Its been awhile and i have not stopped modding my cobra, I just haven't kept up with posting. Ive been lurking for the past 2 years or so.....

Anyway on to the pics

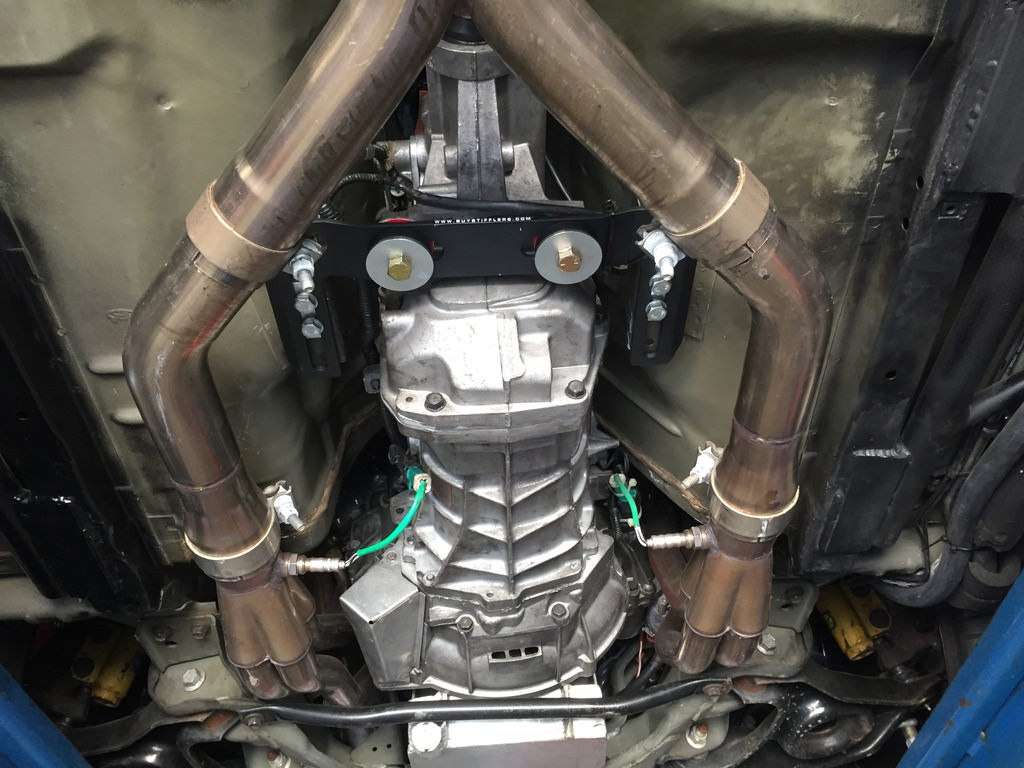

Added a Stifflers solid trans mount to clean up some sloppy shifting. I think it make a difference and my shifts felt alot more solid after installing. I didnt notice much of a change in NVH

Random pictures from last year in the driveway

I bought one of racebronco's hoods.... its still sitting upstairs!

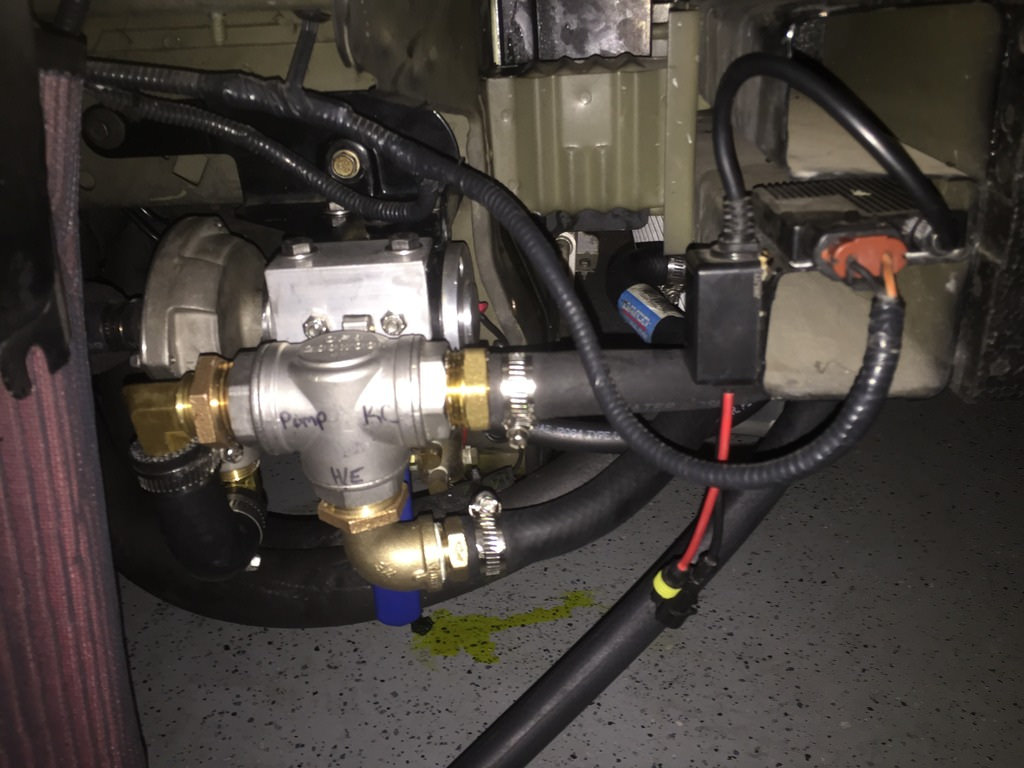

Installed a killer chiller.... will probably remove soon...

I bought a 1" ball valve to switch between killer chiller and Heat exchanger. At no time will it go through the H/E and K/C at the same time. A 3/4" ball valve ball portion necks down alot so i went with a 1" and used 3/4" fittings and lines. I also made a bracket to mount it where and how I wanted it.

**See post 67 for updated ball valve fitting setup**

All installed with lines routed.

It gets the fluid nice and cold as advertised

I went to the track a few times last year breaking a total of two half shafts and busting up my diff. Here is a pic from november 2016. On this pass I was testing out a newly installed WOT box and broke my last half shaft and diff. I was on drag radials and was supposed to be slipping the clutch at 3200rpm. I ended up dumping it...

You can vaguely see the cracks in the spider gears.

Ok so this lead to my car sitting over winter waiting on G-force to release their new lifetime warranty axles. I bought a pair soon as they became avaiable.

Man thats a tight fit.... Gforce says thats ok.... i have a few miles on them and so far so good.

CC311E4E-3807-4D79-85F5-3F6D17D8DD18_zpshfwsgid1 by Troy, on Flickr

CC311E4E-3807-4D79-85F5-3F6D17D8DD18_zpshfwsgid1 by Troy, on Flickr

A couple of guys on modular fords (Ed) also talked me into getting the lifetime warranty wavetrac diff.... along with Mark Williams differential steel main caps, solid pinion spacer and ARP studs! I replaced all the bearings and races in the diff as well.

You have to mill the MW caps in order to get them to fit. They make them slightly larger since they know every ford housing will be different. I did not take a pic of this process unfortunately. It is very easy to do if you have access to a mill, just make sure you shave off less rather than more. Another option is to send your diff housing into MW and pay them to do it for you.

If you want to use ARP studs over the supplied bolts you will have two options since the nuts and washers do not fit into the MW cap holes. You either mill the ends of the caps off or put the washers and nuts on a lathe to reduce their OD. Here is a pic showing how I set it up to put on a lathe. Basically what your looking at is a ARP 12 point nut, 2 washers and another ARP nut tightened on the stud in order to put on the lathe and reduce the OD to fit inside the MW cap hole. I do not remember the OD measurement I reduced them to but just measure the ID of the MW cap hole and subtract a small amount.

Parts I used:

All done and sealed off with another lube locker gasket. So far It isn't leaking a drop!

Anyway on to the pics

Added a Stifflers solid trans mount to clean up some sloppy shifting. I think it make a difference and my shifts felt alot more solid after installing. I didnt notice much of a change in NVH

Random pictures from last year in the driveway

I bought one of racebronco's hoods.... its still sitting upstairs!

Installed a killer chiller.... will probably remove soon...

I bought a 1" ball valve to switch between killer chiller and Heat exchanger. At no time will it go through the H/E and K/C at the same time. A 3/4" ball valve ball portion necks down alot so i went with a 1" and used 3/4" fittings and lines. I also made a bracket to mount it where and how I wanted it.

**See post 67 for updated ball valve fitting setup**

All installed with lines routed.

It gets the fluid nice and cold as advertised

I went to the track a few times last year breaking a total of two half shafts and busting up my diff. Here is a pic from november 2016. On this pass I was testing out a newly installed WOT box and broke my last half shaft and diff. I was on drag radials and was supposed to be slipping the clutch at 3200rpm. I ended up dumping it...

You can vaguely see the cracks in the spider gears.

Ok so this lead to my car sitting over winter waiting on G-force to release their new lifetime warranty axles. I bought a pair soon as they became avaiable.

Man thats a tight fit.... Gforce says thats ok.... i have a few miles on them and so far so good.

A couple of guys on modular fords (Ed) also talked me into getting the lifetime warranty wavetrac diff.... along with Mark Williams differential steel main caps, solid pinion spacer and ARP studs! I replaced all the bearings and races in the diff as well.

You have to mill the MW caps in order to get them to fit. They make them slightly larger since they know every ford housing will be different. I did not take a pic of this process unfortunately. It is very easy to do if you have access to a mill, just make sure you shave off less rather than more. Another option is to send your diff housing into MW and pay them to do it for you.

If you want to use ARP studs over the supplied bolts you will have two options since the nuts and washers do not fit into the MW cap holes. You either mill the ends of the caps off or put the washers and nuts on a lathe to reduce their OD. Here is a pic showing how I set it up to put on a lathe. Basically what your looking at is a ARP 12 point nut, 2 washers and another ARP nut tightened on the stud in order to put on the lathe and reduce the OD to fit inside the MW cap hole. I do not remember the OD measurement I reduced them to but just measure the ID of the MW cap hole and subtract a small amount.

Parts I used:

- Mark Williams 8.8" Ford Steel Main Cap: Part#: 59300

- ARP 9" Carrier Bearing Stud Kit UHL: 3.250": Part#: 250-3004

- ARP 12-Point Nuts 1/2"-20: Part#: 300-8324

- Solid Pinion Spacer: purchased from Ratechmfg.com part #4105

All done and sealed off with another lube locker gasket. So far It isn't leaking a drop!

Last edited: