Now that I have an open road race under my belt, I feel comfortable reporting success on my second iteration of an oil cooler.

Parts list:

I did not install a fan. At the high-speed open road race, it was completely unnecessary with the fog light removed. I did not install an oil thermostat. That will lengthen the life of the engine, but will require more hose fitting and more fabrication. I might do that later.

Top bracket fabricated for the cooler. Note that this picture is from my first cooler, not the second, so it got modified a bit compared to this pic.

The top bracket mounts beneath the battery at the red holes. I also had to move the horn to the blue holes.

Here is the block adapter wired up with Aeroforce analog sensors for temp and pressure

Here's the adapter fully plumbed with -10an lines. The inbound end is a 30-degree bend and the outbound end is straight. Because of tension on the hoses, I later replaced the 30-degree bend with a 45 instead. It's pretty tight. You have to work a compromise between getting the oil lines away from the radiator hose while at the same time not pointing them too far away from where they are going.

Here's the routing of the radiator hose. You can see the tstat housing on the right, the block adapter on the left. The stock hose is shortened and connects the tstat housing to the exhaust reducer. The generic 90-degree bend rad hose connects the reducer to the block adapter.

Here is the remote filter adapter, filter, lower cooler bracket, and the original oil cooler. Note that this oil cooler is wrong, it is not the Mocal but a much smaller one!

Here is a shot of the correct Mocal oil cooler in front of the driver tire, with the front fascia back on

Parts list:

- MOC-25210: Mocal 25 Row, 235 Matrix Oil Cooler - Mocal 25 Row, 235 Matrix Oil Cooler with -10AN Fittings (Note: this cooler might be too large!)

- PRM-61791: Perma-Cool 61791 Oil Filter Mount, Single Filter, -10 AN O-ring Inlet/Outlet, 3/4 in.-16 Thread Filter, Anodized Finish

- M-6881-C: 1996-04 Mustang Water Inlet/Remote Filter Adapter

- 90-degree radiator hose (cut to fit)

- Exhaust reducer (to adapt 2" hose from adapter to stock hose prior to tstat)

- FRA-710010: Hose, Series 3000, Braided Stainless Steel, -10 AN, 10 ft. Length

- Qty 3: FRA-109010: Fitting, Hose End, Reusable, 90 Degree, -10 AN Hose to Female -10 AN, Aluminum, Red/Blue Anodized

- FRA-100110: Fitting, Hose End, Reusable, Straight, -10 AN Hose to Female -10 AN, Aluminum, Red/Blue Anodized

- FRA-104510: Fitting, Hose End, Reusable, 45 Degree, -10 AN Hose to Female -10 AN, Aluminum, Red/Blue Anodized

- FRA-180110: Fitting, Hose End, Reusable, Straight, -10 AN Hose to Male -10 AN, Aluminum, Red/Blue Anodized

- Qty 2: FRA-481510: Fitting, Coupler, Straight, Male -10 AN to Male -10 AN, Aluminum, Blue Anodized

- Qty 2: SUM-220164: -10 O-RING TO-10 FLARE FITTING

I did not install a fan. At the high-speed open road race, it was completely unnecessary with the fog light removed. I did not install an oil thermostat. That will lengthen the life of the engine, but will require more hose fitting and more fabrication. I might do that later.

Top bracket fabricated for the cooler. Note that this picture is from my first cooler, not the second, so it got modified a bit compared to this pic.

The top bracket mounts beneath the battery at the red holes. I also had to move the horn to the blue holes.

Here is the block adapter wired up with Aeroforce analog sensors for temp and pressure

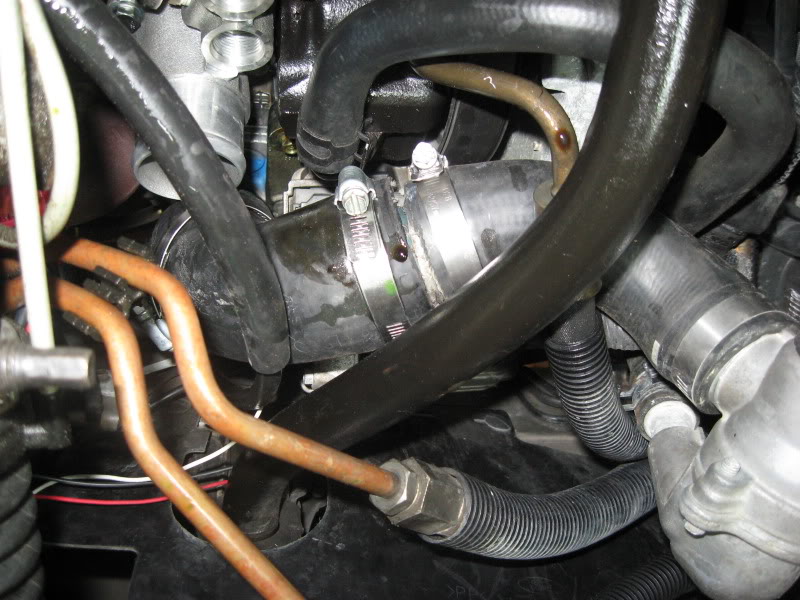

Here's the adapter fully plumbed with -10an lines. The inbound end is a 30-degree bend and the outbound end is straight. Because of tension on the hoses, I later replaced the 30-degree bend with a 45 instead. It's pretty tight. You have to work a compromise between getting the oil lines away from the radiator hose while at the same time not pointing them too far away from where they are going.

Here's the routing of the radiator hose. You can see the tstat housing on the right, the block adapter on the left. The stock hose is shortened and connects the tstat housing to the exhaust reducer. The generic 90-degree bend rad hose connects the reducer to the block adapter.

Here is the remote filter adapter, filter, lower cooler bracket, and the original oil cooler. Note that this oil cooler is wrong, it is not the Mocal but a much smaller one!

Here is a shot of the correct Mocal oil cooler in front of the driver tire, with the front fascia back on