I noticed the other day I can grab my supercharger pulley and turn it back and forth. Whoops that's not supposed to happen. The whole belt and all accessories turn a tiny amount as I wiggle back and forth. Looking a little closer I see my stock lower is failing... or failed depending on your view. The rubber connections midway in it seem to have given out and you can wiggle it back and forth. Guess I need a new stock lower. Anyone else had this happen before?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I can wiggle my pulleys and serp belt back and forth

- Thread starter MalcolmV8

- Start date

How does the rubber look? Seems like an odd failure, rubber does deteriorate. Think you may have gotten something on it to speed up the degradation?

Mine does the same thing. The little rubber bushings are coming apart in the lower pulley. That's what appears to be happening anyway. I will need a new lower pulley too at some point.

Come on Malcolm, haven't you seen the threads on this? Maybe a bunch of posts in one thread or something, but I have read about this a lot.

I actually have a stock lower that appears in good condition I was going to be putting up for sale. The center hub came out when removing so basically it is mostly dissassembled

I actually have a stock lower that appears in good condition I was going to be putting up for sale. The center hub came out when removing so basically it is mostly dissassembled

Just had mine apart ...was doing both belts and all coolant hoses..

I did find away...maybe not right. ..but works..not like we have many options..

I did find away...maybe not right. ..but works..not like we have many options..

How does the rubber look? Seems like an odd failure, rubber does deteriorate. Think you may have gotten something on it to speed up the degradation?

Nothing on it, it's dry and clean. I think the bushings just failed. They're squished looking. Probably just to much abuse turning over the Whipple.

Just had mine apart ...was doing both belts and all coolant hoses..

I did find away...maybe not right. ..but works..not like we have many options..

Any pics or links to what you did?

Another guy to try would be the guy that built the 4lb caged lowers. I know he mentioned replacing the rubber bushings in them. I think I saw him posting in the Terminator car for sale section just this week.

Using any thing you can find as rubber would be fine..

some link shows you can grind back of pulley to fit there replacement..

dont..that lip is all that holds rubber in..and what suxs is that rubber is all that is used to turn pulley..

so it will wear again...

I had taken post out..replaced with wheel stud...took round stock and threaded it to fit stud..

what might be wrong on mine is balance..I didnt weigh all pieces to make same..

hardest part is removing from car...

allen hex is left hand also in tribar...

I re installed just snug last time...and getting it apart was just as hard as originally. ..

the threaded studs I made also stayed tight. ..

Cost was drill bits...tap...3 studs...1ft hose..grinding disc for metal to remove old post

25 bucks tops...

some link shows you can grind back of pulley to fit there replacement..

dont..that lip is all that holds rubber in..and what suxs is that rubber is all that is used to turn pulley..

so it will wear again...

I had taken post out..replaced with wheel stud...took round stock and threaded it to fit stud..

what might be wrong on mine is balance..I didnt weigh all pieces to make same..

hardest part is removing from car...

allen hex is left hand also in tribar...

I re installed just snug last time...and getting it apart was just as hard as originally. ..

the threaded studs I made also stayed tight. ..

Cost was drill bits...tap...3 studs...1ft hose..grinding disc for metal to remove old post

25 bucks tops...

Using any thing you can find as rubber would be fine..

some link shows you can grind back of pulley to fit there replacement..

dont..that lip is all that holds rubber in..and what suxs is that rubber is all that is used to turn pulley..

so it will wear again...

I had taken post out..replaced with wheel stud...took round stock and threaded it to fit stud..

what might be wrong on mine is balance..I didnt weigh all pieces to make same..

hardest part is removing from car...

allen hex is left hand also in tribar...

I re installed just snug last time...and getting it apart was just as hard as originally. ..

the threaded studs I made also stayed tight. ..

Cost was drill bits...tap...3 studs...1ft hose..grinding disc for metal to remove old post

25 bucks tops...

Thanks for the tips. I'm sure a lot of it will make more sense once I get it off the car and look it over closer. I've removed it before when I rebuilt the engine so no problem there. I'll report back once I have it off.

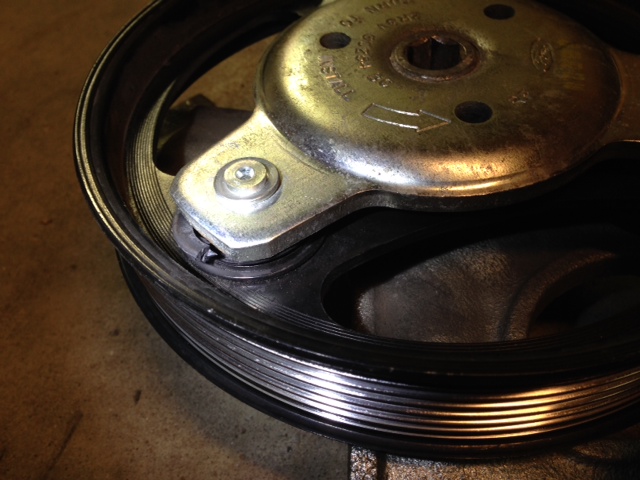

I ended grabbing a spare lower from a buddy and back on the road but coming back to this i would like to figure out how to repair mine for when the next lower is done. Not sure if you can see in these pics but the rubber bushings are just plain flattened and done. That 2.9 Whipple must put a crazy amount of stress on them or something.

So is there a way to take this lower apart without been destructive? Are the two halves pressed together so it's not easily serviceable and pulled apart? any ideas, tips?

So is there a way to take this lower apart without been destructive? Are the two halves pressed together so it's not easily serviceable and pulled apart? any ideas, tips?

Now you unscrew allen from piece with posts..

its left hand also..

And tight..

I also posted on this site..lower pulley bearing number..

inside there is a bearing..its staked over to hold in..

its left hand also..

And tight..

I also posted on this site..lower pulley bearing number..

inside there is a bearing..its staked over to hold in..

Last edited:

So that's why there's a big square indention on the back. You can unscrew those two pieces apart. Left hand thread again. I wonder if a little heat on the front side around the allen piece would help them come apart easier.

I'm thinking it's really really tight if I was able to use the car's weight with a 6 foot breaker bar to release from the car and it still didn't undo these two pieces. Did you clamp in a vice and use some massive breaker bars?

I'm thinking it's really really tight if I was able to use the car's weight with a 6 foot breaker bar to release from the car and it still didn't undo these two pieces. Did you clamp in a vice and use some massive breaker bars?

Heat will release the loctite on the mandrel

That square is the allen...its a bolt..

you turn allen while holding tribar/pulley..

you turn allen while holding tribar/pulley..

1st time I bolted cage to a old frame rail ..had u shaped piece of metal with hole to put allen tool thru..

I used heat..but caution..bearing on other side has plastic covers..

2nd time I used stand up press...

I put press in 1 opening in pulley as to use as a deadman post..

than put bar in a second hole in pulley..

this held cage so I could put 5ft pipe on breaker bar..

I used heat..but caution..bearing on other side has plastic covers..

2nd time I used stand up press...

I put press in 1 opening in pulley as to use as a deadman post..

than put bar in a second hole in pulley..

this held cage so I could put 5ft pipe on breaker bar..

Dont use square. .use allen side..

just like on car...its how to hold pulley so you can use that amount of force

just like on car...its how to hold pulley so you can use that amount of force

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)