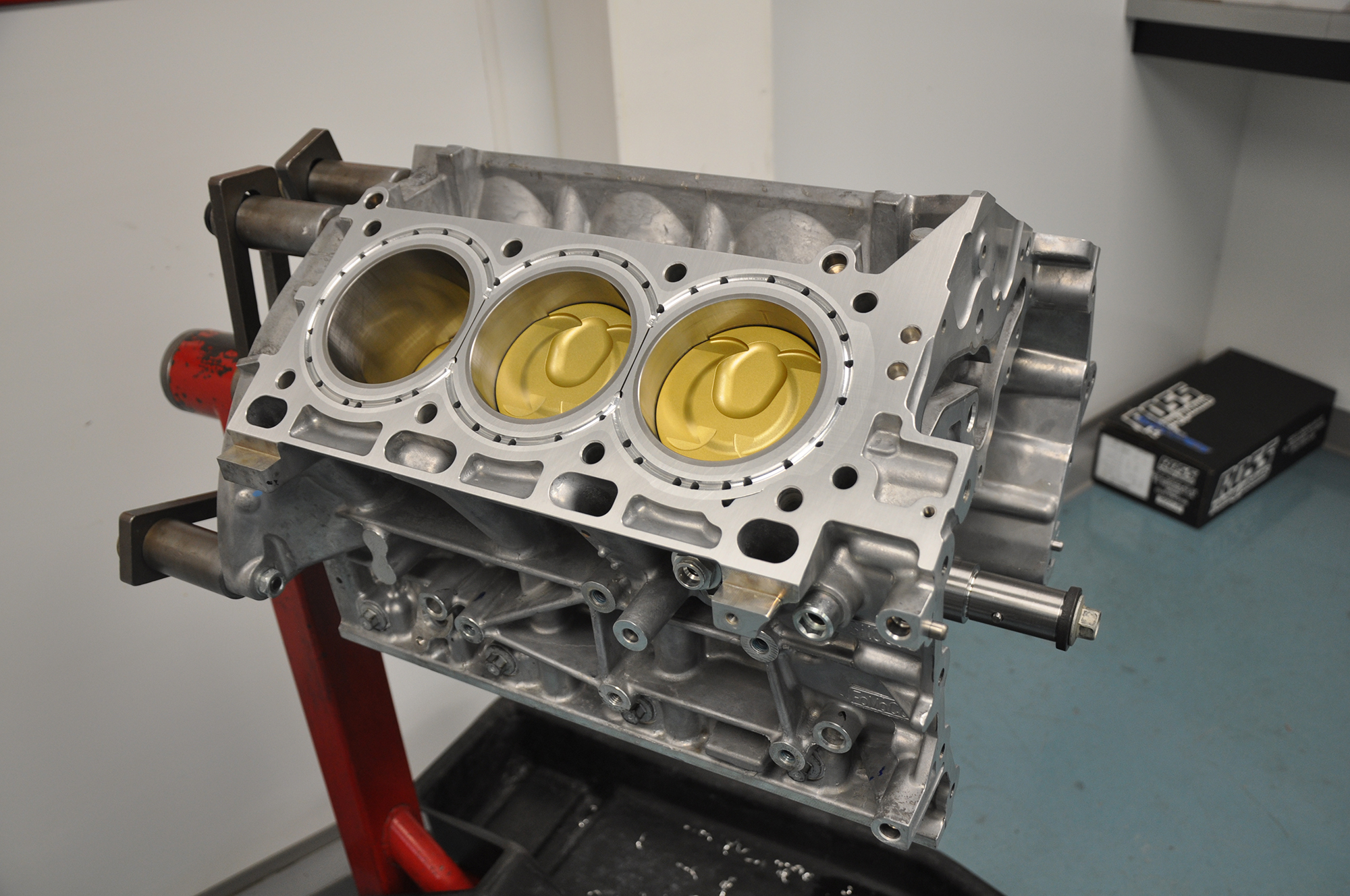

We will putting the rings and pistons in soon!

(Not pictured - deck plate)

We will putting the rings and pistons in soon!

(Not pictured - deck plate)

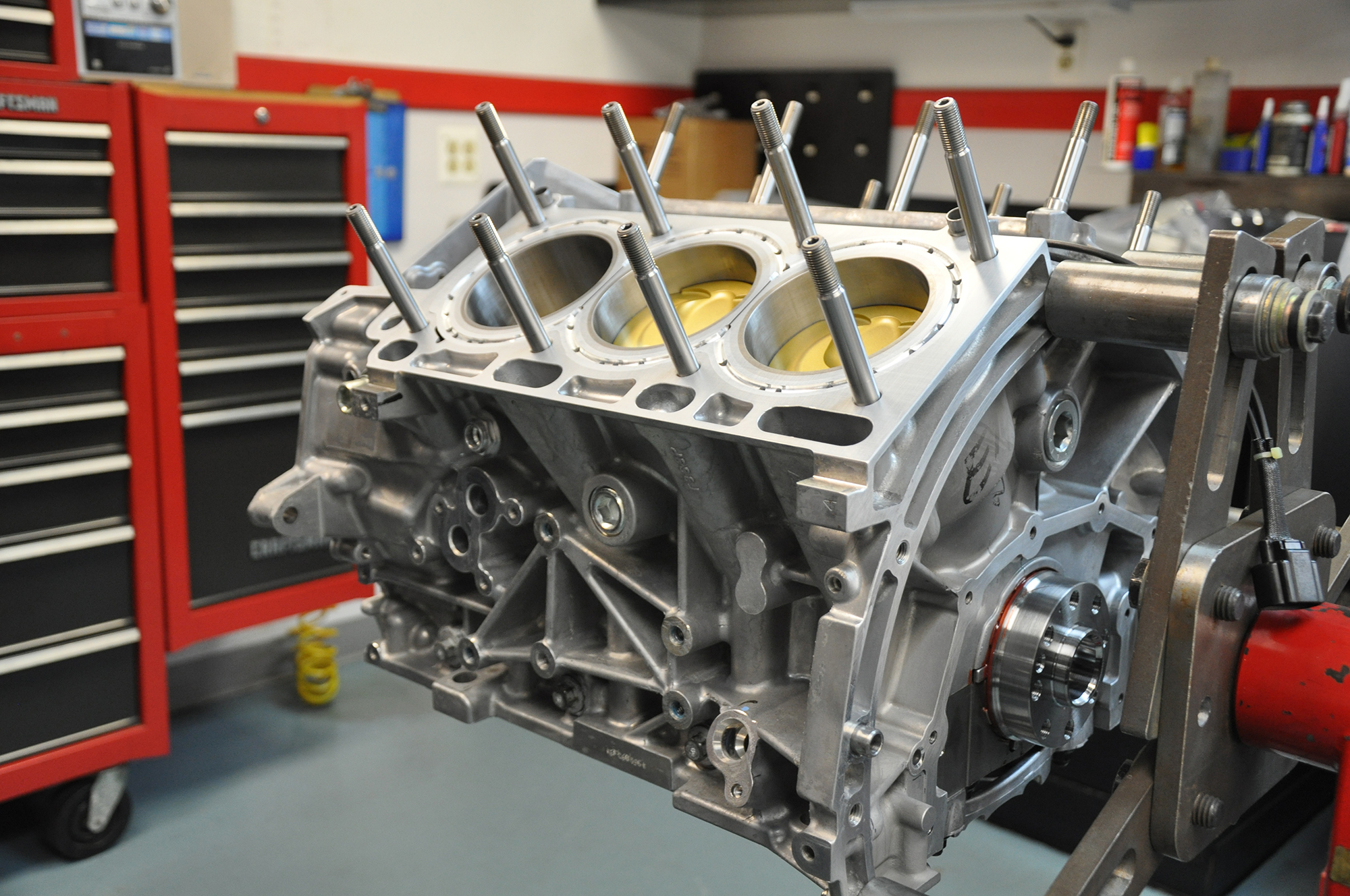

Putting the piston rings in the cylinder to set the proper ring end gap before the assembly is dropped in. A few more final details before the piston/rod assemble is placed.

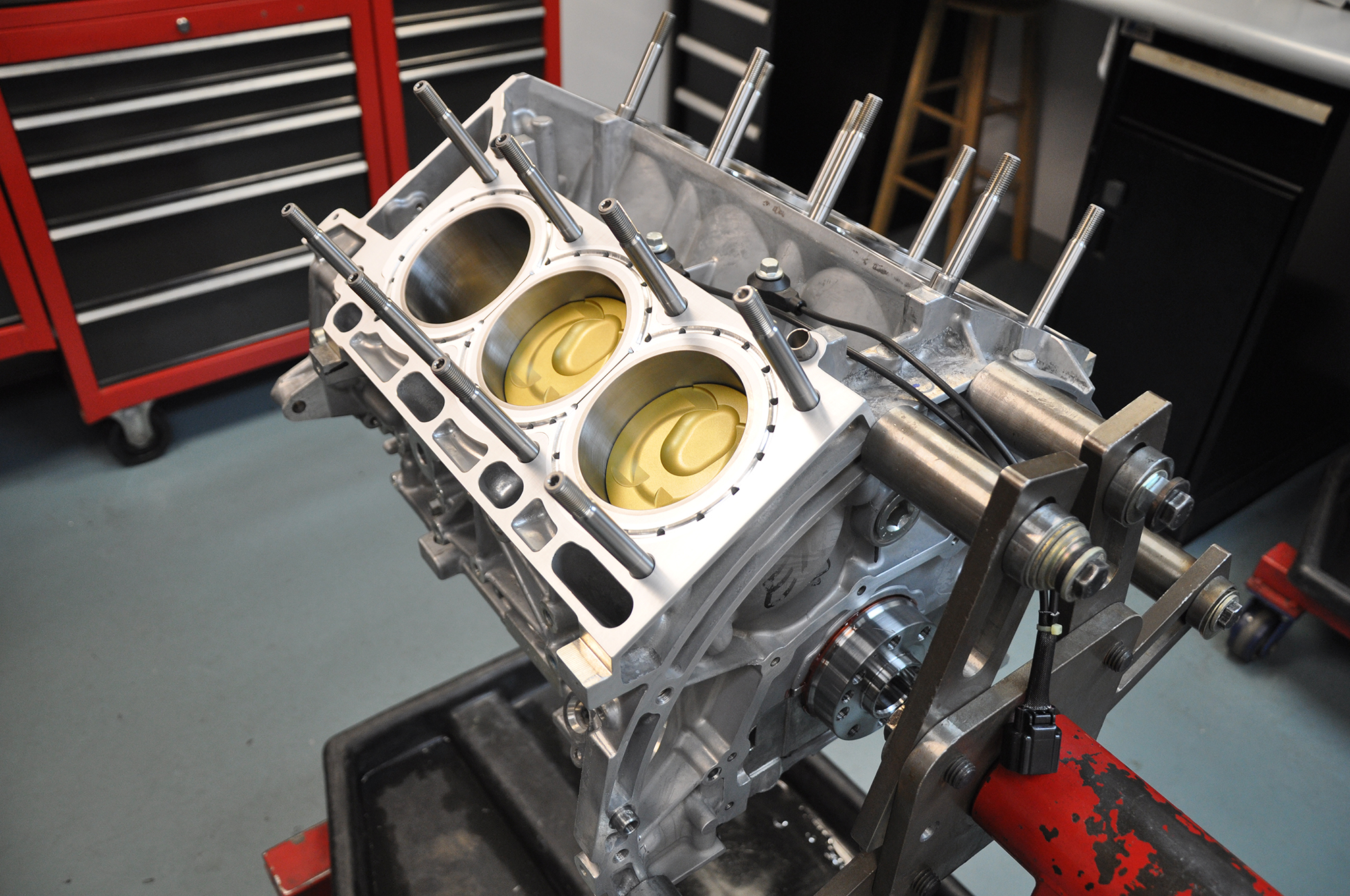

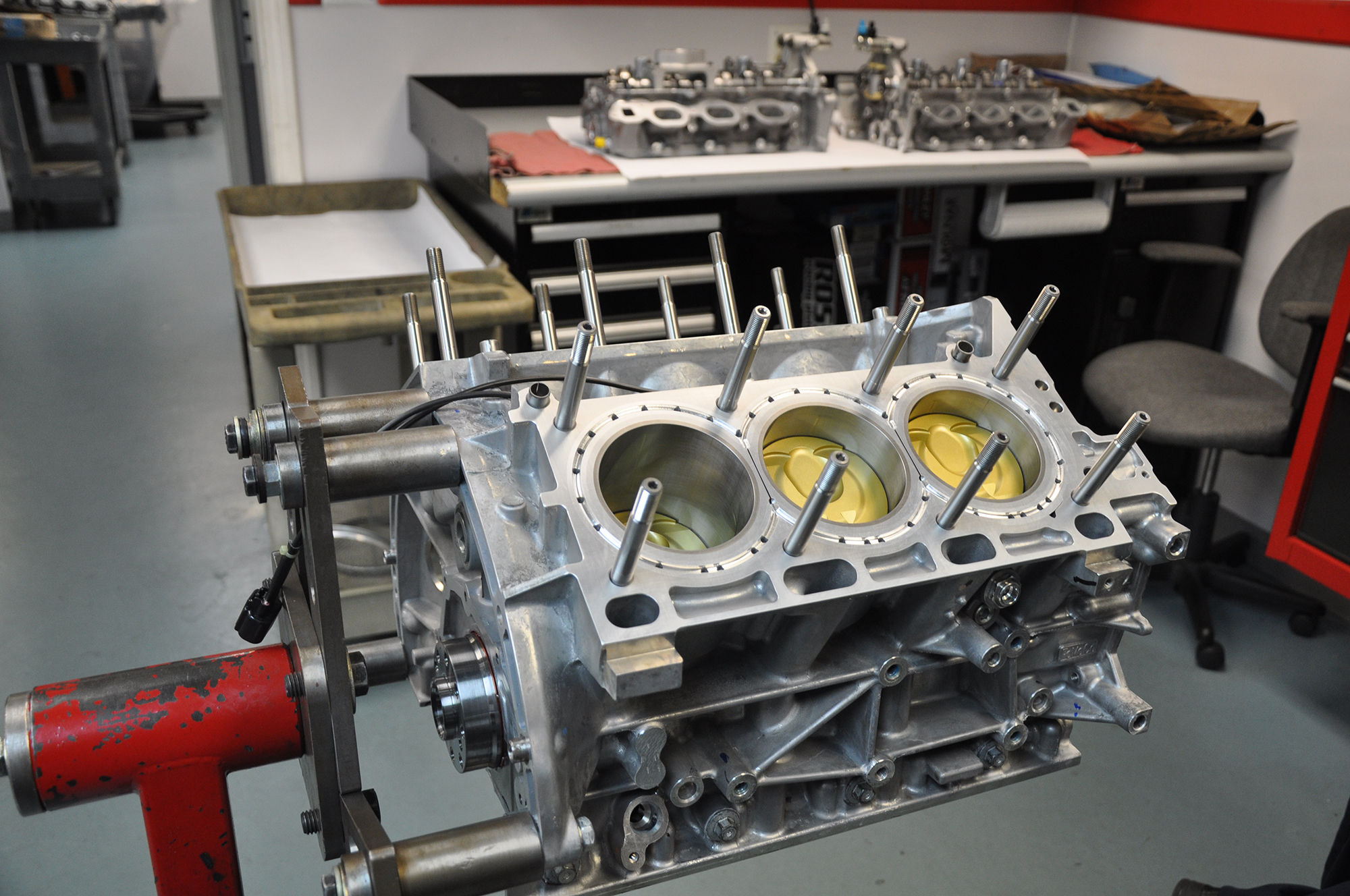

Rings are ground to fit, rods are attached to the pistons and everything has made it in! On the home stretch!

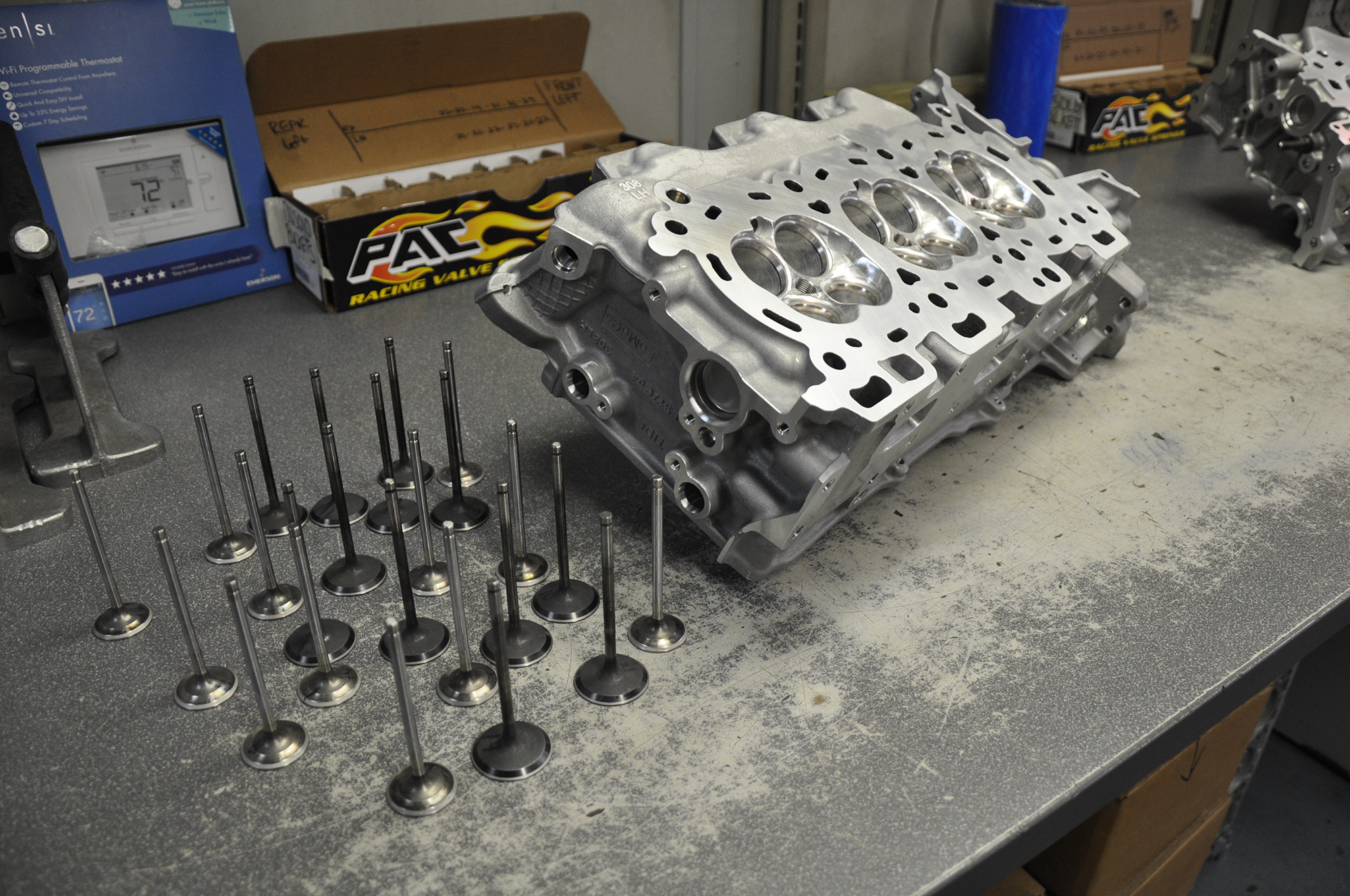

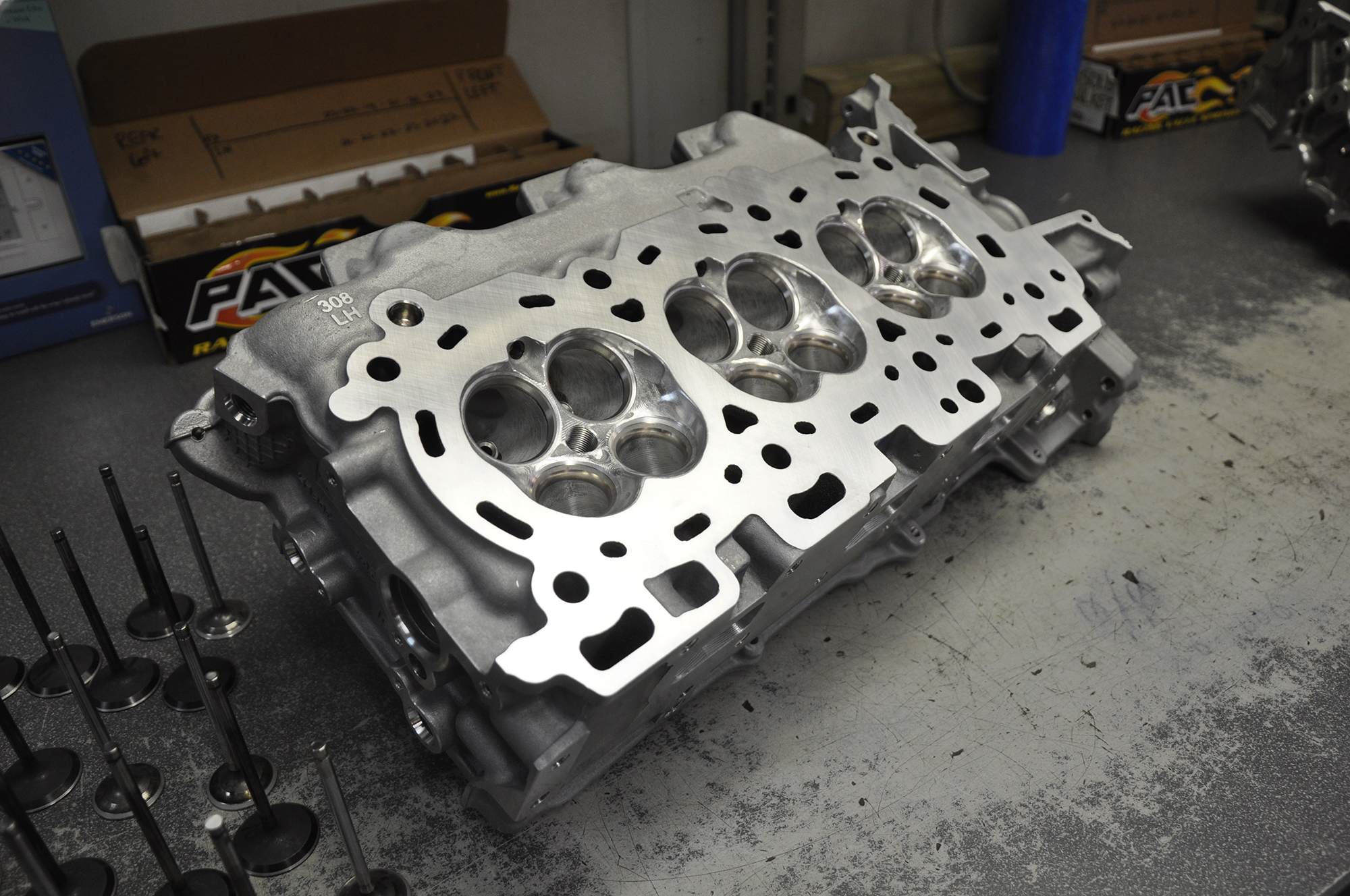

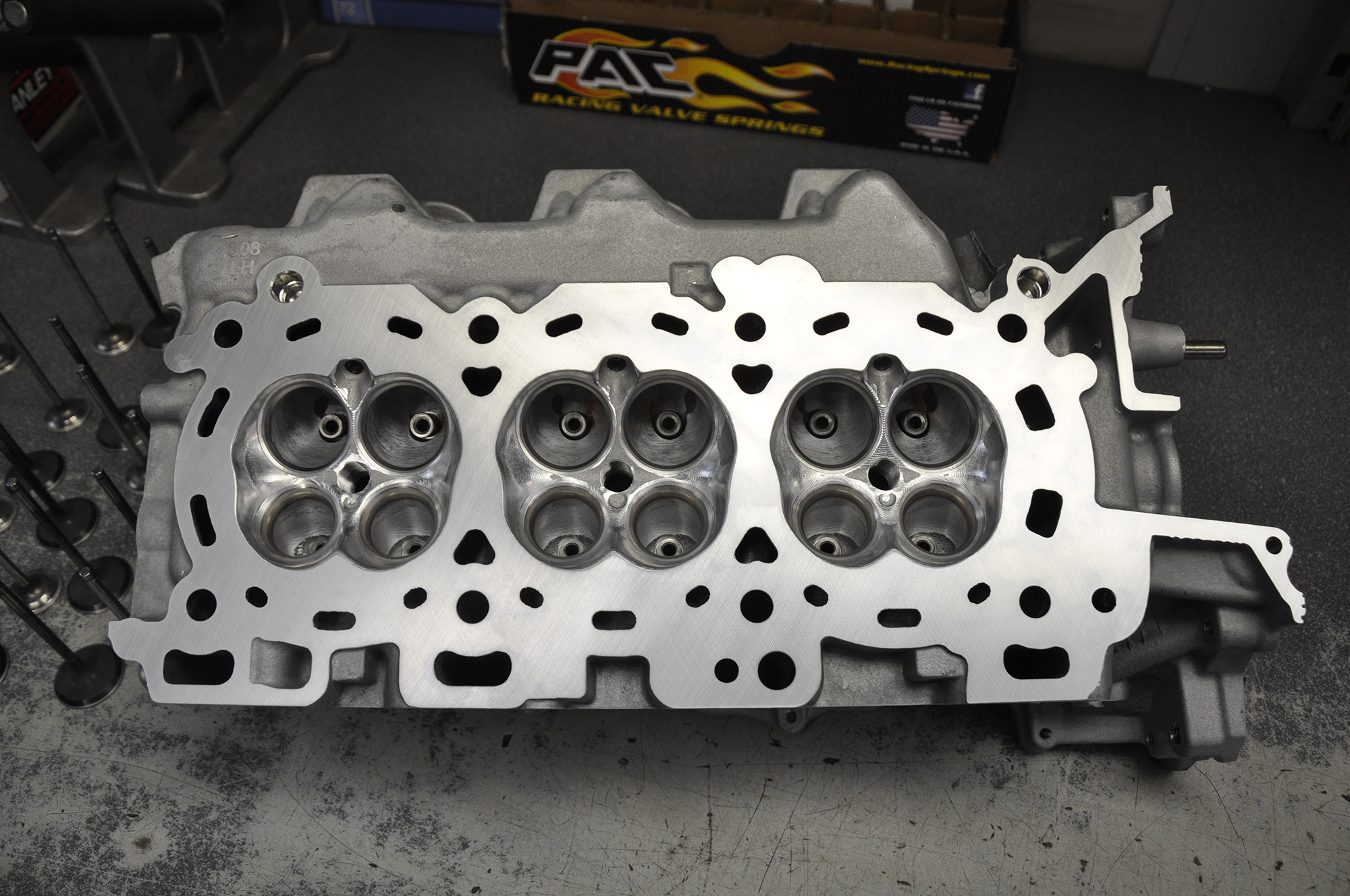

With the short block coming together, we turn our attention to the cylinder head department.

First steps in taking these stock 3.5L heads to the next level is a proper cleaning and inspection. We must ensure that there are no imperfections, cracks, or issues that could cause harm to the motor down the road.

A few photos in the cleaning bay before they are moved into the Cylinder Head room for final inspection and assembly.

First steps in taking these stock 3.5L heads to the next level is a proper cleaning and inspection. We must ensure that there are no imperfections, cracks, or issues that could cause harm to the motor down the road.

A few photos in the cleaning bay before they are moved into the Cylinder Head room for final inspection and assembly.

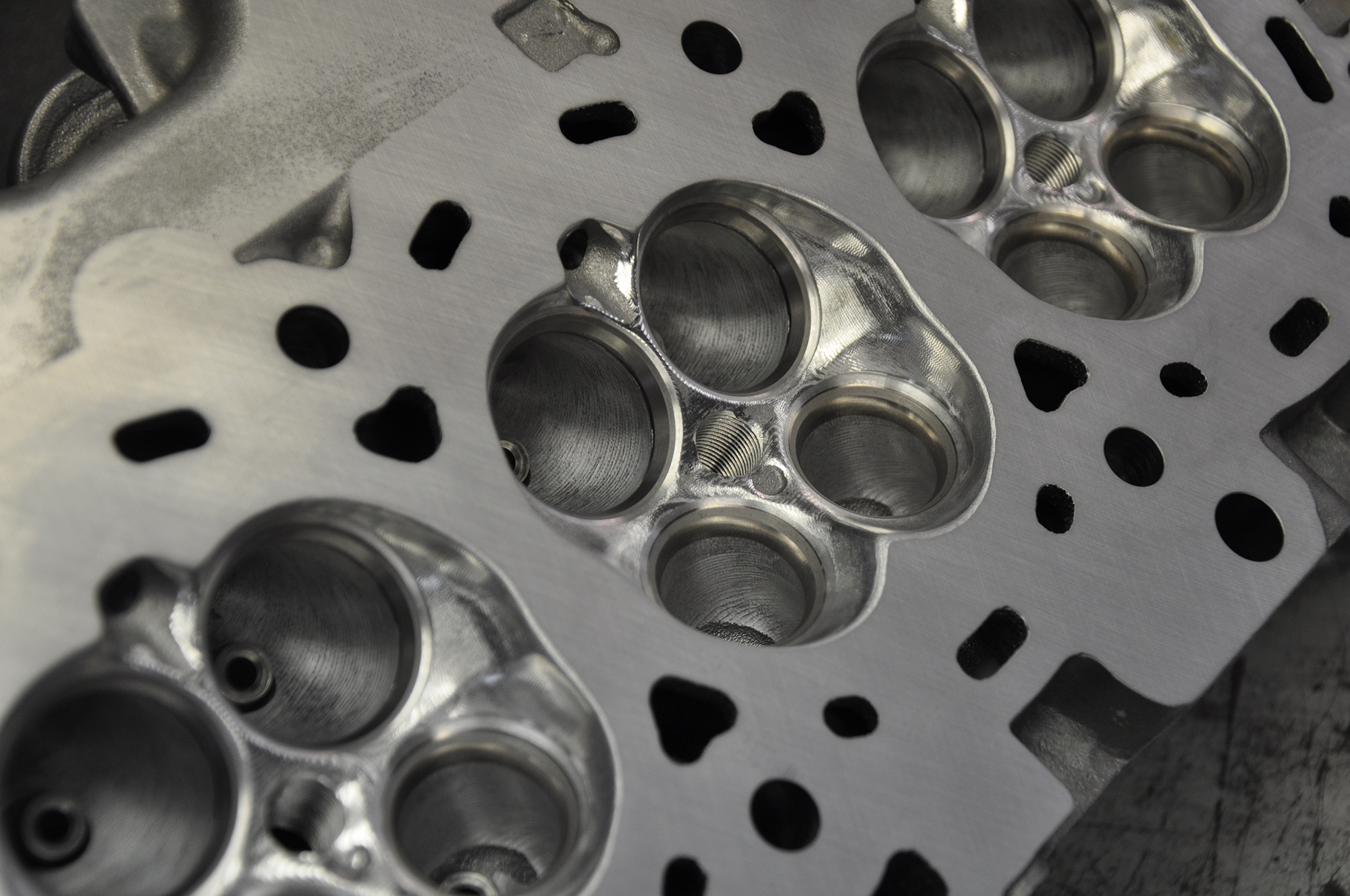

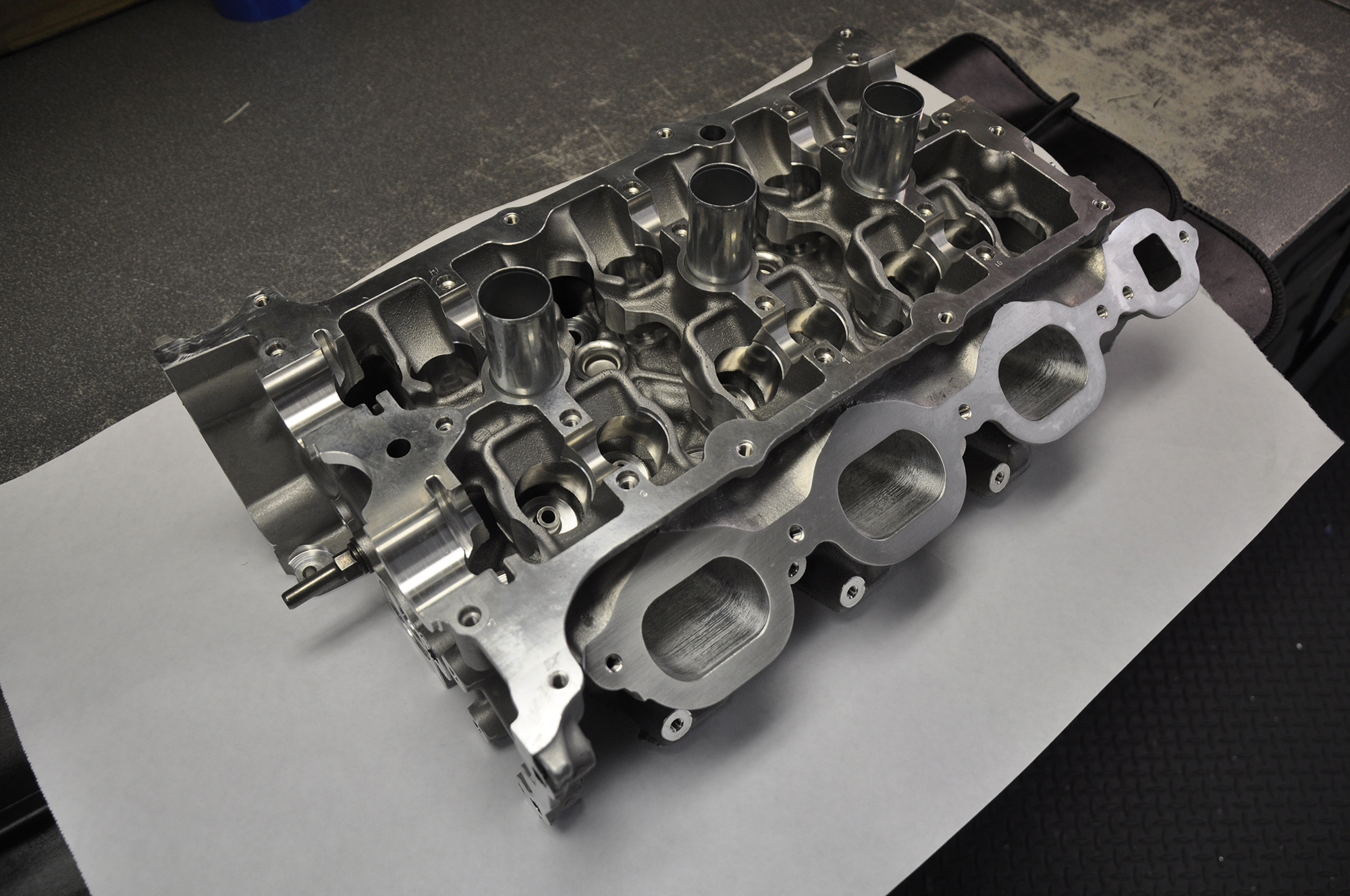

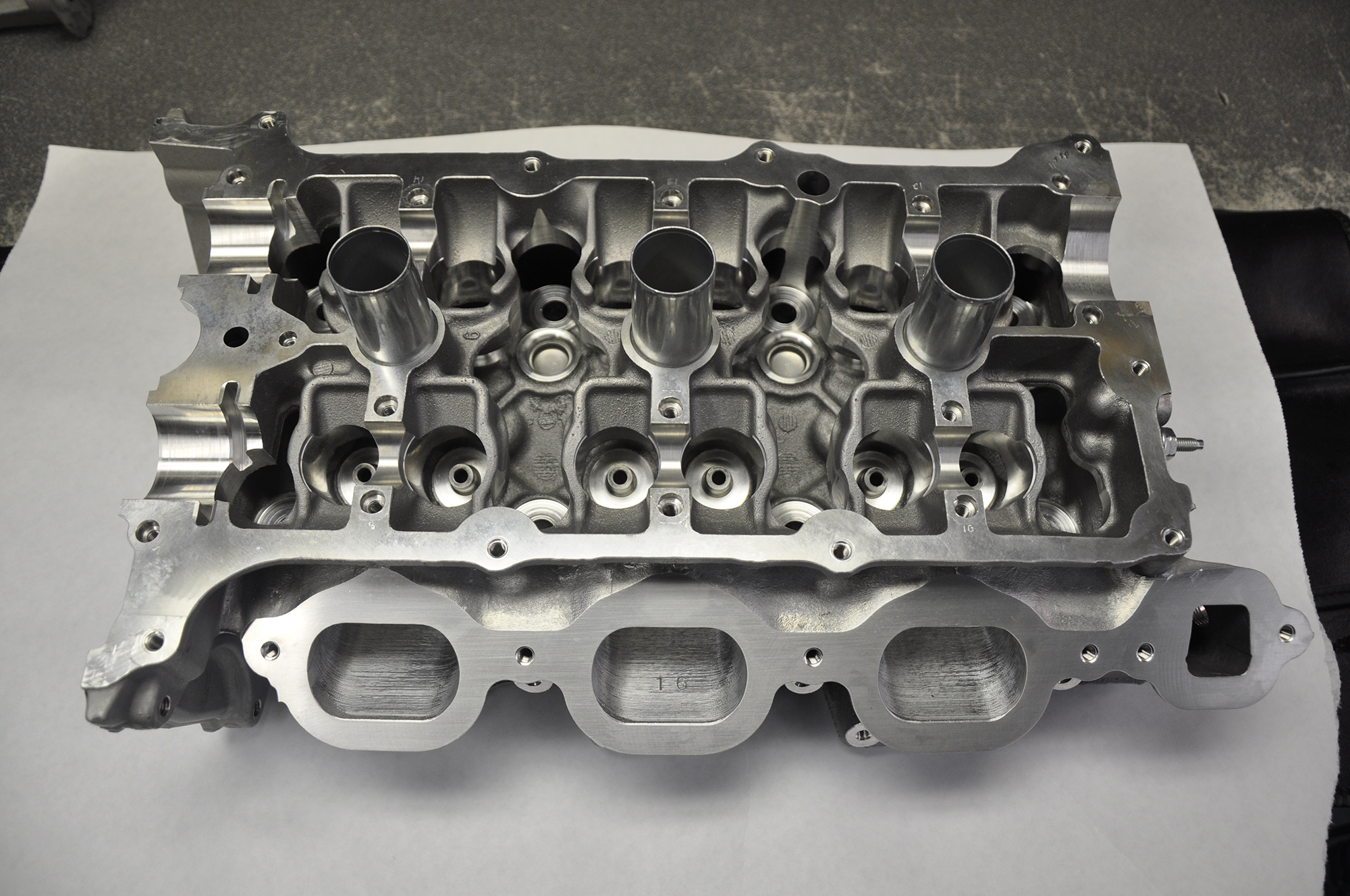

The heads have made it into the climate controlled cylinder head department! Everything is laid out nicely before the assembly process starts.

After the thorough cleaning, the valves are lubed and dropped into place followed by the valve stems. The springs are compressed using one of our hydraulic bench presses and the retainers are added. Buckets will be followed by the cams and topped off with the caps where everything is torqued to spec!

After re-assembly, we move the heads to the engine build department where they should be putting the head studs in now!

After the thorough cleaning, the valves are lubed and dropped into place followed by the valve stems. The springs are compressed using one of our hydraulic bench presses and the retainers are added. Buckets will be followed by the cams and topped off with the caps where everything is torqued to spec!

After re-assembly, we move the heads to the engine build department where they should be putting the head studs in now!

A few more photos..

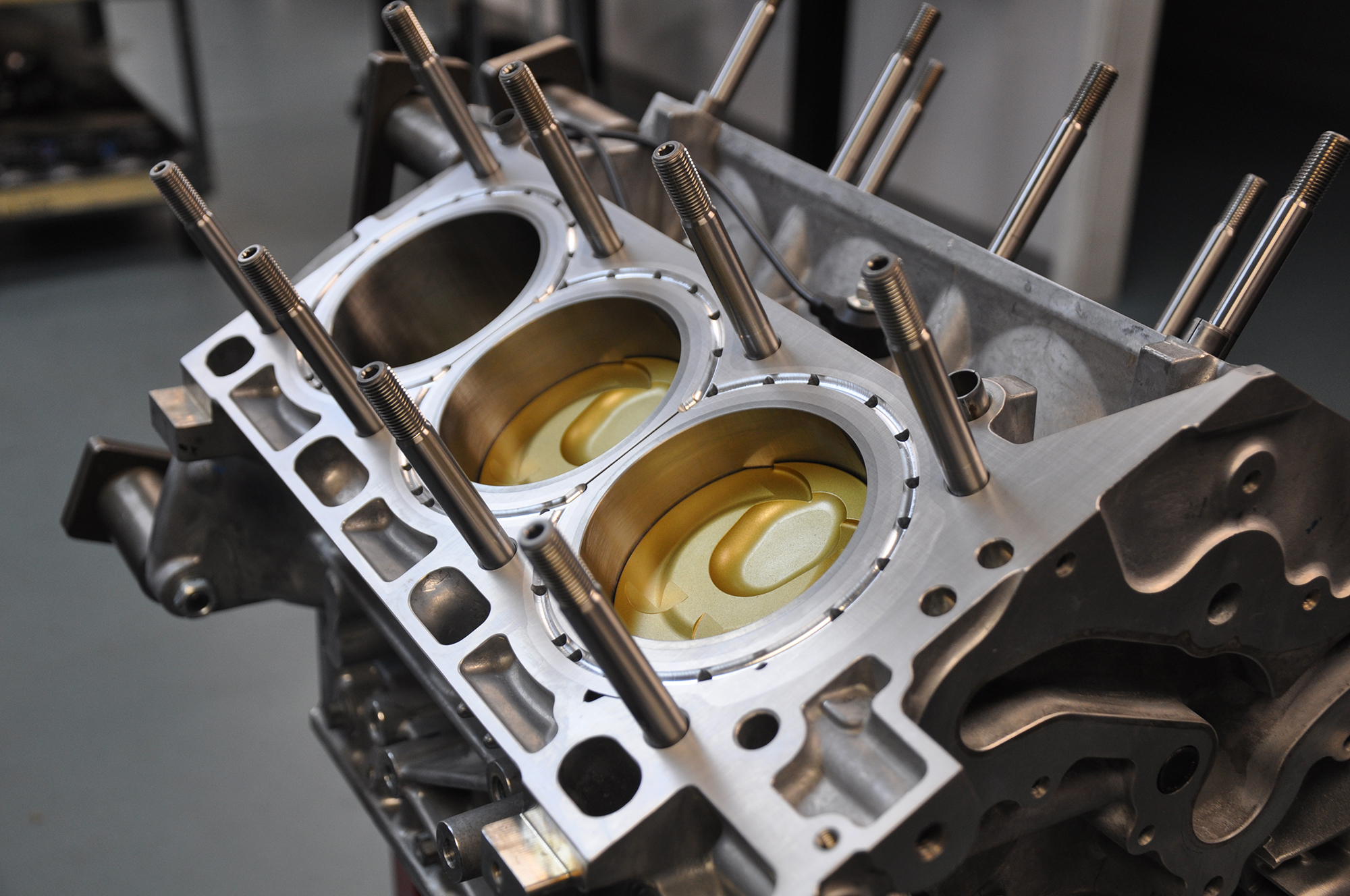

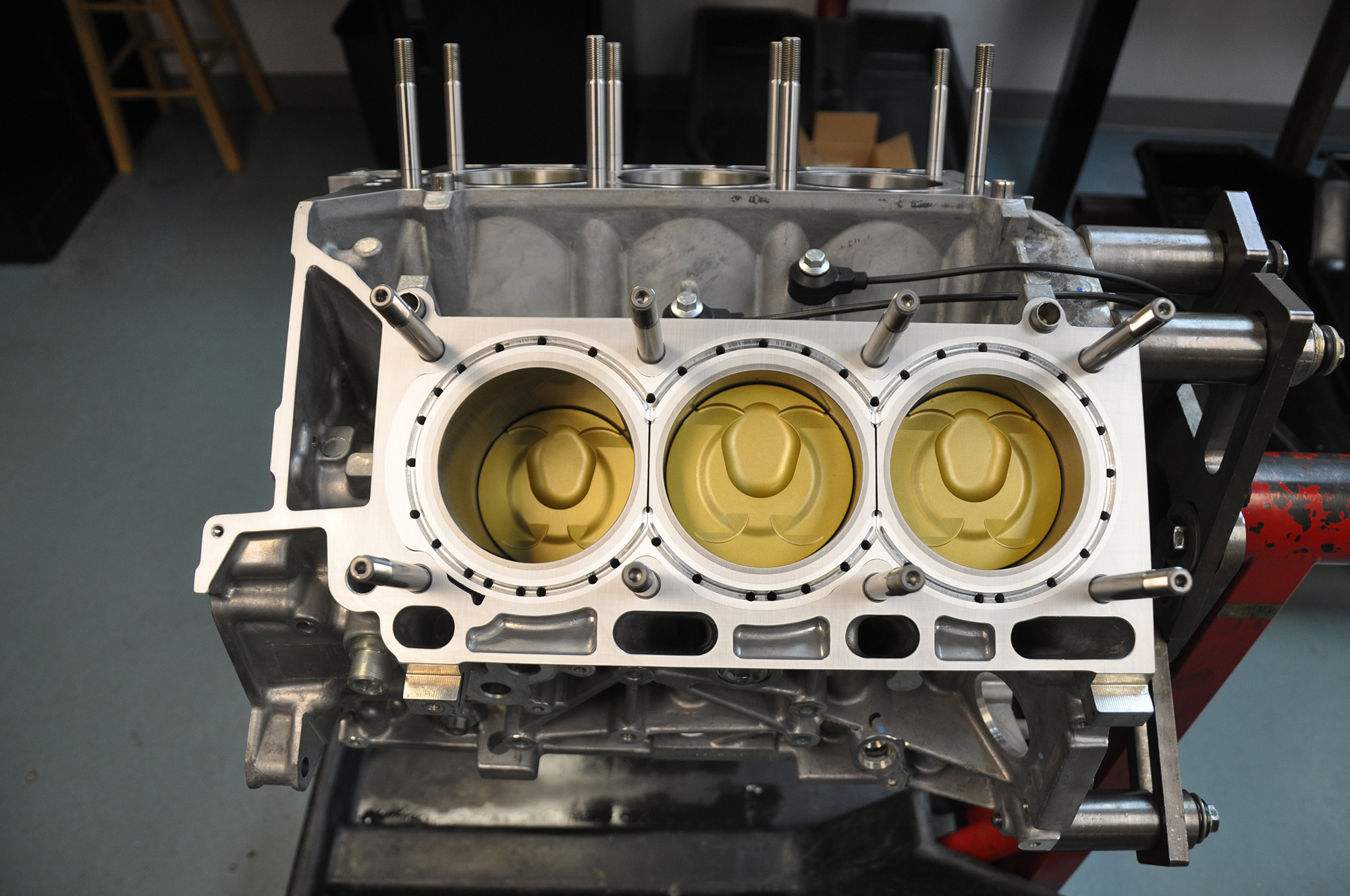

Our Powerstorm 3.5L EcoBoost Head Studs have made it into the short block! These Powerstorm Head Studs allow for greater clamping force to keep the cylinder heads in place under high loads from built 3.5L EcoBoost engines like this one. The studs are also broached for ease of installation and come with all the required hardware.

With the studs in, we are waiting on the final assembly of the heads and we are set to finish this project!

With the studs in, we are waiting on the final assembly of the heads and we are set to finish this project!

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)