First a description of the engine. A new Ford Racing short block. To that a new pair of TFS track heat 185 heads. A pair of mild Bullet camshafts, Cloyes adjustable cam gears, ARP head studs, balancer bolt, and flexplate bolts. All new Ford OEM parts everywhere else for the long block. New cam chains, chain tensioners, cam chain guides, crank cam chain gear, harmonic balancer, flexplate, waterpump, GT 500 cam followers and lash adjusters, and of course a new upper and lower gasket set.

Piston to valve clearance checked using the clay method, cams timed with the TFS cam degree kit (plus their supplemental kit).

Both TFS tech support and Fox Lake Performance Products were repeatedly consulted when I had questions. Both were excellent to work with.

So far here's the problems. The passenger side head was installed and torqued to spec. Attempting to install spark plugs the number 1 plug bore had gouging in it not letting the spark plug socket go down the bore. Initially, I didn't think to look down the bores. TFS was contacted, they requested pictures, sent those, they then issued a UPS pick up tag to have the head shipped back to them. The head was replaced by TFS. It took a month and a half to get the new head back. Kinda slow.

New head installed and torqued, cams installed and timed, engine made ready to install in the truck. After getting all the ancillary items on, the engine was started. Had a leak at the back of the passenger side head. The plug for the oil galley was dripping on the exhaust manifold. Not excessively, but a slow steady drip. Managed to come up with a tool to remove and reinstall the plug; four times with different sealant used each time. No luck, could not get the leak to completely stop. This with the engine at a high idle and no load on the engine. Engine came out.

That plug was found to not be completely seating for a seal. There was a lip where the machining process took place for the pipe threads and the pipe plug was bottoming on that lip before getting far enough in to make a complete seal. Carefully tapped the hole a slight amount more to give a better seal for the pipe plug. Engine went back in.

Start up was unremarkable, no leaks, no codes, nothing showing any problems. Oil leak was corrected on the passenger head as well.

I elected to do a 1000 mile breakin. Lots of different opinions on a break in procedure for new engines. I chose on I was comfortable with. On initial startup idle was held at 1600 RPM for 20 minutes then shut down. Oil and filter changed, oil being used was 5-20 conventional oil. Then it was out on the road with constant acceleration and compression of the engine Speeds for the truck were from 25 to 70 MPH. I developed an 86 mile loop and ran the truck late at night to have much less traffic to deal with. First 255 miles there was no boost on the engine. After that boost was brought up to 5 PSI for the first 500 miles.

Oil and filter changed at 500 miles again with conventional oil. Up to 855 miles I would accelerate and de-accelerate as before but increased boost during acceleration. After 700 miles boost was going up to 10 PSI. Still not full throttle. AFR and fuel pressure were unremarkable during all my driving.

At 855 miles the truck suddenly started to run a little rough. It acted as if two spark plug wires were crossed initially which of course can't happen but it describes the feel of the engine. It quickly became MUCH worse not being able to run without substantial throttle applied. The truck was bucking so I coasted into a fire station and shut it off. This all happened in less than a minute. Once shut off I checked under the hood and under the truck for fluids. None were found. Under the hood nothing externally on the engine looked abnormal. Truck would not start up after being shut off.

Called a tow truck to load the truck up and haul it home.

Once in my shop disassembly started to get the engine out of the truck. Peeled all the miscellaneous stuff off to get down to the midplate. Once there I pulled the spark plugs. 1, 2, and 3 were good. Didn't reach all the way back to get # 4. Pulled 5, then 6. Here's what I found on # 6 plug.

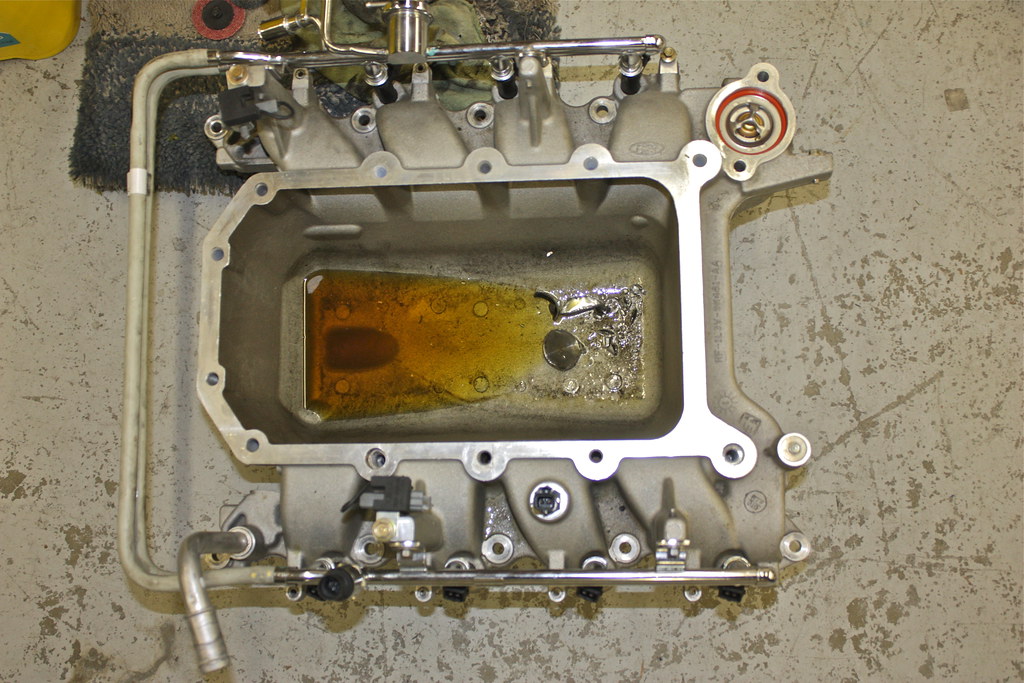

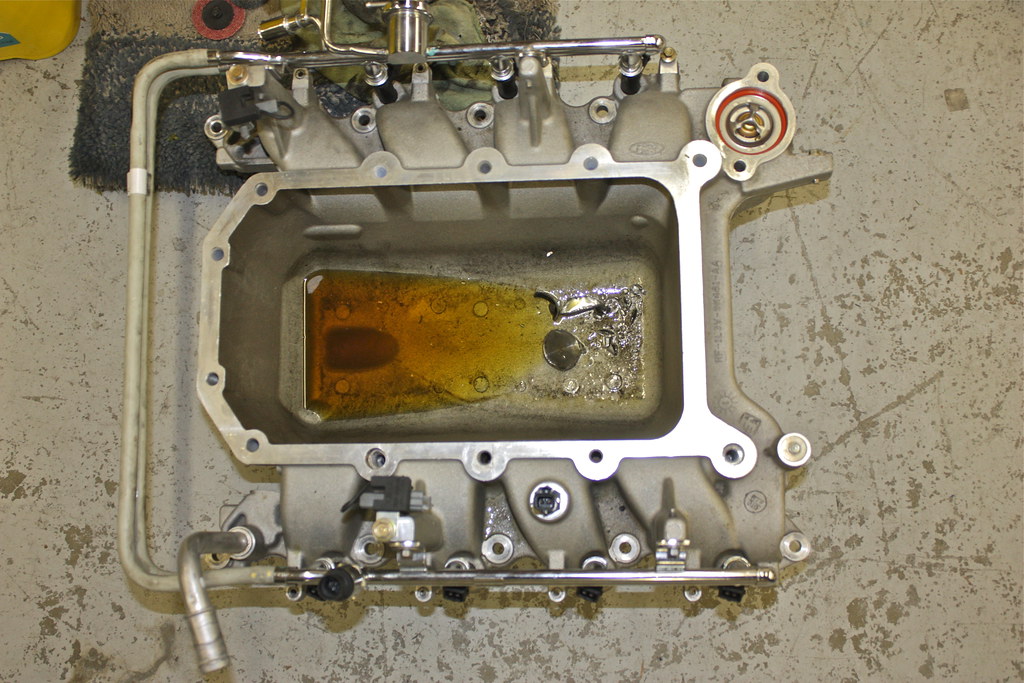

# 7 was fine. Seems I found the cylinder that has the issue. Off comes the midplate and what greets me is about a pint of coolant and a lot of damaged parts. In the bottom of the lower intake manifold was the exhaust valve head, a crescent of the intake valve head, two pieces of the exhaust valve seat plus a bunch of aluminum debris. At this point I didn't know specifically which valve head was in the bottom of the manifold. The parts and pieces were later determined after further engine disassembly.

Lower intake manifold and debris found after removing the intercooler.

Once the lower intake manifold was removed it provided a visual to the intake ports. All the ports had valve heads except one. Number 6 had the valve stem sticking down the port into nothingness. No valve head on the valve stem. Odd looking down the port expecting to see the backside of the head of a valve and it not being there. You'll really be surprised where the intake valve ended up.

Number 6 intake port.

Overall view of the drivers side head. Note # 6 missing that valve head.

Engine came out of the truck, placed on an engine stand. Now those of us here in my shop could view more. The exhaust port could be viewed close up. Again, there was no head on the exhaust valve. There is a little bit of a valve head showing in the bottom of the exhaust port though. The exhaust valve stem was found bent. Had a nice gentle curve to it. The valve guide has a piece broken off and a crack in it as well. The missing piece is suspected of going out the exhaust as it was not found.

Pics of the exhaust port of # 6 cylinder.

Exhaust valve guide cracked plus missing a piece. Not really noticeable but the valve stem is bent.

Photo of the exhaust port showing a small portion of the intake valve at the bottom of the port.

Valve covers (OK I know cam covers) came off to have a look at the top side of the valve train. Rotated the engine, it had no resistance, the exhaust valve would not come all the way up due to being bent. Cam follower was loose because of this. Nothing at all noticeable on the intake side. Valve train for the intake side moved up and down as normal.

Nothing left to do now but pull the head off to ascertain the damage in #6.

Here's photos of damage to the combustion chamber of the head and to the bore of the cylinder. Note the exhaust valve seat is completely missing, the intake valve seat is intact.

Then there's the cylinder itself.

This photo shows the top of the cylinder bore with a piece of metal missing at the 9 o'clock position of the bore.

The approximately 3 inch long crack in the cylinder bore at the 2 o'clock position in the bore.

And of course I know all want to see the top of the piston in #6 bore. Here it is.

TFS was notified via email with some photos. They requested both heads be sent back to them with the valve train (cams, followers, lash adjusters). That was done. TFS received the heads 6 weeks ago today (7/1/2014) They have requested some additional photos which were sent. They did also ask what the cams were timed too, that was provided. With the heads when they were shipped was an inventory of additional parts and copies of both cam cards.

The last communication with TFS was via email in answer to my question of what is going on with my heads. They advised that they sent the valves out to a metallurgist for analysis and expected that info back last Friday and would have an answer for me no later than Monday. Email was sent June 26th, the Monday mentioned was yesterday, June 30th.

Meanwhile, I now have a block that is junk, one severely damaged head, a lot of time invested in assembly of the engine plus installation twice of the engine.

Engine is stripped down to the original short block as delivered from Ford Racing. Since most of the coolant was found in the lower intake, cylinders, and oil pan all parts that are salvageable have been cleaned and put away for the next engine. All parts, including gaskets, and fluids were saved too.

Scott

Piston to valve clearance checked using the clay method, cams timed with the TFS cam degree kit (plus their supplemental kit).

Both TFS tech support and Fox Lake Performance Products were repeatedly consulted when I had questions. Both were excellent to work with.

So far here's the problems. The passenger side head was installed and torqued to spec. Attempting to install spark plugs the number 1 plug bore had gouging in it not letting the spark plug socket go down the bore. Initially, I didn't think to look down the bores. TFS was contacted, they requested pictures, sent those, they then issued a UPS pick up tag to have the head shipped back to them. The head was replaced by TFS. It took a month and a half to get the new head back. Kinda slow.

New head installed and torqued, cams installed and timed, engine made ready to install in the truck. After getting all the ancillary items on, the engine was started. Had a leak at the back of the passenger side head. The plug for the oil galley was dripping on the exhaust manifold. Not excessively, but a slow steady drip. Managed to come up with a tool to remove and reinstall the plug; four times with different sealant used each time. No luck, could not get the leak to completely stop. This with the engine at a high idle and no load on the engine. Engine came out.

That plug was found to not be completely seating for a seal. There was a lip where the machining process took place for the pipe threads and the pipe plug was bottoming on that lip before getting far enough in to make a complete seal. Carefully tapped the hole a slight amount more to give a better seal for the pipe plug. Engine went back in.

Start up was unremarkable, no leaks, no codes, nothing showing any problems. Oil leak was corrected on the passenger head as well.

I elected to do a 1000 mile breakin. Lots of different opinions on a break in procedure for new engines. I chose on I was comfortable with. On initial startup idle was held at 1600 RPM for 20 minutes then shut down. Oil and filter changed, oil being used was 5-20 conventional oil. Then it was out on the road with constant acceleration and compression of the engine Speeds for the truck were from 25 to 70 MPH. I developed an 86 mile loop and ran the truck late at night to have much less traffic to deal with. First 255 miles there was no boost on the engine. After that boost was brought up to 5 PSI for the first 500 miles.

