I purchased a Whipple Monoblade so we could start supporting that TB on the Coyote platform, and hoped it would not suffer from the issues we see with the FRPP version.

The whipple unit came in without electronics so we purchased a new GT500 TB and gutted it for use on the Whipple. This makes the Whipple a little more expensive than the FRPP unit FYI.

Upon initial dyno hits the throttle performed as expected at WOT, but on decel she threw a wrench, just like we see with the FRPP units on occausion. After MUCH investigation we identified the problem.

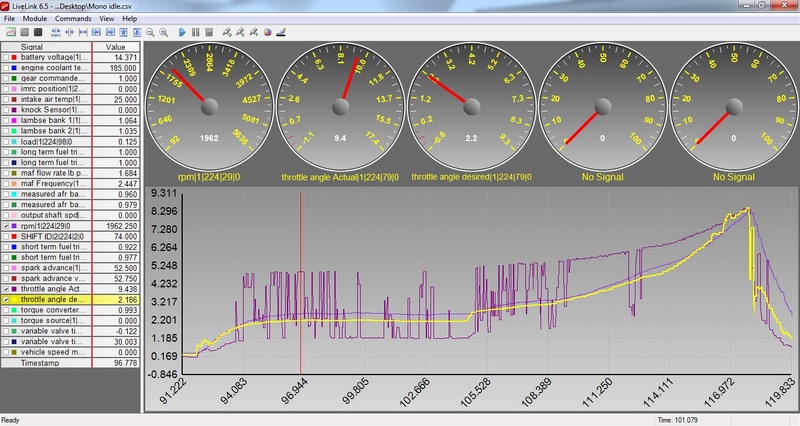

I was lucky enough to capture the problem in a data log. Below is a screen shot of it.

The 'soft' spring loaded idle stop holds the TB at 8 degrees when not in use. On a Coyote the TB tends to idle below 1 degree, which is virtually closed. In the log below Desired Throttle angle is smooth, going up with RPM, but Actual Throttle angle jumps from 1.x to 9 degrees. It's jumping because the blade is sticking in the throttle bore and the throttle motor is over compensating for the sticking blade. This is what causes the Wrench light.

So why is it sticking? I thuroughly inspected this TB before installation and it showed no signs of sticking, it operated as smooth as could be expected when opened by hand, yet when on the vehicle it sticks. In an attempt to 'break in' the TB I drove the car around for about an hour and she went into failsafe mode (wrench light) another 3 times, each time a KAM reset was required before the vehicle would restart. (2015+ TB wrenches act different than 11-14). FYI, 2015+ also throw different codes than the 11-14 for a sticking TB.

Back to the shop for more troubleshooting. A quick phone call to a Tuner buddy in FL shed some light on what was going on. When the TB is not installed it operates very smoothly, but once bolted to the manifold sometimes the Throttle housing will slightly distort causing the blade to bind in the bore at low throttle angle. So here is what we did (that worked):

1. Loosened the TB completely and re-bolted it to the manifold lightly. Just enough to keep the bolts tight and seal the TB but not torqued down hard.

2. Opened the TB and applied a very light/thin coat of grease to the throttle blade and housing on either side near the shaft. This area showed rubbing, which is normal.

Fired her back up and no more wrench issues, throttle angle actual vs desired are back to matching.

When the Mono is bolted to a GT500's it's mounted on a flat aluminum plate, but the SCJ manifold seems to be bowed out in the center of the throttle opening and puts force on the center of the TB, slightly distorting the housing and causing the blade/shaft to bind. Over time (driving) these TB's should 'break in' to their housings and you can later bolt them down harder. We've had a few customers who have simply driven the cars and cleared the wrench when it popped up and eventually the TB's stopped throwing a wrench.

So, take note. Not all Monoblades are faulty, they could simply be slightly bound up from torquing down onto the manifold.

The whipple unit came in without electronics so we purchased a new GT500 TB and gutted it for use on the Whipple. This makes the Whipple a little more expensive than the FRPP unit FYI.

Upon initial dyno hits the throttle performed as expected at WOT, but on decel she threw a wrench, just like we see with the FRPP units on occausion. After MUCH investigation we identified the problem.

I was lucky enough to capture the problem in a data log. Below is a screen shot of it.

The 'soft' spring loaded idle stop holds the TB at 8 degrees when not in use. On a Coyote the TB tends to idle below 1 degree, which is virtually closed. In the log below Desired Throttle angle is smooth, going up with RPM, but Actual Throttle angle jumps from 1.x to 9 degrees. It's jumping because the blade is sticking in the throttle bore and the throttle motor is over compensating for the sticking blade. This is what causes the Wrench light.

So why is it sticking? I thuroughly inspected this TB before installation and it showed no signs of sticking, it operated as smooth as could be expected when opened by hand, yet when on the vehicle it sticks. In an attempt to 'break in' the TB I drove the car around for about an hour and she went into failsafe mode (wrench light) another 3 times, each time a KAM reset was required before the vehicle would restart. (2015+ TB wrenches act different than 11-14). FYI, 2015+ also throw different codes than the 11-14 for a sticking TB.

Back to the shop for more troubleshooting. A quick phone call to a Tuner buddy in FL shed some light on what was going on. When the TB is not installed it operates very smoothly, but once bolted to the manifold sometimes the Throttle housing will slightly distort causing the blade to bind in the bore at low throttle angle. So here is what we did (that worked):

1. Loosened the TB completely and re-bolted it to the manifold lightly. Just enough to keep the bolts tight and seal the TB but not torqued down hard.

2. Opened the TB and applied a very light/thin coat of grease to the throttle blade and housing on either side near the shaft. This area showed rubbing, which is normal.

Fired her back up and no more wrench issues, throttle angle actual vs desired are back to matching.

When the Mono is bolted to a GT500's it's mounted on a flat aluminum plate, but the SCJ manifold seems to be bowed out in the center of the throttle opening and puts force on the center of the TB, slightly distorting the housing and causing the blade/shaft to bind. Over time (driving) these TB's should 'break in' to their housings and you can later bolt them down harder. We've had a few customers who have simply driven the cars and cleared the wrench when it popped up and eventually the TB's stopped throwing a wrench.

So, take note. Not all Monoblades are faulty, they could simply be slightly bound up from torquing down onto the manifold.