So I purchased an RXT for my car to replace my heavy and troublesome Spec 3+. I was really between the DYAD and the RXT, but with the past Lethal Christmas sale, I couldn't pass up the deal and went with the RXT. I have a Fidanza aluminum flywheel, and purchased a replacement center section, along with new flywheel bolts, ford racing throw out bearing and ford racing pilot bearing.

I've done a ton of research on setups, pivot ball length, and issues. I've come to the conclusion that most RXT issues are caused by improper setup and adjustment, mainly due to so many variables and opinions on whether or not an adjustable pivot is needed, or how much shorter one should set the pivot. Most of this is due to the amount of flywheel options out there, which directly effect the needed pivot ball length due to thickness of the flywheel itself. I've ran across countless threads and Facebook group posts with pivot ball length recommendations ranging from stock to 15mm shorter. So this leads to a lot of guess work, and trial/error having to pull and re install the transmission until its right. Stock flyheel and the Mcleod seem to require the least amount of shortening, and Spec/Fidanza require the most. Of course my opinion.

The other thing is that a lot of these threads and posts here, and on Facebook seem to make this whole install way more complicated, and discouraging to some. The whole process is very simple once you get into it, and not a big deal what so ever. So I wanted to show how I set mine up, and hopefully try and take some of the guess work out for any one installing their RXT. I am not gonna go over the process for pulling the transmission and the actual procedure of installing the clutch as that's fairly basic and the same for everyone.

Two other things that will really help you out other than a straight edge and a tape measure, is a paint pen/chalk marker and a set of break pad measurement gauges like this.

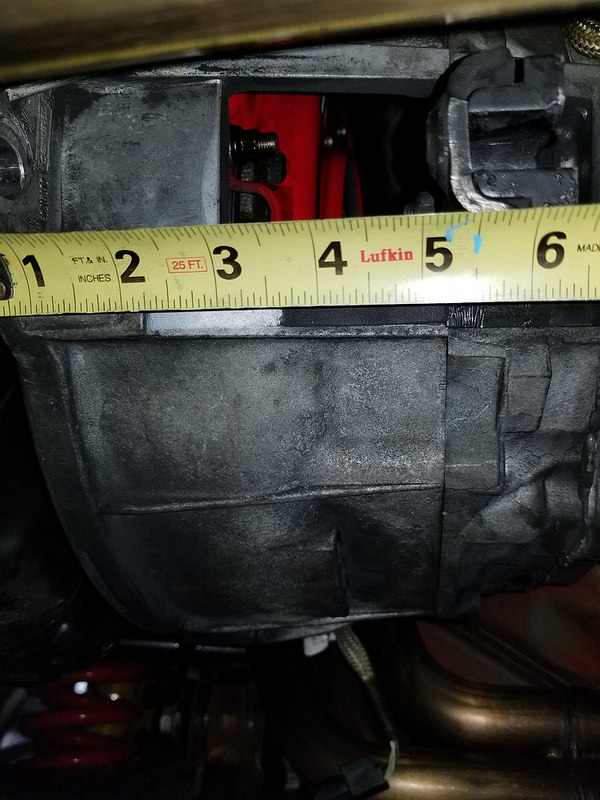

Step one, is to measure the current position of the clutch fork in relation to the fork opening. You'll want to re measure this when putting everything back together, and getting the fork in the same position, or really close, should net you similar engagement to your previous clutch setup. As shown, I measured 5 1/2".

I always remove the transmission separate from the bellhousing. Makes things way easier. Here's the Spec.

Transmission is out. I went ahead and brake cleaned everything off.

Bellhousing is next. Went ahead and tied the harnesses up in the shifter opening as well.

Here is the Fidanza after getting the clutch off of it. Center section wasn't too bad after about 12,000 miles I guess. New center section comes with hardware as well. I saved this for after all the measurements are done.

So now what you want to do is to place the flywheel down on a flat surface. Place the old clutch assembly down on top of the flywheel. I set the throw out bearing on the pressure plate surface to take this measurement, as the pressure plate surface is different between assemblies. It is "indented" on the spec, and not so on the RXT, so just using a straight edge would yield inaccurate measurements. Record your measurement as shown. Remove the old clutch assembly, and place the RXT in the same position. NOTE, you will have to snug up the floater/pressure plate to read an accurate measurement. Record the measurement as shown. This is where the brake pad measurement tools come in. I simply marked the tape measure in two spots. One mark for the old assembly, and another with the RXT assembly and used the pad depth tool to measure the difference. Made things simpler as most people measure the pivot ball length in mm anyways. The difference between these two measurements will be how much shorter you should set the pivot ball. This should get you damn near perfect. Also note, this picture is a rough idea of taking the measurement. You can notice my paint marks on the tape measure. You'll of course want a flat surface with no towel under anything HAHA. The RXT is 12mm taller than the Spec, per my measurement.

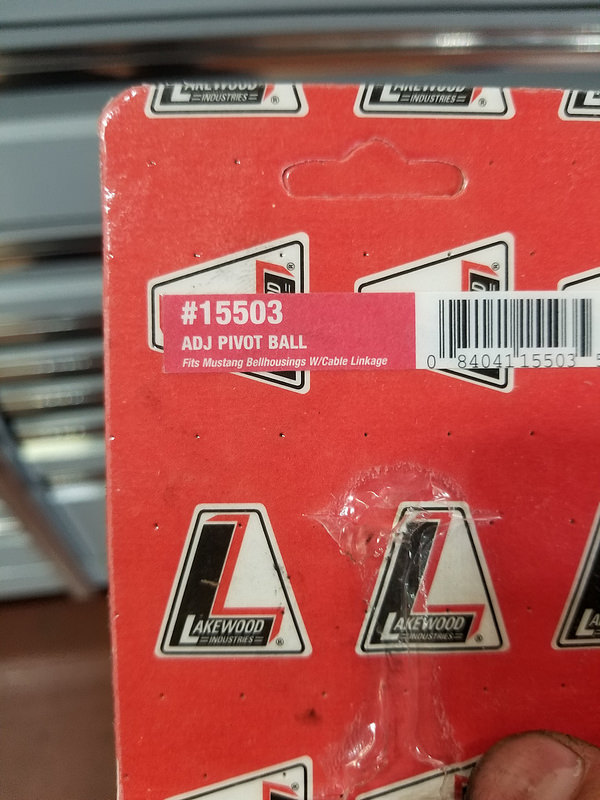

Stupid me didn't take a picture of measuring and installing the pivot ball. Just a picture of the package of which pivot ball I used. Anyways, you'll measure from the face of the transmission to the tip of the stock pivot. I used the "boss" or "webbing" on the face of the transmission as my base for the tape measure. I marked this measurement on the tape measure with the paint pen. Then used the brake measurement tool, and made another mark 11/12mm shorter than my previous measurement on the tape measure. Then just install the lakewood pivot into the transmission. Using the same method as before for measuring, rotate the pivot into the transmission until the tip of the pivot ball is at the second mark you've made on your tape measure. Lock the pivot ball down, and double check you're measurement hasn't changed.

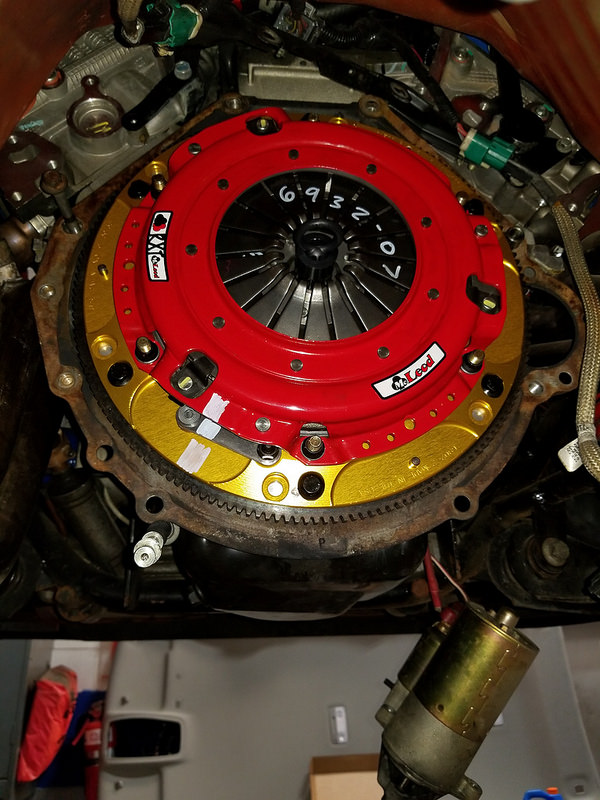

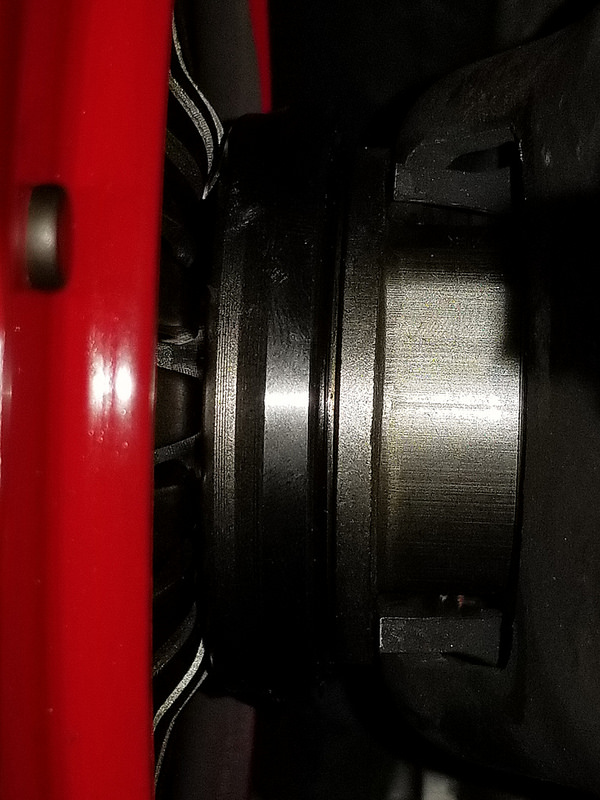

RXT in.

Now that you have the clutch in and bellhousing installed. Go ahead and get the transmission installed. Like me, you will most likely not be able to slide the transmission right in to the bellhousing. You will need to drop the transmission back down and re install the clutch disk alignment tool and adjust the clutch disk alignment a tad. I was able to stick my head up into the tunnel and get the disks centered as close as possible after 2 tries. You may have to wiggle the transmission around a bit while installing, but the transmission should slide in, all the way up flush to the bellhousing, without having to "draw" it in with bolts. Doing this will damage the clutch/disks.

Hold the transmission in by a couple of snugged bolts. Take another measurement of the clutch fork position. Also take note of how much room/play you have in the clutch fork from throwout bearing contact with the pressure plate, to the transmission stops fully rearward. You want to make sure you have enough play for proper clutch operation, and room for some adjustment. Good rule of thumb is to make sure the clutch fork is slightly off center of the opening, toward the rear slightly. In my case, my clutch fork position was good compared to my previous measurement in step one. You can see the paint mark at 5 1/2" and the new mark where the fork is now. I was happy with this position visually, and as it left me with 6mm of play from throwout bearing contact with the pressure plate, to the transmission stops rearward.

I did not have to pull my transmission down to adjust anything, as I was happy with the measurements, and fork position. I went ahead and finished up installing the transmission. I set the throwout bearing to ever so slightly touch the pressure plate fingers. I know this is against what mcleod says, but I've always set my clutches this way in the past and have had no issues. I set the TO bearing to spin at half speed per-say when idling, if that makes sense.

