Installing a nitrous system isn’t hard but there is a lot of wiring to be done. I refuse to trouble shoot electrical issues at the drag strip so I did the highest quality job possible. Every connection is soldered and heat shrunk, all wires are unique colors.

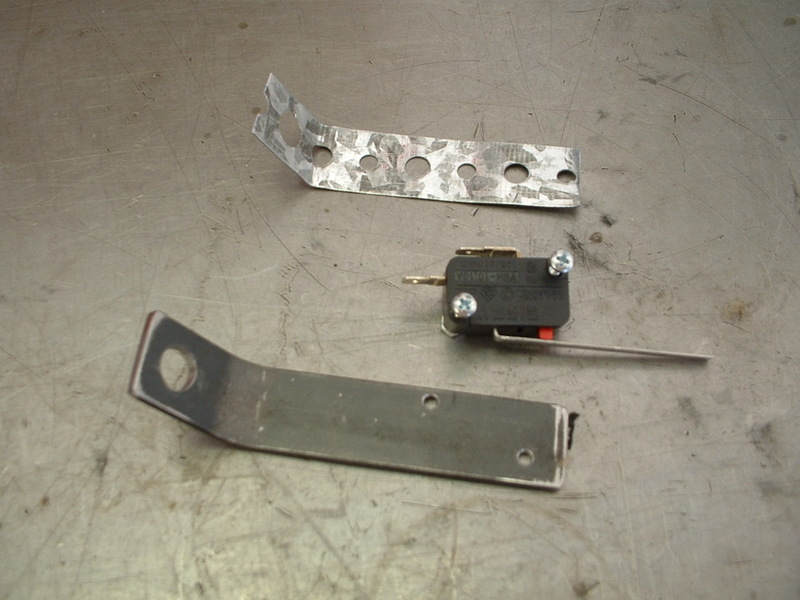

The supplied brackets for the WOT SW/solenoids are flimsy so I made a custom bracket. I started with a plumbers tape template and used some 1/8” steel.

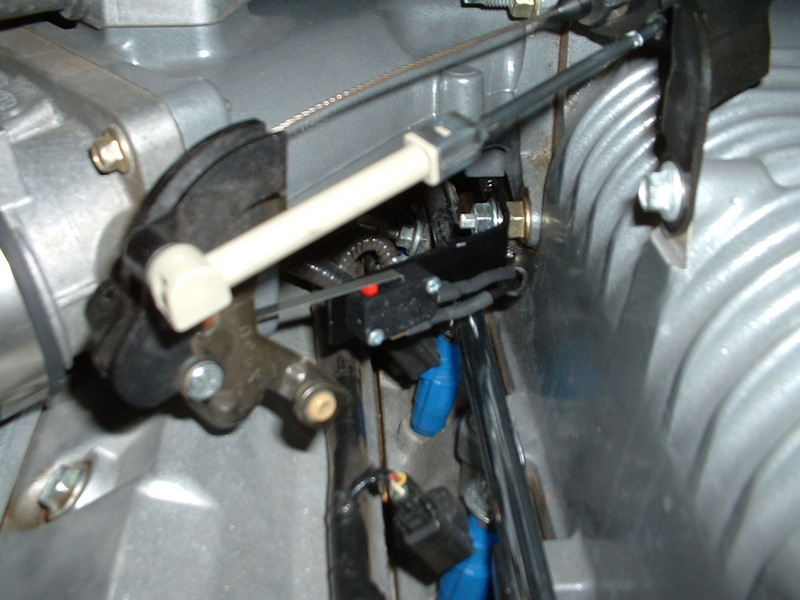

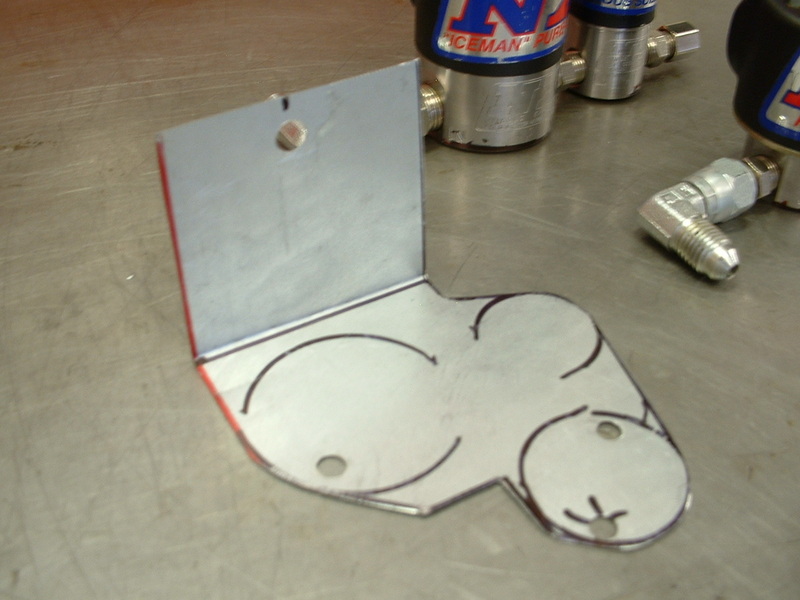

Next was the solenoid mounting. I chose to place them on the right fender apron, and relocated the I/C pump relay box. I started with a thin sheet metal template that could be easily cut with tin snips. After a few tries I found the best fit and look.

The bracket is fabricated from sheet aluminum. All pipe threads are sealed with thread sealer.

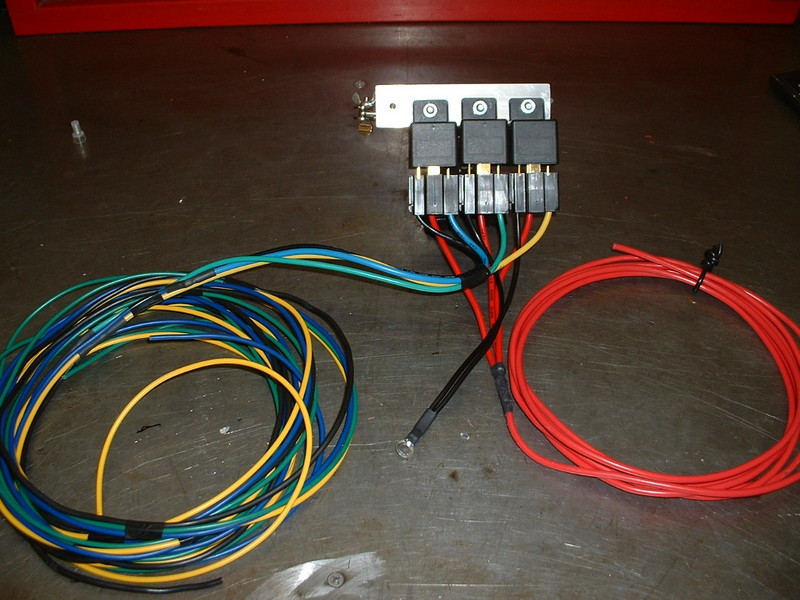

I fabricated the wiring harness for the 3 relays. (nitrous/fuel, purge and Line lock). A 12 ga wire and a 30 amp fuse go to the fuse box stud. The relay sockets are mounted with countersunk flat head screws to a piece of aluminum so only one hole is drilled and used for coil grounds.

Relays mounted above CCM relays.

Another relay for the heater circuit is mounted on the right side of the trunk. A pressure sensor is wired in series with the heater rocker switch and the relay coil. I wasn’t paying attention and bought the ZEX heater off ebay and it already has thermistor for temp/pressure control.

The tank is mounted and the blow off tube is bent to use the existing hole in the trunk floor. Instead of hacking up the factory carpet I added a new piece of carpet and felt under the tank and just folded the factory carpet over on itself.

The MSD rpm window switch is mounted in the glove box. The counter input is wired to #1 cylinder coil- trigger at the computer harness. This is Pin 26 (light green/white).

I made my own version of a cup holder switch plate for about $10. It disconnects with a monitor extension cable and can be removed so the nitrous, heater and line lock cannot be accidently activated.

JLT (aka PVC drain pipe) intake drilled and tapped to 1/8 NTP and lines run. While the tubing was off I pulled all the plugs and gapped to 0.032”. The purge line is run to the cowl and exits next to the right windshield wiper.

I filled the tank and noticed the new NX gauge was off by 300 psi. Need to get a replacement.

I installed a 0.035/0.022 combo (~65 hp @ 900psi) and tried a few 2nd gear pulls. AFR was about 10.7 to 11.0. With the BAP fuel duty cycle is only 70% at 5krpms. No lean spike on activation. I think the fuel system will support at least a 100 shot. The XCAL can be used to pull timing out at the track.

The supplied brackets for the WOT SW/solenoids are flimsy so I made a custom bracket. I started with a plumbers tape template and used some 1/8” steel.

Next was the solenoid mounting. I chose to place them on the right fender apron, and relocated the I/C pump relay box. I started with a thin sheet metal template that could be easily cut with tin snips. After a few tries I found the best fit and look.

The bracket is fabricated from sheet aluminum. All pipe threads are sealed with thread sealer.

I fabricated the wiring harness for the 3 relays. (nitrous/fuel, purge and Line lock). A 12 ga wire and a 30 amp fuse go to the fuse box stud. The relay sockets are mounted with countersunk flat head screws to a piece of aluminum so only one hole is drilled and used for coil grounds.

Relays mounted above CCM relays.

Another relay for the heater circuit is mounted on the right side of the trunk. A pressure sensor is wired in series with the heater rocker switch and the relay coil. I wasn’t paying attention and bought the ZEX heater off ebay and it already has thermistor for temp/pressure control.

The tank is mounted and the blow off tube is bent to use the existing hole in the trunk floor. Instead of hacking up the factory carpet I added a new piece of carpet and felt under the tank and just folded the factory carpet over on itself.

The MSD rpm window switch is mounted in the glove box. The counter input is wired to #1 cylinder coil- trigger at the computer harness. This is Pin 26 (light green/white).

I made my own version of a cup holder switch plate for about $10. It disconnects with a monitor extension cable and can be removed so the nitrous, heater and line lock cannot be accidently activated.

JLT (aka PVC drain pipe) intake drilled and tapped to 1/8 NTP and lines run. While the tubing was off I pulled all the plugs and gapped to 0.032”. The purge line is run to the cowl and exits next to the right windshield wiper.

I filled the tank and noticed the new NX gauge was off by 300 psi. Need to get a replacement.

I installed a 0.035/0.022 combo (~65 hp @ 900psi) and tried a few 2nd gear pulls. AFR was about 10.7 to 11.0. With the BAP fuel duty cycle is only 70% at 5krpms. No lean spike on activation. I think the fuel system will support at least a 100 shot. The XCAL can be used to pull timing out at the track.