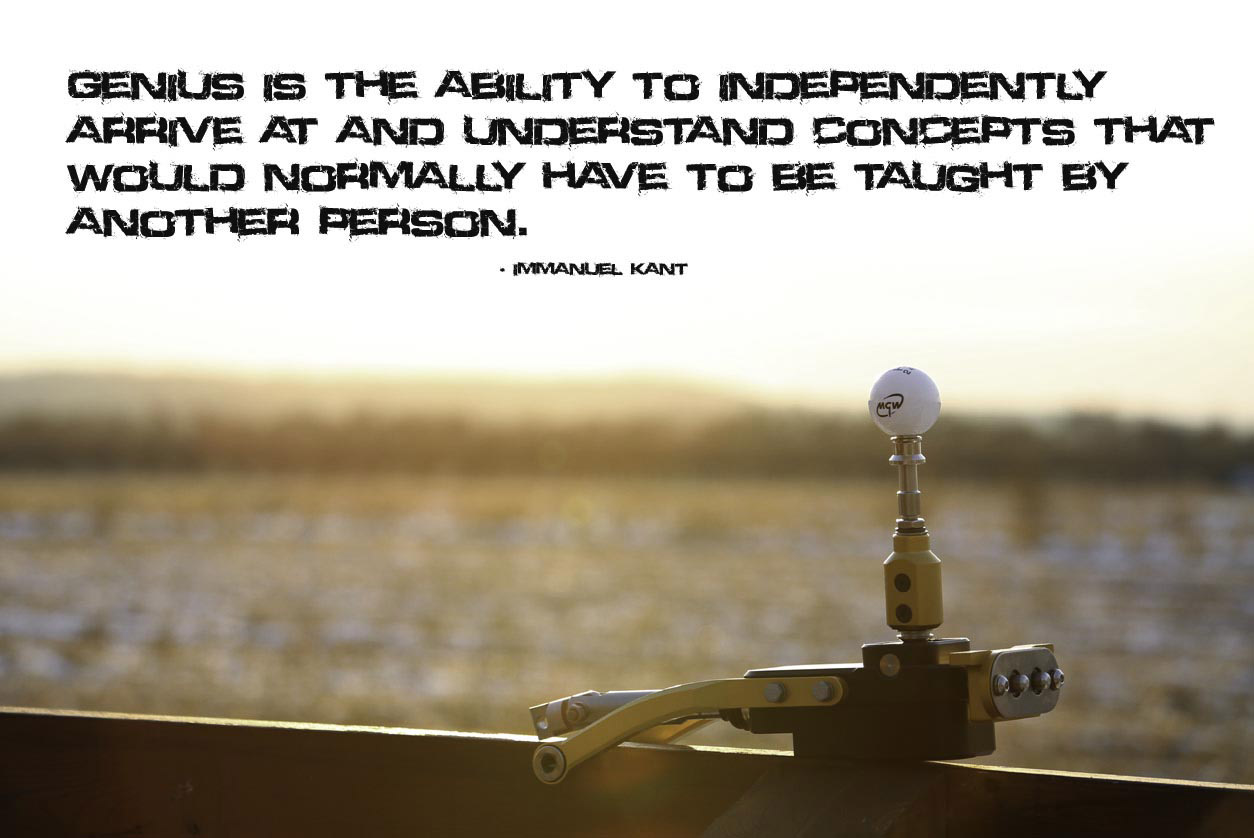

SVTP has an endless list of threads related to 2007-2014 GT500 TR6060 shifting issues. Everything but the kitchen sink has been thrown at the factory shifter, clutch, or the transmission itself in an attempt to mitigate shift mechanism woes. The aftermarket did its best to come to the rescue but even that didn't provide the cure. What we've learned is that fast shifts at high rpms are not always met with a high degree of success - and quick ratio shifters have only served to exacerbate the issue. Thankfully, the world still has a few men determined to find a better way when many others have either given up or are content to look the other way. In our case, that man is George Ciamillo of MGW and his latest effort shows just how far outside the box he can think.

