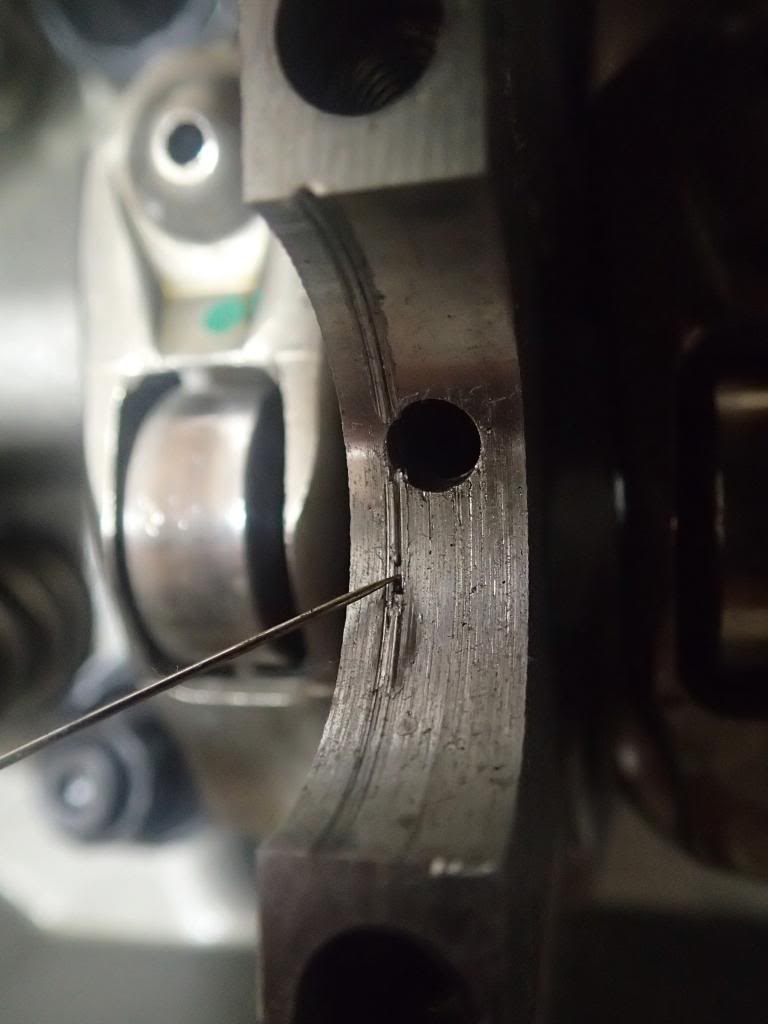

I was in the process of swapping my cams out and found a couple rough looking cam journals. The picture shows only one which I believe to be the worst. I think it needs to be professionally repaired.

Iv'e had a guy tell me that they would be ok as the head is aluminum and the steel cam would just smooth out the journal during normal operation without damaging the new cam.

What do y'all think? I just don't have the experience and wanted a second opinion. If it is ok I was thinking about taking a scotch brute pad and some fine grit sand paper to them at a minimum.

Iv'e had a guy tell me that they would be ok as the head is aluminum and the steel cam would just smooth out the journal during normal operation without damaging the new cam.

What do y'all think? I just don't have the experience and wanted a second opinion. If it is ok I was thinking about taking a scotch brute pad and some fine grit sand paper to them at a minimum.