On a scale of 0 to really f'd, how bad is it to fix the threads on the aluminum timing cover for the bolt that holds to supercharger belt? will i need a new timing cover or can those be tapped out?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

timing cover oops

- Thread starter einehund

- Start date

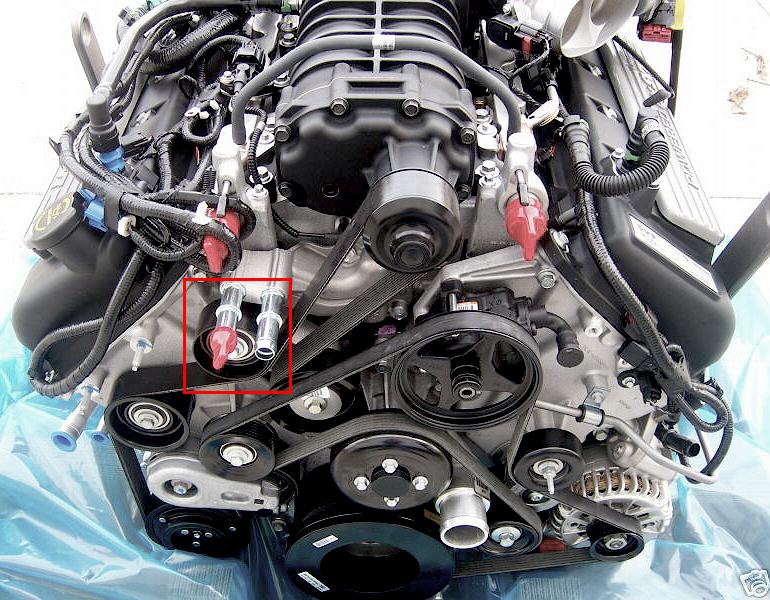

Are you referring to this bolt that is boxed in red?

I had the same issue the first time I removed my stock tensioner. When the bolt was about halfway out it became quite a bit harder to turn, so I knew it wasn't going back in without issues, and sure enough it didn't. I lucked out and was able to run a thread chaser through there....went back in with no issues at that point. Did you give that a try already?

It's weird that you bring this up. I've had a terrible chirping/squeeling for some time that I isolated to the blower belt. Last night I took a good look at everything with a flashlight and saw a bunch of crap around my Thump tensioner bolt and pulley, leading me to suspect that pulley is going bad. That made me remember all the horror stories about not having the tensioner lined up perfectly when installing that bolt.

Good luck to you my friend. Hope it's an easy fix.

Good luck to you my friend. Hope it's an easy fix.

I had the same issue the first time I removed my stock tensioner. When the bolt was about halfway out it became quite a bit harder to turn, so I knew it wasn't going back in without issues, and sure enough it didn't. I lucked out and was able to run a thread chaser through there....went back in with no issues at that point. Did you give that a try already?

I didn't have time to run a thread chaser, but I looked and there aren't really any threads to chase. I'm going to have to helicoil it, which I've never done before, so I guess it is time to learn.

I bought the tensioner used, and asked about the center bolt. The response I got was that the stock bolt would work. Due to the vastly different thicknesses of the tensioners, I looked at it, and debated on whether or not to proceed with using the stock bolt. I decided to go for it, which ended up being the wrong choice. If anyone is wondering, the bolt that you need is an M10x80mm. Not sure of the thread pitch. I am going to just buy a fine thread and coarse thread bolt and figure out which works better with the helicoil.

So you're saying all the threads stripped out? I wish you the best of luck man. Not much room to maneuver down there, would be difficult to get a drill in there for a helicoil install. Right angle drill might work. Let us know how it goes.I didn't have time to run a thread chaser, but I looked and there aren't really any threads to chase. I'm going to have to helicoil it, which I've never done before, so I guess it is time to learn.

I bought the tensioner used, and asked about the center bolt. The response I got was that the stock bolt would work. Due to the vastly different thicknesses of the tensioners, I looked at it, and debated on whether or not to proceed with using the stock bolt. I decided to go for it, which ended up being the wrong choice. If anyone is wondering, the bolt that you need is an M10x80mm. Not sure of the thread pitch. I am going to just buy a fine thread and coarse thread bolt and figure out which works better with the helicoil.

What tensioner are you using that requires an 80mm length bolt? For reference, my stock bolt is an M10, 1.5 pitch, 65mm length.

That measures out to a tad more than 25mm of thread engagement if you count the little nubby on the end of the bolt.

That measures out to a tad more than 25mm of thread engagement if you count the little nubby on the end of the bolt.

Last edited:

What tensioner are you using that requires an 80mm length bolt? For reference, my stock bolt is an M10, 1.5 pitch, 65mm length.

That measures out to a tad more than 25mm of thread engagement if you count the little nubby on the end of the bolt.

I have the Ford Racing tensioner, which was made by Thump if I remember correctly.

Well, shade tree mechanics work (little help from metallurgy, of course. Always need science to back it up)! I moved the radiator tank and intercooler tanks and tied them so they sat on top of the supercharger (I didn't have to drain either system), removed the radiator fan, loosened up the water pump belt, and the supercharger belt. I remove the 6-rib belt idler pulley that is directly above the 10 rib belt tensioner. I noticed that the ford racing tensioner had a different clocking position at rest than the stock tensioner, which made it impossible to install without removing that 6-rib belt idler.

With all the crap removed, there was plenty of room to work, which always makes the job easier. I had bought some 16 gauge and 14 gauge copper wire (as I wasn't sure which I would use) and cut 3 lengths of about 2 1/2 inches, which I folded in half, and used needle-nosed pliers to bend about 1/8 inch of each end 90* outward. The resulting shape looked like a V with the open end being about 3/8". I ended up using the 16 gauge and placed the copper in the stripped out hole on the timing cover so that one was 12 o'clock to 6 o'clock, one was 2 o'clock to 8 o'clock, and the third was 4 o'clock to 10 o'clock. the only pieces of the copper wire that was visible was the 1/8" tails of the wire. I then placed the Ford racing tensioner dowels in their respective holes, and then took a stainless steel M10x1.5x80 bolt and slid it in the retaining bolt hole of the tensioner. I pushed as hard as I could while tightening it by hand until I felt it grip/cut into the copper. At that point, I took a small hammer and gave the head of the bolt a decent whack. This sets the copper wire into the aluminum (as copper is harder than aluminum and will cut into it). Then I grabbed a normal wratchet and tightened it down. The stainless steel bolt simultaneously cut groves in the copper (as steel is harder than copper) and set the copper in the aluminum. I got it tightened down flush with the tensioner, and I then backed it out a quarter of a turn. Finally I grabbed my torque wrench and tightened it down to 30 ft. lbs (the only measurement I had found online).

Buttoned everything up, fixed my exhaust leak from my new-to-me MRT O/R H pipe (sounds goddamn glorious, by the way: like an entire heard of demons flying out of my exhaust!) and went to put some miles on the tensioner. Drove like a sane person until the engine and all fluids were up to operating temperature, and then proceeded to find the closest "end restriction" portion of the Autobahn. Although I was not able to test to the top of 4th and 5th gear (to see if the tensioner resolved my belt slip issue), I was able to do a few 25% throttle to WOT to 0% throttle romps to stress out the tensioner mount. I drove home, popped the hood, and waited a couple of hours for everything to cool down. I quickly moved the radiator fluid tank, and verified that the tensioner bolt was still at 30 ft lbs, which it was. I now consider the problem solved! Hope this long winded epic helps someone out in the future!

With all the crap removed, there was plenty of room to work, which always makes the job easier. I had bought some 16 gauge and 14 gauge copper wire (as I wasn't sure which I would use) and cut 3 lengths of about 2 1/2 inches, which I folded in half, and used needle-nosed pliers to bend about 1/8 inch of each end 90* outward. The resulting shape looked like a V with the open end being about 3/8". I ended up using the 16 gauge and placed the copper in the stripped out hole on the timing cover so that one was 12 o'clock to 6 o'clock, one was 2 o'clock to 8 o'clock, and the third was 4 o'clock to 10 o'clock. the only pieces of the copper wire that was visible was the 1/8" tails of the wire. I then placed the Ford racing tensioner dowels in their respective holes, and then took a stainless steel M10x1.5x80 bolt and slid it in the retaining bolt hole of the tensioner. I pushed as hard as I could while tightening it by hand until I felt it grip/cut into the copper. At that point, I took a small hammer and gave the head of the bolt a decent whack. This sets the copper wire into the aluminum (as copper is harder than aluminum and will cut into it). Then I grabbed a normal wratchet and tightened it down. The stainless steel bolt simultaneously cut groves in the copper (as steel is harder than copper) and set the copper in the aluminum. I got it tightened down flush with the tensioner, and I then backed it out a quarter of a turn. Finally I grabbed my torque wrench and tightened it down to 30 ft. lbs (the only measurement I had found online).

Buttoned everything up, fixed my exhaust leak from my new-to-me MRT O/R H pipe (sounds goddamn glorious, by the way: like an entire heard of demons flying out of my exhaust!) and went to put some miles on the tensioner. Drove like a sane person until the engine and all fluids were up to operating temperature, and then proceeded to find the closest "end restriction" portion of the Autobahn. Although I was not able to test to the top of 4th and 5th gear (to see if the tensioner resolved my belt slip issue), I was able to do a few 25% throttle to WOT to 0% throttle romps to stress out the tensioner mount. I drove home, popped the hood, and waited a couple of hours for everything to cool down. I quickly moved the radiator fluid tank, and verified that the tensioner bolt was still at 30 ft lbs, which it was. I now consider the problem solved! Hope this long winded epic helps someone out in the future!

Nice fix! Seems like a low torque value for that bolt thought. I remember the tensioner bolt on my Thump being fairly large.

OEM torque spec for the belt tensioner bolt is 35 lb-ft.

Supercharger Belt Tensioner

Removal and Installation

Removal and Installation

- Rotate the Supercharger (SC) belt tensioner clockwise and remove the SC belt from the SC pulley.

- NOTE: The SC belt is routed behind the SC belt tensioner.

Remove the SC belt tensioner bolt and tensioner.- To install, tighten to 48 Nm (35 lb-ft).

- To install, reverse the removal procedure.

Never heard of the copper wire method. Very interesting! Glad you got it fixed.

Never heard of the copper wire method. Very interesting! Glad you got it fixed.

I've heard of that method before, but I haven't heard of anybody doing it in ages. I probably would've tried to retap it and/or put an insert in it. Though, I don't really trust inserts in locations that will see more than a few loosening and tightening session. They tend to back out in high torque applications. I wouldn't trust one for more than about 80 ft-lbs.

I ordered helicoil, but being that I'm in Germany, it takes an abysmally long time to get anything. I figured that i would try the copper thing, especially with the low torque value, and if it didn't work, the helicoil was on the way. As it is, so far it is holding so i have no issues. The weather has not been coopertive to REALLY get on it, but I plan to soon.I've heard of that method before, but I haven't heard of anybody doing it in ages. I probably would've tried to retap it and/or put an insert in it. Though, I don't really trust inserts in locations that will see more than a few loosening and tightening session. They tend to back out in high torque applications. I wouldn't trust one for more than about 80 ft-lbs.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)