So, if you order the optional 3" pulley how does Ford know to provide the correct calibration and what is the HP/TQ spec?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FRPP/Whipple kit content and install on '09 GT500

- Thread starter Tob

- Start date

Does the FRP kit come with the 3.0 or the 3.25 normally?

Sure would like to know what pumps Paul's HP used in the fuel hat. Hey looks like a killer kit. Good luck with it and take your time with the install.

+1 why no injectors?

Tob you da man with write ups ...

Tob you da man with write ups ...

Sure would like to know what pumps Paul's HP used in the fuel hat. Hey looks like a killer kit. Good luck with it and take your time with the install.

Walbro GSS342 (return style) pumps inside a stock GT500 pump assembly.

cool deal, enjoy the power man, funny that blower looks small to me... but then again.. I'm spoiled

shut up

After reading everything relevant to the install at least three times, I dove into the install yesterday afternoon. It was not without a few twists and turns.:dw:

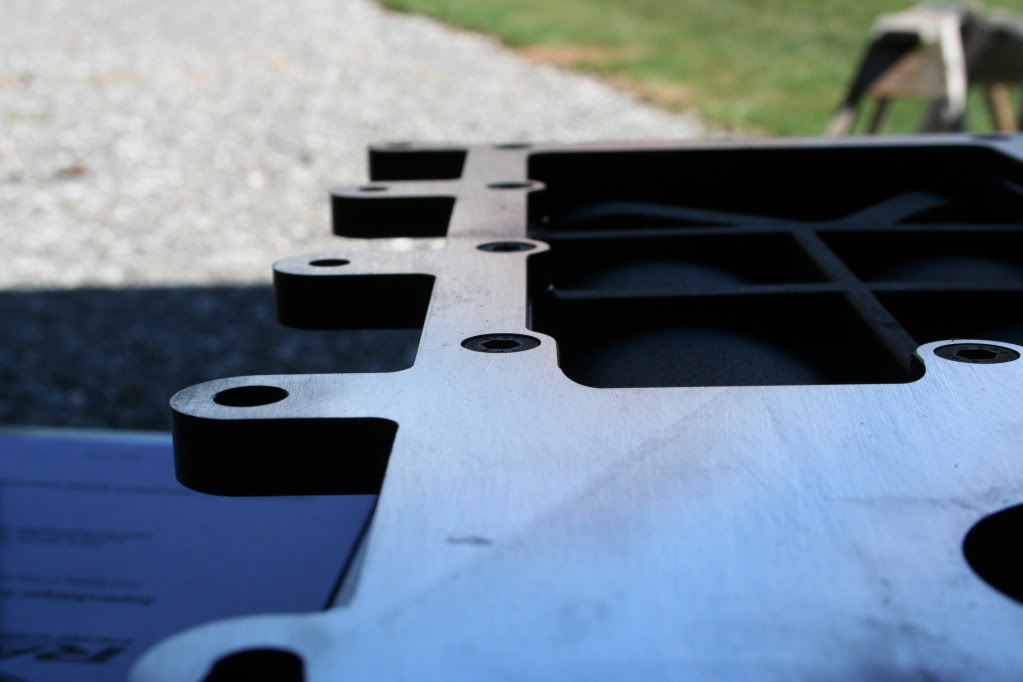

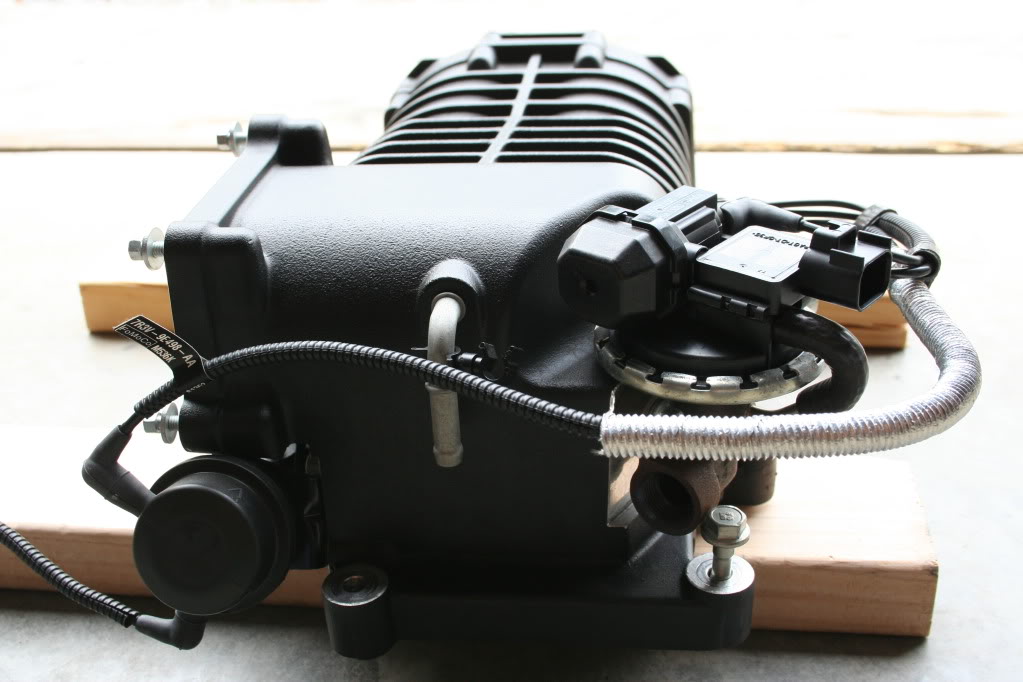

I started by flipping the blower over and peeling off the protective "Gorilla Tape" so that I could dab some RTV into the adapter plate holes.

And since I notice everything, I wondered why there was some residual adhesive-like goo emanating from the machined hole in the baseplate that leads to the bypass actuator. I cleaned off the excess.

Looks like the housing was cast on 5/26/09 and I'm not sure what dimension (clearance?) the notation on the rotor is calling out.

Anyhow, the O-ring on the intake manifold runs across the bolts that are recessed into the blower itself through the baseplate. There is the possibility of pressurized air to escape via this juncture so I did as recommended and started RTV'ing.

After the "dabs" setup, I sliced off the excess with a razor (note- there is more RTV to come).

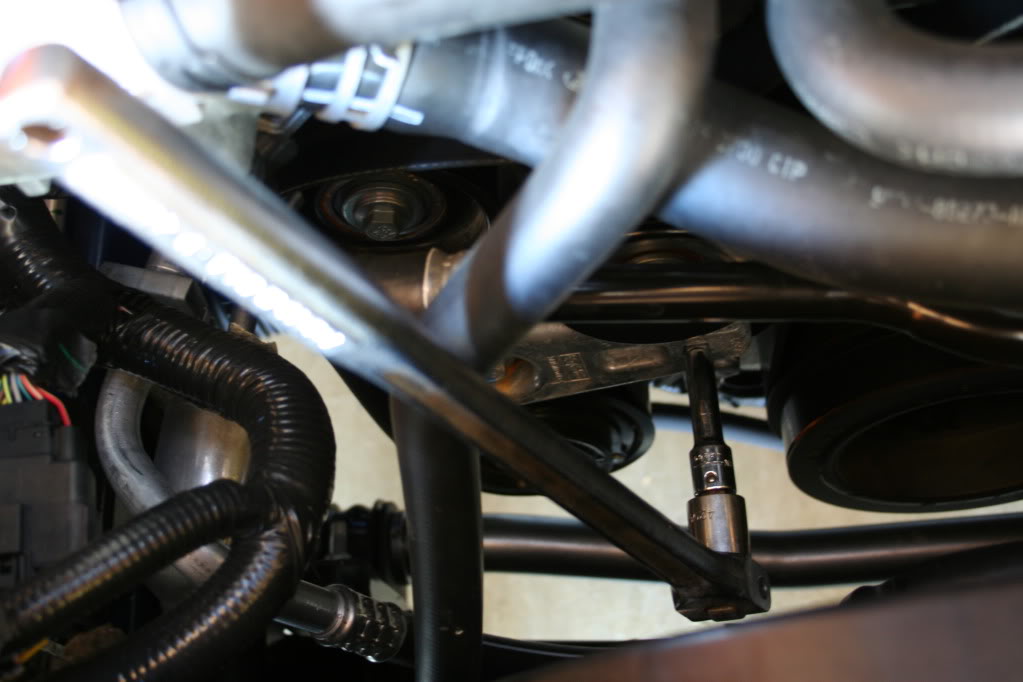

Since I like getting the PIA stuff out of the way first, I followed Chris' recommendation to remove the battery and tray in order to access the EGR tube which must be switched out. It runs from the passenger side exhaust manifold up to the EGR valve itself. It winds through a labyrinth of wiring, etc, I wanted to get this one out of the way early.

An 8mm deepwell socket makes easy work of it.

I don't see how you could do it with taking the battery and tray out.

A WD40 can with the extended tip made placement rather simple. A light shot just above the nut so it would run downward along the threads. I gave it a couple of minutes.

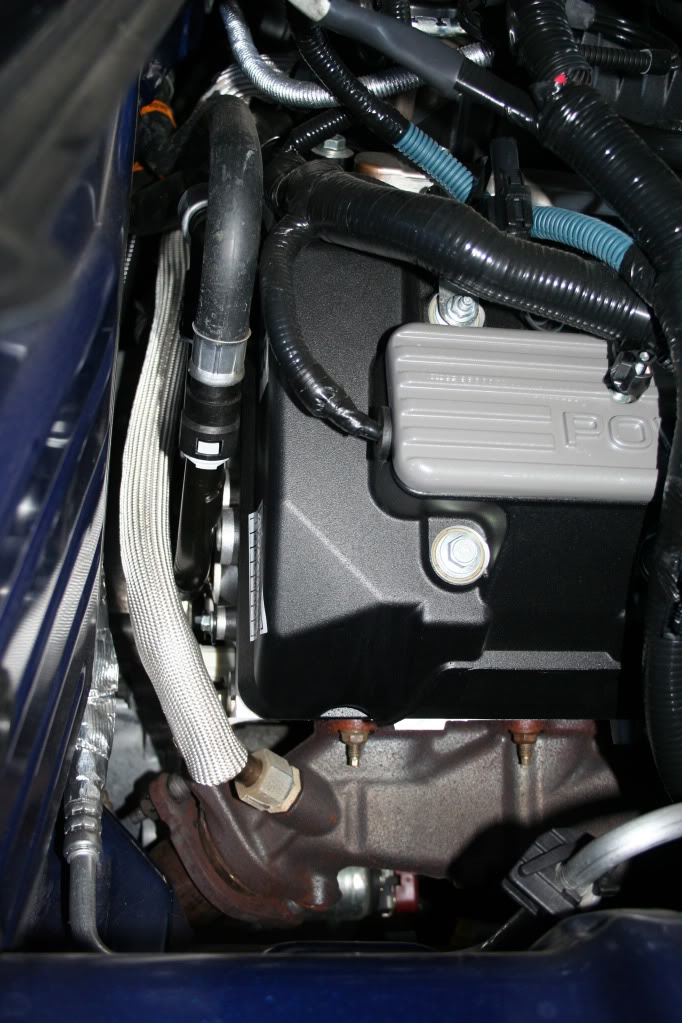

While waiting, I moved on to slipping the blower belt off. In order to gain access to the tensioner you need to move the left coolant tank out of the way.

A breaker bar, 1/2" to 3/8" adapter, and a short 3/8" extension fits perfectly. Rotate clockwise.

Back to the EGR tube, up top. Since I didn't have the requisite open ended wrench, I used a 12" Crescent instead.

Moving over to the driver side for the pull. Leverage made it easy, as it cracked loose with little effort.

I used the same 12" Crescent at the manifold connection. Much easier than I would have thought as it came right off.

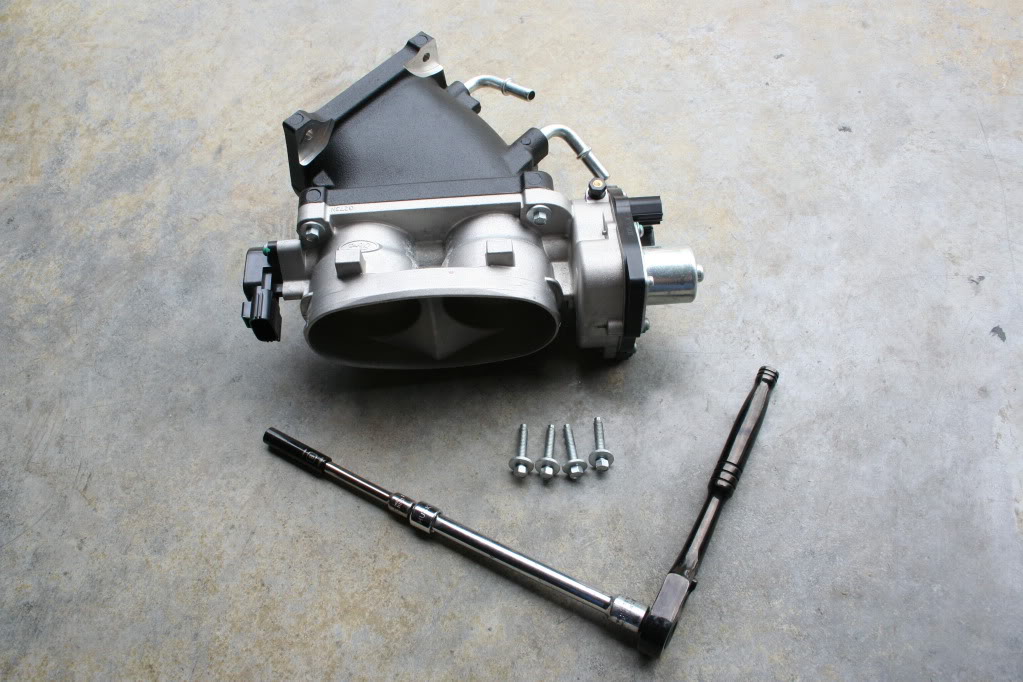

I removed the FRPP CAI I previously installed. Simple.

Sticking with intake tract removal, an 8mm deep well, removing a few electrical connectors, and wala.

Very little oil in either the TB or the blower.

I started by flipping the blower over and peeling off the protective "Gorilla Tape" so that I could dab some RTV into the adapter plate holes.

And since I notice everything, I wondered why there was some residual adhesive-like goo emanating from the machined hole in the baseplate that leads to the bypass actuator. I cleaned off the excess.

Looks like the housing was cast on 5/26/09 and I'm not sure what dimension (clearance?) the notation on the rotor is calling out.

Anyhow, the O-ring on the intake manifold runs across the bolts that are recessed into the blower itself through the baseplate. There is the possibility of pressurized air to escape via this juncture so I did as recommended and started RTV'ing.

After the "dabs" setup, I sliced off the excess with a razor (note- there is more RTV to come).

Since I like getting the PIA stuff out of the way first, I followed Chris' recommendation to remove the battery and tray in order to access the EGR tube which must be switched out. It runs from the passenger side exhaust manifold up to the EGR valve itself. It winds through a labyrinth of wiring, etc, I wanted to get this one out of the way early.

An 8mm deepwell socket makes easy work of it.

I don't see how you could do it with taking the battery and tray out.

A WD40 can with the extended tip made placement rather simple. A light shot just above the nut so it would run downward along the threads. I gave it a couple of minutes.

While waiting, I moved on to slipping the blower belt off. In order to gain access to the tensioner you need to move the left coolant tank out of the way.

A breaker bar, 1/2" to 3/8" adapter, and a short 3/8" extension fits perfectly. Rotate clockwise.

Back to the EGR tube, up top. Since I didn't have the requisite open ended wrench, I used a 12" Crescent instead.

Moving over to the driver side for the pull. Leverage made it easy, as it cracked loose with little effort.

I used the same 12" Crescent at the manifold connection. Much easier than I would have thought as it came right off.

I removed the FRPP CAI I previously installed. Simple.

Sticking with intake tract removal, an 8mm deep well, removing a few electrical connectors, and wala.

Very little oil in either the TB or the blower.

I then moved onto removing the fuel rail and injectors. Four bolts, release the fuel line to rail connection, and lift.

Err...

This is where I was...

The blower is ready to be removed. Don't forget (like I did) that there are 10 bolts and not 8.

Minimal oil intrusion at this point as well.

I figured now was a good time to switch EGR tubes, just in case I couldn't get the new one in with the new blower in place. While they look very similar, there are some minor bend differences between the two.

This is where the fun starts. Note the vertical clearance to the rear most blower bolt holes on the stocker - there's plenty. Also note the 90* downward elbow fitting, as well as the stock bypass actuator. Store the mental images.

Hope there's room...

Oh, one more of inside the stock blower case...

Uh oh. Where did all that clearance go?

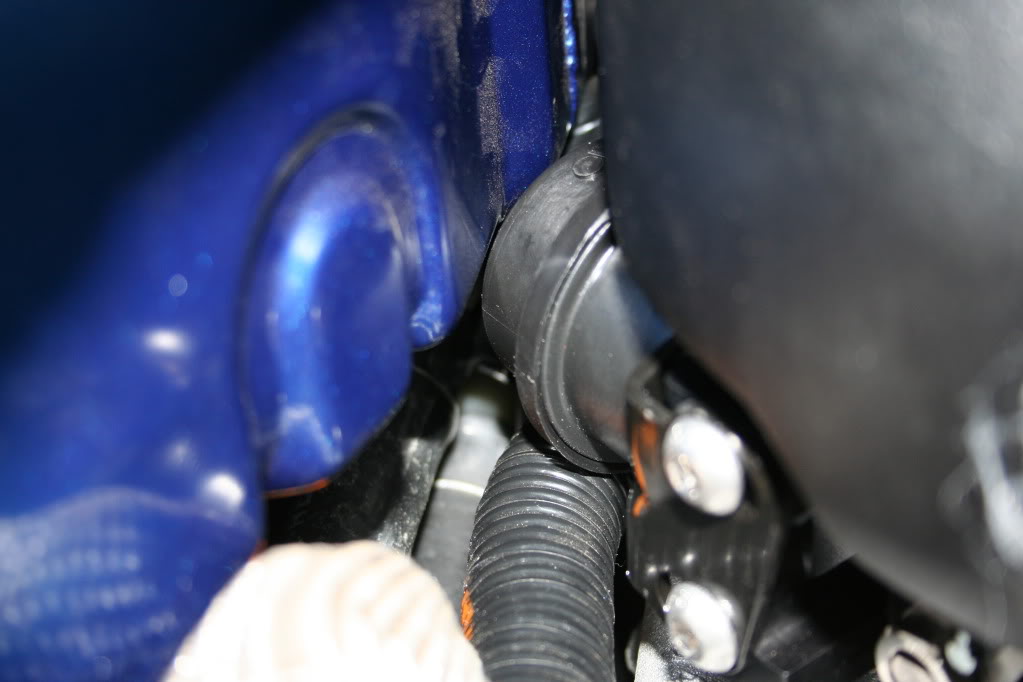

I couldn't bare to look any longer so I moved onto extending the existing 3/8" hose with the supplied assembly.

This slowed me down a bit. Whipple's instructions don't give you an illustration as to how to orient the fittings. I went in the house and looked at how Chris had done it. I matched what I saw in a photo he posted in his install write up. This is important, as the hose extension I just added needs to fit properly onto the barbed elbow as you are installing the blower. I don't have three hands, so orientation is critical.

THE BITCH

This was where the fun started. After laying a continuous bead of RTV around the perimeter of the factory intake O-ring. I placed a block of wood to support the assembly until I was ready to lower (and slide back) the monster.

I slipped on the 3/8" hose - note clamp orientation. If it faces the rear it will gouge into a portion of the firewall, so keep it up, which also eases squeezing/releasing it.

This is the point in the install where I shook my head. First - get another set of hands. If your first shot is successful, then fine. Mine wasn't. I couldn't get the blower to go back far enough to get any of the bolts in. After a few minutes of investigating, I realized the blower was being restricted from rearward movement by a large wiring harness, which was held firmly into place by a metal bracket with two holes. For now, I removed it (note the two holes in the manifold, then the bracket).

But wait, there's more. Once I relieved the harness, I found there was another obstruction. The plastic body of the bypass actuator was up against the firewall, and I needed to go back another 1/4" plus a reasonable amount of additional clearance for engine movement. The following shot is with the blower laid down (don't ask me how many times I had to clean up and redo the RTV) and moved forward.

I marked the area. Since I couldn't mark the area directly (due to there being no room) I made a quick reference mark (yellow mark on the left). I then measured with a stick rule to the point of interference. I then placed a mark there as well (yellow mark to the right). There is three inches between the two marks.

Since there was no way I was going to get into mving anything at either the K-member or the mounts, I was left with only one choice. Cringe if you must.

Some medicine helped to ease the pain.

The wood block didn't gouge or scratch, it just lightly scuffed, if you will.

Finally.

Now back to the difficult part of the install. Remember that bolt hole access that just about vanished at the driver side rear? Unless you are the guy with the gooey stretchable hands from The Fantastic Four, it ain't happenin'. I tried everything, including the "lay on top of the engine and..." method that somehow worked for Chris. You simply can't get your hand close enough to even touch the bolt with the tip of any finger. A quick study after Houdini failed to return my call, and I whipped up something quick. A few tacks on a piece of steel strapping on the end of a wrench.

It worked for a few turns, but I needed to tweak the wrench end for more clearance. I placed it in a vice, applied pressure, and...

My bad. Not a good idea to try to bend it after it had cooled down. Tools just don't like heat cycles.

Thinking quick, as I had just put the welder away - I grabbed a piece of conduit and the previously used BFH (the tape was for sharp edges so as not to cut anything). The wrench is inside the conduit, placed at the right angle for tightening, and beaten in tight. A few strategic bends later...

Seriously, for the coin, it'd be nice if FRPP could step up to the plate and include some sort of tool.

More later, after some more work today.

Tob

Err...

This is where I was...

The blower is ready to be removed. Don't forget (like I did) that there are 10 bolts and not 8.

Minimal oil intrusion at this point as well.

I figured now was a good time to switch EGR tubes, just in case I couldn't get the new one in with the new blower in place. While they look very similar, there are some minor bend differences between the two.

This is where the fun starts. Note the vertical clearance to the rear most blower bolt holes on the stocker - there's plenty. Also note the 90* downward elbow fitting, as well as the stock bypass actuator. Store the mental images.

Hope there's room...

Oh, one more of inside the stock blower case...

Uh oh. Where did all that clearance go?

I couldn't bare to look any longer so I moved onto extending the existing 3/8" hose with the supplied assembly.

This slowed me down a bit. Whipple's instructions don't give you an illustration as to how to orient the fittings. I went in the house and looked at how Chris had done it. I matched what I saw in a photo he posted in his install write up. This is important, as the hose extension I just added needs to fit properly onto the barbed elbow as you are installing the blower. I don't have three hands, so orientation is critical.

THE BITCH

This was where the fun started. After laying a continuous bead of RTV around the perimeter of the factory intake O-ring. I placed a block of wood to support the assembly until I was ready to lower (and slide back) the monster.

I slipped on the 3/8" hose - note clamp orientation. If it faces the rear it will gouge into a portion of the firewall, so keep it up, which also eases squeezing/releasing it.

This is the point in the install where I shook my head. First - get another set of hands. If your first shot is successful, then fine. Mine wasn't. I couldn't get the blower to go back far enough to get any of the bolts in. After a few minutes of investigating, I realized the blower was being restricted from rearward movement by a large wiring harness, which was held firmly into place by a metal bracket with two holes. For now, I removed it (note the two holes in the manifold, then the bracket).

But wait, there's more. Once I relieved the harness, I found there was another obstruction. The plastic body of the bypass actuator was up against the firewall, and I needed to go back another 1/4" plus a reasonable amount of additional clearance for engine movement. The following shot is with the blower laid down (don't ask me how many times I had to clean up and redo the RTV) and moved forward.

I marked the area. Since I couldn't mark the area directly (due to there being no room) I made a quick reference mark (yellow mark on the left). I then measured with a stick rule to the point of interference. I then placed a mark there as well (yellow mark to the right). There is three inches between the two marks.

Since there was no way I was going to get into mving anything at either the K-member or the mounts, I was left with only one choice. Cringe if you must.

Some medicine helped to ease the pain.

The wood block didn't gouge or scratch, it just lightly scuffed, if you will.

Finally.

Now back to the difficult part of the install. Remember that bolt hole access that just about vanished at the driver side rear? Unless you are the guy with the gooey stretchable hands from The Fantastic Four, it ain't happenin'. I tried everything, including the "lay on top of the engine and..." method that somehow worked for Chris. You simply can't get your hand close enough to even touch the bolt with the tip of any finger. A quick study after Houdini failed to return my call, and I whipped up something quick. A few tacks on a piece of steel strapping on the end of a wrench.

It worked for a few turns, but I needed to tweak the wrench end for more clearance. I placed it in a vice, applied pressure, and...

My bad. Not a good idea to try to bend it after it had cooled down. Tools just don't like heat cycles.

Thinking quick, as I had just put the welder away - I grabbed a piece of conduit and the previously used BFH (the tape was for sharp edges so as not to cut anything). The wrench is inside the conduit, placed at the right angle for tightening, and beaten in tight. A few strategic bends later...

Seriously, for the coin, it'd be nice if FRPP could step up to the plate and include some sort of tool.

More later, after some more work today.

Tob

Last edited:

install looks awesome. that last bolt was very tricky. the only other difficult part was the fuel rail bolts. great looking car

good idea placing tape over the injector holes...

also good idea pushing back part of the firewall to get the blower to fit. almost makes me want to take mine off and do that, but not quite.

did you get fuel everywhere like i did when you took off the fuel rails?

also good idea pushing back part of the firewall to get the blower to fit. almost makes me want to take mine off and do that, but not quite.

did you get fuel everywhere like i did when you took off the fuel rails?

Tob,

Was this in the instruction for the kit? I just bought a 2011 and thought about this kit for the reason it had FRPP on it. I would have figure the fit would have been better. I don't think I could have bashed the firewall on the car.

Was this in the instruction for the kit? I just bought a 2011 and thought about this kit for the reason it had FRPP on it. I would have figure the fit would have been better. I don't think I could have bashed the firewall on the car.

...the only other difficult part was the fuel rail bolts...

Since you brought it up, I'll start there.:banana:

Whipple supplies you with a bolt to use under the inlet and at the rear of the fuel rail on the driver side. It is the zinc coated one on the right.

It is too long. I ended up cutting a second time because it still wouldn't clear the inlet and thread into the fuel rail boss. The magic number was 7/16" of thread under the bolt head.

Pain enough trying to seat the rear most injector, let alone deal with the bolt. Tip - you don't have to remove the safety clip from the injector as the directions state. I tried it both ways (since I'm such a glutton I figured why not?). You can see both in the following photo. The bolt has been fit, is at the bare minimum length and is ready for David Copperfield to show up and get the threads started.

Passenger side rail went on without a hitch.

Back to my other favorite place. You can see why Whipple utilized button head fasteners for the bypass actuator bracket. The harness that I released previously would be squished if regular bolts were used. The contour my finger is holding the harness over to is what I was looking for. The idea is to keep it away from the EGR tube.

I wanted to use the original bracket, but at the current length it was yet again trying to force it into the bypass hardware. I compromised and settled on a shortened bracket that would redirect the harness away from the EGR tube but still allow it to be directed away from blower interference.

One bolt did the trick. Two would have made things tight again.

I used red RTV on the EGR adapter (EGR to blower case side) due to its higher heat capacity (if that makes any difference).

I reused the steel gasket between the EGR valve itself and the adapter.

It is a little tricky joining the EGR tube at the manifold, at the EGR valve itself, and being able to thread the included fasteners to draw the EGR valve in tight. Once the valve was tight, I tightened the tube up at either end (12"crescent still worked without issue).

I actually had to back and loosen the passenger side fuel rail bolts so that the rail no longer made contact with the rail. Were I to do it again, I would have dressed up the bottom of the valve casting with a die grinder to minimize thermal transfer of heat to the rail from the EGR valve.

As to the rest of the connections at the back, you have to "borrow" the original blower's pieces in order for the EGR valve to work. Whipple changes some of this with their unit. First is to pull off the what you see disconnected below. The line running to the original bypass actuator gets plugged with a small plastic piece that Whipple supplies.

I inserted the plug as directed but also put a dab of RTV inside to ensure a good seal.

You also add the threaded fittings to the machined aluminum adapter at this time.

You can also attach the requisite connectors to the back of the inlet at this time as well. I'm not big on the necessary bend to the hose coming from the brake booster. I may shorten it for a more natural radius. Also, note the sheet metal above the top hose on the left. I had to disconnect a wiring harness and then bend the sheet metal back with my hand to allow clearance.

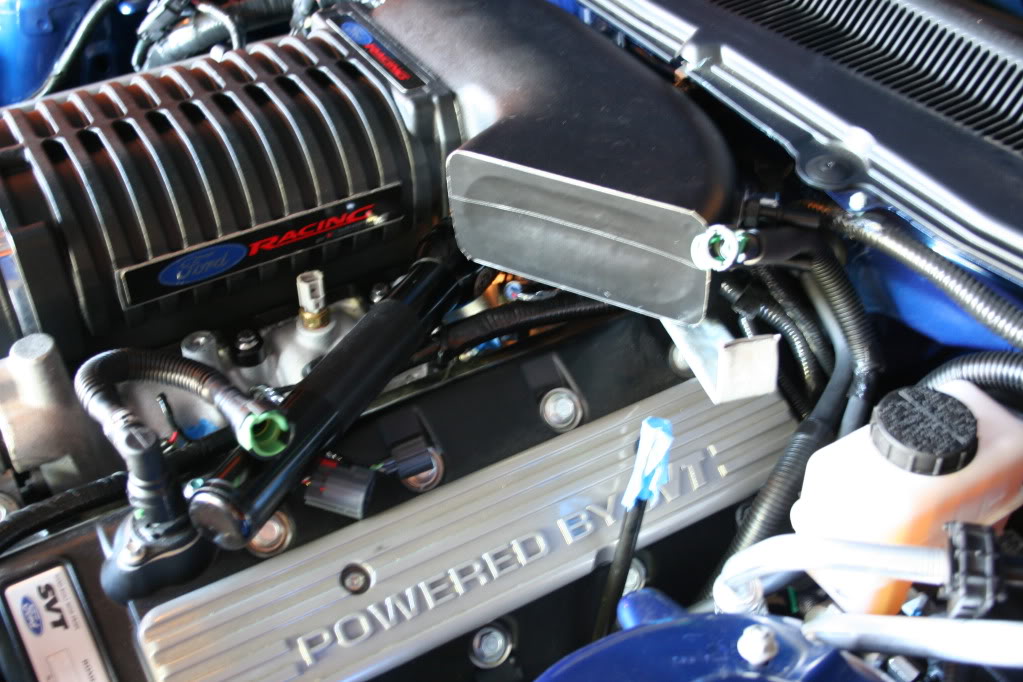

I moved onto slipping the blower belt, using the method that Chris mentioned in his write up. It worked perfectly. The blower lube then went in. Note the sight glass.

Since I'm still waiting for a response to my "what is the proper gap for the included spark plugs?" question, I couldn't finish that or the intake tract. I did want to see how the included air cleaner assembly would fit.

While the holes in the '09 body do line up with the locating rubber bungs on the underside of the housing, it seems an odd fit.

I can forget any visions I had of trying to adapt the hole on the side to the newer ducting. That'd be a road to nowhere as there simply isn't any room. I need the plug that Whipple shows in the directions but that I didn't get.

Brief interlude...and a comparison of the FRPP CAI and the Whipple/SVT hybrid.

Mocked into place, I'm hoping there will be more clearance than what I see now...

So, I'm awaiting the Procal tuner and tune. I still need to change the fuel pump. It would be nice if that is a simple switch (for once!:-D) New plugs, intake tract....then I'll turn the key.

This is where I am as of now.

Believe it or not, I'm rather enjoying this. I hope it helps anyone be better prepared for their own install.

Tob

Last edited:

good idea placing tape over the injector holes...

also good idea pushing back part of the firewall to get the blower to fit. almost makes me want to take mine off and do that, but not quite.

did you get fuel everywhere like i did when you took off the fuel rails?

Willie, I wasn't comfortable at all having the bypass valve in direct contact with the firewall. Engine movement over time may very well have caused a failure here, leading to much larger engine woes. It felt good to do what needed to be done.

Fuel everywhere? I'll let you in on something. I didn't run the system dry as indicated in the directions. I only had a minor "dribble" from the fuel supply line when I disconnected it from the rail. The key is to remove the rails while keeping the injectors seated up into the rail as well. You can't tip the assembly either or you 'll be surprised at how much fuel the rail holds. So I can honestly say that part went without a hitch.

Willie, did you change your plugs? If so, do you remember the gap?

Tob,

Was this in the instruction for the kit? I just bought a 2011 and thought about this kit for the reason it had FRPP on it. I would have figure the fit would have been better. I don't think I could have bashed the firewall on the car.

Spaz, the 2011 actually has a few more steps than an install on any of the earlier versions. There is nothing here that anyone with a modicum of skills couldn't conquer. This install is a bit detailed and with production variances, some fine tuning is to be expected. If you planned on buying this kit, the information I'm trying to provide could only help. Once complete, I'm sure it will all be worth it. The best part? Now you know the types of things that an installer goes through for you but never mentions when you pay the bill and ask how it went.

Tob

You are going to like the results. I found the install pretty easy. Get ready for a clutch install. :lol:

No, I didnt change the plugs with the whipple install....I had them changed previously with the pulley swap. I didnt even ask them what the gap was. I'll be home in a few days and I could pull one out and check if you still havent gotten an answer.

Last edited:

Excellent pics and write up. Convinced me to stick with a TVS! LOL

if your running 15-17 psi then you wanna gap from .29-.32

:beer: i was thinking mine were at .31.

This is an *Awesome* read. Better than a book!

On using the wood to "modify" the firewall- maybe a strip of that blue painters tape added to the firewall at point of impact before the hammer swing?

On using the wood to "modify" the firewall- maybe a strip of that blue painters tape added to the firewall at point of impact before the hammer swing?

I probably should have used the piece of sheet rubber I had sitting ten feet away.

Tob

I wouldn't want to miss out on the benefits of the baby Whipple (if you could call it that) simply because the install deviated a bit from a stock-like install. Once the blower is on, it's on! For me, I already had the FRPP CAI and I couldn't see spending ~$4,500 for only another 65 HP. For more power than that and an FRPP tune, the Whipple fits the bill, AFAIC.Shaker said:Convinced me to stick with a TVS! LOL

Tob

Users who are viewing this thread

Total: 3 (members: 0, guests: 3)