You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Self ported blower pic's and numbers

- Thread starter Posi

- Start date

My port progress

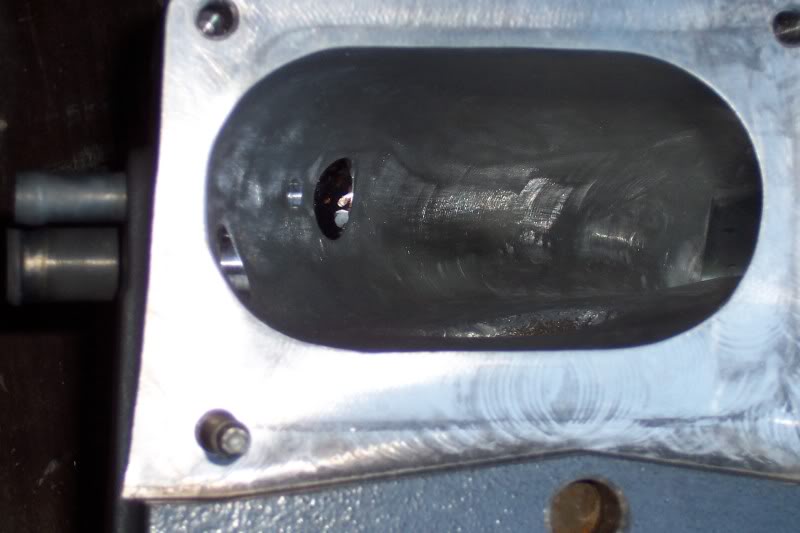

Heres a few pictures of my port. It already had some port work that was not done by me. This is my first time porting. What do you think of it so far? Im not done yet. I still have to work on it a bit more obviously. Are there any suggestions you might have?

Heres a few pictures of my port. It already had some port work that was not done by me. This is my first time porting. What do you think of it so far? Im not done yet. I still have to work on it a bit more obviously. Are there any suggestions you might have?

Here is where it broke through, Posi! I will use the tip you gave me to patch it unless you see where another measure needs to be taken.

Disregard the discoloration below it, all I can think is the flash made the oil I was using to keep the bit from gumming up shine. I had the oil everywhere LOL!

Disregard the discoloration below it, all I can think is the flash made the oil I was using to keep the bit from gumming up shine. I had the oil everywhere LOL!

Last edited:

What do you think of this for patch work?

http://www.permatex.com/documents/tds/Automotive/26346.pdf

http://www.permatex.com/products/au...ir/Permatex_Hi-Temp_Metal_Repair_Compound.htm

http://www.permatex.com/documents/tds/Automotive/26346.pdf

http://www.permatex.com/products/au...ir/Permatex_Hi-Temp_Metal_Repair_Compound.htm

what does it mean when people talk about welding the TB and plenum?

Also after looking at my plenum and thinking about porting I noticed there are some spots inside where it looks like if you were to port then your deff going to make holes. How much do you port a plenum?

Also after looking at my plenum and thinking about porting I noticed there are some spots inside where it looks like if you were to port then your deff going to make holes. How much do you port a plenum?

that's exactly what they mean by welding the plenum. If you round the curve out on the plenum you will expose a hole. They just weld up some material in this indention in the elbow and then port the inside, making a smooth transition from the TB to the blower inlet.

what does it mean when people talk about welding the TB and plenum?

Also after looking at my plenum and thinking about porting I noticed there are some spots inside where it looks like if you were to port then your deff going to make holes. How much do you port a plenum?

The large spots you can do some cutting on and actually quite a bit but you have to be careful. As you're cutting it you can feel underneath where your cutting to see if it's getting really hot or you can tap around with something to see how hollow the sound is getting.

I've done dyno testing on a welded plenum and a non-welded plenum and my car put out the same numbers with both of them on it. It was dyno'd with a 2.9/6lb combo on it too. If nothing shows up there then nothing is going to show up on an upper only car imo. Same day testing with the car staying strapped down on the dyno.:beer:

thanks man,

this will be my first time porting anything and like you suggested somewhere else Im going to practice first on the plenum. Ill be running a 2.76 upper and stock lower. Also I plan on using the design you put up in your post but I in no means am going to try to pass it off as my own. I will tell people I tried to copy your design. I cant wait man.

this will be my first time porting anything and like you suggested somewhere else Im going to practice first on the plenum. Ill be running a 2.76 upper and stock lower. Also I plan on using the design you put up in your post but I in no means am going to try to pass it off as my own. I will tell people I tried to copy your design. I cant wait man.

Great stuff!:rockon::beer:

Bump TTT

Bump TTT

I just finished porting mine. I have a thread over in Posi's thread under the vendor forums. I have a few pics of mine when it was roughed out. I'll try to get some pics and post up tomorrow. Next step for me is sanding and painting the blower. He says 12-15 hours and I wish I had logged my time spent, but I'd say that is pretty close to what I spent on it. The outlet is the easiest part. The inlet is where you will spend alot of time. Its really tight in there. Take your time and do it right.

added pics:

added pics:

Last edited:

Is it necessary to port the inlet?

What tool did you use to get into that tight of a space?

I used an electric die grinder. It is really tight. Just work slowly. An air die grinder would work better I think because they are smaller. I don't have a compressor though. I wanted to get my rotor leadins a little larger or closer to the sides but I couldn't with the size of the grinder I was using. You can do it. Just take your time. I bought a used blower to work on. So I wasn't in any hurry.

posi. have you ever done a m112 eaton. I could use some help,I bought a new take off for my gt500 for $200 so i thought i would try doing it myself. thanks

Users who are viewing this thread

Total: 11 (members: 0, guests: 11)