Oil and filter changed at 500 miles again with conventional oil. Up to 855 miles I would accelerate and de-accelerate as before but increased boost during acceleration. After 700 miles boost was going up to 10 PSI. Still not full throttle. AFR and fuel pressure were unremarkable during all my driving.

At 855 miles the truck suddenly started to run a little rough. It acted as if two spark plug wires were crossed initially which of course can't happen but it describes the feel of the engine. It quickly became MUCH worse not being able to run without substantial throttle applied. The truck was bucking so I coasted into a fire station and shut it off. This all happened in less than a minute. Once shut off I checked under the hood and under the truck for fluids. None were found. Under the hood nothing externally on the engine looked abnormal. Truck would not start up after being shut off.

Called a tow truck to load the truck up and haul it home.

Once in my shop disassembly started to get the engine out of the truck. Peeled all the miscellaneous stuff off to get down to the midplate. Once there I pulled the spark plugs. 1, 2, and 3 were good. Didn't reach all the way back to get # 4. Pulled 5, then 6. Here's what I found on # 6 plug.

# 7 was fine. Seems I found the cylinder that has the issue. Off comes the midplate and what greets me is about a pint of coolant and a lot of damaged parts. In the bottom of the lower intake manifold was the exhaust valve head, a crescent of the intake valve head, two pieces of the exhaust valve seat plus a bunch of aluminum debris. At this point I didn't know specifically which valve head was in the bottom of the manifold. The parts and pieces were later determined after further engine disassembly.

Lower intake manifold and debris found after removing the intercooler.

Once the lower intake manifold was removed it provided a visual to the intake ports. All the ports had valve heads except one. Number 6 had the valve stem sticking down the port into nothingness. No valve head on the valve stem. Odd looking down the port expecting to see the backside of the head of a valve and it not being there. You'll really be surprised where the intake valve ended up.

Number 6 intake port.

Overall view of the drivers side head. Note # 6 missing that valve head.

Engine came out of the truck, placed on an engine stand. Now those of us here in my shop could view more. The exhaust port could be viewed close up. Again, there was no head on the exhaust valve. There is a little bit of a valve head showing in the bottom of the exhaust port though. The exhaust valve stem was found bent. Had a nice gentle curve to it. The valve guide has a piece broken off and a crack in it as well. The missing piece is suspected of going out the exhaust as it was not found.

Pics of the exhaust port of # 6 cylinder.

Exhaust valve guide cracked plus missing a piece. Not really noticeable but the valve stem is bent.

Photo of the exhaust port showing a small portion of the intake valve at the bottom of the port.

Valve covers (OK I know cam covers) came off to have a look at the top side of the valve train. Rotated the engine, it had no resistance, the exhaust valve would not come all the way up due to being bent. Cam follower was loose because of this. Nothing at all noticeable on the intake side. Valve train for the intake side moved up and down as normal.

Nothing left to do now but pull the head off to ascertain the damage in #6.

Here's photos of damage to the combustion chamber of the head and to the bore of the cylinder. Note the exhaust valve seat is completely missing, the intake valve seat is intact.

Then there's the cylinder itself.

This photo shows the top of the cylinder bore with a piece of metal missing at the 9 o'clock position of the bore.

The approximately 3 inch long crack in the cylinder bore at the 2 o'clock position in the bore.

And of course I know all want to see the top of the piston in #6 bore. Here it is.

TFS was notified via email with some photos. They requested both heads be sent back to them with the valve train (cams, followers, lash adjusters). That was done. TFS received the heads 6 weeks ago today (7/1/2014) They have requested some additional photos which were sent. They did also ask what the cams were timed too, that was provided. With the heads when they were shipped was an inventory of additional parts and copies of both cam cards.

The last communication with TFS was via email in answer to my question of what is going on with my heads. They advised that they sent the valves out to a metallurgist for analysis and expected that info back last Friday and would have an answer for me no later than Monday. Email was sent June 26th, the Monday mentioned was yesterday, June 30th.

Meanwhile, I now have a block that is junk, one severely damaged head, a lot of time invested in assembly of the engine plus installation twice of the engine.

Engine is stripped down to the original short block as delivered from Ford Racing. Since most of the coolant was found in the lower intake, cylinders, and oil pan all parts that are salvageable have been cleaned and put away for the next engine. All parts, including gaskets, and fluids were saved too.

Scott

Last edited: