Thank you for your input on the subject of the floor plate reinforcement.To be honest, I don't think it is a big deal. You can slightly manipulate these components, without any ill effects.

For example, you can have a K-Member "spring" off of a jig, after it is built. When installing said piece, you may have to manipulate (I guess you could say bend / flex) it to align perfectly, or square it up.

Going from the front mounts, all the way to the rear....should not cause much of any issue. The mounting plates on the K-Members will easily conform.

Now, if you were going to put a 1/2" or larger spacer there....I'd day, yes, space both ends.

At the end of the day, if someone does not feel comfortable with a 3/16" plate on the rear only, it would only take an hour or so to make some plates in the same thickness for the fronts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maximum Motorsports S197 K-Member

- Thread starter Tob

- Start date

I maybe seeing it. I definitely like what I'm seeing, but I doubt I'll be spending money on this car any time soon.You're seeing it my man.

Exactly what I was thinking. And while I can follow the argument Bad Company's mechanic was making, the implication is that there has to be flex somewhere when a rigid K-member and factory chassis are mated. I don't see a more rigid rear mount transferring to overly excessive loads being shifted to the front K-member mounts. The energy it takes to deform the factory floorpan is distributed over a larger surface which handles the load. The same leverage is there, just a more rigid structure would be in place that previously allowed deflection or deformation.

I'd like to know if they adjusted the anti-dive geometry of the front suspension with this piece. If the floorpan is deforming under hard braking then adding more anti-dive geometry into the suspension mounting points will transfer more of this braking energy to the rear mounts of the K-member and floorpan of the car. It would be very beneficial to add plating to the floorpan when installing the K-member from the pictures of the car posted in this thread

I'm sure we'll find out soon enough. I'm pretty confident in Maximum's ability to identify a specific issue and either eliminate or design around it so that it is no longer a concern. The fact that they've been testing it in a racing environment for some time now as well as MM always being staffed with some pretty sharp minds puts me entirely at ease. Maximum knows exactly how much stronger this piece is when compared to the stock one and I'm quite sure they are on top of any geometric changes made in terms of the net result(s). I'm not big on faith but I am when it comes to Maximum and a new part.

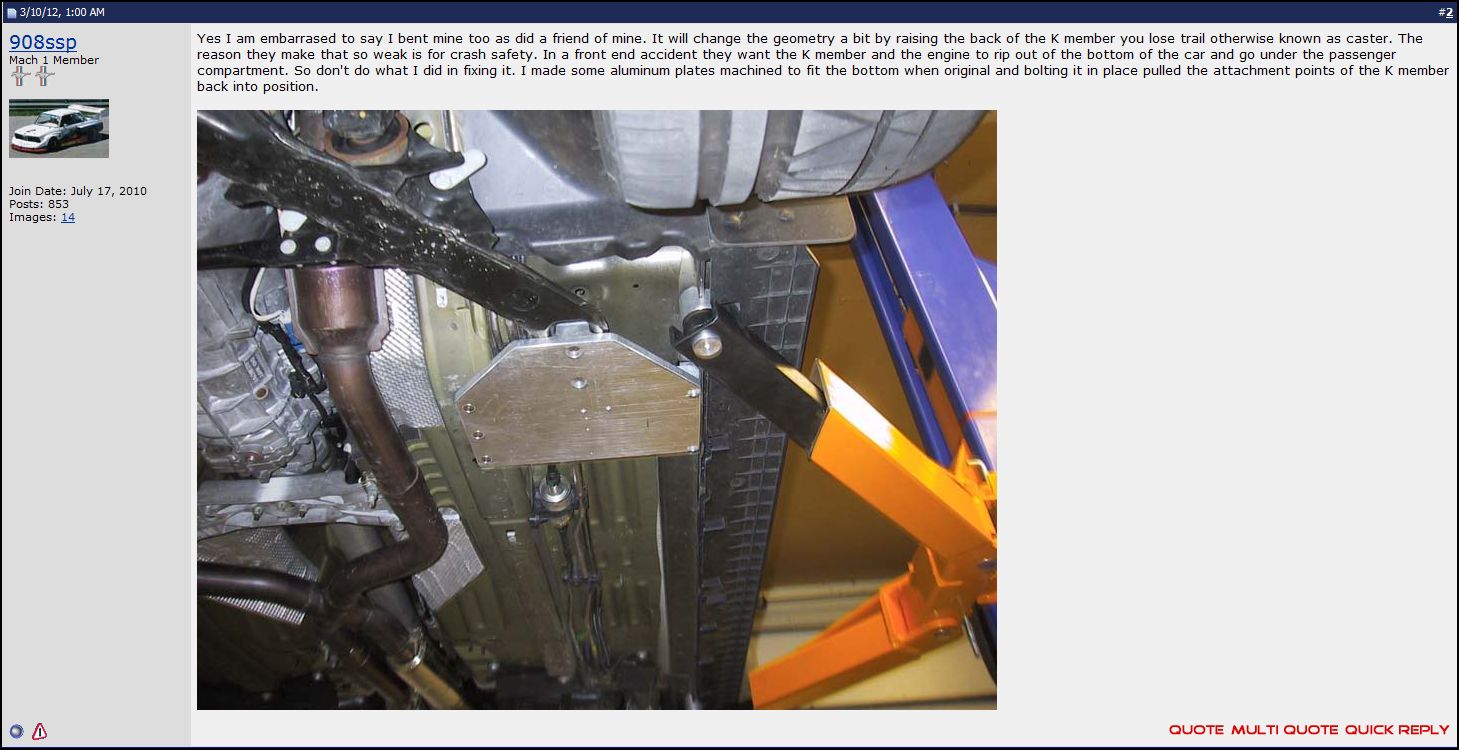

With respect to the floorpan deforming, this is a tough one. I've spent much of the weekend searching for any available data, photos, etc, on the issue. Kelly brought something to my attention (a photo) and it took me a few hours to nail down the source. What struck me in the above photos I took of the tails of the S197 factory K-member was the reasoning for using two thin layers of sheetmetal, stitch welded, to make them. Why wouldn't Ford use a single, thicker stamping? Surely it would be less money. The only rationalization I could come up with was crash testing. So when I saw the explanation in the following photo from 908SSP, it started to make a little more sense.

Bridging the rocker at the pinch weld over to the inner frame rail and then pulling the deformed sheetmetal back (while positively locating the K-member tail) would absolutely provide for a more rigid structure, which should transfer to more accurate alignment settings under varying dynamic load conditions. The part about the weak floorpan being engineered to facilitate certain crash constraints - I wanted to see that for myself. So I spent a few more hours watching every frame of a large number of S197 crash test videos. And guess what? The K-member does indeed "rip-out" of the floor on the S197 chassis. Every frontal impact video I could find was consistent and rather ugly. A quick GIF I put together...

Taken from here. Here's another one.

It does appear as though the design was such that tearing the floor downward was the goal. In many of these videos you see the strut towers being bend back towards the rear of the car and any side view footage shows the floor tearing/buckling down towards the road surface. Interesting that the sheetmetal was designed to yield as opposed to a more rigid (read: thicker, etc) floor but with a fastener that was likely to shear under these conditions. What is even more interesting is how GM didn't follow Ford's playbook here on the Camaro. Note that they chose to mount the rear of their K-member right to the face of the inner framerail, a much stronger anchor point than what the S197 uses. Their K-member ends up folding over itself. Another quick GIF, this time a late model Camaro...

From this video.

For me, reinforcing would be rather easy were I so inclined. But after seeing numerous crash tests it would certainly be a tough call from a liability perspective (how I loathe that term). I'm definitely interested in seeing how many more have had this area deform without ever having jacked from that spot.

With respect to where I am now, I adjusted the spacer stack on the MM bumpsteer kit to lower the rod end as per Maximum's recommendations when used with this K-member. I'm using a number of Chuck's suggestions regarding simplifying a home alignment. I'm using two pieces of conduit now with equidistant stringline centers for faster, more consistent setup and measuring. I verified that my toe isn't in or out at the rear axle and am refining my camber and toe settings up front. Repeating the process over and over, you can't help but get better at it.

With respect to the floorpan deforming, this is a tough one. I've spent much of the weekend searching for any available data, photos, etc, on the issue. Kelly brought something to my attention (a photo) and it took me a few hours to nail down the source. What struck me in the above photos I took of the tails of the S197 factory K-member was the reasoning for using two thin layers of sheetmetal, stitch welded, to make them. Why wouldn't Ford use a single, thicker stamping? Surely it would be less money. The only rationalization I could come up with was crash testing. So when I saw the explanation in the following photo from 908SSP, it started to make a little more sense.

Bridging the rocker at the pinch weld over to the inner frame rail and then pulling the deformed sheetmetal back (while positively locating the K-member tail) would absolutely provide for a more rigid structure, which should transfer to more accurate alignment settings under varying dynamic load conditions. The part about the weak floorpan being engineered to facilitate certain crash constraints - I wanted to see that for myself. So I spent a few more hours watching every frame of a large number of S197 crash test videos. And guess what? The K-member does indeed "rip-out" of the floor on the S197 chassis. Every frontal impact video I could find was consistent and rather ugly. A quick GIF I put together...

Taken from here. Here's another one.

It does appear as though the design was such that tearing the floor downward was the goal. In many of these videos you see the strut towers being bend back towards the rear of the car and any side view footage shows the floor tearing/buckling down towards the road surface. Interesting that the sheetmetal was designed to yield as opposed to a more rigid (read: thicker, etc) floor but with a fastener that was likely to shear under these conditions. What is even more interesting is how GM didn't follow Ford's playbook here on the Camaro. Note that they chose to mount the rear of their K-member right to the face of the inner framerail, a much stronger anchor point than what the S197 uses. Their K-member ends up folding over itself. Another quick GIF, this time a late model Camaro...

From this video.

For me, reinforcing would be rather easy were I so inclined. But after seeing numerous crash tests it would certainly be a tough call from a liability perspective (how I loathe that term). I'm definitely interested in seeing how many more have had this area deform without ever having jacked from that spot.

With respect to where I am now, I adjusted the spacer stack on the MM bumpsteer kit to lower the rod end as per Maximum's recommendations when used with this K-member. I'm using a number of Chuck's suggestions regarding simplifying a home alignment. I'm using two pieces of conduit now with equidistant stringline centers for faster, more consistent setup and measuring. I verified that my toe isn't in or out at the rear axle and am refining my camber and toe settings up front. Repeating the process over and over, you can't help but get better at it.

It'd be similar to lowering the stock K-member only way easier.

Seriously, if you couldn't get away with leaving the blocks/engine in place and had to lower that as well, you'd just leave the blocks attached to the engine mounts and remove the two nuts that attach to the studs (that pass through the blocks) on each frame rail. Plus you now have easier access to the rack hardware, the exhaust where the manifold meets the H/X/Whatever pipe, etc.

Seriously, if you couldn't get away with leaving the blocks/engine in place and had to lower that as well, you'd just leave the blocks attached to the engine mounts and remove the two nuts that attach to the studs (that pass through the blocks) on each frame rail. Plus you now have easier access to the rack hardware, the exhaust where the manifold meets the H/X/Whatever pipe, etc.

I spent much of the day playing with the settings again. I think I thought of at least three designs for home alignment tools to make it easier when going it alone. Anyway, I sat down in front of the computer when done and noticed an email had come from Maximum. Chuck provided everything I had asked for and much, much more.

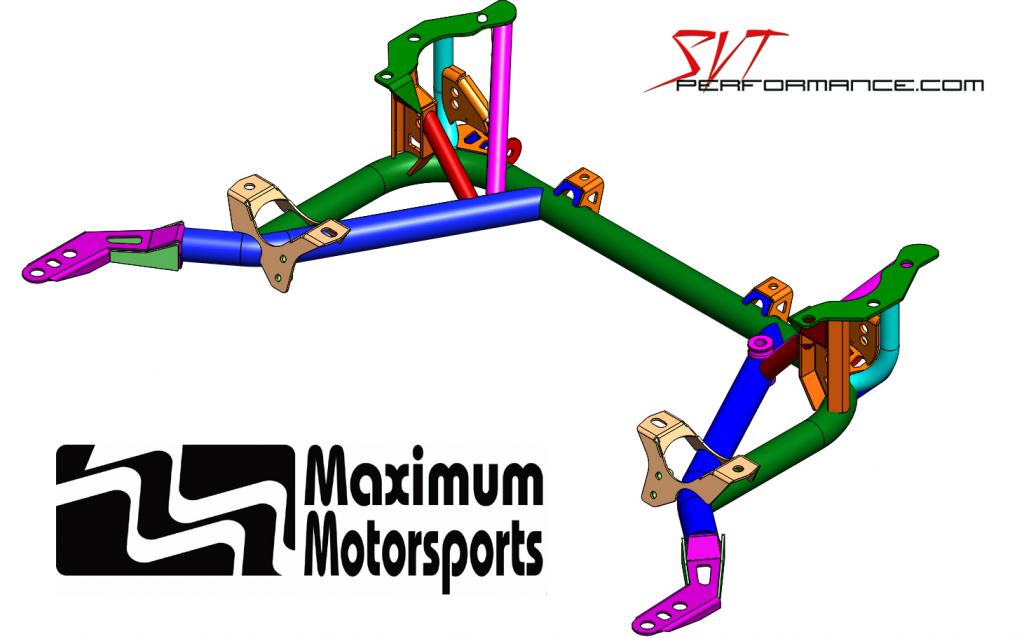

Look closely and you'll see each part used to comprise the overall assembly (sans the rear bar). The weldments aren't shown and as such you can see how many different pieces are used as well as where any bends are made. Very cool.

Chuck also provided the following...

Design Goals

When it comes to the k-member, we feel that improved geometry and strength/stiffness are head and shoulders above all other considerations. For the S197 k-member we put not increasing NVH at the secondary level. Reducing weight comes last because it is nearly impossible to reduce weight without also reducing strength and stiffness. Since the k-member supports the entire front suspension while also holding up the engine, we feel that simply in the interest of safety we need to maintain a particular level of strength. If one is serious about weight reduction, we feel it should be done by reducing the weight of something that is not a mission-critical part, as the k-member is. Fiberglass or carbon fiber body panels are our first choice. This does not mean that we ignore weight-saving, as one can readily see from the lightening holes in the k-member. We do what we can, as long as we are maintaining our desired strength and stiffness.

This k-member is not aimed at drag racers who want to save weight at any cost. We know the majority of our customers are using their vehicle on the street, with occasional track events. Durability and low NVH are their primary concerns. Most of our Fox/SN95 parts were designed for street driving, and then tested and proven on racecars. We followed the same path when we designed this k-member.

Strength/Stiffness

With the S197 strut suspension design, most of the cornering loads are fed into the forward control arm pivots on the k-member. The highest loads at the rearward control arm pivot mounts of the k-member are during heavy braking. We focused on making the section forward of the rear pivots stiffer than the stock k-member. We also concentrated on feeding those loads primarily through the upper frame rails.

We built two fixtures to load test the k-members. The MM k-member deflected 30% less than the stock k-member during a simulated cornering load. We tested one aftermarket k-member, and it deflected 40% more than the stock k-member did in the same test scenario.

NVH

NVH is increased by using non-stock motor mounts. Many people complain of excessive vibration, especially at ide, when using urethane motor mounts. Some NVH comes from non-stock FCA bushings. These cause more of an increase in impact harshness than vibration. NVH is certainly subjective. What one person finds acceptable for daily driving another considers intolerable. In our opinion, the S197 is far less tolerant of changes that affect NVH than the previous generation. Bushing changes that cause unnoticeable or minor increases in NVH on a Fox/SN95 chassis cause big NVH increases with the S197 chassis.

Motor Mounts

Over the past several years we heard many complaints from people about increased NVH, primarily caused by the proprietary urethane motor mounts used in their aftermarket S197 k-member, regardless of the manufacturer. We also heard from our dealers, and other installers, who disliked having their customers complain about increased NVH after installing a k-member.

Through the building of a couple of iterations of our first design, one of which is on the yellow Vortech SEMA car, we encountered many design issues trying to route tubes around the stock motor mounts while also offering two control arm mounting heights. When MM’s head design engineer, Luka, had the idea to make machined aluminum blocks to lower the top mounting flange of the k-member, those difficulties went away. As a bonus, by mounting the motor mounts to the aluminum blocks, the engine could stay in its stock location even when the rest of the k-member was removed. That greatly improves access for maintenance and header installation.

Aluminum Blocks

Each aluminum block is aligned to the frame rail with a close-fitting pin that fits into the same hole in the frame rail that Ford used for alignment on the assembly line.

The k-member mounting flange has over-sized holes to allow shifting it relative to the blocks, allowing precise squaring because it can move more than the stock k-member can. In the event that even more movement is needed, the pins can be easily removed from the aluminum blocks to allow shifting the blocks on the frame rails.

The blocks were designed to place the top of the k-member below the pinch weld on the underside of the frame rails. This lower position allows the k-member to be adjusted without running into the pinch welds.

Yet another bonus: The blocks were designed to provide an accurate mounting point for the upper control arm of an SLA suspension. We are still in the testing stages of our design and have no planned release date.

FCA Height

We did not send Tob spacers for the rearmost front control arm mounts because we knew he would not be using the upper set of holes. For extreme lowering, when moving the FCAs to the upper set of holes would be beneficial, several things are required. Spacers are needed to move the rearmost FCA mount upwards to match the front mount. The stock rearward FCA bushing must be replaced because its large diameter would interfere with the frame rail; smaller diameter aftermarket bushings of either Delrin or urethane are required. Bumpsteer must be addressed by installing a bolt-through bumpsteer kit. The stronger bolt-through style is required instead of the tapered stud to prevent breakage from the increased load from the extra leverage of the greater length required to properly locate the outer tie-rod end to match the FCA in the upper set of holes.

Anti-dive

We did not alter the angle of the FCA pivot axis because we did not want to significantly change the stock anti-dive percentage. The act of lowering an S197 will cause an increase in anti-dive. With the stock k-member, lowering the car one inch increases anti-dive from about 15% to about 20%. With this MM k-member, lowering one inch with the FCAs in the lower set of holes also increases anti-dive to about 20%.

We learned 15 years ago through testing that significantly increasing the anti-dive of the Mustang strut suspension caused a bad effect that far outweighed any beneficial effects: Encountering even small bumps during heavy braking would easily cause front wheel lock up.

There are two main reasons why increased anti-dive worsens braking on an S197 chassis. First, and this applies to all cars, as anti-dive is increased the resulting suspension geometry causes the tire to move more forward with bump travel. This makes the slope of the bump steeper, increasing the vertical acceleration of the tire, bouncing it off of the ground. Second, the geometry required for increased anti-dive increases the bending load on the strut. This increases friction in the strut, causing poor compliance of the tire to the road. This second problem is missing from an SLA front suspension because it does not have a strut.

Bumpsteer

A bumpsteer kit is required with the MM k-member. The stock front suspension has the usual Ford design of a small amount of bumpsteer (toe-out under compression) to promote understeer. Raising the inner FCA pivot points requires changing either the inner or outer tie-rod pivot points to match, just to maintain the stock bumpsteer (toe-change). The easiest way to do this is to use a bumpsteer kit at the outer tie-rod end.

Front Control Arms

We are not in a hurry to make our own. The 2010-14 Ford arms, with the larger ball joints, are very robust. A lighter weight arm would likely not be as strong and stiff.

Floorpan Distortion

Until this thread we had not heard of floorpan distortion at the rearward mount caused by anything other than incorrectly jacking up the car at that point. We also have not seen any permanent floorpan deformation on any of our test cars, driven both on the street and on track.

We knew of the k-member rear leg failure shown in a photo posted in this thread, and designed a strengthening brace for the rear k-member mount. We did not include it on the first pilot run of k-members because it would have added 2-3 lb. We are still discussing making it an option; not choosing it would still add weight, but well under 0.5 lb.

Steering Vibrations

The advent of the electric rack in 2011 brought both good and bad. The stock EPAS anti-nibble programming was based on the stiffness of the stock rubber FCA bushings. Replacing those bushings with stiffer urethane or Delrin causes the feedback loop in the anti-nibble programming to become unstable, causing the system to oscillate. These oscillations are felt in the steering wheel as vibrations. By allowing the use of the stock control arm bushings, we are able to minimize any EPAS steering related issues until a solution cheaper than upgrading the rack can be found.

Material

All tubes are mild steel DOM tubing. The main tubes, on the lower plane, are 1.75” diameter with a 0.095” wall thickness.

The Envelope

We maintained the same ground plane as the stock k-member. The other tubes are located to provide more clearance towards the engine, exhaust, etc., than does the stock k-member.

Weight

Yes, it is heavier than a stock k-member; 42.54 lb vs. 40.52 lb. We tried, but upon meeting our design goals, this is where it is. Handling is improved. Stability and predictability are improved; the front end feels much more… Planted is the best word for it. There is less front-end drama when cornering. Maintenance and header installation is greatly improved. Someday an easy SLA upgrade will be possible.

Radiator Core Support

We have finalized the design. Production fixtures will be built once the k-member is steadily rolling off the line. It is a fair bit lighter than the stock core support. Provision for a stock-location swaybar mount is an option, as well as mounting points for a splitter.

Forward Braces

These connect the MM core support to the MM k-member. They add stiffness to the front end. The swaybar mounts are located on the braces. The braces include a provision for shifting the swaybar pivots fore/aft to better align the end links on adjustable front swaybars. The design is not finalized.

Engine Support Beam

We’ve designed a reasonably cheap tool to greatly aid in the installation of the k-member. When using an engine hoist to support the engine during k-member removal, the legs block access to the underside of the vehicle. Our engine support beam spans the strut towers and uses ratchet straps to temporarily suspend the engine while the k-member is swapped.

Availability

Mid-November. The design is finalized, except for perhaps adding the option for the rear mount area brace.

Pricing

Still TBD. Should be finalized within two weeks.

I'm currently going through a thesaurus looking for a better word than wow. It'll work until I do.

Tob

Look closely and you'll see each part used to comprise the overall assembly (sans the rear bar). The weldments aren't shown and as such you can see how many different pieces are used as well as where any bends are made. Very cool.

Chuck also provided the following...

Design Goals

When it comes to the k-member, we feel that improved geometry and strength/stiffness are head and shoulders above all other considerations. For the S197 k-member we put not increasing NVH at the secondary level. Reducing weight comes last because it is nearly impossible to reduce weight without also reducing strength and stiffness. Since the k-member supports the entire front suspension while also holding up the engine, we feel that simply in the interest of safety we need to maintain a particular level of strength. If one is serious about weight reduction, we feel it should be done by reducing the weight of something that is not a mission-critical part, as the k-member is. Fiberglass or carbon fiber body panels are our first choice. This does not mean that we ignore weight-saving, as one can readily see from the lightening holes in the k-member. We do what we can, as long as we are maintaining our desired strength and stiffness.

This k-member is not aimed at drag racers who want to save weight at any cost. We know the majority of our customers are using their vehicle on the street, with occasional track events. Durability and low NVH are their primary concerns. Most of our Fox/SN95 parts were designed for street driving, and then tested and proven on racecars. We followed the same path when we designed this k-member.

Strength/Stiffness

With the S197 strut suspension design, most of the cornering loads are fed into the forward control arm pivots on the k-member. The highest loads at the rearward control arm pivot mounts of the k-member are during heavy braking. We focused on making the section forward of the rear pivots stiffer than the stock k-member. We also concentrated on feeding those loads primarily through the upper frame rails.

We built two fixtures to load test the k-members. The MM k-member deflected 30% less than the stock k-member during a simulated cornering load. We tested one aftermarket k-member, and it deflected 40% more than the stock k-member did in the same test scenario.

NVH

NVH is increased by using non-stock motor mounts. Many people complain of excessive vibration, especially at ide, when using urethane motor mounts. Some NVH comes from non-stock FCA bushings. These cause more of an increase in impact harshness than vibration. NVH is certainly subjective. What one person finds acceptable for daily driving another considers intolerable. In our opinion, the S197 is far less tolerant of changes that affect NVH than the previous generation. Bushing changes that cause unnoticeable or minor increases in NVH on a Fox/SN95 chassis cause big NVH increases with the S197 chassis.

Motor Mounts

Over the past several years we heard many complaints from people about increased NVH, primarily caused by the proprietary urethane motor mounts used in their aftermarket S197 k-member, regardless of the manufacturer. We also heard from our dealers, and other installers, who disliked having their customers complain about increased NVH after installing a k-member.

Through the building of a couple of iterations of our first design, one of which is on the yellow Vortech SEMA car, we encountered many design issues trying to route tubes around the stock motor mounts while also offering two control arm mounting heights. When MM’s head design engineer, Luka, had the idea to make machined aluminum blocks to lower the top mounting flange of the k-member, those difficulties went away. As a bonus, by mounting the motor mounts to the aluminum blocks, the engine could stay in its stock location even when the rest of the k-member was removed. That greatly improves access for maintenance and header installation.

Aluminum Blocks

Each aluminum block is aligned to the frame rail with a close-fitting pin that fits into the same hole in the frame rail that Ford used for alignment on the assembly line.

The k-member mounting flange has over-sized holes to allow shifting it relative to the blocks, allowing precise squaring because it can move more than the stock k-member can. In the event that even more movement is needed, the pins can be easily removed from the aluminum blocks to allow shifting the blocks on the frame rails.

The blocks were designed to place the top of the k-member below the pinch weld on the underside of the frame rails. This lower position allows the k-member to be adjusted without running into the pinch welds.

Yet another bonus: The blocks were designed to provide an accurate mounting point for the upper control arm of an SLA suspension. We are still in the testing stages of our design and have no planned release date.

FCA Height

We did not send Tob spacers for the rearmost front control arm mounts because we knew he would not be using the upper set of holes. For extreme lowering, when moving the FCAs to the upper set of holes would be beneficial, several things are required. Spacers are needed to move the rearmost FCA mount upwards to match the front mount. The stock rearward FCA bushing must be replaced because its large diameter would interfere with the frame rail; smaller diameter aftermarket bushings of either Delrin or urethane are required. Bumpsteer must be addressed by installing a bolt-through bumpsteer kit. The stronger bolt-through style is required instead of the tapered stud to prevent breakage from the increased load from the extra leverage of the greater length required to properly locate the outer tie-rod end to match the FCA in the upper set of holes.

Anti-dive

We did not alter the angle of the FCA pivot axis because we did not want to significantly change the stock anti-dive percentage. The act of lowering an S197 will cause an increase in anti-dive. With the stock k-member, lowering the car one inch increases anti-dive from about 15% to about 20%. With this MM k-member, lowering one inch with the FCAs in the lower set of holes also increases anti-dive to about 20%.

We learned 15 years ago through testing that significantly increasing the anti-dive of the Mustang strut suspension caused a bad effect that far outweighed any beneficial effects: Encountering even small bumps during heavy braking would easily cause front wheel lock up.

There are two main reasons why increased anti-dive worsens braking on an S197 chassis. First, and this applies to all cars, as anti-dive is increased the resulting suspension geometry causes the tire to move more forward with bump travel. This makes the slope of the bump steeper, increasing the vertical acceleration of the tire, bouncing it off of the ground. Second, the geometry required for increased anti-dive increases the bending load on the strut. This increases friction in the strut, causing poor compliance of the tire to the road. This second problem is missing from an SLA front suspension because it does not have a strut.

Bumpsteer

A bumpsteer kit is required with the MM k-member. The stock front suspension has the usual Ford design of a small amount of bumpsteer (toe-out under compression) to promote understeer. Raising the inner FCA pivot points requires changing either the inner or outer tie-rod pivot points to match, just to maintain the stock bumpsteer (toe-change). The easiest way to do this is to use a bumpsteer kit at the outer tie-rod end.

Front Control Arms

We are not in a hurry to make our own. The 2010-14 Ford arms, with the larger ball joints, are very robust. A lighter weight arm would likely not be as strong and stiff.

Floorpan Distortion

Until this thread we had not heard of floorpan distortion at the rearward mount caused by anything other than incorrectly jacking up the car at that point. We also have not seen any permanent floorpan deformation on any of our test cars, driven both on the street and on track.

We knew of the k-member rear leg failure shown in a photo posted in this thread, and designed a strengthening brace for the rear k-member mount. We did not include it on the first pilot run of k-members because it would have added 2-3 lb. We are still discussing making it an option; not choosing it would still add weight, but well under 0.5 lb.

Steering Vibrations

The advent of the electric rack in 2011 brought both good and bad. The stock EPAS anti-nibble programming was based on the stiffness of the stock rubber FCA bushings. Replacing those bushings with stiffer urethane or Delrin causes the feedback loop in the anti-nibble programming to become unstable, causing the system to oscillate. These oscillations are felt in the steering wheel as vibrations. By allowing the use of the stock control arm bushings, we are able to minimize any EPAS steering related issues until a solution cheaper than upgrading the rack can be found.

Material

All tubes are mild steel DOM tubing. The main tubes, on the lower plane, are 1.75” diameter with a 0.095” wall thickness.

The Envelope

We maintained the same ground plane as the stock k-member. The other tubes are located to provide more clearance towards the engine, exhaust, etc., than does the stock k-member.

Weight

Yes, it is heavier than a stock k-member; 42.54 lb vs. 40.52 lb. We tried, but upon meeting our design goals, this is where it is. Handling is improved. Stability and predictability are improved; the front end feels much more… Planted is the best word for it. There is less front-end drama when cornering. Maintenance and header installation is greatly improved. Someday an easy SLA upgrade will be possible.

Radiator Core Support

We have finalized the design. Production fixtures will be built once the k-member is steadily rolling off the line. It is a fair bit lighter than the stock core support. Provision for a stock-location swaybar mount is an option, as well as mounting points for a splitter.

Forward Braces

These connect the MM core support to the MM k-member. They add stiffness to the front end. The swaybar mounts are located on the braces. The braces include a provision for shifting the swaybar pivots fore/aft to better align the end links on adjustable front swaybars. The design is not finalized.

Engine Support Beam

We’ve designed a reasonably cheap tool to greatly aid in the installation of the k-member. When using an engine hoist to support the engine during k-member removal, the legs block access to the underside of the vehicle. Our engine support beam spans the strut towers and uses ratchet straps to temporarily suspend the engine while the k-member is swapped.

Availability

Mid-November. The design is finalized, except for perhaps adding the option for the rear mount area brace.

Pricing

Still TBD. Should be finalized within two weeks.

I'm currently going through a thesaurus looking for a better word than wow. It'll work until I do.

Tob

Tob

Give Chuck a high five and a case of beer for his explanations. As far as why they didn't add anti-dive, I completely understood. Thank you for the time and effort you put into this thread and MM for their willingness to explain the logic that went into building it in the manner they did.

Give Chuck a high five and a case of beer for his explanations. As far as why they didn't add anti-dive, I completely understood. Thank you for the time and effort you put into this thread and MM for their willingness to explain the logic that went into building it in the manner they did.

Radiator Core Support

We have finalized the design. Production fixtures will be built once the k-member is steadily rolling off the line. It is a fair bit lighter than the stock core support. Provision for a stock-location swaybar mount is an option, as well as mounting points for a splitter.

Beautiful engineering all around. The splitter mount provision particularly excites me.

I have been holding off upgrading the A-Arms and spindles for some time. The MM Kmember seems like a good time to get it all handled. Would love to get my hands on one.

:beer:

Tob

Give Chuck a high five and a case of beer for his explanations. As far as why they didn't add anti-dive, I completely understood. Thank you for the time and effort you put into this thread and MM for their willingness to explain the logic that went into building it in the manner they did.

If I could reach that far I'd gladly shake his hand and slide the case their way. That was a far more detailed explanation than I expected. I credit them for their willingness to share that information. Same goes for Kelly at BMR who has never been averse to giving you an inside look. This level of detail allows for a far more educated buying decision.

Beautiful engineering all around. The splitter mount provision particularly excites me.

I have been holding off upgrading the A-Arms and spindles for some time. The MM Kmember seems like a good time to get it all handled. Would love to get my hands on one.

:beer:

Ron, the pictures you shared of the yellow car with the K-member prototype on it from last year were what got me excited and hoping that this was actually going to happen. Thanks for posting all of it.

I had a chance to inspect this K-Member and it is very well made piece, very nice install on this and the headers Tob, you have earned a VACATION! :thumbsup:

JTB, I did the headers FRPP headers after seeing them on your car. I saw them and simply had to have them despite the fact that they were discontinued and a bit hard to come by. I now just hope the season is long enough to start playing with the tunes Justin from VMP wrote for me.

I redid the alignment over the past couple of days after changing the bumpsteer spacer stack. Each time I've done it I've learned to be more exacting. Having worked in the construction industry for almost thirty years, I have the necessary equipment to do everything at home. And with Maximum's caster camber plates in place this was a giant leap over trying to get the numbers I wanted with the stock components. But there is still plenty of jacking, bouncing, rolling, verifying via a caster camber gauge, tightening, loosening - all over and over again. Anyway, I got the numbers I wanted...

Caster was +7.6* passenger side and +7.5* driver side.

Camber was set to -1.25* on each side.

Toe is in at 1/16."

There is no better feeling than doing the setup yourself, verifying each number, and not being satisfied until you have what you wanted. I lowered the car down, packed up my new homebrew conduit/stringline setup and fired up the car. Steering wheel is perfectly level and the car tracks straight and true. I was only supposed to be running a couple of errands before dinner but I called the wife to say that I was going to be a while as I wanted to spend some time with the car. She knows how much time I have put into with this so she encouraged me to take all the time I wanted.

I know the roads around me very well having lived here for a few decades. I had the electronic Bilsteins in sport mode where the road surface was fairly smooth and comfort mode on where there were plenty of expansion joints, grooved concrete bridges, etc. Somewhere in the midst of the drive it hit me. I was completely in tune with what the suspension was telling me. The front half of the car has indeed changed. It is somehow quieter and is allowing the springs to do their job while the dampers do theirs. I sense less resonance than I did before and believe me, the '13/'14 struts in sport let you know when they don't like a particular surface. Previous to adding the Maximum K-member, a front damper "event" seemed to travel a bit beyond the strut and its respective bushings. Now, I can sense that the springs/dampers work as they should and keep it to themselves. Almost as if I have added some sound deadener.

I can tell what is going on out back as that part of the overall structure simply isn't as subdued (I can't wait to attack the rear of the car now). Chuck described the car after this modification as feeling more "planted" and I couldn't agree more on his word selection. Color me very satisfied that I now have an extremely strong structural element that also acts as a noise hindering foundation, designed to accommodate what I'm convinced will be the best designed SLA that the S197 chassis will see. Thirty percent less deflection than the stock K-member definitely changes the driving experience and all for the better.

I redid the alignment over the past couple of days after changing the bumpsteer spacer stack. Each time I've done it I've learned to be more exacting. Having worked in the construction industry for almost thirty years, I have the necessary equipment to do everything at home. And with Maximum's caster camber plates in place this was a giant leap over trying to get the numbers I wanted with the stock components. But there is still plenty of jacking, bouncing, rolling, verifying via a caster camber gauge, tightening, loosening - all over and over again. Anyway, I got the numbers I wanted...

Caster was +7.6* passenger side and +7.5* driver side.

Camber was set to -1.25* on each side.

Toe is in at 1/16."

There is no better feeling than doing the setup yourself, verifying each number, and not being satisfied until you have what you wanted. I lowered the car down, packed up my new homebrew conduit/stringline setup and fired up the car. Steering wheel is perfectly level and the car tracks straight and true. I was only supposed to be running a couple of errands before dinner but I called the wife to say that I was going to be a while as I wanted to spend some time with the car. She knows how much time I have put into with this so she encouraged me to take all the time I wanted.

I know the roads around me very well having lived here for a few decades. I had the electronic Bilsteins in sport mode where the road surface was fairly smooth and comfort mode on where there were plenty of expansion joints, grooved concrete bridges, etc. Somewhere in the midst of the drive it hit me. I was completely in tune with what the suspension was telling me. The front half of the car has indeed changed. It is somehow quieter and is allowing the springs to do their job while the dampers do theirs. I sense less resonance than I did before and believe me, the '13/'14 struts in sport let you know when they don't like a particular surface. Previous to adding the Maximum K-member, a front damper "event" seemed to travel a bit beyond the strut and its respective bushings. Now, I can sense that the springs/dampers work as they should and keep it to themselves. Almost as if I have added some sound deadener.

I can tell what is going on out back as that part of the overall structure simply isn't as subdued (I can't wait to attack the rear of the car now). Chuck described the car after this modification as feeling more "planted" and I couldn't agree more on his word selection. Color me very satisfied that I now have an extremely strong structural element that also acts as a noise hindering foundation, designed to accommodate what I'm convinced will be the best designed SLA that the S197 chassis will see. Thirty percent less deflection than the stock K-member definitely changes the driving experience and all for the better.

Maximum Motorsports indicates that the k member will be on their site for preorder at the end of next week. I will be waiting.Beautiful engineering all around. The splitter mount provision particularly excites me.

I have been holding off upgrading the A-Arms and spindles for some time. The MM Kmember seems like a good time to get it all handled. Would love to get my hands on one.

:beer:

That Lufkin looks like it's been to hell and back and would likely survive another trip.

Roger, knowing the level of detail you ascribe to I suspect you'll be highly impressed should you choose to take this one on.

And Michael, yes indeedy, many of my on-site tools were put to the test. For three decades I had a tape measure glued to my side but always carried a stick rule when shooting grades, etc. I think I singed that one after laying it down on a hot weld.

And Michael, yes indeedy, many of my on-site tools were put to the test. For three decades I had a tape measure glued to my side but always carried a stick rule when shooting grades, etc. I think I singed that one after laying it down on a hot weld.

Tob, thanks for posting this. I might not have seen it otherwise. Having installed poly motor mounts with my build to be able to lower the engine for a KB, I understand the issue most have with them. Since I went Gen II TVS, I was going to put the stock mounts back in the car. I'm going to wait and install one of these with that change over. I got a deal working to snag a '13 transmission, so this effort is going to be a bit more involved. I think I'll wait to tackle it all when the radiator support and braces are ready to roll. Any idea of an ETA on these latter components?

I'm glad you saw it.

Are you talking about in terms of increased NVH or installation issues?

Regarding availability, I can only quote what Chuck provided and was posted on the previous page.

Radiator Core Support

- We have finalized the design. Production fixtures will be built once the k-member is steadily rolling off the line. It is a fair bit lighter than the stock core support.

Forward Braces

- These connect the MM core support to the MM k-member. They add stiffness to the front end. The design is not finalized.

Personally, I wouldn't wait. I don't have either of those items as of yet but absolutely plan on ordering them when they become available. I don't think they approach the magnitude of the effort you'd put into installing the K-member or transmission and could always be added at a later date. I do have a sense that Maximum is working very hard to get these products to the market once the design has been finalized. One of the things that Chuck shared with me when I asked his permission to do a detailed writeup on the K-member was that by doing so, Maximum is then put in a position to respond to inquiries as well as orders for something that may yet to be finalized or in production. I fully understand, and I think anyone seriously interested would prefer to wait until something is completed as opposed to production being rushed to get things moving and simply make adjustments later.

I have used quite a bit of Maximum's pieces on the three Mustangs I've owned and they have made each car better. Especially the Fox bodies as Ford left a lot to be desired with the suspension they included. I know it's a different chassis but I found a video of Jack and Luka equipping one with quite a bit of their hardware. Worth a look if you are interested in improving your suspension, S197 or otherwise, as much of it is similar. Pay particular attention to what Jack says at the 3:50 mark.

http://powernationtv.com/episode/EP2014-13/barely-legal-mustang-part-2

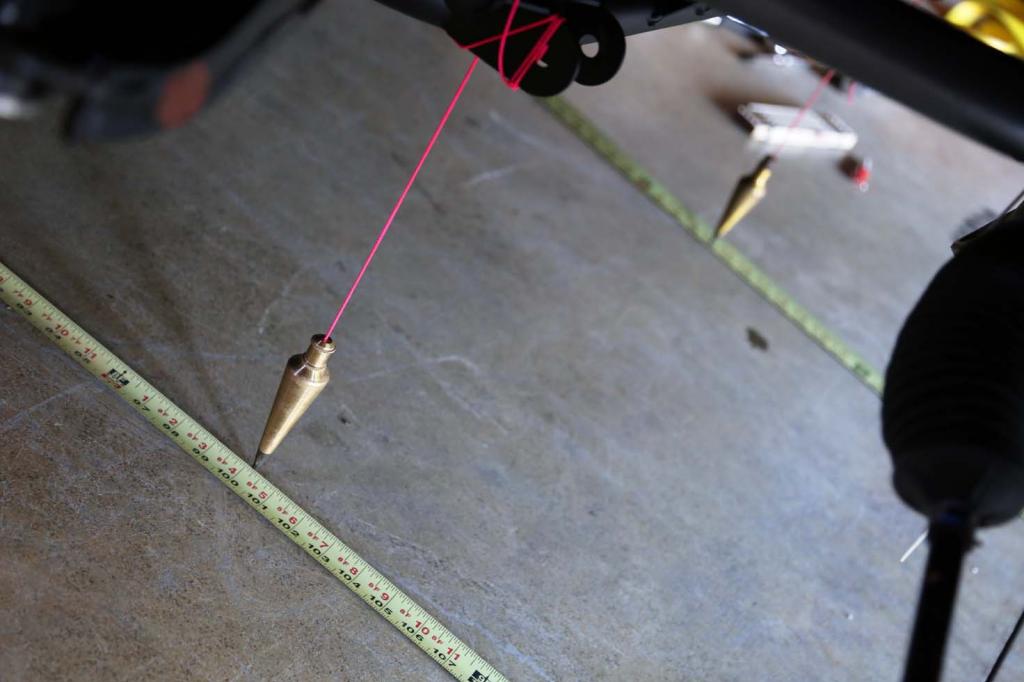

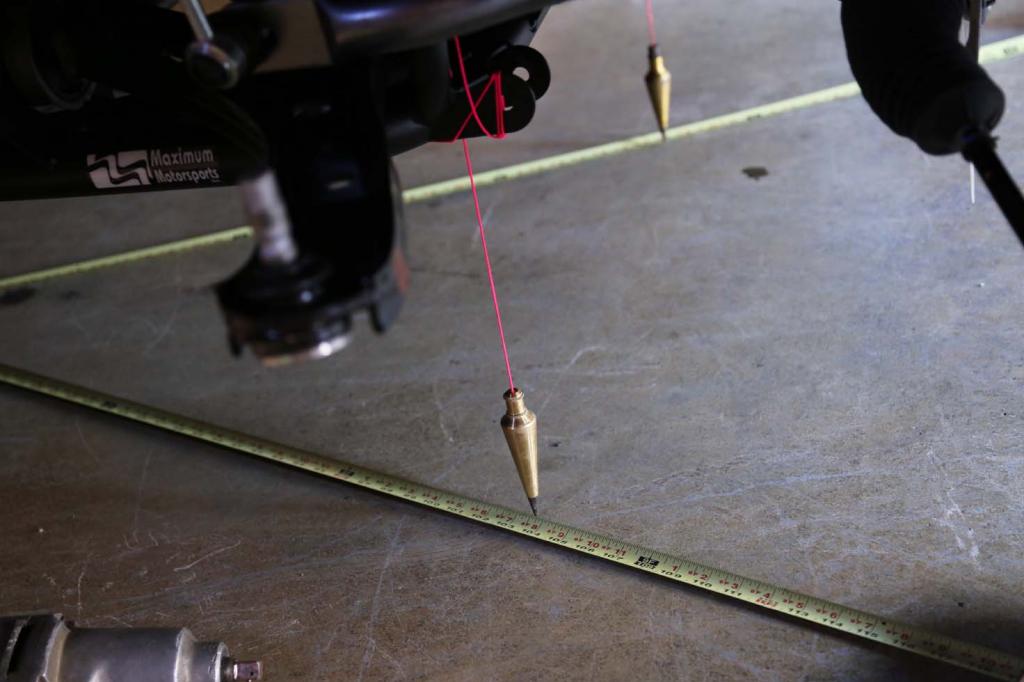

I did spend the time to ensure that various pickup points dimensioned the same from front to rear as well as diagonally, as Jack was absolutely right with his commentary. I used a laser to shoot the rear points (and transferred the marks to the floor), and plumb bobs up front at the K-member.

I have a lot of experience laying out anchor bolts for structural steel building foundations so doing this by myself was rather simple. I was rather impressed at how close everything was and maximum ensured to provide ample room for adjustments, if necessary. Squaring everything up was so much easier with the engine held in place by the aluminum blocks (which is obviously a bit different than what was done in the clip I just linked). I was able to simply bump the K-member in the direction it needed to go by hand followed by locking everything down by tightening the requisite fasteners. All of which is great if you do all your own work or rarely ever have a second set of hands to help.

Catmonkey said:Having installed poly motor mounts with my build to be able to lower the engine for a KB, I understand the issue most have with them.

Are you talking about in terms of increased NVH or installation issues?

Catmonkey said:I think I'll wait to tackle it all when the radiator support and braces are ready to roll. Any idea of an ETA on these latter components?

Regarding availability, I can only quote what Chuck provided and was posted on the previous page.

Radiator Core Support

- We have finalized the design. Production fixtures will be built once the k-member is steadily rolling off the line. It is a fair bit lighter than the stock core support.

Forward Braces

- These connect the MM core support to the MM k-member. They add stiffness to the front end. The design is not finalized.

Personally, I wouldn't wait. I don't have either of those items as of yet but absolutely plan on ordering them when they become available. I don't think they approach the magnitude of the effort you'd put into installing the K-member or transmission and could always be added at a later date. I do have a sense that Maximum is working very hard to get these products to the market once the design has been finalized. One of the things that Chuck shared with me when I asked his permission to do a detailed writeup on the K-member was that by doing so, Maximum is then put in a position to respond to inquiries as well as orders for something that may yet to be finalized or in production. I fully understand, and I think anyone seriously interested would prefer to wait until something is completed as opposed to production being rushed to get things moving and simply make adjustments later.

I have used quite a bit of Maximum's pieces on the three Mustangs I've owned and they have made each car better. Especially the Fox bodies as Ford left a lot to be desired with the suspension they included. I know it's a different chassis but I found a video of Jack and Luka equipping one with quite a bit of their hardware. Worth a look if you are interested in improving your suspension, S197 or otherwise, as much of it is similar. Pay particular attention to what Jack says at the 3:50 mark.

http://powernationtv.com/episode/EP2014-13/barely-legal-mustang-part-2

I did spend the time to ensure that various pickup points dimensioned the same from front to rear as well as diagonally, as Jack was absolutely right with his commentary. I used a laser to shoot the rear points (and transferred the marks to the floor), and plumb bobs up front at the K-member.

I have a lot of experience laying out anchor bolts for structural steel building foundations so doing this by myself was rather simple. I was rather impressed at how close everything was and maximum ensured to provide ample room for adjustments, if necessary. Squaring everything up was so much easier with the engine held in place by the aluminum blocks (which is obviously a bit different than what was done in the clip I just linked). I was able to simply bump the K-member in the direction it needed to go by hand followed by locking everything down by tightening the requisite fasteners. All of which is great if you do all your own work or rarely ever have a second set of hands to help.

Installation wasn't any more difficult than swapping in OEM motor mounts, probably easier because they aren't as large and there's less mass. While you experience more vibration at idle, which I could live with, for me it's more of the engine noises that are transmitted into the cabin. I was going to swap them out this weekend and install the new MGW shifter, but now that this transmission and K-member are on the horizon, I'm going to wait and do it all at one time.Are you talking about in terms of increased NVH or installation issues?

I plan on getting the K, but over the next few months, I'm not sure how much opportunity I will have to install it, especially if they ship later than mid-November. If the other parts are available when I'm able to do the work, which is likely to be late January 2015, I just as soon install them together. I'm getting lazy in my old age.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)