I'm in process of swapping to a 26 Spline input..

The first issue, is that my D&D input did not come with a bearing. I have found the part number "M88048-10R" Can anyone verify this?

Next I suppose I can walk you guys through what i've done.. some input would be great.. I just want to make sure I'm doing this right!

To start with, I have a pretty nice magnetic base and mount that I borrowed from work... It's a NOGA unit, one knob in the arms tightens all three joints. One knob tightens the end pivot point, and another knob is a "fine adjustment" that allows you to slowly move the head after everything is tight. I'm using an SPi contact indicator. Both seem to be great products... Much nicer than another setup I was going to try to use... .

I have read that end play should be .000 - .002. (inches correct?) This would convert to .00 - .05mm. I assume this is shaft direction (" end and out") ? How much side-to-side or up-and-down play should there be? I expected to see none, but to be honest I can pull upwards on the shaft and see a considerable amount of play when measured with the stock 10 spline. (.50-.80mm) 0.019 - 0.03" ... This seems bad but I never had any issues... ?

With the front cover bolts removed, the old input shaft easily came out.. At this point I was careful to remove the shaft so that I could take note of how the (blocking ring?) was sitting on the shaft. Turns out you really can't screw that up as it has notches that mate up. (the teeth point toward the front)

Looking at the stock throwout bearing sleeve, I can see where the bearing rode on the shaft, but when cleaning it off there doesn't seem to be any damage or heavy marks. I plan to re-use the stock sleeve:

And... Thats about as far as I got... It's apart, I just don' have a bearing on the new shaft to continue... Any advice on pressing on the new bearing? I really don't want to screw up my new input shaft. I had planned to buy the bearing from napa, take the shaft + bearing to work and using a larger press I would place the input shaft with shaft facing upward ( likely supported by the gear on each side with the "race" hanging through) .. then using a pipe similar in size to the bearing slowly press it on to the shaft... Input / advice?

Stock 10 spline input endplay:

I hadn't taken the race out of the front cover, but I assume the shims go here behind the race?

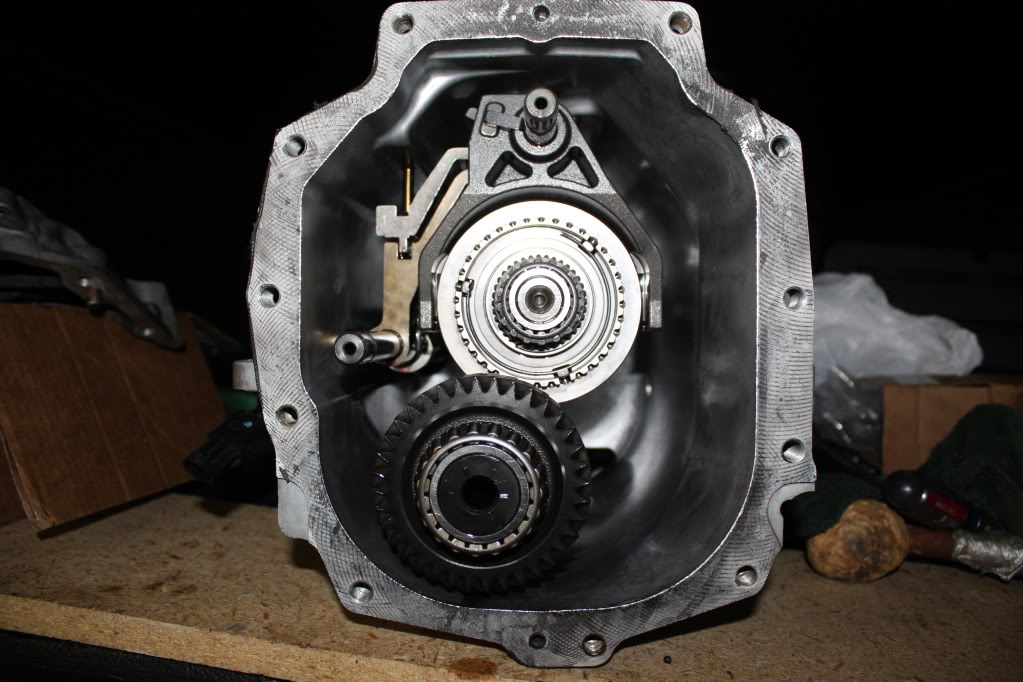

The clutch going in it... hopefully it'l work out okay!

The first issue, is that my D&D input did not come with a bearing. I have found the part number "M88048-10R" Can anyone verify this?

Next I suppose I can walk you guys through what i've done.. some input would be great.. I just want to make sure I'm doing this right!

To start with, I have a pretty nice magnetic base and mount that I borrowed from work... It's a NOGA unit, one knob in the arms tightens all three joints. One knob tightens the end pivot point, and another knob is a "fine adjustment" that allows you to slowly move the head after everything is tight. I'm using an SPi contact indicator. Both seem to be great products... Much nicer than another setup I was going to try to use... .

I have read that end play should be .000 - .002. (inches correct?) This would convert to .00 - .05mm. I assume this is shaft direction (" end and out") ? How much side-to-side or up-and-down play should there be? I expected to see none, but to be honest I can pull upwards on the shaft and see a considerable amount of play when measured with the stock 10 spline. (.50-.80mm) 0.019 - 0.03" ... This seems bad but I never had any issues... ?

With the front cover bolts removed, the old input shaft easily came out.. At this point I was careful to remove the shaft so that I could take note of how the (blocking ring?) was sitting on the shaft. Turns out you really can't screw that up as it has notches that mate up. (the teeth point toward the front)

Looking at the stock throwout bearing sleeve, I can see where the bearing rode on the shaft, but when cleaning it off there doesn't seem to be any damage or heavy marks. I plan to re-use the stock sleeve:

And... Thats about as far as I got... It's apart, I just don' have a bearing on the new shaft to continue... Any advice on pressing on the new bearing? I really don't want to screw up my new input shaft. I had planned to buy the bearing from napa, take the shaft + bearing to work and using a larger press I would place the input shaft with shaft facing upward ( likely supported by the gear on each side with the "race" hanging through) .. then using a pipe similar in size to the bearing slowly press it on to the shaft... Input / advice?

Stock 10 spline input endplay:

I hadn't taken the race out of the front cover, but I assume the shims go here behind the race?

The clutch going in it... hopefully it'l work out okay!

Last edited: