I finally got the opportunity to weigh the '07-'12 bare flange/adapter combination. The two of them fitted together (but without all the bolts to tie them together) came in at 7 lbs 5.4 ounces. This means that the adapter combination comes in at 3 lbs 5.1 ounces more than a stock 2013 flange (which weighs 4 lbs 0.3 ounces). For '07-'09 owners, this still means a net reduction in weight at the flange of 2 lbs 4.6 ounces ('07-'09 comes in at 9 lbs 10 ounces).

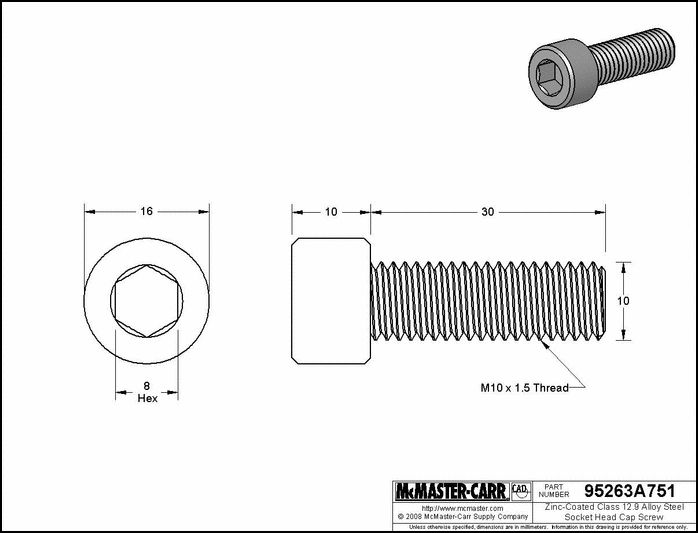

Dimensionally, these are the bolts that will be going through the rear face of the original flange...

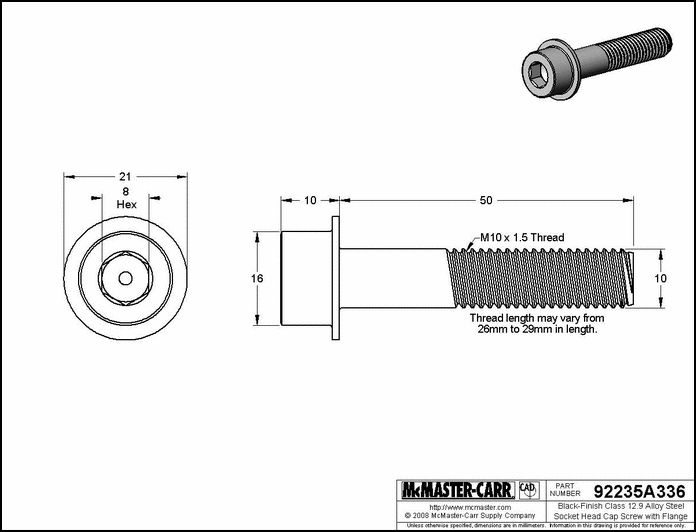

And this is the size/length of the bolts that will retain the CV joint/shaft...

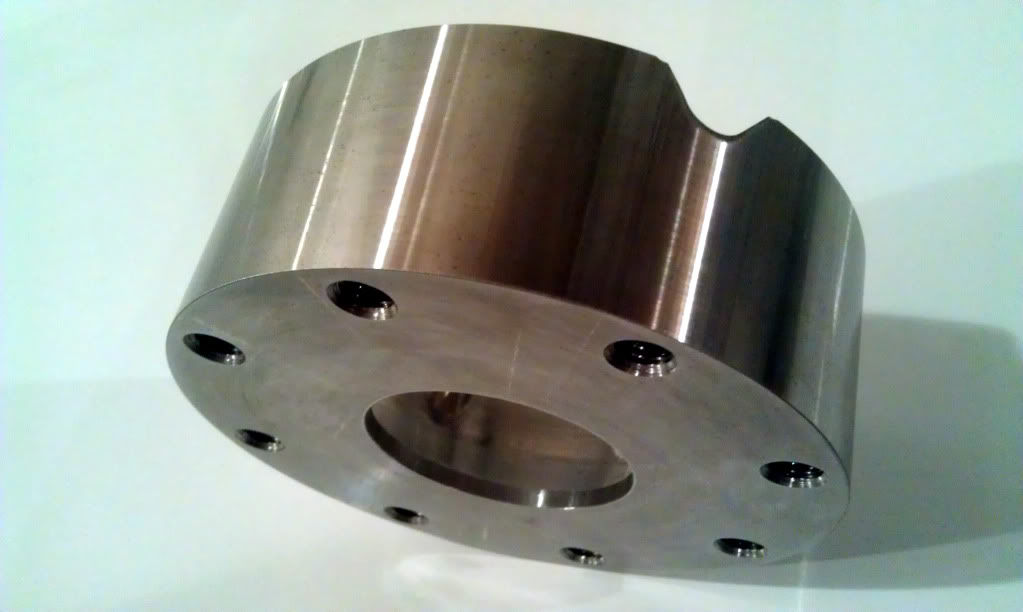

And because I finally got a few moments this morning I took the two apart and cleaned up the threads...

Down in the basement finishing up two water heater tanks and an expansion tank (pressure relief valve kept burping), I took a quick video of the assembly with my phone. I wanted to show how precise the pilot fit is...CLICK HERE...

Dimensionally, these are the bolts that will be going through the rear face of the original flange...

MC said:Class 12.9 screws are high strength and coated with a layer of zinc for rust resistance. Size M3 screws are zinc plated; all other sizes have a coating of zinc flake, which provides 600 hours of salt spray resistance. All screws are fully threaded and have a Class 5g6g thread fit. They have a minimum Rockwell hardness of C37 and tensile strength of 174,000 psi. Dimensions meet DIN 912/ISO 4762. Screw length is measured from under the head.

And this is the size/length of the bolts that will retain the CV joint/shaft...

MC said:The flange distributes holding pressure, so screws are less likely to come loose. All screws are made from alloy steel and have a black finish. They're fully threaded (unless noted) and have a Class 5g6g thread fit.

Minimum Rockwell hardness is C39; minimum tensile strength is 176,900 psi. Head height is measured from the bottom of the flange to the top of the head. Screw length is measured from under the flange.

And because I finally got a few moments this morning I took the two apart and cleaned up the threads...

Down in the basement finishing up two water heater tanks and an expansion tank (pressure relief valve kept burping), I took a quick video of the assembly with my phone. I wanted to show how precise the pilot fit is...CLICK HERE...