Well, I was pretty set on getting my Mach 1 running properly and putting it up for sale. I guess the Mach didn't like that idea so it decided to break on me. Apparently 03/04 Mach 1's aren't really selling well right now anyway so seems like it was meant to be.

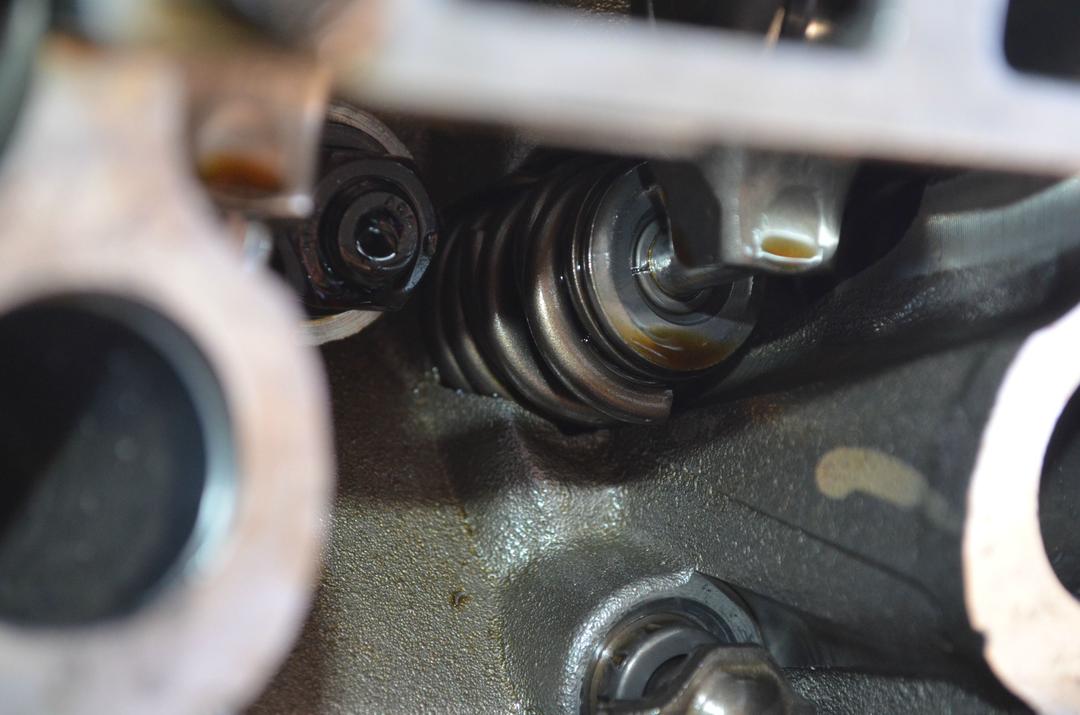

Anyway, as some may have seen in my other thread, the engine was making a horrible clattering noise from under the passenger side valve cover. No I was not beating on the car - I just turned it on to go to lunch from the office and it immediately started making this horrible noise. So I left it on for a bit while I tried to narrow down the location of the noise. The car probably wasn't on for more than two minutes. After getting it towed back home and in my garage, I had a hell of a time pulling the valve cover even though everyone claims the passenger side is easy. But I finally man-handled it enough to get it off and the only out of place thing was this:

I believe that is a broken valve spring. I also believe I may have gotten lucky and had a clean break since the car was never above idle and not have any debris in the cylinder and perhaps not have bent the valve. We shall see.

Well, I really don't feel like getting the car towed to a shop and paying to get it fixed and since I've never dug into this engine before and I've wanted to know what components the previous owner used, etc, I figure now is as good of a time as any.

Yes, some might think, with such a clean break, I could get away with replacing the spring and going on my merry way hoping for the best and pulling the engine is too much work but I decided to say screw it, lets see what happens.

I've had a full Maximum Motorsports front end waiting to go into the car since December so I figured now is as good of a time as any. And if I'm going to be dropping the k-member (currently a QA1 tubular - not best for auto-x or corner carving), I might as well see how high I can raise the car and try to drop the engine out the bottom. If I don't get enough room, then I'll at least have a ton of room with the k-member out of the way to get a good angle on the engine and pull it out the top worst-case-scenario.

So here's the plan:

I'm going to use the engine support beam I already bought from Harbor Freight to hold the engine in place while I drop the k-member assembly. I could drop the whole k-member assembly and engine in one procedure but I need to consistently move forward on this little project and I won't have the opportunity to rent an engine hoist for a while, whereas I've already got the support beam.

I'll remove the hood (otherwise the garage door will hit it), raise the car up on jack stands as high as possible, and use an engine hoist to drop the long block onto a couple (or more) furniture dollies and slide it out the side of the car with transmission attached (I've got a few things to do to the IRS in the rear as well - change fluid, tighten up some bolts, etc).

I'll then separate the transmission and engine and get the engine on an engine stand for free access to all parts of it.

My plan at the very least is to replace all valve springs with a different brand (believe they're comp right now), replace the MMR oil pan with a Canton Road Race pan and baffle I have lying around right now, and get the valve covers powder coated Wrinkle Ford Blue and get my coil covers powdercoated silver. With the oil pan off, I'm hoping I'll be able to figure out what crank, rods, and pistons are in the engine and maybe finally figure out what the hell the compression ratio might be (I may be completely wrong here, I've never done this before, but I'm assuming the cast/machined pieces will have a part number stamped somewhere).

As I'm sure you're all aware, the chances of me not messing with anything else during this process is essentially zero, so perhaps I'll swap out the clutch and a few other things while I have complete access to all drivetrain parts. But that all depends on funds.

And so we begin:

Oil drained - no signs of metal shavings so I may have gotten lucky with no damage besides the valve spring.

This all happened over last week and the car went up on stands yesterday.

I didn't get to do anything tonight but I had a few gift cards to Lowe's from my birthday so I went and bought some possibly helpful tools:

Brand wasn't really a preference but it had decent enough reviews and the gift cards covered the expense so it's what I went with. Got a 3/8" wrench to go along with it since I've got an electric 1/2" impact that should carry me for the time being.

Plan for tomorrow is to drain the coolant and get the brake calipers and rotors off and out of the way. I'm going to take this whole thing slow since having the car running isn't critical and hopefully I can keep track of all nuts and bolts and lose as few parts as possible.

I want to get pictures of the whole process since NOBODY has a write-up with pictures of dropping the engine out the bottom of the car so hopefully I'll be able to stay on top of this and update this thread with plenty of info. But as some of you may be aware, sometimes you get on a roll and get carried away and taking pictures is the last thing on your mind, so we shall see.

Anyway, as some may have seen in my other thread, the engine was making a horrible clattering noise from under the passenger side valve cover. No I was not beating on the car - I just turned it on to go to lunch from the office and it immediately started making this horrible noise. So I left it on for a bit while I tried to narrow down the location of the noise. The car probably wasn't on for more than two minutes. After getting it towed back home and in my garage, I had a hell of a time pulling the valve cover even though everyone claims the passenger side is easy. But I finally man-handled it enough to get it off and the only out of place thing was this:

I believe that is a broken valve spring. I also believe I may have gotten lucky and had a clean break since the car was never above idle and not have any debris in the cylinder and perhaps not have bent the valve. We shall see.

Well, I really don't feel like getting the car towed to a shop and paying to get it fixed and since I've never dug into this engine before and I've wanted to know what components the previous owner used, etc, I figure now is as good of a time as any.

Yes, some might think, with such a clean break, I could get away with replacing the spring and going on my merry way hoping for the best and pulling the engine is too much work but I decided to say screw it, lets see what happens.

I've had a full Maximum Motorsports front end waiting to go into the car since December so I figured now is as good of a time as any. And if I'm going to be dropping the k-member (currently a QA1 tubular - not best for auto-x or corner carving), I might as well see how high I can raise the car and try to drop the engine out the bottom. If I don't get enough room, then I'll at least have a ton of room with the k-member out of the way to get a good angle on the engine and pull it out the top worst-case-scenario.

So here's the plan:

I'm going to use the engine support beam I already bought from Harbor Freight to hold the engine in place while I drop the k-member assembly. I could drop the whole k-member assembly and engine in one procedure but I need to consistently move forward on this little project and I won't have the opportunity to rent an engine hoist for a while, whereas I've already got the support beam.

I'll remove the hood (otherwise the garage door will hit it), raise the car up on jack stands as high as possible, and use an engine hoist to drop the long block onto a couple (or more) furniture dollies and slide it out the side of the car with transmission attached (I've got a few things to do to the IRS in the rear as well - change fluid, tighten up some bolts, etc).

I'll then separate the transmission and engine and get the engine on an engine stand for free access to all parts of it.

My plan at the very least is to replace all valve springs with a different brand (believe they're comp right now), replace the MMR oil pan with a Canton Road Race pan and baffle I have lying around right now, and get the valve covers powder coated Wrinkle Ford Blue and get my coil covers powdercoated silver. With the oil pan off, I'm hoping I'll be able to figure out what crank, rods, and pistons are in the engine and maybe finally figure out what the hell the compression ratio might be (I may be completely wrong here, I've never done this before, but I'm assuming the cast/machined pieces will have a part number stamped somewhere).

As I'm sure you're all aware, the chances of me not messing with anything else during this process is essentially zero, so perhaps I'll swap out the clutch and a few other things while I have complete access to all drivetrain parts. But that all depends on funds.

And so we begin:

Oil drained - no signs of metal shavings so I may have gotten lucky with no damage besides the valve spring.

This all happened over last week and the car went up on stands yesterday.

I didn't get to do anything tonight but I had a few gift cards to Lowe's from my birthday so I went and bought some possibly helpful tools:

Brand wasn't really a preference but it had decent enough reviews and the gift cards covered the expense so it's what I went with. Got a 3/8" wrench to go along with it since I've got an electric 1/2" impact that should carry me for the time being.

Plan for tomorrow is to drain the coolant and get the brake calipers and rotors off and out of the way. I'm going to take this whole thing slow since having the car running isn't critical and hopefully I can keep track of all nuts and bolts and lose as few parts as possible.

I want to get pictures of the whole process since NOBODY has a write-up with pictures of dropping the engine out the bottom of the car so hopefully I'll be able to stay on top of this and update this thread with plenty of info. But as some of you may be aware, sometimes you get on a roll and get carried away and taking pictures is the last thing on your mind, so we shall see.