I'm getting a set of gt40p heads and I'm gonna ha e them port polished and machined. Does anything need to be milled down to fit with a heavier cam? K352463 is the can kit I got and 143116 for rocker kit from cjpony. Any help would be great!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gt40p head questions

- Thread starter CobraT_Type

- Start date

if you are installing P heads on a 5.0 you are going to need P specific headers due to the angle of the spark plug wires. Also make sure the springs are sufficient for the cam. What motor is in your car? Year model and engine model please.

I have a 95 with the 5.0

that cam kit you listed will not work with your car. Its listed as a flat tappet cam. Your going to need a hydraulic roller camshaft.

Ok well thanks for that catch, I didn't notice it. Is there any milling on the valve spring seats that need to be done?

I dunno, i remember reading that you may have to machine the seats OR you can buy springs from a place called Alex's springs or parts and they have springs specifically for P heads. Also if you have the stock 95 shortblock then the 274 cam may be a little big. I did research and the roller 270 is about the limit on a stock shortblock before you have piston to valve issues so ive read but im no expert so just do some research. check out corral.net it has ALOT of 5.0 information.

What kind of power levels are you looking for and whats your rough budget?

Id rather upgrade to a set of aluminum heads, even if it means eating Saltines and water for a few weeks.

Id rather upgrade to a set of aluminum heads, even if it means eating Saltines and water for a few weeks.

What kind of power levels are you looking for and whats your rough budget?

Id rather upgrade to a set of aluminum heads, even if it means eating Saltines and water for a few weeks.

x2 what he said! lol

I'm getting a set of gt40p heads and I'm gonna ha e them port polished and machined. Does anything need to be milled down to fit with a heavier cam? K352463 is the can kit I got and 143116 for rocker kit from cjpony. Any help would be great!

you need to check PTV clerance ( piston to valve ) clay the person. you can " notch" the pistons for more clerance. and you can always mill the head and or deck the block to get more compression stock compression was around 9 to 1 with stock heads. not sure what cc the heads are, if you can get the heads to a 54-58cc or 58cc to 61cc like trickflow heads etc you can get little more compression 9 8 to 1 or 10 to 1 get a little more power out of it. I to like others said would save $ and buy a set of aluminum heads or set of aluminum heads. more power .

However,

Crane makes a spring kit, 44308-1. As does Trick Flow, but I havent read any current reviews if they are any better than they used to be.

Alex"s parts springs: http://www.alexsparts.com/categories/FORD,-SMALL-BLOCK-302-HO-&-GT40P,-GT40/

Crane makes a spring kit, 44308-1. As does Trick Flow, but I havent read any current reviews if they are any better than they used to be.

Alex"s parts springs: http://www.alexsparts.com/categories/FORD,-SMALL-BLOCK-302-HO-&-GT40P,-GT40/

I used GT40P heads on my V8 Ranger. Fully ported with the Trick Flow Spring kit, OE style flat top pistons with 1605 compression height and the XE264XR-14 cam with 512 lift and 1.6 rockers. There was plenty of piston to valve clearance. The heads were milled a couple thousand but the block deck was stock. 58cc gave me approx. 9.25 compression. I love the combination, it makes a great daily driver and can get 22 MPG when it needs to.

I used GT40P heads on my V8 Ranger. Fully ported with the Trick Flow Spring kit, OE style flat top pistons with 1605 compression height and the XE264XR-14 cam with 512 lift and 1.6 rockers. There was plenty of piston to valve clearance. The heads were milled a couple thousand but the block deck was stock. 58cc gave me approx. 9.25 compression. I love the combination, it makes a great daily driver and can get 22 MPG when it needs to.

did you dyno it yet>?

did you dyno it yet>?

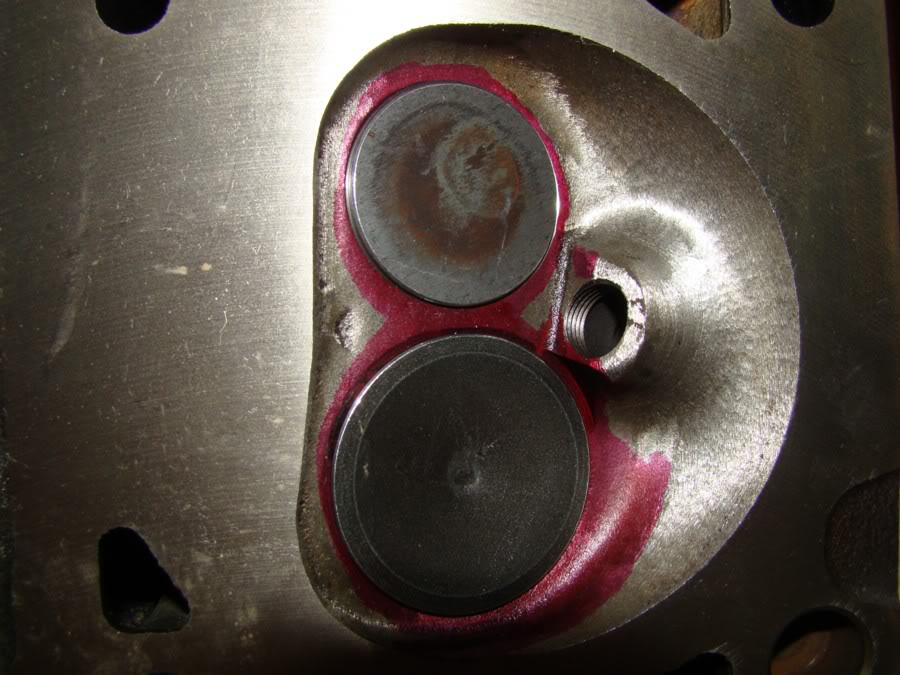

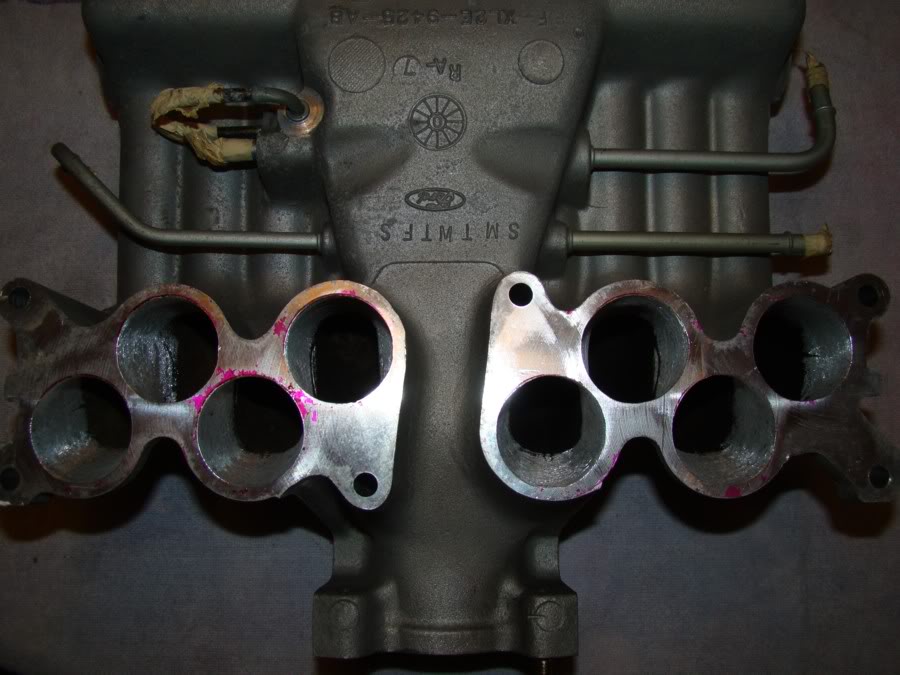

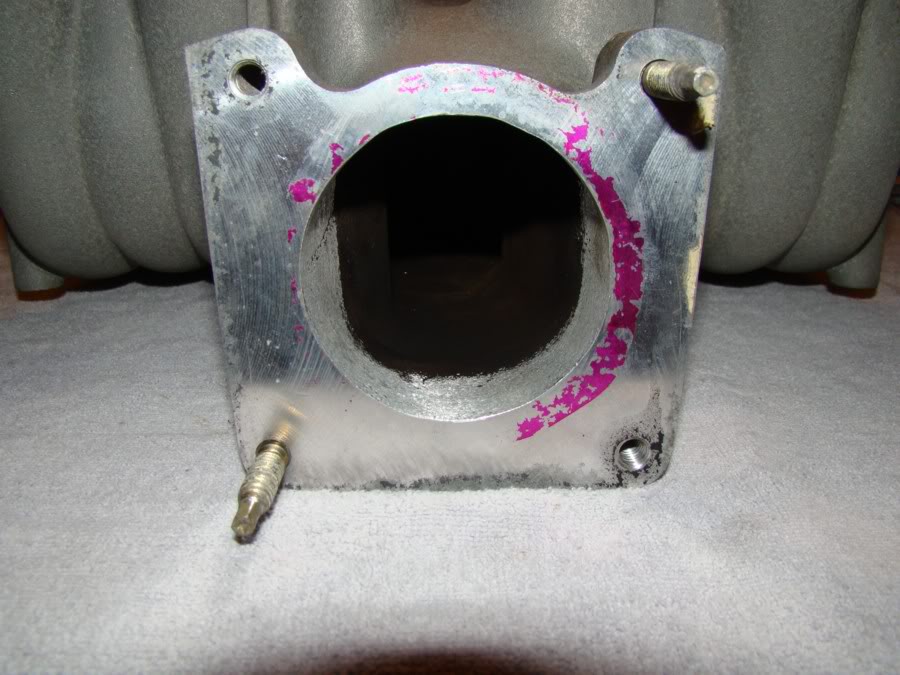

No, I really don't plan to have it dyno'ed. I had a custom mail order tune done and revised by data logging a few times. It is dialed in pretty nice for what it is. It is well mannered, drives consistent 8-10 hours a day without beating you to death and has plenty of stop light to stop light power. It isn't anything crazy but sure is a lot of fun. You can definitely tell a big difference from the stock 5.0 set up. An estimate on rwhp is probably 275 on the lowside and 295 on the highside. It is mostly OE style parts, everything is new but most of the time and money was spent on quality machine work and balancing everything down to +/- .5 of a gram. Here are a few photos and the basics on the head work.

1. Trim and knock down the valve guide bumps in both intake and exhaust bowls

2. Back-cut the intake valves for better flow

3. Widen the push rod pinches to gasket-match the intake ports

4. Rough edge cleanup on the bowl / Bowl Blending

5. Increase & smooth the short side radius in the intake port

6. Raise/lower the intake port floor

7. Gasket match the intake ports

8. 3 angle valve job

9. Surfaced

The upper was gasket match ported and the lower was completely ported the entire length of the runners as well as gasket matched on both ends.

Last edited:

No, I really don't plan to have it dyno'ed. I had a custom mail order tune done and revised by data logging a few times. It is dialed in pretty nice for what it is. It is well mannered, drives consistent 8-10 hours a day without beating you to death and has plenty of stop light to stop light power. It isn't anything crazy but sure is a lot of fun. You can definitely tell a big difference from the stock 5.0 set up. An estimate on rwhp is probably 275 on the lowside and 295 on the highside. It is mostly OE style parts, everything is new but most of the time and money was spent on quality machine work and balancing everything down to +/- .5 of a gram. Here are a few photos and the basics on the head work.

1. Trim and knock down the valve guide bumps in both intake and exhaust bowls

2. Back-cut the intake valves for better flow

3. Widen the push rod pinches to gasket-match the intake ports

4. Rough edge cleanup on the bowl / Bowl Blending

5. Increase & smooth the short side radius in the intake port

6. Raise/lower the intake port floor

7. Gasket match the intake ports

8. 3 angle valve job

9. Surfaced

The upper was gasket match ported and the lower was completely ported the entire length of the runners as well as gasket matched on both ends.

nice!

I wouldn't drop one penny into a set of GT40's, let alone GT40ps

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)