There you have it. This process worked out fantastic for me, so I hope it will help someone else out! I only have roughly 50 miles on it so far. This clutch really changed the car IMO, and makes the car so much more enjoyable to drive than with the Spec 3+. The clutch is butter smooth, with no noise, and the pedal is hydraulic light. Some very slight chatter once and a while, which I've read will go away with more break in. Pedal engagement is the same as with my spec, so I was happy there as well.

So next up. With my Spec, I had a very stiff pedal obviously. What bothered me was last year, my cable broke, but in a weird spot. The cable almost "overheated" and pulled through here.

You may remember the thread I made about it a long while ago. But basically I am thinking this is a heat related issue from the long tubes, as the cable does run down pretty close. I decided to insulate the cable. This may be over kill, and not even required now that the RXT requires so much less effort to operate when compared to the Spec, or other single disc clutches. I had everything apart anyways, so I figured it wouldn't hurt. This may help other people running single disc clutches and long tubes with inconstant pedal effort concerns like I was having before.

I purchased these products from Summit racing. I bought the MM clutch cable insulation they sell, and decided not to use it as I wanted to do the whole entire cable. The tubing is basically the same as the MM stuff, but you get more, and it's cheaper. I wanted to tape the upper portion of the cable, so it didn't stick out like a sore thumb. So I wrapped the cable in a high heat "racers" tape to make it appear more stock like. I cant say there was much difference, because I did this along with the RXT, but I feel this is just some extra insurance.

Finished product....

So, thanks for reading! Hope this helps someone out!

I've done a ton of research on setups, pivot ball length, and issues. I've come to the conclusion that most RXT issues are caused by improper setup and adjustment, mainly due to so many variables and opinions on whether or not an adjustable pivot is needed, or how much shorter one should set the pivot. Most of this is due to the amount of flywheel options out there, which directly effect the needed pivot ball length due to thickness of the flywheel itself. I've ran across countless threads and Facebook group posts with pivot ball length recommendations ranging from stock to 15mm shorter. So this leads to a lot of guess work, and trial/error having to pull and re install the transmission until its right. Stock flyheel and the Mcleod seem to require the least amount of shortening, and Spec/Fidanza require the most. Of course my opinion.

The other thing is that a lot of these threads and posts here, and on Facebook seem to make this whole install way more complicated, and discouraging to some. The whole process is very simple once you get into it, and not a big deal what so ever. So I wanted to show how I set mine up, and hopefully try and take some of the guess work out for any one installing their RXT. I am not gonna go over the process for pulling the transmission and the actual procedure of installing the clutch as that's fairly basic and the same for everyone.

Two other things that will really help you out other than a straight edge and a tape measure, is a paint pen/chalk marker and a set of break pad measurement gauges like this.

Step one, is to measure the current position of the clutch fork in relation to the fork opening. You'll want to re measure this when putting everything back together, and getting the fork in the same position, or really close, should net you similar engagement to your previous clutch setup. As shown, I measured 5 1/2".

I always remove the transmission separate from the bellhousing. Makes things way easier. Here's the Spec.

Transmission is out. I went ahead and brake cleaned everything off.

Bellhousing is next. Went ahead and tied the harnesses up in the shifter opening as well.

Here is the Fidanza after getting the clutch off of it. Center section wasn't too bad after about 12,000 miles I guess. New center section comes with hardware as well. I saved this for after all the measurements are done.

So now what you want to do is to place the flywheel down on a flat surface. Place the old clutch assembly down on top of the flywheel. I set the throw out bearing on the pressure plate surface to take this measurement, as the pressure plate surface is different between assemblies. It is "indented" on the spec, and not so on the RXT, so just using a straight edge would yield inaccurate measurements. Record your measurement as shown. Remove the old clutch assembly, and place the RXT in the same position. NOTE, you will have to snug up the floater/pressure plate to read an accurate measurement. Record the measurement as shown. This is where the brake pad measurement tools come in. I simply marked the tape measure in two spots. One mark for the old assembly, and another with the RXT assembly and used the pad depth tool to measure the difference. Made things simpler as most people measure the pivot ball length in mm anyways. The difference between these two measurements will be how much shorter you should set the pivot ball. This should get you damn near perfect. Also note, this picture is a rough idea of taking the measurement. You can notice my paint marks on the tape measure. You'll of course want a flat surface with no towel under anything HAHA. The RXT is 12mm taller than the Spec, per my measurement.

Stupid me didn't take a picture of measuring and installing the pivot ball. Just a picture of the package of which pivot ball I used. Anyways, you'll measure from the face of the transmission to the tip of the stock pivot. I used the "boss" or "webbing" on the face of the transmission as my base for the tape measure. I marked this measurement on the tape measure with the paint pen. Then used the brake measurement tool, and made another mark 11/12mm shorter than my previous measurement on the tape measure. Then just install the lakewood pivot into the transmission. Using the same method as before for measuring, rotate the pivot into the transmission until the tip of the pivot ball is at the second mark you've made on your tape measure. Lock the pivot ball down, and double check you're measurement hasn't changed.

RXT in.

Now that you have the clutch in and bellhousing installed. Go ahead and get the transmission installed. Like me, you will most likely not be able to slide the transmission right in to the bellhousing. You will need to drop the transmission back down and re install the clutch disk alignment tool and adjust the clutch disk alignment a tad. I was able to stick my head up into the tunnel and get the disks centered as close as possible after 2 tries. You may have to wiggle the transmission around a bit while installing, but the transmission should slide in, all the way up flush to the bellhousing, without having to "draw" it in with bolts. Doing this will damage the clutch/disks.

Hold the transmission in by a couple of snugged bolts. Take another measurement of the clutch fork position. Also take note of how much room/play you have in the clutch fork from throwout bearing contact with the pressure plate, to the transmission stops fully rearward. You want to make sure you have enough play for proper clutch operation, and room for some adjustment. Good rule of thumb is to make sure the clutch fork is slightly off center of the opening, toward the rear slightly. In my case, my clutch fork position was good compared to my previous measurement in step one. You can see the paint mark at 5 1/2" and the new mark where the fork is now. I was happy with this position visually, and as it left me with 6mm of play from throwout bearing contact with the pressure plate, to the transmission stops rearward.

I did not have to pull my transmission down to adjust anything, as I was happy with the measurements, and fork position. I went ahead and finished up installing the transmission. I set the throwout bearing to ever so slightly touch the pressure plate fingers. I know this is against what mcleod says, but I've always set my clutches this way in the past and have had no issues. I set the TO bearing to spin at half speed per-say when idling, if that makes sense.

There you have it. This process worked out fantastic for me, so I hope it will help someone else out! I only have roughly 50 miles on it so far. This clutch really changed the car IMO, and makes the car so much more enjoyable to drive than with the Spec 3+. The clutch is butter smooth, with no noise, and the pedal is hydraulic light. Some very slight chatter once and a while, which I've read will go away with more break in. Pedal engagement is the same as with my spec, so I was happy there as well.

So next up. With my Spec, I had a very stiff pedal obviously. What bothered me was last year, my cable broke, but in a weird spot. The cable almost "overheated" and pulled through here.

You may remember the thread I made about it a long while ago. But basically I am thinking this is a heat related issue from the long tubes, as the cable does run down pretty close. I decided to insulate the cable. This may be over kill, and not even required now that the RXT requires so much less effort to operate when compared to the Spec, or other single disc clutches. I had everything apart anyways, so I figured it wouldn't hurt. This may help other people running single disc clutches and long tubes with inconstant pedal effort concerns like I was having before.

I purchased these products from Summit racing. I bought the MM clutch cable insulation they sell, and decided not to use it as I wanted to do the whole entire cable. The tubing is basically the same as the MM stuff, but you get more, and it's cheaper. I wanted to tape the upper portion of the cable, so it didn't stick out like a sore thumb. So I wrapped the cable in a high heat "racers" tape to make it appear more stock like. I cant say there was much difference, because I did this along with the RXT, but I feel this is just some extra insurance.

Finished product....

So, thanks for reading! Hope this helps someone out!

Last edited: