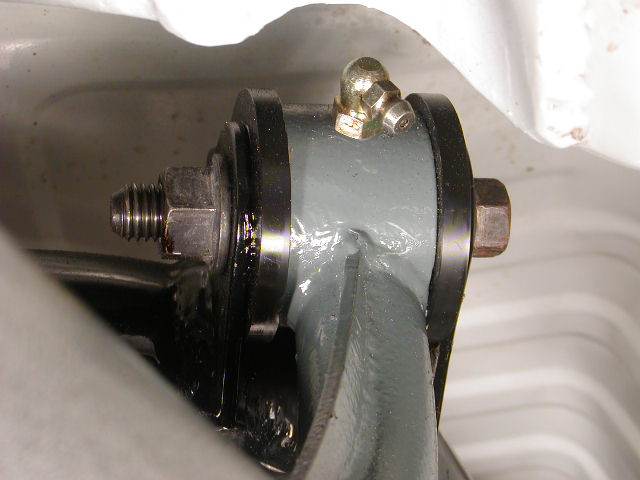

Well I finally got some time to work on the car again. The IRS is reassembled and it's back in the car now. It took some extra effort to squeeze the assembly back in the car with the new underside support brackets on it. But it went in nicely. Here are some shots of the fix and reinstall:

left rear front

left rear back

right rear front

right rear back

:thumbsup::coolman::beer:

left rear front

left rear back

right rear front

right rear back

:thumbsup::coolman::beer: