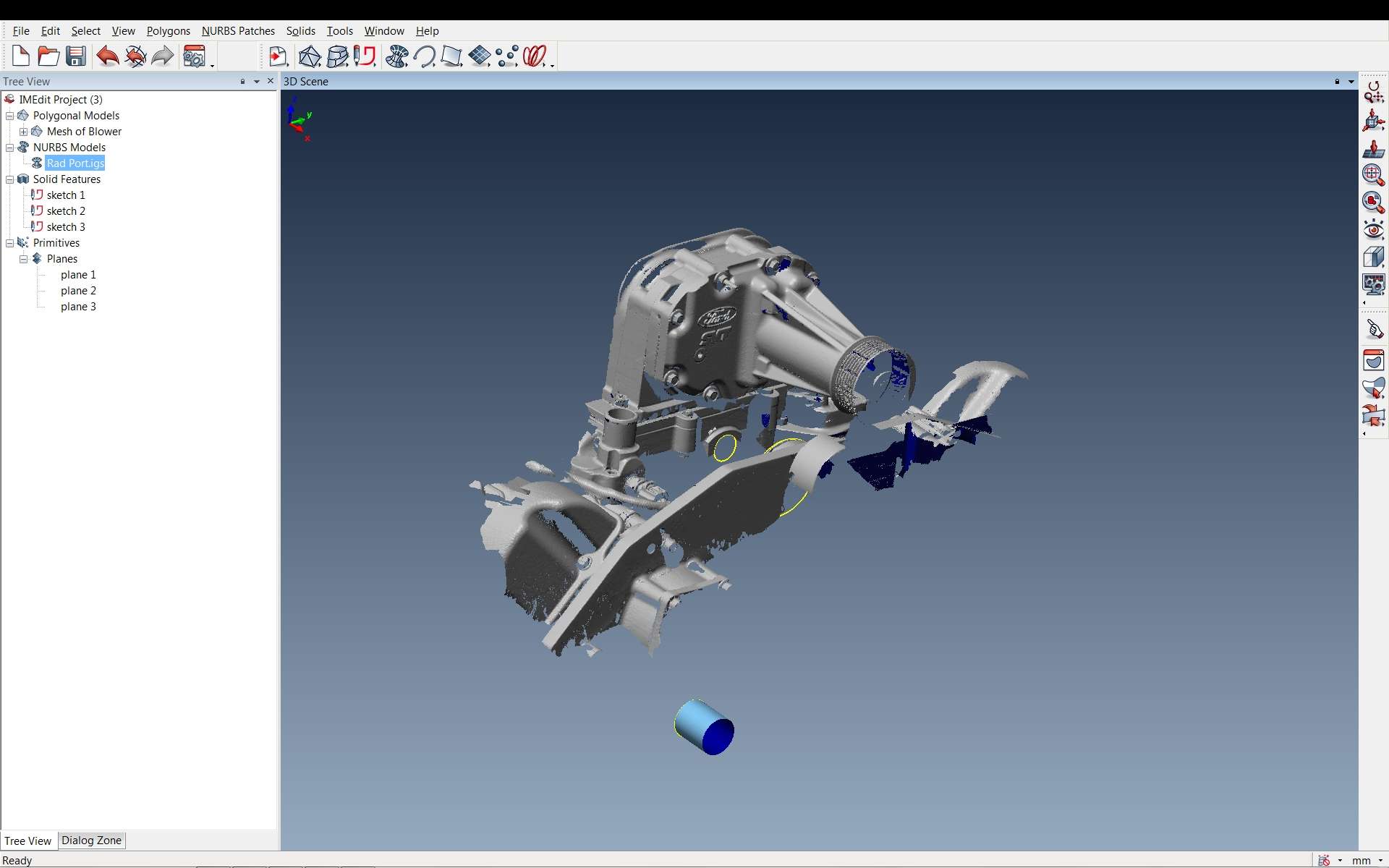

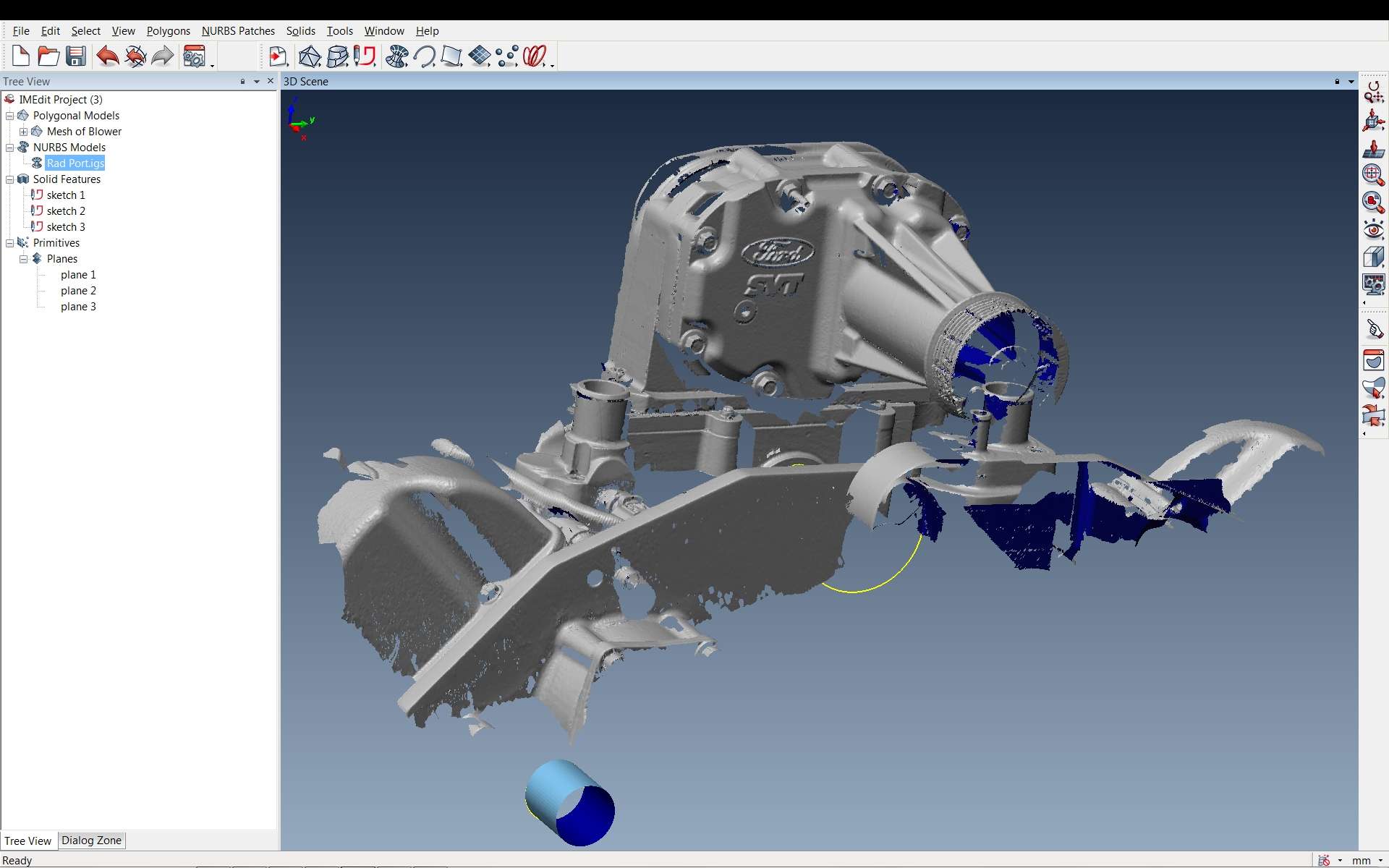

Block Coolant Hose Tork Tech Terminator install

While I have some down time. Thought I would back track a little bit and post a few comments on the cooling pipe that runs in the valley of the block. I think this is the only required step I have not posted yet.

The instructions call for you to cut out an adapter elbow out of the stock heater core hose. Mine didn't have that. So I went to the parts house and asked for a heater hose 5/8" that had a 90 degree bend on it. Go figure, Gates makes one just for the type of job I was doing. joined the stock hose and new hose together.

Coolant Hose in the block valley http://imageshack.us

http://imageshack.us

While I have some down time. Thought I would back track a little bit and post a few comments on the cooling pipe that runs in the valley of the block. I think this is the only required step I have not posted yet.

The instructions call for you to cut out an adapter elbow out of the stock heater core hose. Mine didn't have that. So I went to the parts house and asked for a heater hose 5/8" that had a 90 degree bend on it. Go figure, Gates makes one just for the type of job I was doing. joined the stock hose and new hose together.

Coolant Hose in the block valley

http://imageshack.us

http://imageshack.us

Last edited: