I thought it would be nice to data log boost & vacuum and see exactly how the car is doing. Obviously just glancing at a gauge here and there only tells you so much.

So I picked up a 3 BAR GM MAP sensor and started playing around. Testing the voltages and seeing how they behave.

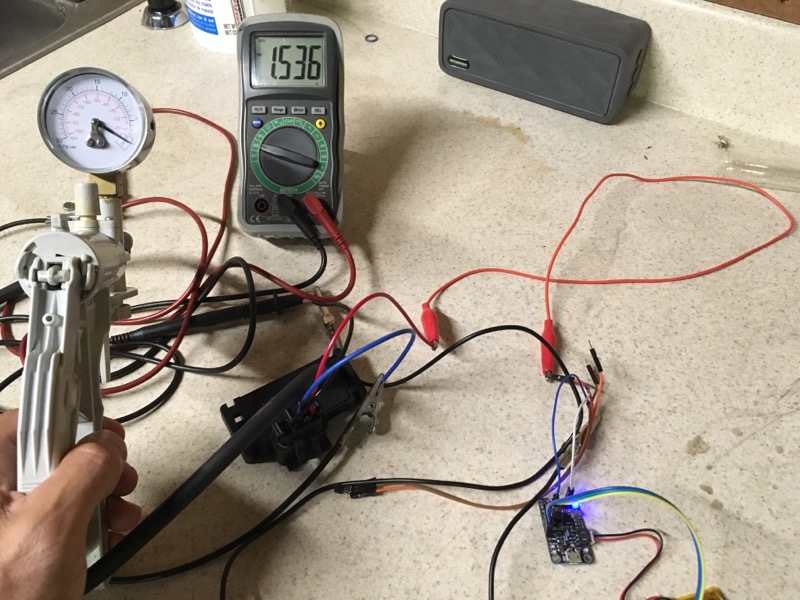

What I found was very interesting. Zero pressure or just atmospheric pressure doesn't give zero volts. For me about 1.55 volts. Curious how these work I did a little reading and found there's a silicon wafer slice in there with a perfect vacuum on one side of it. So anything other than a perfect vacuum on the other side gives a reading. They output between 0-5 volts. 0 volts been perfect vacuum and 5 volts been 3 bar. 3 bar been 43.5 PSI. Max reading is actually 45.7 PSI. Sounds overkill but wait here's why.

The atmosphere pushes down with 14.7 PSI of pressure so really the max reading of the sensor would be 45.7 PSI subtract 14.7 atmosphere for 31 PSI actual boost in your manifold pressure.

The specs I could find for the sensor were in KPA. So I threw it in a spreadsheet and converted to PSI, then to PSI corrected as I labeled it which takes into account the 14.7 PSI atmosphere and then finally for values in vacuum I converted from PSI to inches of vacuum which is what we're used to seeing and working with. Turned out like this.

Next I did some calibration testing to make sure the values I was data logging on the computer matched the readings on the laptop in both boost and vacuum. The help of an air compressor regulator right there for boost and the hand held vacuum pump you see up top for vacuum readings.

I then wired the sensor behind the glove box and tee'd into the existing boost line right there that feeds the factory boost gauge on the dash. Works like magic.

Here's just a quick randomly chosen tiny excerpt from a pretty big 37 minute long data log driving around testing various things.

Green is throttle position

Yellow is RPM (jittery because I had spark blow out on that pull)

Purple is boost

Notice how my boost slightly fades off with RPM. That's about a 1 PSI fade down there. That first peak you see is 2nd gear from 4200 RPM to 5600 RPM. To me that shows the blower is to small for my setup, that's a whole different topic.

So its quit interesting having boost on the logs now. So much to learn and look at going forward. I find it very interesting anyways.

So I picked up a 3 BAR GM MAP sensor and started playing around. Testing the voltages and seeing how they behave.

What I found was very interesting. Zero pressure or just atmospheric pressure doesn't give zero volts. For me about 1.55 volts. Curious how these work I did a little reading and found there's a silicon wafer slice in there with a perfect vacuum on one side of it. So anything other than a perfect vacuum on the other side gives a reading. They output between 0-5 volts. 0 volts been perfect vacuum and 5 volts been 3 bar. 3 bar been 43.5 PSI. Max reading is actually 45.7 PSI. Sounds overkill but wait here's why.

The atmosphere pushes down with 14.7 PSI of pressure so really the max reading of the sensor would be 45.7 PSI subtract 14.7 atmosphere for 31 PSI actual boost in your manifold pressure.

The specs I could find for the sensor were in KPA. So I threw it in a spreadsheet and converted to PSI, then to PSI corrected as I labeled it which takes into account the 14.7 PSI atmosphere and then finally for values in vacuum I converted from PSI to inches of vacuum which is what we're used to seeing and working with. Turned out like this.

Next I did some calibration testing to make sure the values I was data logging on the computer matched the readings on the laptop in both boost and vacuum. The help of an air compressor regulator right there for boost and the hand held vacuum pump you see up top for vacuum readings.

I then wired the sensor behind the glove box and tee'd into the existing boost line right there that feeds the factory boost gauge on the dash. Works like magic.

Here's just a quick randomly chosen tiny excerpt from a pretty big 37 minute long data log driving around testing various things.

Green is throttle position

Yellow is RPM (jittery because I had spark blow out on that pull)

Purple is boost

Notice how my boost slightly fades off with RPM. That's about a 1 PSI fade down there. That first peak you see is 2nd gear from 4200 RPM to 5600 RPM. To me that shows the blower is to small for my setup, that's a whole different topic.

So its quit interesting having boost on the logs now. So much to learn and look at going forward. I find it very interesting anyways.

Last edited: