I picked up a slightly used Trilogy supercharger from Hotford, he upgraded to a twin screw, all the other Trilogy accessories were kept on his car, I got the SC with a 3.0 upper pully, and a stock Trilogy lower pully. As more Trilogy owners make the transition to twin screw their old superchargers will become more and more available. Hopefully this thread will help someone else put a kit together.

The rotors show no visible signs of wear

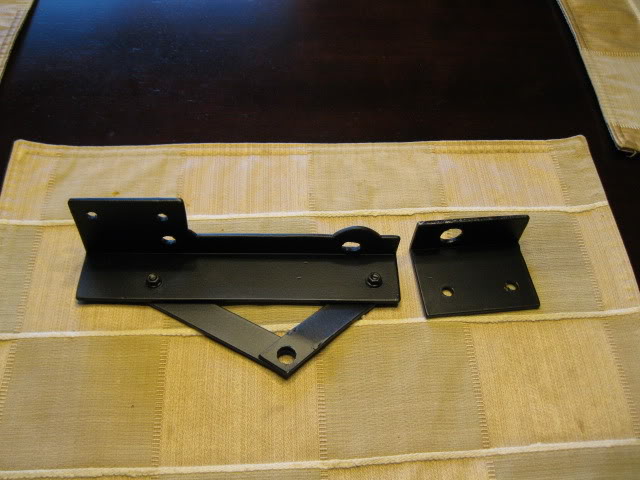

All of the Trilogy specific parts will have to be fabricated, unfortunatly they are now out of the Marauder market. Here is what I did to make the IC reservoir bracket

These were easy to make, I used a piece of angled 1-1/2" aluminum stock and hit them with 2 coats primer, 3 coats semi gloss paint, then 2 coats of matte finish clear coat. I began by making a cardboard cut out of the fender contour, then transfered it to the aluminum stock

To install the bracket you have to remove the mount for the shock that supports the hood with a 1/2" deep socket.

You will need to put a flat screwdriver through the slot to remove the shock

Give it a pull and it comes right out

Slide the bracket into place then reinstall the shock for the hood

I made the mount so it has 3 points to bolt to the fender, this will keep the reservoir from vibrating while driving, heres a pic with the reservoir in place

The short bracket I made goes under the reservoir to give it strength, soo it's a sandwich design. I didn't feel comfortable bolting directly to the bottom of the plastic unit.

Here is a side shot of the install

I fabbed up some PCV hard lines out of 5/8" aluminum tubing, the ends are flared. My plan is to paint them black or maybe polish them

Now I have plenty of clearance for the top hose to connect to the reservoir

Before attempting to install the heat exchanger I had to make a horn relocate bracket. I used a piece of 1-1/4" aluminum flat stock (be sure to heat the aluminum with a torch before bending it). I decided to reuse the stock horn mount, all I had to do is flip the horns on the bracket to reverse the orientation for additional clearance

Make sure the new bracket does not contact the evaporator core

Now is also a good time to relocate the Ambient Temp sensor. I always solder the connectors, crimp connectors have a higher possibility of failure from corrosion

Cut the wires to the sensor diffrent lengths so there is no chance of having a short

A pair of helping hands is a good tool to have

After the solder cools hit them with shrink tape and a heat gun. Last wrap them in wire loom and secure the harness to the car with tywraps

The ambient temp sensor was relocated down below where the air diverter is located. Here is a shot of the new mount for the sensor. I used a nut from a brass 3/8" NPT connector

It bolts through the center piece of hardware on the diverter. I added some weatherstripping to the back side of the diverter to seal the gap thats created by adding the bracket.

Here is the sensor in place

Now all thats done I got the heat exchanger fabbed up. I used some 1-1/2" angled aluminum stock and some leftover 5/8" SS pipe. I wanted to use materials that even if the paint chips rust wont be an issue down the road.

For the bottom mounts I had to break out the Dewalt close quater drill. This came in very handy for getting holes drilled in tight spots

Here is a shot of the stud inplace

Before you install the IC pump its a good idea to extend the wire harness to the proper length.

I did'nt use the SS sheet metal screws included with the I/C pump kit from frozenboost.com. I drilled it out and installed nuts with nylon inserts and bolts to keep the hardware from vibrating loose.

Here's the pump installed. It wasn't tightened down when I took this pic.

Wire harness installed

Here is the relay I'm using for the pump. I picked it up from a local 4x4 shop, it's waterproof on both ends (wireharness and relay housing)

I went ahead and finished wiring the relay for the I/C pump. Here's where I put the weatherproof relay for easy accessability

I installed the KB BAP and put it on the inside of the rail to keep the carpet cover in its original form. I put rubber bumpers on the back side of the BAP to avoid any metal to metal contact on these tough Mississippi roads

I put the adjustment knob here after I cut out the extra mile of cable they include with the kit.

I started the modification the I/C flange for the Trilogy adapter plate.

The easiest way to do this is to install the bolts that do line up then transfer the hole pattern to the I/C flange

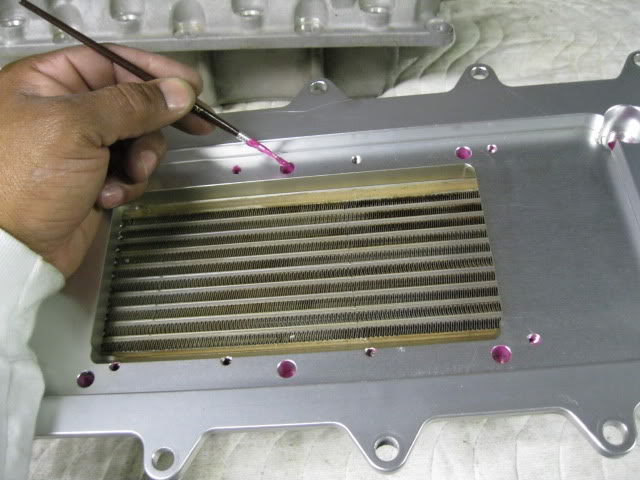

I used my Daughter's paint kit to mark the bolt patern to the I/C flange

This is what it looks like after drilling all the holes out

[imghttp://i790.photobucket.com/albums/yy182/musclemerc/IMG_0805.jpg][/img]

One thing I didn't have to do was drill the adapter plate for an IAT sensor. This is a revision Trilogy made years after making the mistake of leaving it in the stock Marauder MAF.

While I was at it I soldered the brass fittings for the boost guage and FRPS mod

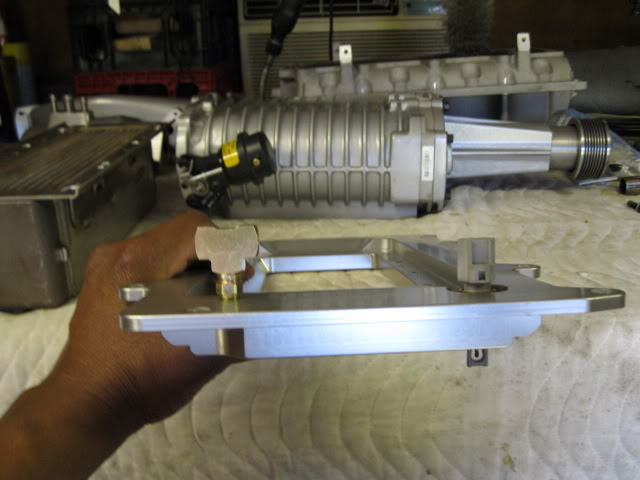

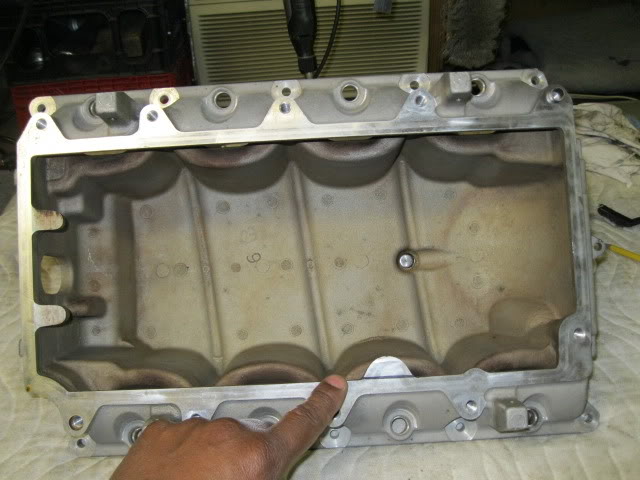

The Eaton lower intake has to be modified to fit the Trilogy. This wedge has to be removed. Also notice I put a plug in the bottom PCV fitting, there is no need to send boost into the PCV track

Here it is after the removal

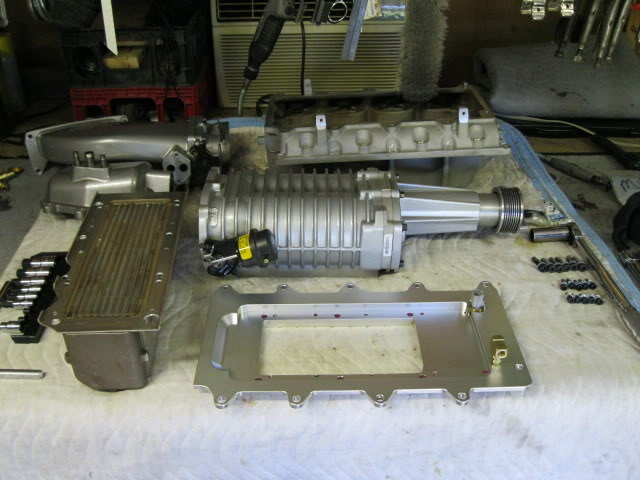

Got everything together for the assembly. I sourced the exact same hardware Trilogy used in their kit.

Here it is ready to go

My hose manifold finally showed up from CNC

I plan on keeping the stock lower tstat location. This manifold will allow me to route the upper radiator hose, tstat bypass hose, and two 3/4" barbed fittings for both cylinder heads.

This is how I plan on burping the system. 5/8" hose to a tall funnel. The barbed fitting is removed after burping the system, a flush (allen head) plug is installed in its place.

I made these fittings to delete the COT, they have a left/right orientation. I want the PS hose to route as low as possible. I want the DS hose to become the high spot in the system (no need to jack up the front end to burp the system). The air gap is installed on the DS.

I installed one of my 5/8" cooling mods. No clearance issues whatsoever

DS cooling mod fitting

I will finish routing the output of the cooling mod to the heater core inlet (Siege's hose routing mod) after I install the wiper cowl. I already plumed the output of the heater core to the pipe that runs under the lower intake to the back of the water pump

I wanted to keep the knock sensor in the stock location so this is what I came up with to keep it there

I drilled/tapped, then put a stud through the original boss. The sensor is held with a lock washer and nut with a nylon insert

One of the biggest hurdles was figuring out how to make a throttle cable bracket. This is what I came up with

I used Terry's Eaton Swap brackets, the SC tensioner bracket had to be shortened 5/16" to line up with the SC belt. I went ahead and polished them while I was at it. They work great without any issues. I also used a Roush 3 bolt tensioner for the SC belt. Cant beat it for $120.00

Here it is after all the work was done )))) It started right up on the first crank

Here's my mod list:

Trilogy SC with 3.0 upper pully

Stock Trilogy lower pully

40A KB BAP

90mm MAF

Mafia MAF extender

96 Cobra cams degreed *108/*112 LCS

JBA 1-5/8"short tube headers

2-1/2" MAC Prochamber

Magnaflow high flow cats

Musclemerc CAI

Musclemerc 5/8" cooling mod

Musclemerc upper/lower CA's

Musclemerc oil catch can

Addco F/R sway bars

Moog end links

Rear ES bushing mod

Power Slot D/S rotors

TCE SS brake lines

Hawk HPS pads

FRPS mod

IAT relocate mod

Yukon 31 Spline Axles

Cobra 31 Spline CF Differential

MAC Stud Girdle

FRPP 4:10 Gears

The rotors show no visible signs of wear

All of the Trilogy specific parts will have to be fabricated, unfortunatly they are now out of the Marauder market. Here is what I did to make the IC reservoir bracket

These were easy to make, I used a piece of angled 1-1/2" aluminum stock and hit them with 2 coats primer, 3 coats semi gloss paint, then 2 coats of matte finish clear coat. I began by making a cardboard cut out of the fender contour, then transfered it to the aluminum stock

To install the bracket you have to remove the mount for the shock that supports the hood with a 1/2" deep socket.

You will need to put a flat screwdriver through the slot to remove the shock

Give it a pull and it comes right out

Slide the bracket into place then reinstall the shock for the hood

I made the mount so it has 3 points to bolt to the fender, this will keep the reservoir from vibrating while driving, heres a pic with the reservoir in place

The short bracket I made goes under the reservoir to give it strength, soo it's a sandwich design. I didn't feel comfortable bolting directly to the bottom of the plastic unit.

Here is a side shot of the install

I fabbed up some PCV hard lines out of 5/8" aluminum tubing, the ends are flared. My plan is to paint them black or maybe polish them

Now I have plenty of clearance for the top hose to connect to the reservoir

Before attempting to install the heat exchanger I had to make a horn relocate bracket. I used a piece of 1-1/4" aluminum flat stock (be sure to heat the aluminum with a torch before bending it). I decided to reuse the stock horn mount, all I had to do is flip the horns on the bracket to reverse the orientation for additional clearance

Make sure the new bracket does not contact the evaporator core

Now is also a good time to relocate the Ambient Temp sensor. I always solder the connectors, crimp connectors have a higher possibility of failure from corrosion

Cut the wires to the sensor diffrent lengths so there is no chance of having a short

A pair of helping hands is a good tool to have

After the solder cools hit them with shrink tape and a heat gun. Last wrap them in wire loom and secure the harness to the car with tywraps

The ambient temp sensor was relocated down below where the air diverter is located. Here is a shot of the new mount for the sensor. I used a nut from a brass 3/8" NPT connector

It bolts through the center piece of hardware on the diverter. I added some weatherstripping to the back side of the diverter to seal the gap thats created by adding the bracket.

Here is the sensor in place

Now all thats done I got the heat exchanger fabbed up. I used some 1-1/2" angled aluminum stock and some leftover 5/8" SS pipe. I wanted to use materials that even if the paint chips rust wont be an issue down the road.

For the bottom mounts I had to break out the Dewalt close quater drill. This came in very handy for getting holes drilled in tight spots

Here is a shot of the stud inplace

Before you install the IC pump its a good idea to extend the wire harness to the proper length.

I did'nt use the SS sheet metal screws included with the I/C pump kit from frozenboost.com. I drilled it out and installed nuts with nylon inserts and bolts to keep the hardware from vibrating loose.

Here's the pump installed. It wasn't tightened down when I took this pic.

Wire harness installed

Here is the relay I'm using for the pump. I picked it up from a local 4x4 shop, it's waterproof on both ends (wireharness and relay housing)

I went ahead and finished wiring the relay for the I/C pump. Here's where I put the weatherproof relay for easy accessability

I installed the KB BAP and put it on the inside of the rail to keep the carpet cover in its original form. I put rubber bumpers on the back side of the BAP to avoid any metal to metal contact on these tough Mississippi roads

I put the adjustment knob here after I cut out the extra mile of cable they include with the kit.

I started the modification the I/C flange for the Trilogy adapter plate.

The easiest way to do this is to install the bolts that do line up then transfer the hole pattern to the I/C flange

I used my Daughter's paint kit to mark the bolt patern to the I/C flange

This is what it looks like after drilling all the holes out

[imghttp://i790.photobucket.com/albums/yy182/musclemerc/IMG_0805.jpg][/img]

One thing I didn't have to do was drill the adapter plate for an IAT sensor. This is a revision Trilogy made years after making the mistake of leaving it in the stock Marauder MAF.

While I was at it I soldered the brass fittings for the boost guage and FRPS mod

The Eaton lower intake has to be modified to fit the Trilogy. This wedge has to be removed. Also notice I put a plug in the bottom PCV fitting, there is no need to send boost into the PCV track

Here it is after the removal

Got everything together for the assembly. I sourced the exact same hardware Trilogy used in their kit.

Here it is ready to go

My hose manifold finally showed up from CNC

I plan on keeping the stock lower tstat location. This manifold will allow me to route the upper radiator hose, tstat bypass hose, and two 3/4" barbed fittings for both cylinder heads.

This is how I plan on burping the system. 5/8" hose to a tall funnel. The barbed fitting is removed after burping the system, a flush (allen head) plug is installed in its place.

I made these fittings to delete the COT, they have a left/right orientation. I want the PS hose to route as low as possible. I want the DS hose to become the high spot in the system (no need to jack up the front end to burp the system). The air gap is installed on the DS.

I installed one of my 5/8" cooling mods. No clearance issues whatsoever

DS cooling mod fitting

I will finish routing the output of the cooling mod to the heater core inlet (Siege's hose routing mod) after I install the wiper cowl. I already plumed the output of the heater core to the pipe that runs under the lower intake to the back of the water pump

I wanted to keep the knock sensor in the stock location so this is what I came up with to keep it there

I drilled/tapped, then put a stud through the original boss. The sensor is held with a lock washer and nut with a nylon insert

One of the biggest hurdles was figuring out how to make a throttle cable bracket. This is what I came up with

I used Terry's Eaton Swap brackets, the SC tensioner bracket had to be shortened 5/16" to line up with the SC belt. I went ahead and polished them while I was at it. They work great without any issues. I also used a Roush 3 bolt tensioner for the SC belt. Cant beat it for $120.00

Here it is after all the work was done )))) It started right up on the first crank

Here's my mod list:

Trilogy SC with 3.0 upper pully

Stock Trilogy lower pully

40A KB BAP

90mm MAF

Mafia MAF extender

96 Cobra cams degreed *108/*112 LCS

JBA 1-5/8"short tube headers

2-1/2" MAC Prochamber

Magnaflow high flow cats

Musclemerc CAI

Musclemerc 5/8" cooling mod

Musclemerc upper/lower CA's

Musclemerc oil catch can

Addco F/R sway bars

Moog end links

Rear ES bushing mod

Power Slot D/S rotors

TCE SS brake lines

Hawk HPS pads

FRPS mod

IAT relocate mod

Yukon 31 Spline Axles

Cobra 31 Spline CF Differential

MAC Stud Girdle

FRPP 4:10 Gears