hey, glad i could help in some largely insignificant way, lol. awesome work thus far, your aftermarket quad exhaust mount looks factory! slap some factory paint on there and no one would ever have a clue that the rocker didn't leave the factory that way!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boss 302 Quad Pipes on a GT500

- Thread starter Tob

- Start date

I made sure to paint it a near factory color a few days ago while it was still unseasonably warm. I got called into work today (arrgh) and have to be there. I work for a contractor responsible for a large portion of work at a local hydropower plant that has just started a large upgrade. Fifty mile an hour gusts and rain all day. I can't wait!:banana: :bored:

I probably won't finish now but I'll see what I can get done on Sunday.

I probably won't finish now but I'll see what I can get done on Sunday.

well done.. can't wait to see this complete:beer:

I haven't much time but I did get a little done. I started by mounting the quad pipes at the rear. The added nut worked perfectly.

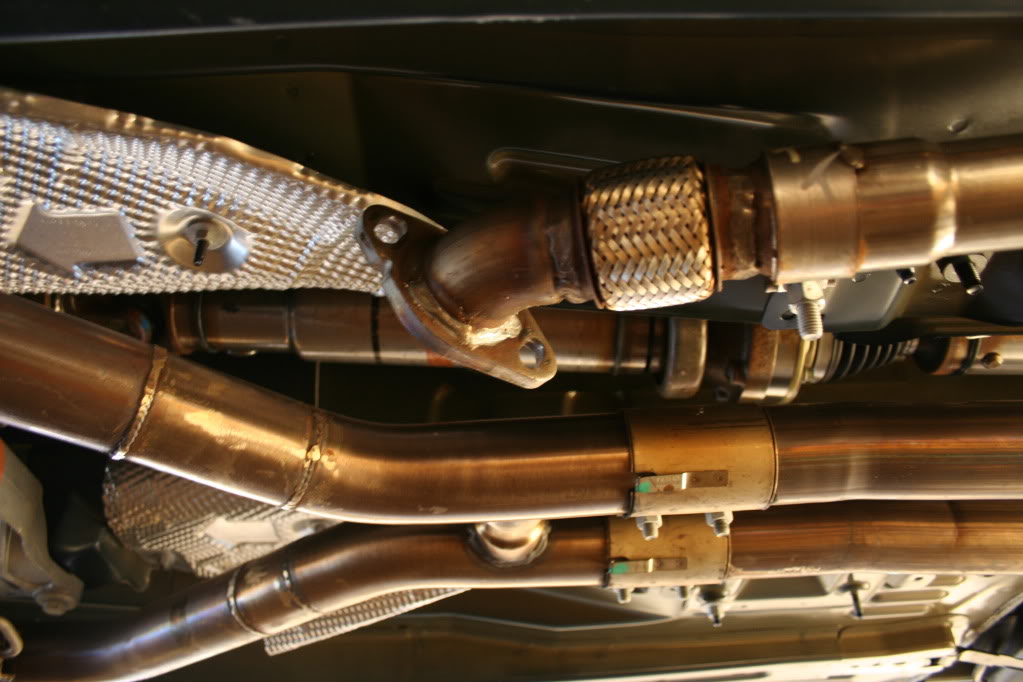

It would seem that the Boss/Coyote H-pipe is forward of the same point on a GT500. When I mocked up the now bolted on pipe, this is where I end up at the front

I decided to shorten the quad pipes (about three inches) in order to keep the "H" centerline running through the quad flanged pipe connection point as well. Otherwise, the stubs I need to weld on would have to carry the exhaust forward. So I started by putting reference marks on everything before disassembling/cutting/welding.

I then measured and made my cuts right at the point where the tiny little muffler begins

Once I had ground the OE welds down I was able to slip one pipe inside the other and then weld each back up

I'm now at the point where I can fab up my flanged H-pipe "stub", mock it up and into position, mark the attachment point, drill out the two new holes, tack everything up, remove the H-pipe and weld fully, reinstall the H-pipe, blah, blah, blah. Tedious, but nowhere near insurmountable.

I think I may end up installing the aforementioned Quick Time Performance's quad pipe cutout. Today I found a thread where a gentleman just finished adding it to his Boss. I like what I see/hear...

[nomedia="http://www.youtube.com/watch?v=RZoLHsOrd-o&feature=player_detailpage"]2012 Boss 302 with QTP Electric Exhaust Cutouts - YouTube[/nomedia]

It would seem that the Boss/Coyote H-pipe is forward of the same point on a GT500. When I mocked up the now bolted on pipe, this is where I end up at the front

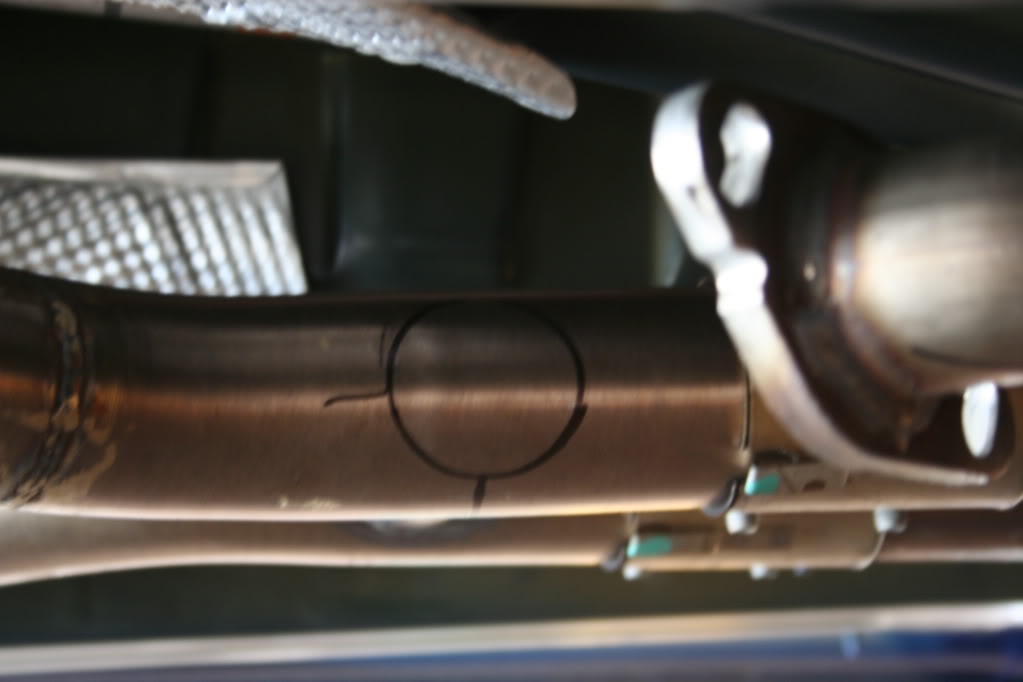

I decided to shorten the quad pipes (about three inches) in order to keep the "H" centerline running through the quad flanged pipe connection point as well. Otherwise, the stubs I need to weld on would have to carry the exhaust forward. So I started by putting reference marks on everything before disassembling/cutting/welding.

I then measured and made my cuts right at the point where the tiny little muffler begins

Once I had ground the OE welds down I was able to slip one pipe inside the other and then weld each back up

I'm now at the point where I can fab up my flanged H-pipe "stub", mock it up and into position, mark the attachment point, drill out the two new holes, tack everything up, remove the H-pipe and weld fully, reinstall the H-pipe, blah, blah, blah. Tedious, but nowhere near insurmountable.

I think I may end up installing the aforementioned Quick Time Performance's quad pipe cutout. Today I found a thread where a gentleman just finished adding it to his Boss. I like what I see/hear...

[nomedia="http://www.youtube.com/watch?v=RZoLHsOrd-o&feature=player_detailpage"]2012 Boss 302 with QTP Electric Exhaust Cutouts - YouTube[/nomedia]

Last edited:

looks like the cutout motors tuck up nicely, i was wondering if they would be hanging too much or not.

Thanks for the heads up. I did however, order up the Boss cutouts on Wednesday from QTP as well as their wireless remote kit. I also just picked up another die grinder for smoothing the holes I have to cut out of the factory H-pipe. My well used electric die grinder isn't variable speed and spins way too fast.

Hopefully nothing gets in my way this weekend. I really want to tie this thing together as much as I'll have to go back to add the cutouts whenever they arrive.

Hopefully nothing gets in my way this weekend. I really want to tie this thing together as much as I'll have to go back to add the cutouts whenever they arrive.

Last edited:

Nate does your kit require welding? Or do you just cut and clamp in pipes?

Tob this is turning out to be an awesome project. I wish you were closer, I really need to learn to weld

The y section will be welded in and the cutouts bolted to that.

Cool, so you just getting a local shop to weld them in?

I guess that's my best option since you can't weld.

I guess that's my best option since you can't weld.

LOL...talk about kicking a guy that is always there to lend a hand

I had some free time this afternoon so I tried to squeeze in as much as I could. I started by deciding what sections of the pipe I purchased would work. I bolted the quad pipes in place at the rear mount and then wired up the front section so that the pipes were pretty much located where they could stay, once done.

I then held up the pre-bent portion of pipe I purchased and marked where I saw the best fit, plus some more just so I wouldn't be short. I didn't measure anything but instead used my good eye . I then laid the pipe on my makeshift work table outside and sharpened up my cut marks. I used the cardboard roll that remains once all the tape it once had wrapped around it is gone to get a neat circumferential cut line.

. I then laid the pipe on my makeshift work table outside and sharpened up my cut marks. I used the cardboard roll that remains once all the tape it once had wrapped around it is gone to get a neat circumferential cut line.

As much as I could have pulled out my chop saw, I prefer to make the cuts by hand with a 4" grinder and a cut off disc.

I then pulled out my extra "H-pipe" section from Shelby Parts to use as a guide when scribing the pipe in order to cope it properly. I started with some "V" cuts made with the cut off disc and then shaped the pipe from there with my "Home Depot Special" air die grinder.

A slight bevel allowed for a really nice fit for the 2" to 2-1/2" joint...

I then slipped back under the car and marked where I had to trim the other end of the pipe. The following shows essentially what I'm doing under the car to the installed "H-pipe"...

I held the pipe where I felt best and traced around where I wanted to weld on the flanged stub sections.

I drilled a pilot hole concentric to the laid out hole and then used a 1-3/4" hole saw mounted in an 18v cordless drill...

While I had a 2" diameter hole saw, I elected not to use it. I wanted to leave some meat for minor adjustment and just cleaned up the hole with the die grinder once I knew exactly where I'd be adding the stub sections. I drilled at a fairly low rpm and used cutting oil as well. It worked better than I expected, being that stainless can be difficult to cut/drill sometimes.

Welding the pipe in, even if only some quick tacks, was a challenge as well. Not much room to maneuver my head and arms, plus holding the pipe where I wanted it to be and being able to weld wasn't that easy. I placed the necessary tacks to hold everything in place until I can unbolt the entire pipe from the exhaust manifolds/rear pipes and weld everything up on a table.

Family duties cut me short but I got started on the other side. Pretty much rinse, wash, repeat...

More later...

I then held up the pre-bent portion of pipe I purchased and marked where I saw the best fit, plus some more just so I wouldn't be short. I didn't measure anything but instead used my good eye

As much as I could have pulled out my chop saw, I prefer to make the cuts by hand with a 4" grinder and a cut off disc.

I then pulled out my extra "H-pipe" section from Shelby Parts to use as a guide when scribing the pipe in order to cope it properly. I started with some "V" cuts made with the cut off disc and then shaped the pipe from there with my "Home Depot Special" air die grinder.

A slight bevel allowed for a really nice fit for the 2" to 2-1/2" joint...

I then slipped back under the car and marked where I had to trim the other end of the pipe. The following shows essentially what I'm doing under the car to the installed "H-pipe"...

I held the pipe where I felt best and traced around where I wanted to weld on the flanged stub sections.

I drilled a pilot hole concentric to the laid out hole and then used a 1-3/4" hole saw mounted in an 18v cordless drill...

While I had a 2" diameter hole saw, I elected not to use it. I wanted to leave some meat for minor adjustment and just cleaned up the hole with the die grinder once I knew exactly where I'd be adding the stub sections. I drilled at a fairly low rpm and used cutting oil as well. It worked better than I expected, being that stainless can be difficult to cut/drill sometimes.

Welding the pipe in, even if only some quick tacks, was a challenge as well. Not much room to maneuver my head and arms, plus holding the pipe where I wanted it to be and being able to weld wasn't that easy. I placed the necessary tacks to hold everything in place until I can unbolt the entire pipe from the exhaust manifolds/rear pipes and weld everything up on a table.

Family duties cut me short but I got started on the other side. Pretty much rinse, wash, repeat...

More later...

Last edited:

subing, this is awesome!

nice progress!

Very interested, nice work by the way.

Users who are viewing this thread

Total: 7 (members: 0, guests: 7)