George already had a TR6060 shifter that was much improved over the best Ford/Ford Racing had to offer. He improved upon the factory design and was offering a shifter for sale with far greater detail in terms of materials and construction. He went so far as to gain US patents on the design which offered an adjustable throw along with excellent NVH characteristics. He made it look easy. Not having one of his shifters I did my best to take the factory unit to a "heightened" level by dissecting, studying, and implementing fixes where possible.

That's just one box...

Improving upon the factory bushings made a difference as well as eliminating stick isolation. But the one thing that couldn't be improved upon was the "pendulum" design that the factory used on its semi-remote, welded tubular steel assembly. Thankfully, George had an epiphany of sorts and realized there was another way to skin this elusive cat and it involved tossing the pendulum design into the trash and starting over.

So what makes it better?

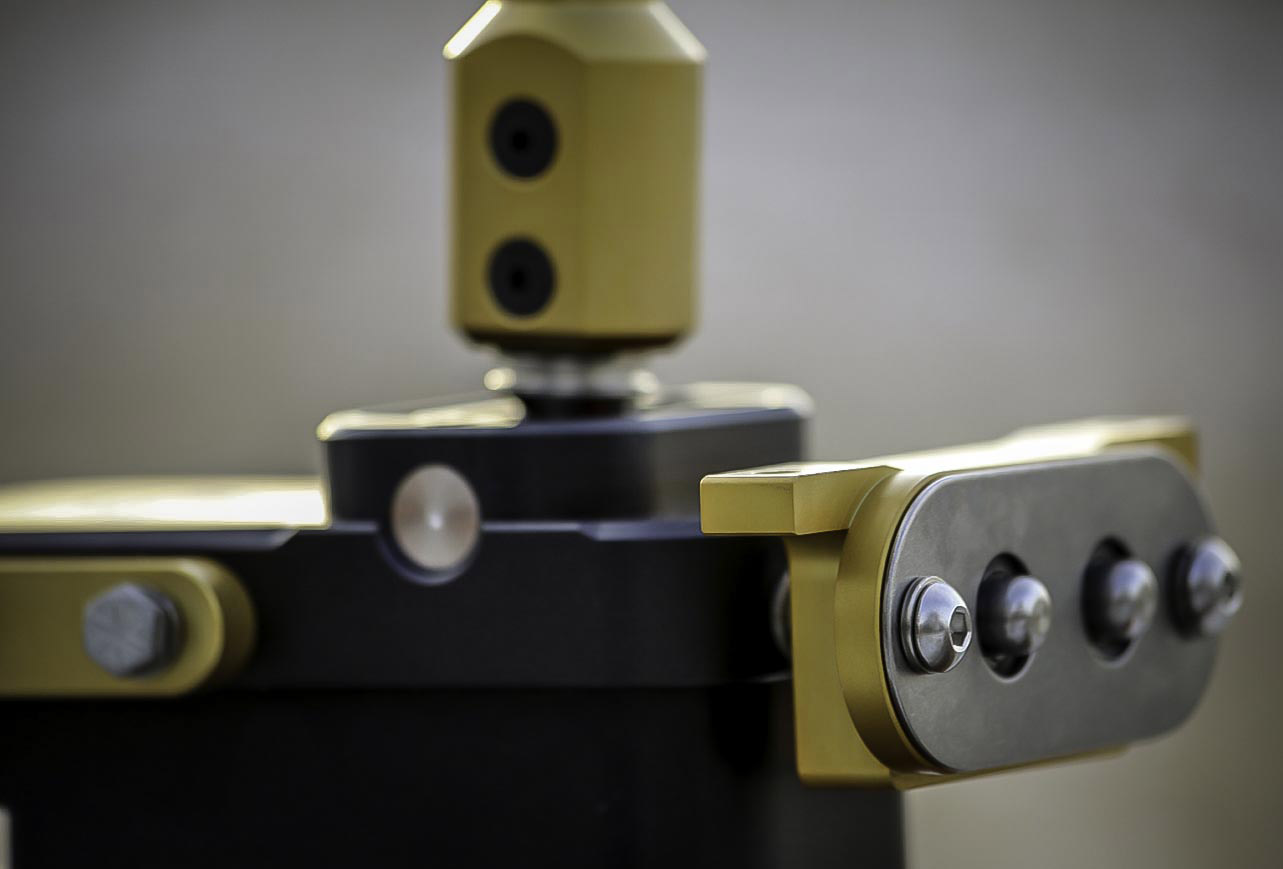

Where do I begin? How about an array of CNC machined billet aluminum and stainless steel throughout? The entire assembly is almost too nice to subject it to the ugliness that resides beneath the typical motor vehicle. But that's where it shines most. Note some of the changes an MGW shifter brings with it.

The rear mount. George ships these works of art with two rear bushings. Installed is the softer of the two with a higher durometer unit included for "track" use. Changing between the two is quick and painless.

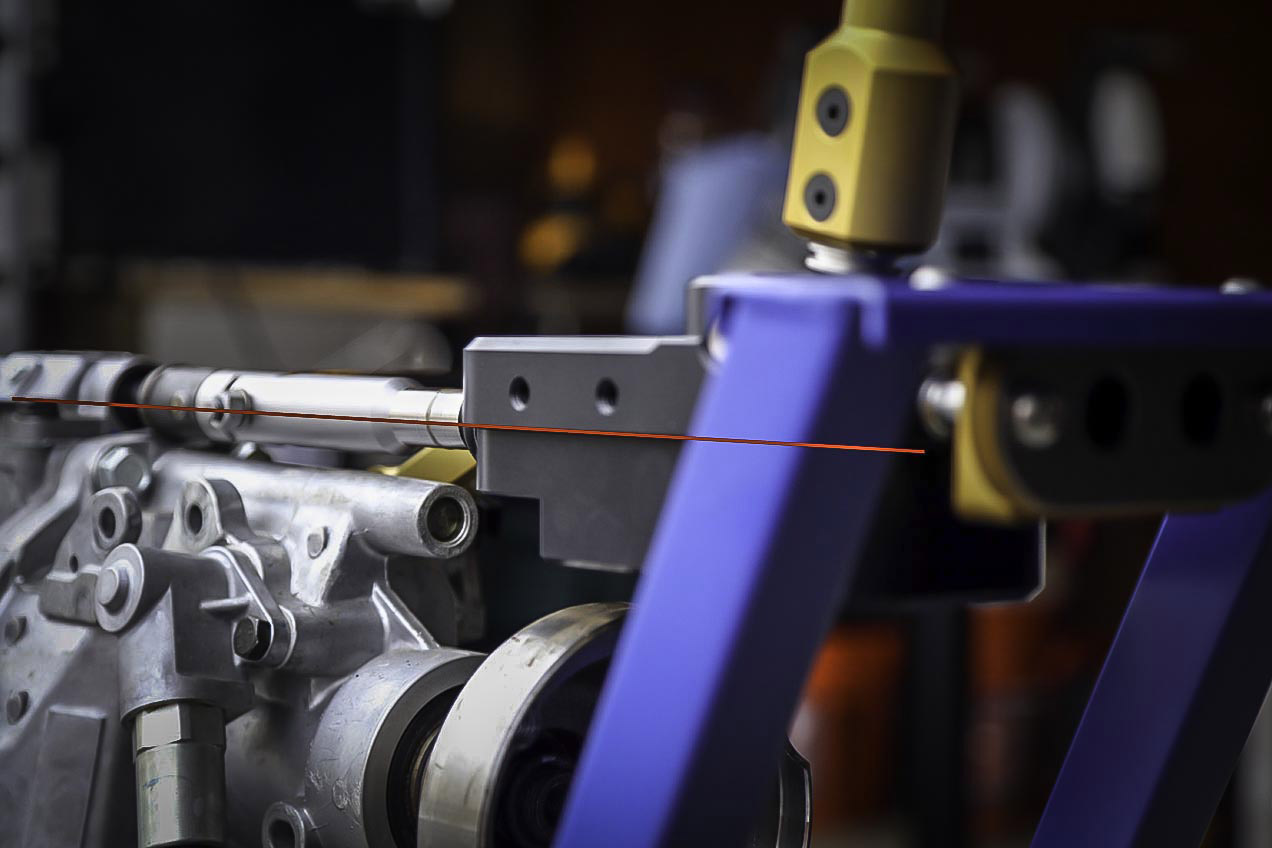

A shift actuating rod that slides fore/aft in a single axis, far simple and more efficient than the factory design.

The red line shows the simplified path that the rod can now follow.

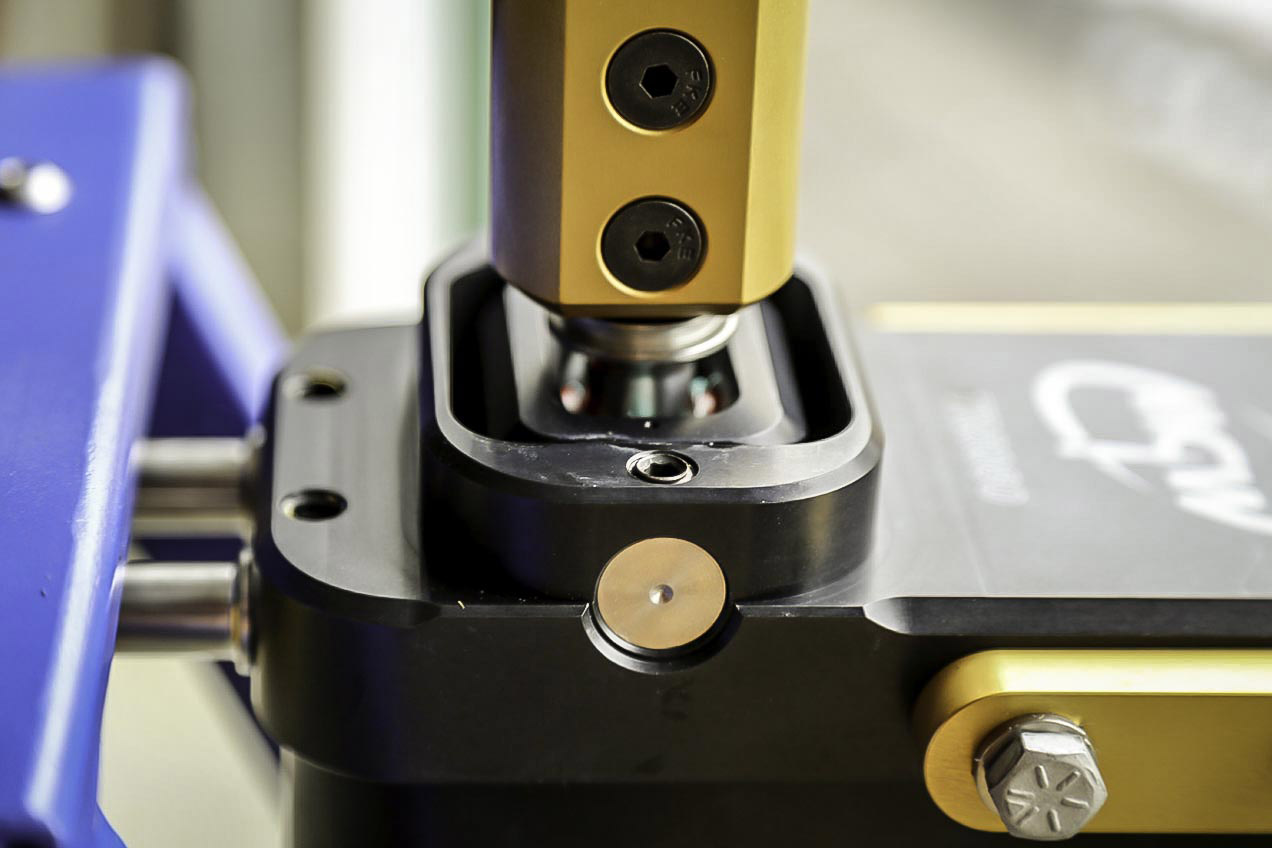

George didn't have to eliminate the isolation at the base of the stick to gain accuracy or "feel." The mechanism internals take care of that. He cleaned up the cluttered factory design and isolated the stick in much better fashion.

The shaft has a seal to keep lubricant inside and moisture from the elements outside.

The much improved bushing design at the front of each arm fit perfectly within the confines of the TR6060 cast-in ears.

The stick and ball exude nothing less than the highest degree of industrial excellence.

For a more detailed look take a look at the video that George and Travis put together.

[video=youtube;DHXYSjOuWzw]https://www.youtube.com/watch?v=DHXYSjOuWzw#t=500[/video]

How difficult is it to install one of these?

I highly encourage anyone contemplating the change to view the following video at least once.

[video=youtube;JO1tqoGXQ2g]https://www.youtube.com/watch?v=JO1tqoGXQ2g[/video]

In my case, I had already pulled a shifter out of my car no less than three times. I had been using FRPP's SVT/KR shifter almost since the car was new and had made bushing changes to firm things up. I'm very familiar with the install but still watched the above video. The challenge for me was that the Whipple I have installed on the engine limits how far back I could tip the engine back/transmission down, restricting available room for my hands as well as tools atop the transmission. Having arms that bolt to the side of the shifter made things much easier than I could have imagined though. I did not have to pull or disconnect the driveshaft or touch the exhaust system in any way.

With the unit in place and the transmission crossmember bolted back up I was able to finish up the install inside. This portion of the install impressed me as much as the shifter itself. George didn't skimp when it came to sealing things up and insulating the cabin from the what goes on underneath the tunnel. After laying down the rubber condensate seal, I dropped the billet and anodized aluminum plate into place and slid the attached boot over the shifter base. The fitment is absolutely perfect.

Same goes for the insulation laid atop the plate.

Consoles differ between years but generally slip back into place with relative ease.

I rather enjoyed finishing up the install of this piece. Everything falls right into place.

Follow George's included note regarding the installation of the shifter ball. Thread it on all the way, then back it off a full turn, and finish by tightening the jam nut with the included wrench. BOOM.

So how does it feel?

You instantly notice how much less lateral movement there both in gear and while in neutral. Fore/aft stick movement is smoother. Diagonal movement (ie, 2nd to 3rd) feels more accurate and much more linear. The shifter ball now resides at a slightly lower elevation than what my previous shifter/stick/ball combination had it at. This is something I really want to get a feel for but I'm a bit climate limited at the moment. I've never been much of a fan of ice racing so my review in that regard will have to be deferred until warmer weather pays my region a visit. I'll add my experience with it here the moment the opportunity arises.

In summation, I honestly can't say enough good things about MGW's newest shifter. The design, materials, fit/finish, all far exceeded my expectations. A huge thanks to George and everyone else at MGW for showing us how good things can be when you try a little harder.

Tob

George already had a TR6060 shifter that was much improved over the best Ford/Ford Racing had to offer. He improved upon the factory design and was offering a shifter for sale with far greater detail in terms of materials and construction. He went so far as to gain US patents on the design which offered an adjustable throw along with excellent NVH characteristics. He made it look easy. Not having one of his shifters I did my best to take the factory unit to a "heightened" level by dissecting, studying, and implementing fixes where possible.

That's just one box...

Improving upon the factory bushings made a difference as well as eliminating stick isolation. But the one thing that couldn't be improved upon was the "pendulum" design that the factory used on its semi-remote, welded tubular steel assembly. Thankfully, George had an epiphany of sorts and realized there was another way to skin this elusive cat and it involved tossing the pendulum design into the trash and starting over.

So what makes it better?

Where do I begin? How about an array of CNC machined billet aluminum and stainless steel throughout? The entire assembly is almost too nice to subject it to the ugliness that resides beneath the typical motor vehicle. But that's where it shines most. Note some of the changes an MGW shifter brings with it.

The rear mount. George ships these works of art with two rear bushings. Installed is the softer of the two with a higher durometer unit included for "track" use. Changing between the two is quick and painless.

A shift actuating rod that slides fore/aft in a single axis, far simple and more efficient than the factory design.

The red line shows the simplified path that the rod can now follow.

George didn't have to eliminate the isolation at the base of the stick to gain accuracy or "feel." The mechanism internals take care of that. He cleaned up the cluttered factory design and isolated the stick in much better fashion.

The shaft has a seal to keep lubricant inside and moisture from the elements outside.

The much improved bushing design at the front of each arm fit perfectly within the confines of the TR6060 cast-in ears.

The stick and ball exude nothing less than the highest degree of industrial excellence.

For a more detailed look take a look at the video that George and Travis put together.

[video=youtube;DHXYSjOuWzw]https://www.youtube.com/watch?v=DHXYSjOuWzw#t=500[/video]

How difficult is it to install one of these?

I highly encourage anyone contemplating the change to view the following video at least once.

[video=youtube;JO1tqoGXQ2g]https://www.youtube.com/watch?v=JO1tqoGXQ2g[/video]

In my case, I had already pulled a shifter out of my car no less than three times. I had been using FRPP's SVT/KR shifter almost since the car was new and had made bushing changes to firm things up. I'm very familiar with the install but still watched the above video. The challenge for me was that the Whipple I have installed on the engine limits how far back I could tip the engine back/transmission down, restricting available room for my hands as well as tools atop the transmission. Having arms that bolt to the side of the shifter made things much easier than I could have imagined though. I did not have to pull or disconnect the driveshaft or touch the exhaust system in any way.

With the unit in place and the transmission crossmember bolted back up I was able to finish up the install inside. This portion of the install impressed me as much as the shifter itself. George didn't skimp when it came to sealing things up and insulating the cabin from the what goes on underneath the tunnel. After laying down the rubber condensate seal, I dropped the billet and anodized aluminum plate into place and slid the attached boot over the shifter base. The fitment is absolutely perfect.

Same goes for the insulation laid atop the plate.

Consoles differ between years but generally slip back into place with relative ease.

I rather enjoyed finishing up the install of this piece. Everything falls right into place.

Follow George's included note regarding the installation of the shifter ball. Thread it on all the way, then back it off a full turn, and finish by tightening the jam nut with the included wrench. BOOM.

So how does it feel?

You instantly notice how much less lateral movement there both in gear and while in neutral. Fore/aft stick movement is smoother. Diagonal movement (ie, 2nd to 3rd) feels more accurate and much more linear. The shifter ball now resides at a slightly lower elevation than what my previous shifter/stick/ball combination had it at. This is something I really want to get a feel for but I'm a bit climate limited at the moment. I've never been much of a fan of ice racing so my review in that regard will have to be deferred until warmer weather pays my region a visit. I'll add my experience with it here the moment the opportunity arises.

In summation, I honestly can't say enough good things about MGW's newest shifter. The design, materials, fit/finish, all far exceeded my expectations. A huge thanks to George and everyone else at MGW for showing us how good things can be when you try a little harder.

Tob