I decided to take a closer look at the damaged strut I purchased so I delivered it to the operating table.

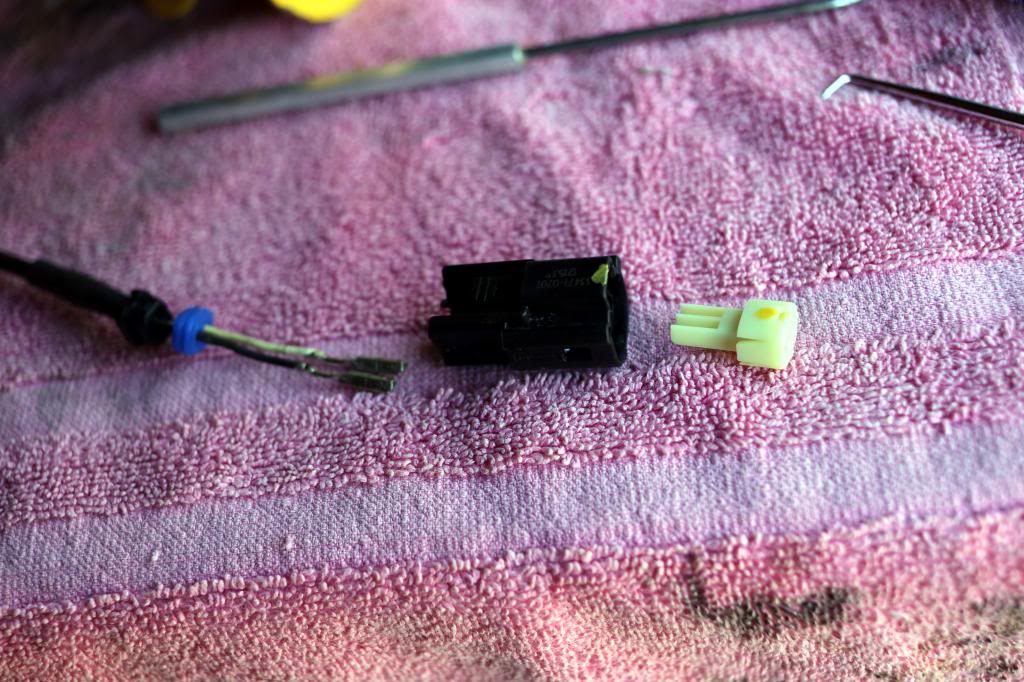

I decided to snip the little bit of sheathing that was still intact. The wires were 100% severed.

Looks like at most I now have a spare Bilstein strut body. The harness is severed at a critical juncture and can't be repaired.

Looks like I'll be ordering a new right side strut.

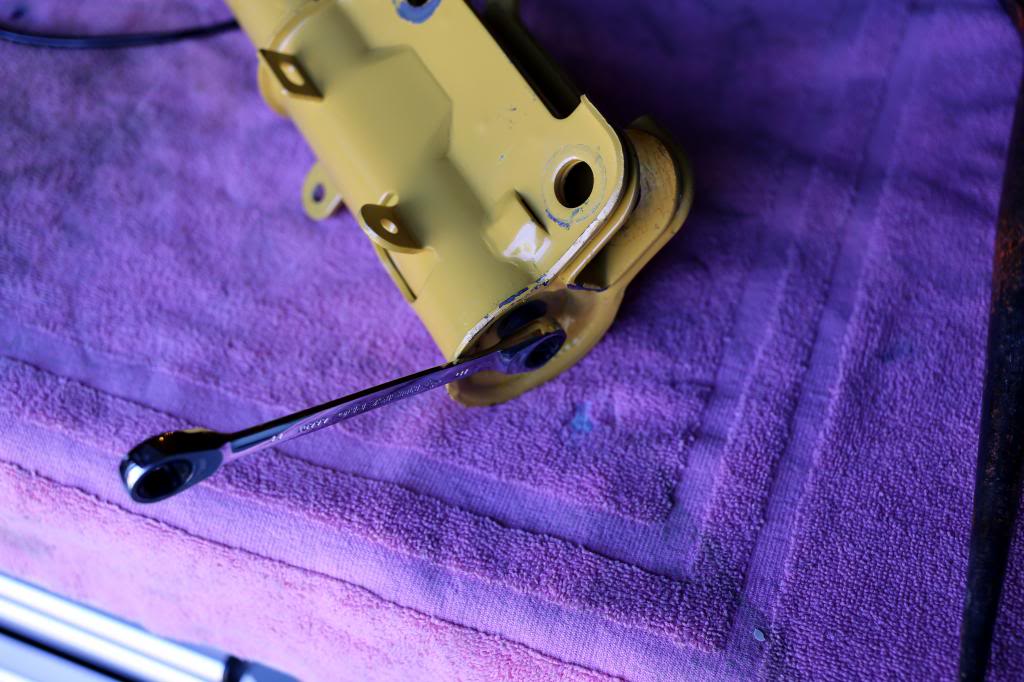

I've studied other Bilstein electronic struts and noticed that in other applications that Bilstein better protected the pigtail than how Ford asked them to do in this application. Note the harness exiting the bottom of the silver strut via a slot in the following picture...

The above hardware was going in this car by the way...

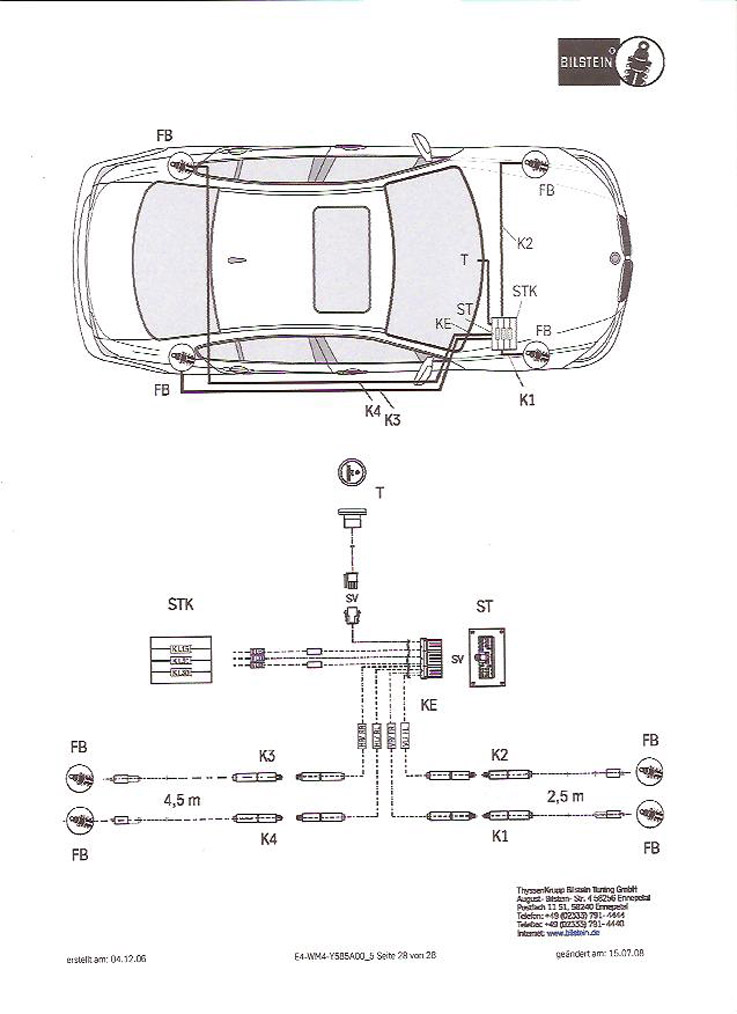

I've noticed that the Damp-Tronics are being used on some serious machinery. The pricing for full kits is out there. Bilstein does sell a wiring kit (I haven't seen one for GT500's though) along with a control unit and switch...

I'm starting to think that Ford engineers were using portions of readily available parts from Bilstein on their development vehicles (photos are from the Nurburgring cars). The illuminated button comes from Bilstein kits for other cars...

Then look at the connectors at the zip tie in the following photo. They mirror what Bilstein uses in their other kits and are not what Ford uses on production '13/'14 GT500 vehicles...

That's all I have for now. This one may take a bit, which is fine by me. But I'll keep digging for a workable solution for retrofit.

I decided to snip the little bit of sheathing that was still intact. The wires were 100% severed.

Looks like at most I now have a spare Bilstein strut body. The harness is severed at a critical juncture and can't be repaired.

Looks like I'll be ordering a new right side strut.

I've studied other Bilstein electronic struts and noticed that in other applications that Bilstein better protected the pigtail than how Ford asked them to do in this application. Note the harness exiting the bottom of the silver strut via a slot in the following picture...

The above hardware was going in this car by the way...

I've noticed that the Damp-Tronics are being used on some serious machinery. The pricing for full kits is out there. Bilstein does sell a wiring kit (I haven't seen one for GT500's though) along with a control unit and switch...

I'm starting to think that Ford engineers were using portions of readily available parts from Bilstein on their development vehicles (photos are from the Nurburgring cars). The illuminated button comes from Bilstein kits for other cars...

Then look at the connectors at the zip tie in the following photo. They mirror what Bilstein uses in their other kits and are not what Ford uses on production '13/'14 GT500 vehicles...

That's all I have for now. This one may take a bit, which is fine by me. But I'll keep digging for a workable solution for retrofit.