Hey all,

First post here! I bought a '97 Cobra back in '14, when I was 18. I bought it with high miles (140k) and quite a few aftermarket mods done to it. The motor was stock, so it didn't live for long after I bought it. I had it for about 2 months and then it developed a really bad rod knock. I pulled the motor and confirmed the damage - a spun rod bearing on cylinder #7, and then let it sit for 8 years.

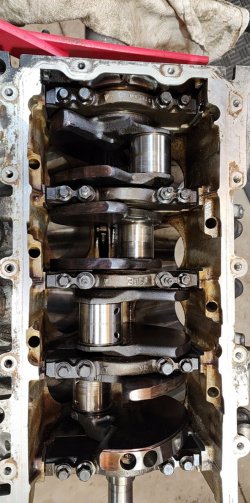

I'd been looking into how to rebuild this engine for quite a while, but recently decided to bite the bullet and get it back on the road. I pulled the motor all the way apart and confirmed all the damage:

With 140k miles, I really wasn't confident in using much of anything from the original motor - my goal with this is longevity. I'm not looking for a crazy high HP build, this is going to be a street car mostly. Besides the block, the heads, and maybe the valves (as of this post, block and heads have yet to go to a machine shop), there is nothing that I'm going to reuse internally.

This is the part list thus far for the rebuild (all parts ordered, some have yet to arrive):

Crankshaft: MMR/Manley 4.6L Forged 8 Bolt crank

Rods: MMR 4340 Forged H Beam Rods with ARP bolts

Pistons: Silverlight/ModMaxRacing 3cc dished hypereutectic pistons (OEM Moly rings) - +.020"

Rod Bearings: Clevite Pro

Cams: Comp Cams 106300

Springs: Manley High Lift 'Nextek' Springs

Lifters: Ford OEM Lifters

Followers: GT500 upgraded followers - M-6529-MSVT

Timing kit: OEM Ford Timing kit - new gears, chains, OEM steel tensioners

Oil Pump: Ford OEM High Volume Oil Pump

Gaskets: Fel-Pro complete 4.6L DOHC kit

MMR Head cooling kit

Misc Sensors and tensioners/pulleys

Water Pump

JBA Shorty Titanium Ceramic Headers

Ford OEM Motor Mounts

Dorman Harmonic Balancer

Screamin Demon Coil Packs

Exedy Mach 350 clutch

When I purchased the car, it already had quite a few upgrades:

4.10 gears

SLP Loudmouth mufflers, X Pipe mid pipe

H&R Lower springs

BBK Upper and lower rear control arms

Eibach front and rear Sway bars + bushings

Tokiko shocks

Full length weld-in sub-frame connectors

Caster/Camber plates

Strut Tower Brace

It should have an electronic speedometer adjuster, but I haven't played around with or even verified if it's installed on the vehicle, but the speedo is off by a large margin

It has short-throw shifter

It also has a Zex Nitrous wet kit - it was hooked up with about the equivalent of 100-110 shot

I ended up wanting to rebuild brakes as well (wanna go fast, gotta stop fast) and ended up with the PowerStop Z26 Drilled/slotted rotors with Ceramic pads.

In addition to purchasing all the parts and having a machine shop verify the tolerances and dimensions of things, I decided to spend a little bit and purchase a bit of piece of mind. I bought a set of mics, as well as a dial bore kit (.7" - 6" ), as well as a straight edge. I also decided, after much research, to bite another bullet and degree the cams. I purchased the Trick Flow timing kit with the 4.6L supplemental kit.

I also plan on doing some mild port-matching and polishing on the intake, as well as the heads. I'm not sure as of now if I'm going to do an IMRC delete or not - my '97 has metal IMRC plates, so it wouldn't be a difficult mod to do.

I measured all of the cylinders for taper, and they didn't measure more than .001" taper in any of the cylinders. They did measure about .003" out of round though. None of the cylinder walls looks terrible, but I'm going to get it bored .020" over. The decks of the block also appeared to be in good condition - no cracks, and from what I could test, they were very straight. The cylinder heads will need to be shaved down some, but that's only due to us marring one a little when we were disassembling the head.

There's only a few things that I'm not 100% sure on, but time will tell, or hopefully someone can answer:

- Piston to valve clearance:

The heads will need at least 2 thousandths taken off if not more, and with the .475 intake and .450 exhaust lift with these cams, am I going to run into piston/valve clearance issues? I'm staying NA, so I went with a small dish piston to keep the CR up.

- Camshaft journal clearances:

My drivers-side front camshaft journal in the head is marred a bit. Nothing crazy, but there's a bit of pitting there. I've heard of there being a bit of room to polish those out and increase clearances there, what is the maximum clearance that I should look for, before having it sent off and a bearing installed? I also purchased the GT500 followers to increase oil pressure in those journals, which I've read helps if you're going to increase those clearances.

- IMRC Delete?

I'm also not sure if deleting the IMRC valves would be a worth-while idea or not. I've got the gear to keep it out of that sub-3000 RPM range, but with the shorty headers and the stage 2 cams, I'm not sure where my power band will be, and if I will be losing on the bottom end or in a noticeable way by getting rid of them. Also, besides just eliminating a potential mechanical failure, is there any benefit to deleting the IMRC valves?

- Camshaft Girdle clearance issues

Am I going to need to notch or cut the camshaft girdles to fit the Comp Cam 106300 cams?

I'm going to attach some photos of some of the findings/failures for now, as well as the car itself, and hopefully in the near future post some more up-lifting pics with shiny new and freshly-machined parts.

Thanks in advance!

First post here! I bought a '97 Cobra back in '14, when I was 18. I bought it with high miles (140k) and quite a few aftermarket mods done to it. The motor was stock, so it didn't live for long after I bought it. I had it for about 2 months and then it developed a really bad rod knock. I pulled the motor and confirmed the damage - a spun rod bearing on cylinder #7, and then let it sit for 8 years.

I'd been looking into how to rebuild this engine for quite a while, but recently decided to bite the bullet and get it back on the road. I pulled the motor all the way apart and confirmed all the damage:

- 5/8 Rod bearings were toasted

- 4/5 Main bearings were toasted

- The spun rod bearing journal on the crank (cylinder #7) measured .019" under (not evenly though, all the wear is on one side of the crankshaft journal)

- Cams were too wore to confidently reuse

- Rods ends were out of round, and they factory rods are crack capped and really not machine-able

- Followers were scored with a bunch of bearing material

- Lifters were full of bearing-filled oil

With 140k miles, I really wasn't confident in using much of anything from the original motor - my goal with this is longevity. I'm not looking for a crazy high HP build, this is going to be a street car mostly. Besides the block, the heads, and maybe the valves (as of this post, block and heads have yet to go to a machine shop), there is nothing that I'm going to reuse internally.

This is the part list thus far for the rebuild (all parts ordered, some have yet to arrive):

Crankshaft: MMR/Manley 4.6L Forged 8 Bolt crank

Rods: MMR 4340 Forged H Beam Rods with ARP bolts

Pistons: Silverlight/ModMaxRacing 3cc dished hypereutectic pistons (OEM Moly rings) - +.020"

Rod Bearings: Clevite Pro

Cams: Comp Cams 106300

Springs: Manley High Lift 'Nextek' Springs

Lifters: Ford OEM Lifters

Followers: GT500 upgraded followers - M-6529-MSVT

Timing kit: OEM Ford Timing kit - new gears, chains, OEM steel tensioners

Oil Pump: Ford OEM High Volume Oil Pump

Gaskets: Fel-Pro complete 4.6L DOHC kit

MMR Head cooling kit

Misc Sensors and tensioners/pulleys

Water Pump

JBA Shorty Titanium Ceramic Headers

Ford OEM Motor Mounts

Dorman Harmonic Balancer

Screamin Demon Coil Packs

Exedy Mach 350 clutch

When I purchased the car, it already had quite a few upgrades:

4.10 gears

SLP Loudmouth mufflers, X Pipe mid pipe

H&R Lower springs

BBK Upper and lower rear control arms

Eibach front and rear Sway bars + bushings

Tokiko shocks

Full length weld-in sub-frame connectors

Caster/Camber plates

Strut Tower Brace

It should have an electronic speedometer adjuster, but I haven't played around with or even verified if it's installed on the vehicle, but the speedo is off by a large margin

It has short-throw shifter

It also has a Zex Nitrous wet kit - it was hooked up with about the equivalent of 100-110 shot

I ended up wanting to rebuild brakes as well (wanna go fast, gotta stop fast) and ended up with the PowerStop Z26 Drilled/slotted rotors with Ceramic pads.

In addition to purchasing all the parts and having a machine shop verify the tolerances and dimensions of things, I decided to spend a little bit and purchase a bit of piece of mind. I bought a set of mics, as well as a dial bore kit (.7" - 6" ), as well as a straight edge. I also decided, after much research, to bite another bullet and degree the cams. I purchased the Trick Flow timing kit with the 4.6L supplemental kit.

I also plan on doing some mild port-matching and polishing on the intake, as well as the heads. I'm not sure as of now if I'm going to do an IMRC delete or not - my '97 has metal IMRC plates, so it wouldn't be a difficult mod to do.

I measured all of the cylinders for taper, and they didn't measure more than .001" taper in any of the cylinders. They did measure about .003" out of round though. None of the cylinder walls looks terrible, but I'm going to get it bored .020" over. The decks of the block also appeared to be in good condition - no cracks, and from what I could test, they were very straight. The cylinder heads will need to be shaved down some, but that's only due to us marring one a little when we were disassembling the head.

There's only a few things that I'm not 100% sure on, but time will tell, or hopefully someone can answer:

- Piston to valve clearance:

The heads will need at least 2 thousandths taken off if not more, and with the .475 intake and .450 exhaust lift with these cams, am I going to run into piston/valve clearance issues? I'm staying NA, so I went with a small dish piston to keep the CR up.

- Camshaft journal clearances:

My drivers-side front camshaft journal in the head is marred a bit. Nothing crazy, but there's a bit of pitting there. I've heard of there being a bit of room to polish those out and increase clearances there, what is the maximum clearance that I should look for, before having it sent off and a bearing installed? I also purchased the GT500 followers to increase oil pressure in those journals, which I've read helps if you're going to increase those clearances.

- IMRC Delete?

I'm also not sure if deleting the IMRC valves would be a worth-while idea or not. I've got the gear to keep it out of that sub-3000 RPM range, but with the shorty headers and the stage 2 cams, I'm not sure where my power band will be, and if I will be losing on the bottom end or in a noticeable way by getting rid of them. Also, besides just eliminating a potential mechanical failure, is there any benefit to deleting the IMRC valves?

- Camshaft Girdle clearance issues

Am I going to need to notch or cut the camshaft girdles to fit the Comp Cam 106300 cams?

I'm going to attach some photos of some of the findings/failures for now, as well as the car itself, and hopefully in the near future post some more up-lifting pics with shiny new and freshly-machined parts.

Thanks in advance!

Attachments

-

20221119_184120.jpg526.3 KB · Views: 149

20221119_184120.jpg526.3 KB · Views: 149 -

Cobra pic.jpeg358.7 KB · Views: 97

Cobra pic.jpeg358.7 KB · Views: 97 -

imagejpeg_0(3).jpg190.5 KB · Views: 88

imagejpeg_0(3).jpg190.5 KB · Views: 88 -

imagejpeg_0(4).jpg276.4 KB · Views: 81

imagejpeg_0(4).jpg276.4 KB · Views: 81 -

imagejpeg_0(6).jpg152.9 KB · Views: 78

imagejpeg_0(6).jpg152.9 KB · Views: 78 -

output_image1670714503065.jpg212.9 KB · Views: 82

output_image1670714503065.jpg212.9 KB · Views: 82 -

Snapchat-1432396934.jpg282 KB · Views: 82

Snapchat-1432396934.jpg282 KB · Views: 82 -

Snapchat-1643651983.jpg298.4 KB · Views: 84

Snapchat-1643651983.jpg298.4 KB · Views: 84