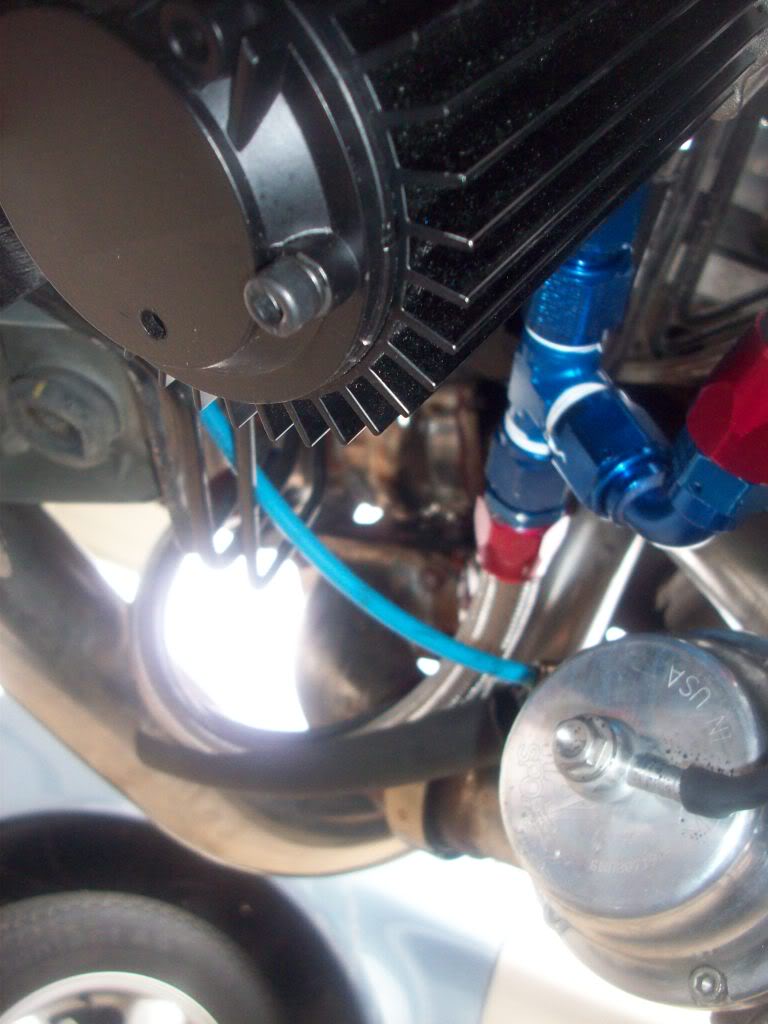

I installed my scavenge pump with my new function 7 fittings which look great. Ok here is my headache. All of a sudden both turbos are leaking oil down the exhaust pipes. It wasnt doing that before the install of the pump. After a while having the car running for a few min. it started smoking like a biotch. I know this should of been really easy, but this may be a dump question: Where the pump reads in, that is where the drain line T together and the one that says out goes to the oil pan. There are no kinks in lines. The turbos have 3k miles on them i cant see how they need a rebuild. Somebody help me out. Ill take some pics of what i got. Im running -10 line for everything. I thought i could do this myself but it doesnt look like it. I think my seals maybe shot.

Last edited: