I'm hoping someone here has rebuilt their t56 and has some knowledge they can share with me. I pulled mine apart to rebuild some syncro issues and I can't for the life of me figure out how to get the shift forks/linkages back in. My dumb self didn't get a pic before the linkage all came apart and I'm lost. I have searched all over the place, read the manual and still haven't got a clear answer. Most of what I've found has been from GM folks and some of my stuff looks different. If anybody could offer some help.

Thanks

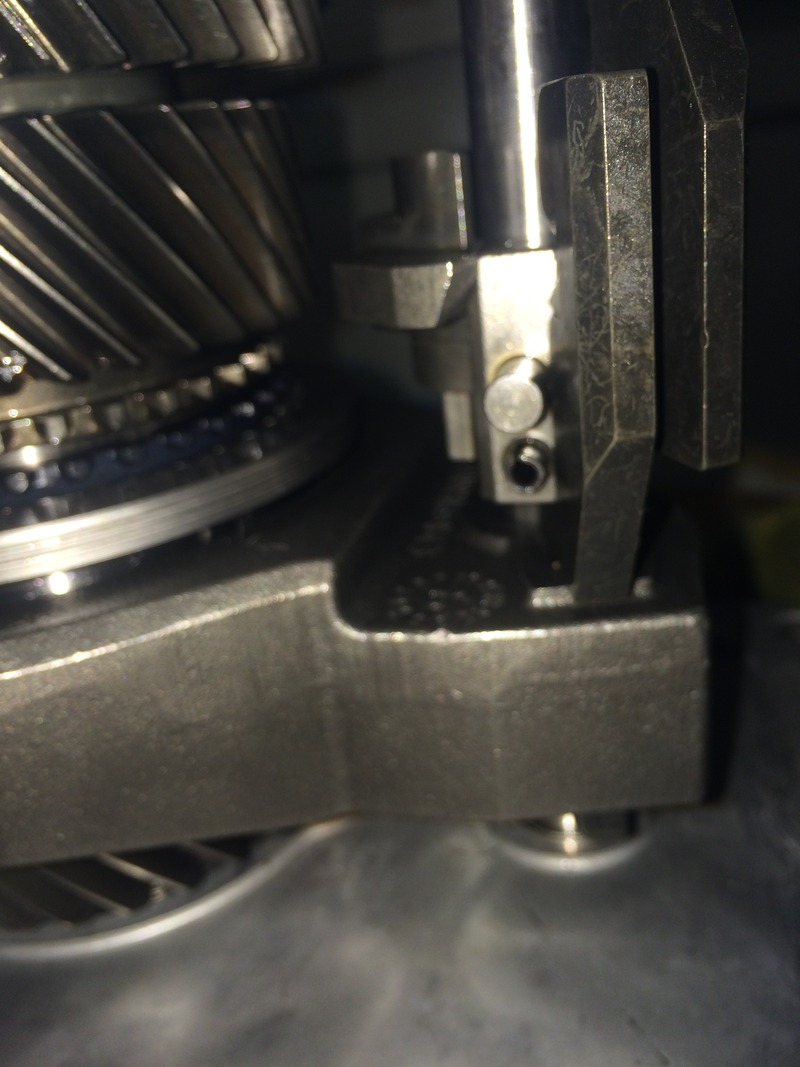

In this pic you can see a roll pin protruding below that other pin. I have it flipped from what I can remember from what it should be. The roll pin should be above the other pin. What I can't figure is how that roll pin goes. The only hole in the shaft that the roll pin could go in is blind, which means I couldn't have driven it out. Should that pin be sticking out? The other end of shaft has a hole that is NOT blind but I'm almost 100% sure that I have the shaft oriented right. With the roll pin protruding it seems to interfere a lot with how I THINK it should move.

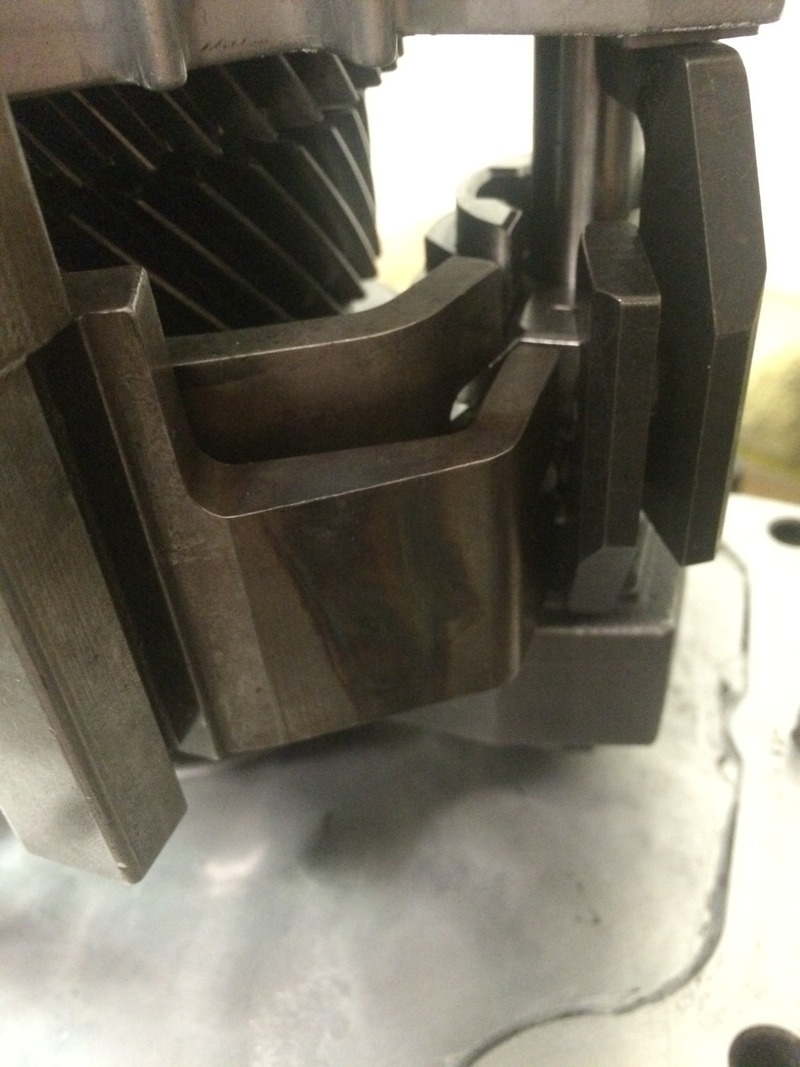

This is a pic of how I thought it should be assembled. Pretty sure its not right.

Another pic of the roll pin.

These dowels go in the holes pictured below.

The reason I'm pretty sure its not right is these dowels won't go in. They won't line up with the slots necessary to allow them to tighten up.

In this pic stolen from the web I don't even see the roll pin???

This pics shows the roll pin drove all the way through the shaft. My shaft doesn't have a hole that allows that.

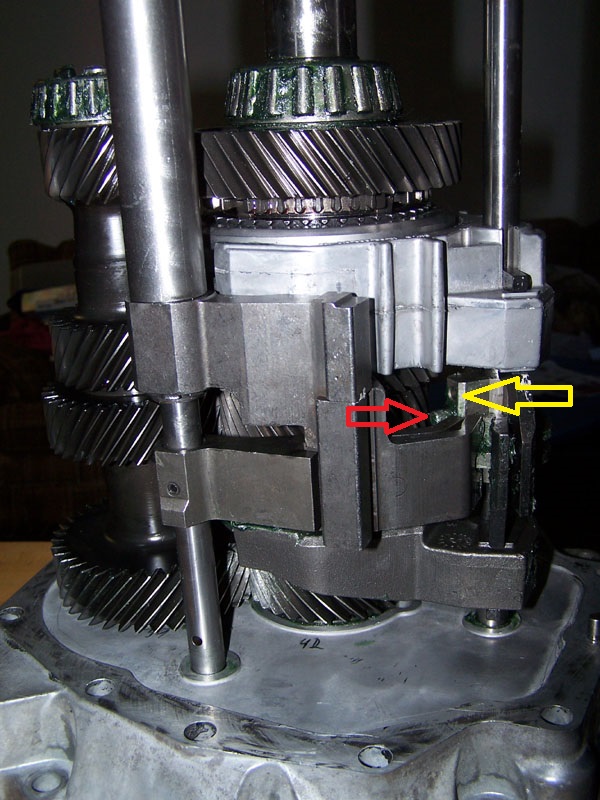

In this pic the yellow arrow points to where my roll pin is. It doesn't even look like there is a roll pin driven in the hole in that pic. The roll pin sticking out on mine stops the pin that the red arrow points to from doing what I think it should

Thanks

In this pic you can see a roll pin protruding below that other pin. I have it flipped from what I can remember from what it should be. The roll pin should be above the other pin. What I can't figure is how that roll pin goes. The only hole in the shaft that the roll pin could go in is blind, which means I couldn't have driven it out. Should that pin be sticking out? The other end of shaft has a hole that is NOT blind but I'm almost 100% sure that I have the shaft oriented right. With the roll pin protruding it seems to interfere a lot with how I THINK it should move.

This is a pic of how I thought it should be assembled. Pretty sure its not right.

Another pic of the roll pin.

These dowels go in the holes pictured below.

The reason I'm pretty sure its not right is these dowels won't go in. They won't line up with the slots necessary to allow them to tighten up.

In this pic stolen from the web I don't even see the roll pin???

This pics shows the roll pin drove all the way through the shaft. My shaft doesn't have a hole that allows that.

In this pic the yellow arrow points to where my roll pin is. It doesn't even look like there is a roll pin driven in the hole in that pic. The roll pin sticking out on mine stops the pin that the red arrow points to from doing what I think it should