I recently traded my procharged GT for this project Mach 1. Car has a built motor. MM suspension. FTBR IRS. T56. Lot of good stuff. But the fuel system wasn't right. The factory ECU had an intermittent coil driver failure on cylinder 7. Wiring was a mess. It was a lot to take on but I'm making some headway.

I generally prefer return systems for the simplicity, and wanted to run return on the Mach. However, after spending a grand with Lethal for the return system I had on the GT, I wanted to go about it a different way to save money, and also not have to run the regulator that hangs off the rail. You can't buy the FPRS Billet block to ORB fitting by itself any longer (at least that I could find), so I set out on another path.

Years ago when I joined the site, I built a C head swapped 98' Cobra. Part of the dance you do with that swap is solving the fuel system issues since C heads are returnless. I ended up cutting the 96-98 rails and flipping the tabs around to fit the C head intake. Turns out that was a perfect solution for this project.

So I started with a 96-98 Cobra fuel rail off a B head car. As you can see, a couple beers, welds, and grinding later, it fits pretty damn well. You do need to bend the passenger side rear most fittings where the hoses attach to clear the intake. But a vice makes quick work of that.

Note: With this you do lose the factory FPRS sensor. But most ECU's can run without if you remove the reference and set the PWM to 100% at the FPDM.

What I started with:

Cut and bent the tabs to sit more inline with the rail bosses

The rail bosses do sit more proud of the rails. So I had to bend the fabricated tabs to take a step inward towards the rails.

Finish welded, ground down, and painted

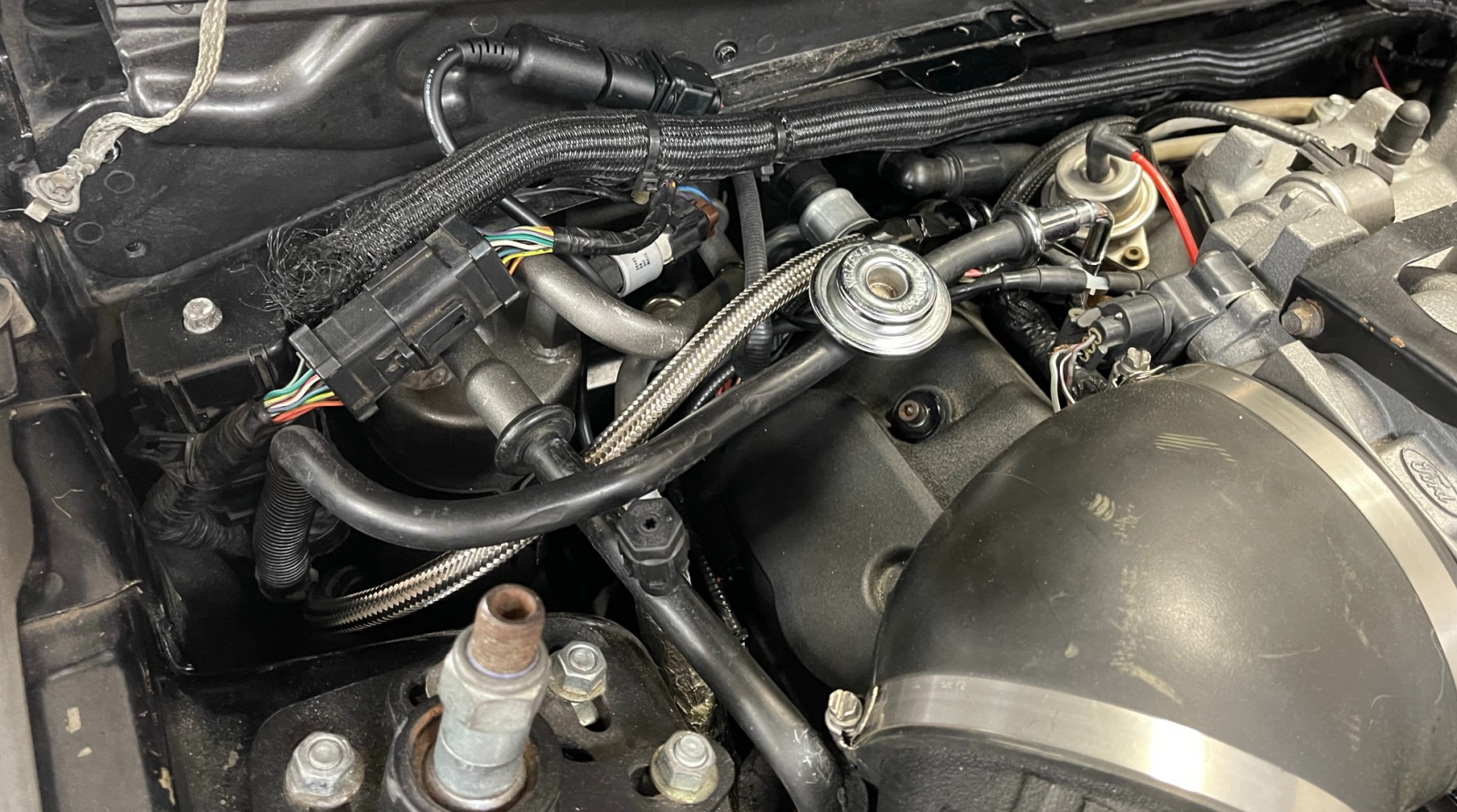

On the car

So from here I felt accomplished and capable. The only issue is.. where should I take the fuel return to on the tank. I was told by previous ownership that the car had an 03/04 Tank with dual 340's. I took it with a grain of salt because people are people and forget things.

My devised solution to the return at the tank ended up being a 6AN bulkhead fitting with PTFE washers next to the feed outlet.

Pulled the tank

Pulled the pumps. I'm in luck, it is all terminator parts with dual 340s. But what's that? A PPRV? Say it ain't so. At 11pm 4 beers deep, I somehow managed to find nylon flex line for fuel pumps that ended up helping me get rid of the PPRV. If you're unaware of why you don't want it, it's a check valve that maintains line pressure after the pumps turn off. All well and good until you throw more volume at it than it can handle. Eventually it breaks and well, fueling is far from consistent.

Drilled and installed the bulkhead (off the tank mind you). I did not do this on the tank.

I had a box of 6an 20ft long Russells Proflex line. Wasn't my first choice but it was free, so I used it for now. Eventually it'll go 8/6 AN feed and return PTFE for E85. Routed it next to the factory fuel line so it had something to ziptie too.

After all of that was said and done, I reinstalled the tank. Attached the fittings. Adjusted the tune. Checked for the leaks, made a few tweaks, and it's ready to go.

For specific tuning notes:

Set your base target psi to 39 (factory cobra regulator)

You can maintain the factory FPDM. I just set mine to 100% PWM for now so it keeps the factory functions without needing any wiring work.

Note: This car does have an aftermarket ECU so I have a ton of flexibility on how I want to tune for the return style system.

Also as an aside, I am working on adding lowdoller motorsport GM/Universal sensors to the car to begin mapping/tracking different fluid pressures/temps, and various other tidbits to build in safeties when the car goes boosted. The addition of a fuel pressure sensor (i'll share that when the project is wrapped up) will allow the use of PWM again to reduce the load on the pumps and keep the fuel cooler.

As for cost, well I traded for the rail. I had the line. I had 3 of the 4 fittings in my spare box. I'm in this for approximately 12 Coors Light (12 bucks), a bulkhead fitting (10 bucks on amazon), some general materials and about a days worth of work.

All in all, not a bad solution for 30-40 bucks.

I generally prefer return systems for the simplicity, and wanted to run return on the Mach. However, after spending a grand with Lethal for the return system I had on the GT, I wanted to go about it a different way to save money, and also not have to run the regulator that hangs off the rail. You can't buy the FPRS Billet block to ORB fitting by itself any longer (at least that I could find), so I set out on another path.

Years ago when I joined the site, I built a C head swapped 98' Cobra. Part of the dance you do with that swap is solving the fuel system issues since C heads are returnless. I ended up cutting the 96-98 rails and flipping the tabs around to fit the C head intake. Turns out that was a perfect solution for this project.

So I started with a 96-98 Cobra fuel rail off a B head car. As you can see, a couple beers, welds, and grinding later, it fits pretty damn well. You do need to bend the passenger side rear most fittings where the hoses attach to clear the intake. But a vice makes quick work of that.

Note: With this you do lose the factory FPRS sensor. But most ECU's can run without if you remove the reference and set the PWM to 100% at the FPDM.

What I started with:

Cut and bent the tabs to sit more inline with the rail bosses

The rail bosses do sit more proud of the rails. So I had to bend the fabricated tabs to take a step inward towards the rails.

Finish welded, ground down, and painted

On the car

So from here I felt accomplished and capable. The only issue is.. where should I take the fuel return to on the tank. I was told by previous ownership that the car had an 03/04 Tank with dual 340's. I took it with a grain of salt because people are people and forget things.

My devised solution to the return at the tank ended up being a 6AN bulkhead fitting with PTFE washers next to the feed outlet.

Pulled the tank

Pulled the pumps. I'm in luck, it is all terminator parts with dual 340s. But what's that? A PPRV? Say it ain't so. At 11pm 4 beers deep, I somehow managed to find nylon flex line for fuel pumps that ended up helping me get rid of the PPRV. If you're unaware of why you don't want it, it's a check valve that maintains line pressure after the pumps turn off. All well and good until you throw more volume at it than it can handle. Eventually it breaks and well, fueling is far from consistent.

Drilled and installed the bulkhead (off the tank mind you). I did not do this on the tank.

I had a box of 6an 20ft long Russells Proflex line. Wasn't my first choice but it was free, so I used it for now. Eventually it'll go 8/6 AN feed and return PTFE for E85. Routed it next to the factory fuel line so it had something to ziptie too.

After all of that was said and done, I reinstalled the tank. Attached the fittings. Adjusted the tune. Checked for the leaks, made a few tweaks, and it's ready to go.

For specific tuning notes:

Set your base target psi to 39 (factory cobra regulator)

You can maintain the factory FPDM. I just set mine to 100% PWM for now so it keeps the factory functions without needing any wiring work.

Note: This car does have an aftermarket ECU so I have a ton of flexibility on how I want to tune for the return style system.

Also as an aside, I am working on adding lowdoller motorsport GM/Universal sensors to the car to begin mapping/tracking different fluid pressures/temps, and various other tidbits to build in safeties when the car goes boosted. The addition of a fuel pressure sensor (i'll share that when the project is wrapped up) will allow the use of PWM again to reduce the load on the pumps and keep the fuel cooler.

As for cost, well I traded for the rail. I had the line. I had 3 of the 4 fittings in my spare box. I'm in this for approximately 12 Coors Light (12 bucks), a bulkhead fitting (10 bucks on amazon), some general materials and about a days worth of work.

All in all, not a bad solution for 30-40 bucks.