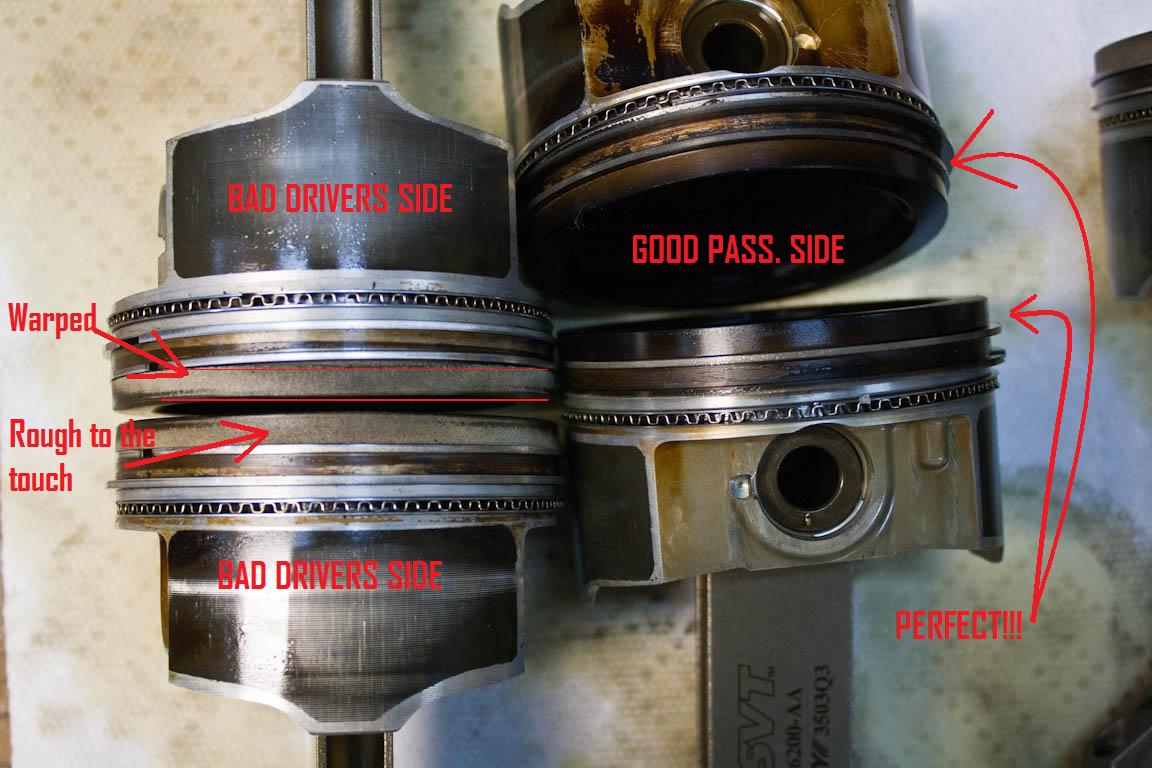

I tore my motor apart and this is what I find. ALL drivers side pistons melted/started to melt the upper ringlands. Passenger side perfect. One of the rings actually broke on the #7? rear drivers side piston.

Why do you think the drives side did this and passenger side didnt? I am thinking maybe all the fuel is being pulled into the passenger rail cause it to lean out the drivers side? AF where always good but I only have 1 wideband on it in the downpipe.