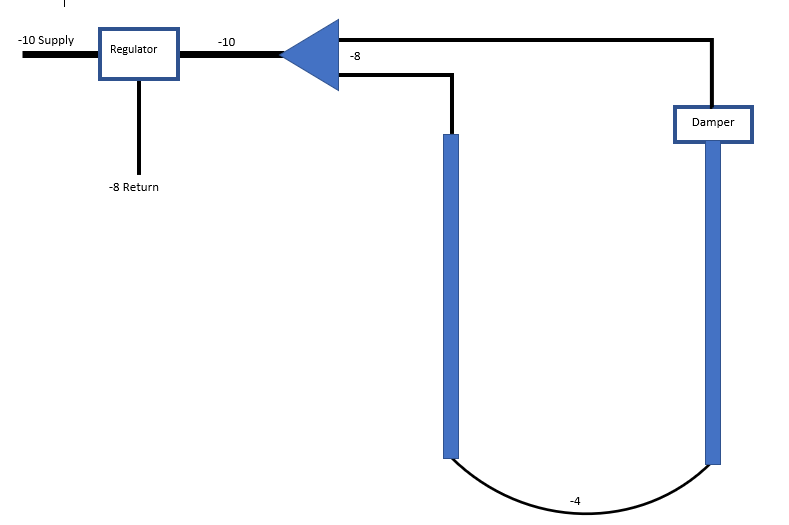

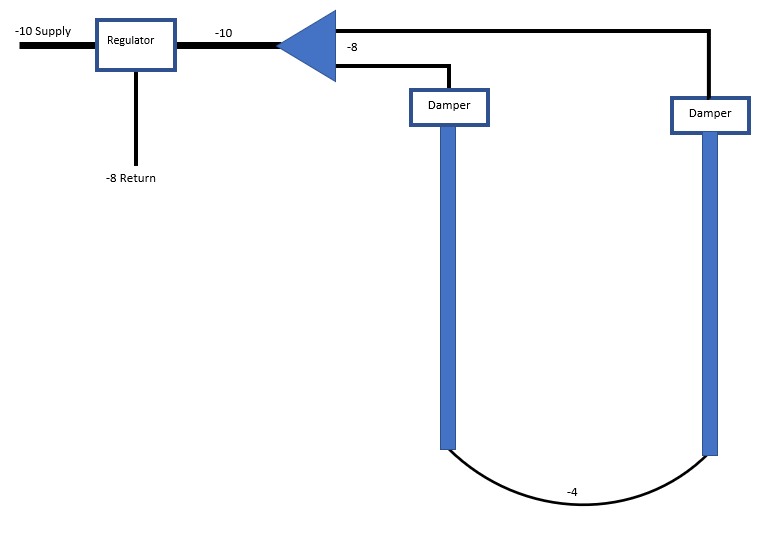

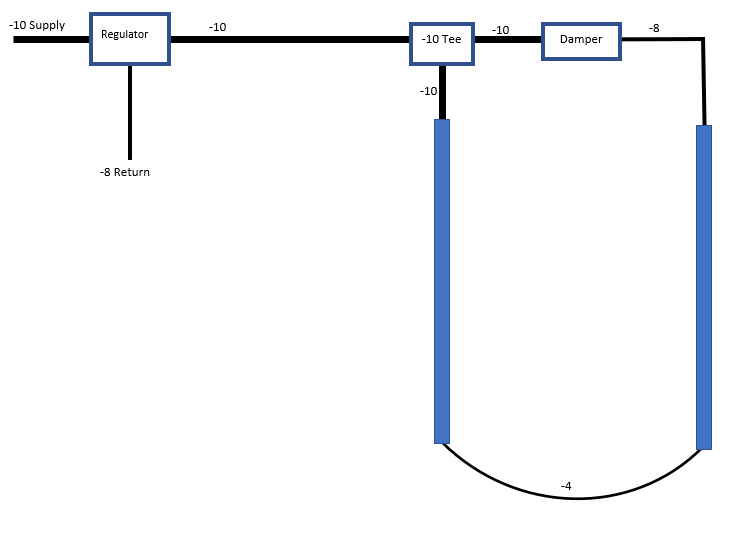

Over the winter I took the plunge in replacing the rest of the fuel system. Ended up going with a fuelab 42401 pump with fuelab pre and post filters. Plan was a glenns performance sleeper tank feeding a -10 supply to an inline motion raceworks e85 sensor block to the fuelab regulator I had already installed returning to the tank with -8, everything in e85 safe ptfe line.

Problems started pretty quick, Glenns tank put the feed straight into the exhaust.

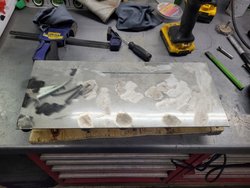

I ended up cutting it off and having a piece of bent 90° tubing welded on to send the output away from the exhaust but forgot to grab pictures. Unfortunately I also found some rust when I pulled the tank which snowballed into another project entirely. Most of it was just surface rust under the car but I found one section under the driver impact absorber mount that was pretty bad. I ended up cutting it out and replacing it.

From there the snowballing continued. I tapped off the back half of the car and set up a proper redneck paint booth.

Spent a while wire wheeling/ sanding from the lower control arm mount back and got it prepped it for primmer.

Two coats of primer later and were looking like this

Problems started pretty quick, Glenns tank put the feed straight into the exhaust.

I ended up cutting it off and having a piece of bent 90° tubing welded on to send the output away from the exhaust but forgot to grab pictures. Unfortunately I also found some rust when I pulled the tank which snowballed into another project entirely. Most of it was just surface rust under the car but I found one section under the driver impact absorber mount that was pretty bad. I ended up cutting it out and replacing it.

From there the snowballing continued. I tapped off the back half of the car and set up a proper redneck paint booth.

Spent a while wire wheeling/ sanding from the lower control arm mount back and got it prepped it for primmer.

Two coats of primer later and were looking like this