...

...

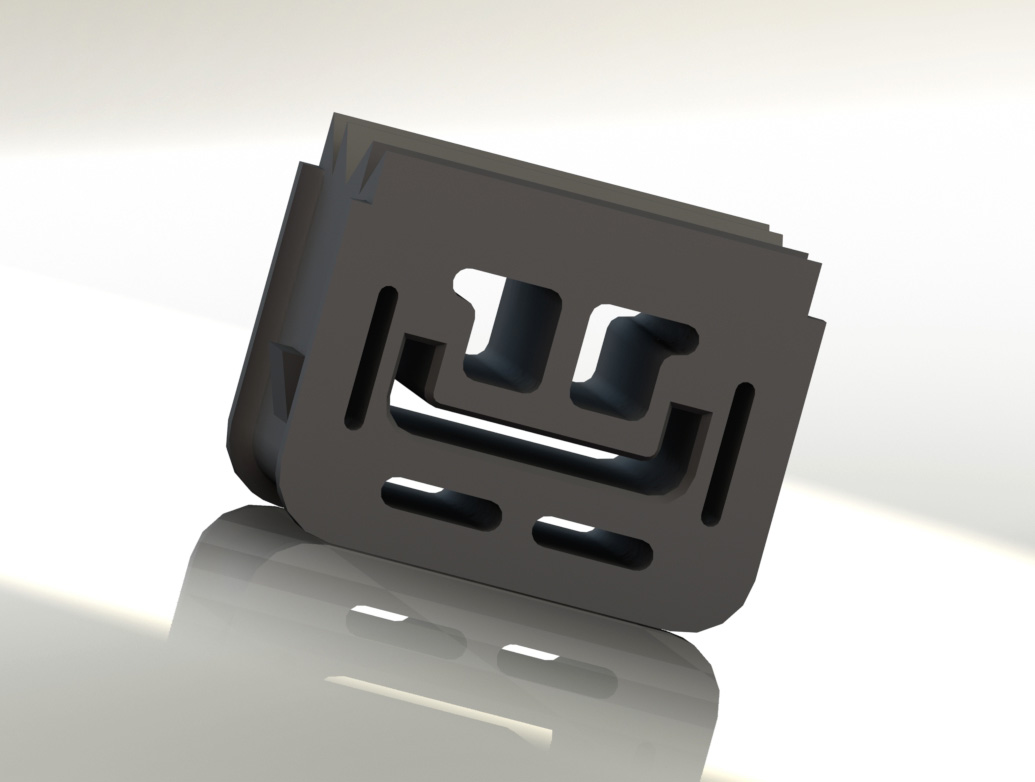

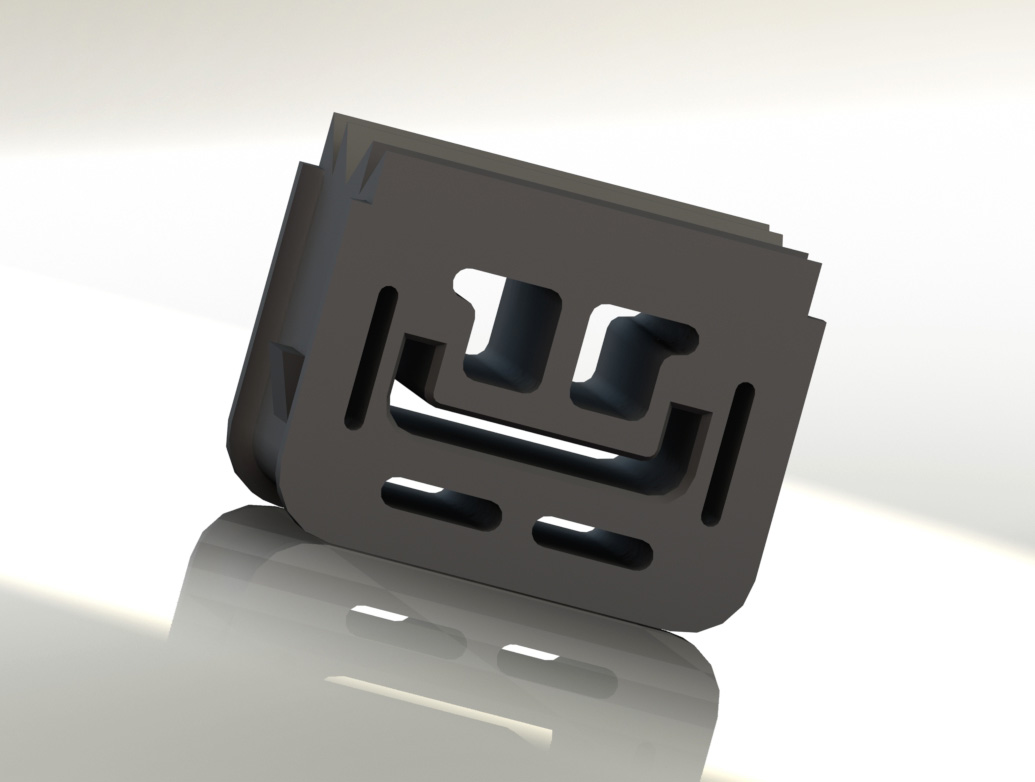

That looks really good, but I'm thinking some of those voids could be eliminated, or maybe all of them?

That could be a way to offer different stiffness levels?

...

...

...would this new bushing your are making TOB be stiffer than the KR style? which I what I have no on mine.

That looks really good, but I'm thinking some of those voids could be eliminated, or maybe all of them?

That could be a way to offer different stiffness levels?

Using a high durometer bushing connecting the shifter to the body structure might increase movement of the shifter in relation to the transmission due to the displacement of the engine-transmission from the torque of the engine. This may cause difficulty in shifting at high revs and power. Would a better option be to provide a third solid link from the shifter to the transmission eliminating the connection of the shifter to the body structure? I have installed the aluminum bushings on my stock shifter and I am very satisfied with the improved shifting. IMO the shifter should be isolated from the body structure to somewhat simulate the shifting mechanism of a T56.

While there is a bit of NVH associated the poly bushed motor mounts, it pretty much eliminates shifter movement when the engine torques over.

Tob,

Don't want to hijack your thread but couldn't the stiffness of the transmission bushing be increased by filling the voids with a hard adhesive. I believe that I am correct in that only the horizontal void that slips over the shifter extension is used.

Regards,

xxxx

rdanzy said:I am assuming that all of the rubber parts are removed and the shifter handle is bushed to fit the two bolts and then the handle is bolted to the shifter.

Sweet! Just placed my order for the front and rear set. Thanks Tob and Van for making this a reality! I wasn't ready to make the jump to a short throw shifter just yet... this should be the perfect upgrade to tighten things up.

+1. If I hadn't already gone the MGW path, I'd be all over both of these.Sweet! Thanks Tob and Van for making this a reality!

Thanks for all your work on this thread Tob!! Also, thanks to Van for listening and assisting. I put in my order yesterday with Van and will follow Tob's directions for my new set up. This is the right route for my needs--certainly for now.

Thanks for all your work on this thread Tob!! Also, thanks to Van for listening and assisting. I put in my order yesterday with Van and will follow Tob's directions for my new set up. This is the right route for my needs--certainly for now.

Just placed my order

The 10/11/12 shifter stub is indeed a perfect match in terms of mechanical advantage to that of the KR/SVT (Ford Racing) shifter. Physically, the two differ in that the stick mounting faces are 90* apart from one another. Other than that they are identical. Makes you wonder why you don't hear the same proportion of KR owners (or those that added the FRPP shifter) complaining about second gear grind as the 10/11/12 owners.

...I was wondering if the 90* rotation could affect the shift by inducing some twist especially with the stock lever which deflects quite a bit. You definitely notice it on the 07-09's having to "force" the lever into gear the last bit and if the 90* rotation does indeed add a twisting motion, it could cause even more havoc than forcing in the last bit.

Also Tob, have you noticed that on buyfordracing.com that the KR and SVT shifter have different shipping weights? I've wondered about that for quite some time... They are the same shifter so why the difference in weight?

Just my thoughts.