I have been thinking about buying a CNC plasma table for a number of years and the cost was crazy. I found a numbe rof resources online on how to build one but they all looked really ghetto. After alot of planning, I started and it took me close to 9 months but its worth it. I am building a modding a chassis and building a suspension for a 2004 Lightning. Its for a friend so he has been great with letting me take my time. All brackets here are cut on 1/4 plate.

[ame="http://www.youtube.com/watch?v=DjdbB_JS5gk"]YouTube- BC Lightning Lower Shock Tabs on Home Built CNC Plasma Table[/ame]

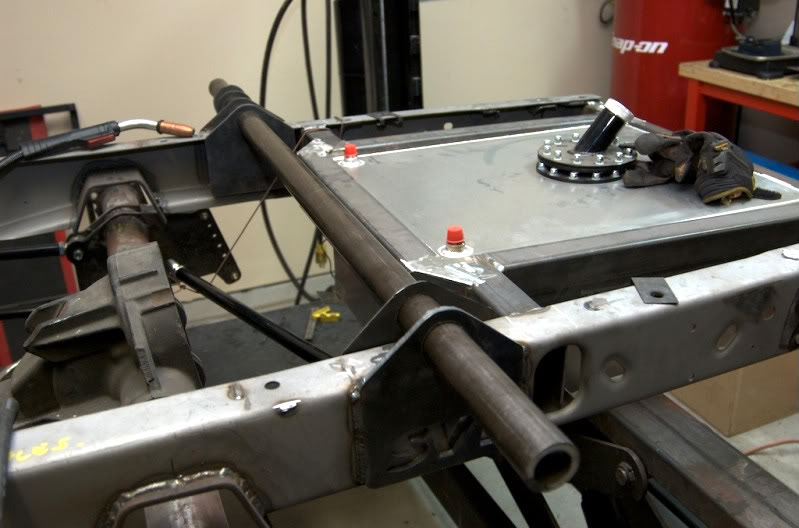

Here are some shots of his frame so far...

[ame="http://www.youtube.com/watch?v=DjdbB_JS5gk"]YouTube- BC Lightning Lower Shock Tabs on Home Built CNC Plasma Table[/ame]

Here are some shots of his frame so far...