You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boss 302 Quad Pipes on a GT500

- Thread starter Tob

- Start date

Tob must be the "Special Project Specialist" for the GT500. Glad he is own our side. I know the project will be great as usual.....

I went out to the shop to put the front fascia back on the car. So I grabbed a Weight scale and brought it with me as well. I cannot believe how much the stock Boss mufflers weigh (each)...

Twenty one point eight pounds. Wow, those are some fatass mufflers! I suspect the stock '10-'12 GT500 mufflers are very similar. For reference, here's what my stock '09 GT500 mufflers weighed

And the KR's that replaced them

Twenty one point eight pounds. Wow, those are some fatass mufflers! I suspect the stock '10-'12 GT500 mufflers are very similar. For reference, here's what my stock '09 GT500 mufflers weighed

And the KR's that replaced them

I've been picking at this during my spare time. Most of it has been research. I always try to see how far down it is before jump...

I figured it made sense to locate the quad pipe exit first, then work my way back to the 5.4 H/X pipe connection. I found a gentleman on "The Mustang Source" willing to take a couple of shots of the exit/chassis connection on his Boss 302 for me...

Same connection on each side of the 2012 Boss 302, a nut located just aft of a longer oblong hole with the nut located up and inside the rocker. A quick look at the same location on my '09 chassis...

I have neither hole, fore or aft ('11 and later GT500 owners - do you have these threaded holes?). Then I remembered I had seen a photo that showed a '12 Boss that looked a little different. I searched and found a photo of an early Boss that was displayed on its side at a Woodward Dream cruise. Zooming in and studying the affected area closely, I saw that Ford had welded a nut to the underside of the rocker at this critical junction

Mulling it over for awhile, I figured I could mimic that or...drill a hole and invert a nut with integral washer assembly by slipping it up through the oblong hole and dropping the nut portion down. A tack and I'd be done.

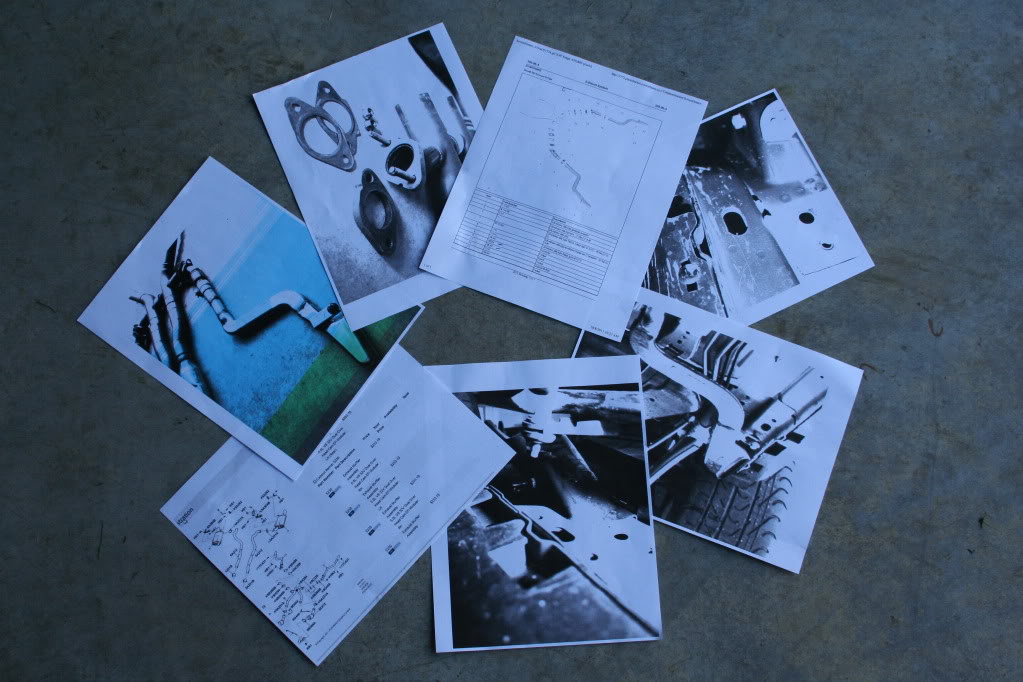

Either way, I visited my local Ford dealer parts desk. The guys there are great and always take their time to help me out. I made sure I brought some backup with me to try to simplify things

I was surprised at how I was able to provide clearer data/illustrations than what they had at their disposal. Ambiguous wording, no specific Boss 302 exhaust listings (once again, you search through 5.0 GT entries to find Boss parts), and photos that are less than clear. My parts guy told me that Ford uses different verbage between service manuals and what they have at their fingertips. I stood there and he showed me the monitor all the while so that I could see how screwed up the system is when searching for somewhat "unique" parts. In any case, we could not find a clear view of a '12 chassis that showed the inverted nut that supports the exit point, nor could we find a shot/part number for the early development welded nut below the rocker.

Again, no biggie, I'd just have to do it my way instead of being able to use a factory part.

Since I'll be fabricating the short run of pipe from the H-pipe to the flanged connection (where the quad pipes begin), I needed a few things. I had planned on cutting my own flanges from some flat stock until I noticed that Ford included a spacer plate (Ford engineers allegedly included this so that Boss owners can bolt in a cut out system and just toss the spacer plate) that gets sandwiched between two other flanges, as well as steel gaskets, etc.

The plate is thick enough that I can weld some 2" pipe inside it just like the factory piece uses.

I also happened to be using some stainless shim stock (1/8") at work that I can use to make my own exhaust discs, each set with progressively larger hole diameters.

As to the short run of 2" tubing that I need for each side, I visited a few parts counters followed by some local exhaust shops. I struck out at each. Nobody uses stainless tubing when they replace newer systems (aside from using factory parts from Ford), just aluminized steel at best. Scouring the web, I found and ordered some T304 stainless tubing from Vibrant Performance. I ordered a length that includes bends in it so that I can weld everything up and be done with it.

I was going to drill/weld in a nut on each side and quickly realized that the GT500 rock deflector has to be removed (Ford never installed them on Boss exhaust systems either). Three fasteners on each side and they are off quickly.

Laying on my back and holding a quad pipe in the general area it will soon reside in, I noticed that the connection I need to add at my factory H/X pipe is not exactly lined up with the crossover portion but instead closer to the front of the car. I figured I could cut open or tweak the system and shorten it to my liking. I unbolted the clamp that releases the flex pipe/flanged section, figuring I could nip one or the other a minor amount...

Note the restrictive, emasculated section in the middle of the following shot...

The quad pipe tubes neck down to an approximately 1-3/4" pipe (just prior to the flattened 1" tall section, cripes!) diameter. Funky, and different than the quad pipes I had seen in early Ford media shots. Notice the longer flex section in the following shot as well as the fact that it doesn't go through as many diameter changes. The 1/2" flange spacer is missing as well...

Why would Ford make so many detail changes in what should be a simple section of exhaust pipe? Were they addressing supplier issues or maybe they were still fine tuning the tone from the system. Hmm, well looky at what I found inside the 1-3/4" section...

I thought "You're kidding me. Looks like a muffler baffle from a Briggs and Stratton engine on a Sears lawn mower had been jammed into the pipe. And at 4" long, why? Was the pipe too damn loud without it? I thought that was what the removable restrictor plate was for. WTF..."

Coloncam time! El clicko...

That baffle knocks the ID of the quad pipe down to 13/16"! Faced with with making a choice at this point, I punted, as I want time to think this thing over. I can simply cut out the baffle and weld in a section of stainless tube. That might upset the balance, having much of the pre-muffler exhaust bellowing out the side while the remaining exhaust exits fairly quietly out the back. It also might backfire like a bitch, I dunno. I could restrict the sound with varying plates or the electric cutout from Quick Time Performance. Or it may sound like ass no matter what I do. I may leave it in...

I just can't believe how small that tubing is restricted to. More when my stainless tubing arrives.

I figured it made sense to locate the quad pipe exit first, then work my way back to the 5.4 H/X pipe connection. I found a gentleman on "The Mustang Source" willing to take a couple of shots of the exit/chassis connection on his Boss 302 for me...

Same connection on each side of the 2012 Boss 302, a nut located just aft of a longer oblong hole with the nut located up and inside the rocker. A quick look at the same location on my '09 chassis...

I have neither hole, fore or aft ('11 and later GT500 owners - do you have these threaded holes?). Then I remembered I had seen a photo that showed a '12 Boss that looked a little different. I searched and found a photo of an early Boss that was displayed on its side at a Woodward Dream cruise. Zooming in and studying the affected area closely, I saw that Ford had welded a nut to the underside of the rocker at this critical junction

Mulling it over for awhile, I figured I could mimic that or...drill a hole and invert a nut with integral washer assembly by slipping it up through the oblong hole and dropping the nut portion down. A tack and I'd be done.

Either way, I visited my local Ford dealer parts desk. The guys there are great and always take their time to help me out. I made sure I brought some backup with me to try to simplify things

I was surprised at how I was able to provide clearer data/illustrations than what they had at their disposal. Ambiguous wording, no specific Boss 302 exhaust listings (once again, you search through 5.0 GT entries to find Boss parts), and photos that are less than clear. My parts guy told me that Ford uses different verbage between service manuals and what they have at their fingertips. I stood there and he showed me the monitor all the while so that I could see how screwed up the system is when searching for somewhat "unique" parts. In any case, we could not find a clear view of a '12 chassis that showed the inverted nut that supports the exit point, nor could we find a shot/part number for the early development welded nut below the rocker.

Again, no biggie, I'd just have to do it my way instead of being able to use a factory part.

Since I'll be fabricating the short run of pipe from the H-pipe to the flanged connection (where the quad pipes begin), I needed a few things. I had planned on cutting my own flanges from some flat stock until I noticed that Ford included a spacer plate (Ford engineers allegedly included this so that Boss owners can bolt in a cut out system and just toss the spacer plate) that gets sandwiched between two other flanges, as well as steel gaskets, etc.

The plate is thick enough that I can weld some 2" pipe inside it just like the factory piece uses.

I also happened to be using some stainless shim stock (1/8") at work that I can use to make my own exhaust discs, each set with progressively larger hole diameters.

As to the short run of 2" tubing that I need for each side, I visited a few parts counters followed by some local exhaust shops. I struck out at each. Nobody uses stainless tubing when they replace newer systems (aside from using factory parts from Ford), just aluminized steel at best. Scouring the web, I found and ordered some T304 stainless tubing from Vibrant Performance. I ordered a length that includes bends in it so that I can weld everything up and be done with it.

I was going to drill/weld in a nut on each side and quickly realized that the GT500 rock deflector has to be removed (Ford never installed them on Boss exhaust systems either). Three fasteners on each side and they are off quickly.

Laying on my back and holding a quad pipe in the general area it will soon reside in, I noticed that the connection I need to add at my factory H/X pipe is not exactly lined up with the crossover portion but instead closer to the front of the car. I figured I could cut open or tweak the system and shorten it to my liking. I unbolted the clamp that releases the flex pipe/flanged section, figuring I could nip one or the other a minor amount...

Note the restrictive, emasculated section in the middle of the following shot...

The quad pipe tubes neck down to an approximately 1-3/4" pipe (just prior to the flattened 1" tall section, cripes!) diameter. Funky, and different than the quad pipes I had seen in early Ford media shots. Notice the longer flex section in the following shot as well as the fact that it doesn't go through as many diameter changes. The 1/2" flange spacer is missing as well...

Why would Ford make so many detail changes in what should be a simple section of exhaust pipe? Were they addressing supplier issues or maybe they were still fine tuning the tone from the system. Hmm, well looky at what I found inside the 1-3/4" section...

I thought "You're kidding me. Looks like a muffler baffle from a Briggs and Stratton engine on a Sears lawn mower had been jammed into the pipe. And at 4" long, why? Was the pipe too damn loud without it? I thought that was what the removable restrictor plate was for. WTF..."

Coloncam time! El clicko...

That baffle knocks the ID of the quad pipe down to 13/16"! Faced with with making a choice at this point, I punted, as I want time to think this thing over. I can simply cut out the baffle and weld in a section of stainless tube. That might upset the balance, having much of the pre-muffler exhaust bellowing out the side while the remaining exhaust exits fairly quietly out the back. It also might backfire like a bitch, I dunno. I could restrict the sound with varying plates or the electric cutout from Quick Time Performance. Or it may sound like ass no matter what I do. I may leave it in...

I just can't believe how small that tubing is restricted to. More when my stainless tubing arrives.

Last edited:

Keep us posted

I don't care how it would sound, 13/16" is ridiculous. That would be getting cut out of my car in a heartbeat!

what's the point in worrying about that? like you said from the start Tob, this is purely about sound, not adding power. how much flow would you actually get out of those pipes anyways, that resonator section being there or not? i certainly wouldn't expect that 13/16" section to make any worthwhile flow difference when you have a long piece of 1" square tubing following it. at minimum, i would think that you would want to get this system fabbed up and give it a test run with the completely stock side pipes before you would even think about cutting that resonator section out. way more risk of hurting your sound than helping it by cutting that section out before trying it IMO.

BTW, everyone make note that this mod is being done by the same guy who said that he didn't like the quad tips that'll show up on the 2013 GT500 because of the added weight

really though, love this mod, can't wait to hear what this sounds like on a GT500:beer:

BTW, everyone make note that this mod is being done by the same guy who said that he didn't like the quad tips that'll show up on the 2013 GT500 because of the added weight

really though, love this mod, can't wait to hear what this sounds like on a GT500:beer:

Good luck with the install. Your work and imagination is incredible.

Thanks Ted. Good to hear from you!

Ry, you echo the voices in my head. The reaffirmation is welcomed. Regarding my '13 comments, they are in the context of my hopes that Ford continues to starve their top dog and continue down the path of raw, brute strength. I suspect the car will waver back in forth in an Oprah-like, excess blubber battle.

Regarding the weight of the quad pipes...I couldn't get a reading when I placed one on my digital scale. I even laid both pipes on the scale and it still wouldn't register. They really are very light.

Ry, you echo the voices in my head. The reaffirmation is welcomed. Regarding my '13 comments, they are in the context of my hopes that Ford continues to starve their top dog and continue down the path of raw, brute strength. I suspect the car will waver back in forth in an Oprah-like, excess blubber battle.

Regarding the weight of the quad pipes...I couldn't get a reading when I placed one on my digital scale. I even laid both pipes on the scale and it still wouldn't register. They really are very light.

Unusually warm weather was the motivation behind taking care of a small but rather important detail today - the rear mounting point. One too many bowls of Lucky Charms resulted in an extended sitting in the "library" and provided an inspirational solution...

I decided to drill the rocker and then weld in a nut, giving me a similar fastening juncture as the '12 Boss offers up. Whipping out my favorite tool as of late, a hand grinder with a 4" cutting disc, I ground down the points of a flanged nut. That way I wouldn't have to drill out as large of a hole to fit the nut into.

I tried to fit everything so that the nut would have a nice, snug fit when pulled through the hole from the top and welded in place. I verified fitment by slipping the nut up from the bottom...

Satisfied with mock up, I removed the surrounding area of paint and then slipped the ground nuts up into the oblong hole and maneuvered them down into their respective drilled holes.

Shielding the gas tanks and tires with my deflector of choice, I aimed light onto the work area to help see where I needed to weld. Hood in place, I laid on my back and fused everything together...

Once welded, I scuffed the work area and hit it with some primer...

Now I can bolt the exit end of the pipe into place, as factory. When the stainless pipe I ordered up comes in I'll get to work on the other end.

Tob

I decided to drill the rocker and then weld in a nut, giving me a similar fastening juncture as the '12 Boss offers up. Whipping out my favorite tool as of late, a hand grinder with a 4" cutting disc, I ground down the points of a flanged nut. That way I wouldn't have to drill out as large of a hole to fit the nut into.

I tried to fit everything so that the nut would have a nice, snug fit when pulled through the hole from the top and welded in place. I verified fitment by slipping the nut up from the bottom...

Satisfied with mock up, I removed the surrounding area of paint and then slipped the ground nuts up into the oblong hole and maneuvered them down into their respective drilled holes.

Shielding the gas tanks and tires with my deflector of choice, I aimed light onto the work area to help see where I needed to weld. Hood in place, I laid on my back and fused everything together...

Once welded, I scuffed the work area and hit it with some primer...

Now I can bolt the exit end of the pipe into place, as factory. When the stainless pipe I ordered up comes in I'll get to work on the other end.

Tob

Last edited:

Outstanding! Interested in the final results.

Once in awhile the stars align perfectly - the wife caught our elusive Fedex guy before he could speed off with the pipe I've been waiting patiently for and my Ford parts guy called to say my stuff had come in. I couldn't wait to see the two mesh.

I needed some 2" OD stainless tubing to fab up the short, radiused and flanged stubs to weld onto my existing "H" pipe, to then be able to bolt on the quad pipes from the Boss exhaust system. I found Vibrant Performance online and chose a length of pipe with a few mandrel bends as well as some straight sections that would allow me to come up with the shape needed to join everything together. I chose this pipe. Foreign sourced but I must admit - the pipe is beautiful.

Thick walled T304 with the stamp inside the pipe. The inside of the pipe is the smoothest metallic surface I've ever dragged my fingertip across.

Again, the idea is to fit the 2" pipe inside a pair of Ford's 'spacers' essentially crating a flanged pipe. And while the system I have already came with two of these, I wanted to start off with a fresh and clean pair to fuse to the Vibrant 2" pipe.

What a relief to see that I had based my order on the proper dimensions. The fit between the two could not have been better...

I'll have to cope one end of a specific section of that pipe and weld that flange to the other end. Drill my H-pipe with a hole saw and then weld the coped end to it. I purchased some new OEM Ford steel shim gaskets so that I'll get a factory seal as well.

While I'm fairly certain I won't be using them for long, I wanted to start with the factory noise restrictor plates and see how that sounds. I'll either drill them out or toss them altogether

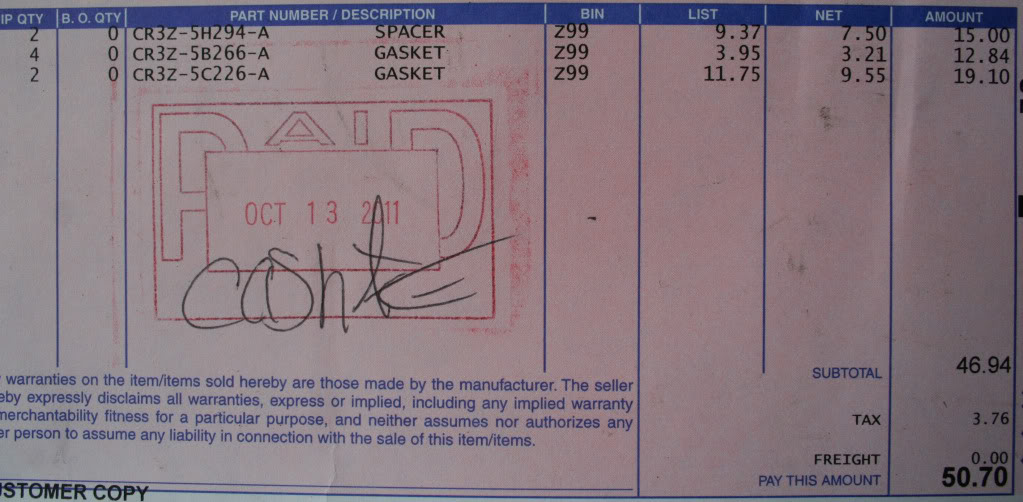

This is what I paid at the dealer for the factory Boss hardware

I paid $52 plus tax and shipping for the mandrel bent section of pipe from Vibrant as well.

I also picked up some hardened and oil quenched bolts from my favorite local commercial fastener supplier.

I now have pretty much everything I need (aside from time) to finish this project. If no other matters prevent me from doing it I should be able to complete this project this weekend. I can't wait to weld/bolt everything up and finally turn the key!

I needed some 2" OD stainless tubing to fab up the short, radiused and flanged stubs to weld onto my existing "H" pipe, to then be able to bolt on the quad pipes from the Boss exhaust system. I found Vibrant Performance online and chose a length of pipe with a few mandrel bends as well as some straight sections that would allow me to come up with the shape needed to join everything together. I chose this pipe. Foreign sourced but I must admit - the pipe is beautiful.

Thick walled T304 with the stamp inside the pipe. The inside of the pipe is the smoothest metallic surface I've ever dragged my fingertip across.

Again, the idea is to fit the 2" pipe inside a pair of Ford's 'spacers' essentially crating a flanged pipe. And while the system I have already came with two of these, I wanted to start off with a fresh and clean pair to fuse to the Vibrant 2" pipe.

What a relief to see that I had based my order on the proper dimensions. The fit between the two could not have been better...

I'll have to cope one end of a specific section of that pipe and weld that flange to the other end. Drill my H-pipe with a hole saw and then weld the coped end to it. I purchased some new OEM Ford steel shim gaskets so that I'll get a factory seal as well.

While I'm fairly certain I won't be using them for long, I wanted to start with the factory noise restrictor plates and see how that sounds. I'll either drill them out or toss them altogether

This is what I paid at the dealer for the factory Boss hardware

I paid $52 plus tax and shipping for the mandrel bent section of pipe from Vibrant as well.

I also picked up some hardened and oil quenched bolts from my favorite local commercial fastener supplier.

I now have pretty much everything I need (aside from time) to finish this project. If no other matters prevent me from doing it I should be able to complete this project this weekend. I can't wait to weld/bolt everything up and finally turn the key!

does all 4 exits run at the same time? would that make it louder or more quiet?

Once in awhile the stars align perfectly - the wife caught our elusive Fedex guy before he could speed off with the pipe I've been waiting patiently...

She's a keeper.

Users who are viewing this thread

Total: 5 (members: 0, guests: 5)