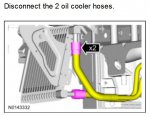

For us track pack guys changing those fluids isn't just draining and refilling the housing to do the job properly you have to disconnect the lines and empty out the coolers also.

I don't remember the part # but Ford specifies a tool to be able to disconnect both the trans. and rear axle lines so you can drain out the coolers and lines.

There is probably something akft. that is avail. to use to do this anybody know what is avail. out there?

I found this on summit's site:

http://www.summitracing.com/parts/otc-6593

Will that work?

I don't remember the part # but Ford specifies a tool to be able to disconnect both the trans. and rear axle lines so you can drain out the coolers and lines.

There is probably something akft. that is avail. to use to do this anybody know what is avail. out there?

I found this on summit's site:

http://www.summitracing.com/parts/otc-6593

Will that work?

Last edited: