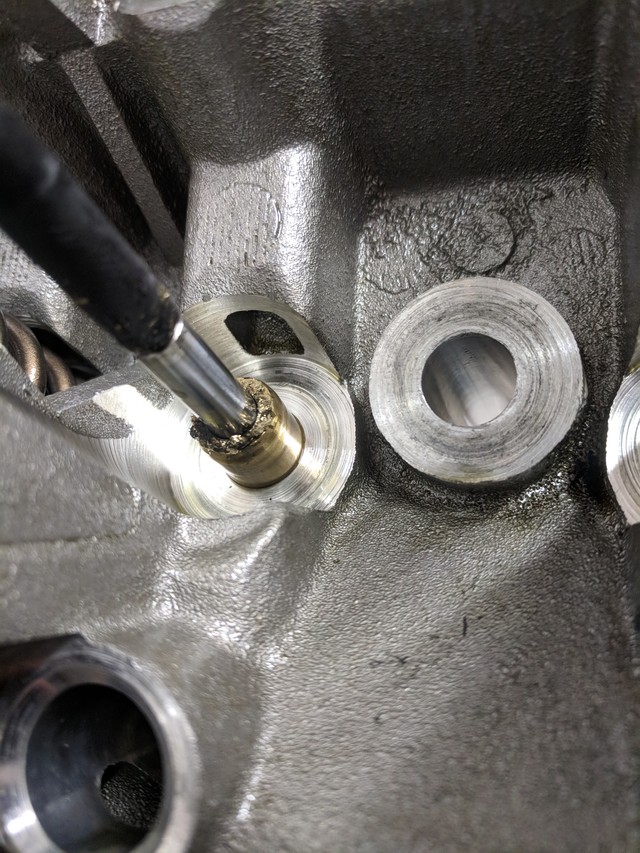

I built an engine for my car last year. It included having the heads worked over with CNC porting and new valves and bronze guides. Car ran great until an intake valve seized in the guide and stuck open. Started tearing things back apart to see what happened. Turned out the valve guide was chewing itself up so bad that all the metal chips jammed between the guide and stem, sticking the valve open. I took the rest of the the head apart and almost every guide looked like the pictures. All those bronze chips were sitting behind the valve seal, and the valves were pretty loose. I was obviously confused and disappointed by the whole thing; I had maybe 250 miles on this stuff since it was assembled. I contacted the head builder and he said he's never seen that before and has no idea what can cause that. However, he took care of me and redid the heads. I've got a few hundred miles on them again and everything's fine so far, but more time will tell if everything's good this time. So my question is has anyone seen something like this, and does anyone have some knowledge as to why this would happen? I'm super curious to know, even if I don't have anymore problems.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brand new bronze valve guide failure

- Thread starter xtreme_exploder

- Start date

Wrong size guides/valves?

Sent from my iPhone using svtperformance.com

Sent from my iPhone using svtperformance.com

^ only thing I could think of.

Sent from my iPhone using svtperformance.com

Sent from my iPhone using svtperformance.com

Valves may have been put in dry and or too tight. Most builders put a coat of anti seize on the stems. There have been some cheap valves out there. Probably Chinese knock offs. They were bad to gall in the guides.

I have also seen builders remove the steel rings from the seals, allowing more lube on the stems.

Really hard to say which applies to your issue. Sounds like the builder did you right.

I have also seen builders remove the steel rings from the seals, allowing more lube on the stems.

Really hard to say which applies to your issue. Sounds like the builder did you right.

I hope it's not the valves, they were reused and the stems still looked new. They're Ferrea valves and seem authentic. There was tons of lube on the stems. He was also very confident that the clearances were set right. The only theory I've had in mind is a bad batch of guides. I've also surmised oil lubrication issues or bad valvetrain geometry side loading the valves, but not sure how/why. Just funny to me that he's done hundreds of these heads and I'm the supposedly the only guy this has happened to.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)