Can't wait to see the finished product done and some track times!! Keep up the good work!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sonic 600...my quest for a 600rw eaton combo. yes I said eaton

- Thread starter Freakingstang

- Start date

- Status

- Not open for further replies.

I had a stage 4 eaton with stock accufad set up, car did 527 540 on 17# with a maxed out exhaust mass air injectors and fuel pumps ... so I added a full 3 inch exhaust sct 3000 88 # injectors 10 an forward and 6 back new hst 2 455 pumps cpr rails whipple 2.3 gen 2 sbtb lighter rotors....add all that up ....I don't want to. Talk about it..... 17# 580 576.... and e 85 on 21# 697 710 ....alot of money for 50 hp.....oh and the eaton set up maxed out with a 55 shot did 585.... with the eaton set up I cound not hook up any less then 3rd gear 60 punch and now I hook up 2nd 40 ....same tires ....how dose that sound ?

I love the "outside the box" thinking going on! The ol doing more with less thing is nice to see these days, very cool. Can't wait to see this thing get finalized, and hearing eaton stories along the way.

I had a stage 4 eaton with stock accufad set up, car did 527 540 on 17# with a maxed out exhaust mass air injectors and fuel pumps ... so I added a full 3 inch exhaust sct 3000 88 # injectors 10 an forward and 6 back new hst 2 455 pumps cpr rails whipple 2.3 gen 2 sbtb lighter rotors....add all that up ....I don't want to. Talk about it..... 17# 580 576.... and e 85 on 21# 697 710 ....alot of money for 50 hp.....oh and the eaton set up maxed out with a 55 shot did 585.... with the eaton set up I cound not hook up any less then 3rd gear 60 punch and now I hook up 2nd 40 ....same tires ....how dose that sound ?

See, I've read up and done homework, and to me spending that much coin for 50-100 hp wasn't in the budget, or worth it to me if I had it. I have other projects and new fixer upper house that takes all my money...

People have shit on the eaton for years about being worthless heat makers... well, data log some 2.2 or 2.3 twin screw blowers sometime... it'll make the little "heaton" more impressive... The power comes on harder and sooner than in a normal twin screw, the little roots are very efficient blowers for what they are.... that's why yours would blow the tires off in 2nd and now it doesn't... unless you've hurt the motor in the process, I'd do a compression check if it was me. your E85 #'s are fantastic and if E was avaialbe here, I'd make the switch, but there are only two places within 80 miles and I drive my car too much.

another reason I haven't pursued this sooner was due to supporting mods... didn't want to dump all kinds of money in supporting mods for 50rwhp (on a ported setup to maximize it). well over the years, I've picked up parts here and there and now its just a mission.

almost have all the parts rounded up.. still waiting on one or two... more welding to finish the blower and new plenum up this week

Crazy awesome setup. Can't wait till it's done

Ready to see the results on this project!

Just to make sure I understand this project, I know your number goal for the eaton. But from the pics it appears you are trying to use the stock m112 case with the largest tbody/plenum/modified you can find as well as use the M122 rotors? And the m122 snout or the m112 snout?

I have a couple questions, why go through all the trouble with the rotors/snout? I know steg had a conversion setup and cobra engineering had a conversion kit to do this that I know wasn't extremely expensive ($6-700). That would have just left the port work and the tbody/plenum work.

Last question, who is doing that welding?

I have a couple questions, why go through all the trouble with the rotors/snout? I know steg had a conversion setup and cobra engineering had a conversion kit to do this that I know wasn't extremely expensive ($6-700). That would have just left the port work and the tbody/plenum work.

Last question, who is doing that welding?

A roots blower doesn't compress air. It moves air. It is a giant "blower". It can only flow as much air as it can take in.

I don't think this comment is entirely accurate... A roots blower does compress air! However as you increase rpm you don't compress the air more. Instead your only moving more air thru the rotors at a higher rate. Creating more boost pressure... Is this what you were meaning?

I don't think this comment is entirely accurate... A roots blower does compress air! However as you increase rpm you don't compress the air more. Instead your only moving more air thru the rotors at a higher rate. Creating more boost pressure... Is this what you were meaning?

No. Read up on roots blowers. They don't compress air at all. They move air. They are blowers, not compressors. The "boost " you see is the restriction or excess air that the motor can't use the blower is discharging more air than the valves can take into the cylinder.. It's a positive displacement blower or "fixed displacement". That means For every revolution the stock blower displaces 112 cubic inches of air. It doesn't matter how fast you spin it, or how slow. It only moves 112 cubic inches of air. Add a 2.76 pulley. It still moves 112 Cubic inches of air, but instead of the rotors spinning at 12,000 rpm impeller speed stock, they are spinning at 17,000 rpm with the smaller pulley. Because you are spinning it faster it is moving more air in the same about of time, so your boost goes up because it's more air than it was at a slow rpm and it's more of a restriction or more air not being used. Please read up on roots blowers, they are mechanical driven fans.

A box fan on low speed and high speed is a good example. You don't get compressed air from your box fan do you? There is more volume of air at a higher speed but not more pressure.. Because there is no restriction.

Think of an conventional Engine. A 281 cubic inch engine only displaces 281 cubic inches per power stroke.. Adding higher flowing intake or Heads doesn't make it a 302 cubic inch engine or revving it to 7k rpm instead of 3k rpm doesn't make it a 400 cubic inch motor...

Just to make sure I understand this project, I know your number goal for the eaton. But from the pics it appears you are trying to use the stock m112 case with the largest tbody/plenum/modified you can find as well as use the M122 rotors? And the m122 snout or the m112 snout?

I have a couple questions, why go through all the trouble with the rotors/snout? I know steg had a conversion setup and cobra engineering had a conversion kit to do this that I know wasn't extremely expensive ($6-700). That would have just left the port work and the tbody/plenum work.

Last question, who is doing that welding?

All of your questions were answered if you read anything I wrote. I'm guessing you just scrolled through the pictures. So here's cliff notes.

Basically the Stock blower case. Welded and opened to supply enough air for the larger 122 rotors.

Since the rotors are 3/4" longer than the stock 112 rotors, the 122 snout has to be used so the belt will line up.

Stegs conversion kit is the same thing as I'm doing. It's 500 bucks for the rotor spacer I made. It uses the stock 03/04 cobra case and the newer Shelby rotors. They don't produce the numbers because the stock case isn't capable of flowing the extra air the larger rotors need. To purchase this setup from steg you would have 500 in the conversion pieces, 750 for the port plus the cost of the rotors and snout. Last I checked they charged 800 for the gt500 core. So sending it to steg you're into it $2k minimum it it won't make anymore power than a posi ported stock blower

The cobra engineering adapter is totally different. It mounts the m122 Shelby blower onto the cobra motor. The blower needs machined to fit after buying the 800 dollar adapter (price has come down). Then you have to come up with your own plenum, and TB mount, then your cold air and the battery has to be moved to the trunk or the passenger side because the Shelly 122 has a driver side inlet which is opposite of the cobra.

I want it to remain stock looking. It's just a personal goal. Your question about why didn't you just buy X adapter, or X kit is how 95% of society is. Hot rodding isn't just buying what's readily available or what everyone else is doing.

I am doing the welding. It is aluminum stick welding. It works and is effective but it's not pretty like tig welding. Since it is being ground and machined, the appearance during the process doesn't matter. Welding cast aluminum is not an easy thing for most welders to do. Also By using stick aluminum Rod, I don't have to preheat the case and run the risk of warping like I would if I was using a tig and had to preheat it with a torch.

Last edited:

Basically the Stock blower case. Welded and opened to supply enough air for the larger 122 rotors.

Since the rotors are 3/4" longer than the stock 112 rotors, the 122 snout has to be used so the belt will line up.

Stegs conversion kit is the same thing as I'm doing. It's 500 bucks for the rotor spacer I made. It uses the stock 03/04 cobra case and the newer Shelby rotors. They don't produce the numbers because the stock case isn't capable of flowing the extra air the larger rotors need. To purchase this setup from steg you would have 500 in the conversion pieces, 750 for the port plus the cost of the rotors and snout. Last I checked they charged 800 for the gt500 core. So sending it to steg you're into it $2k minimum it it won't make anymore power than a posi ported stock blower.

My hats off to you brother for forging a path that most of us don't have the skills, talent or ability to. I have been following this thread with a lot of interest and hope that it pays off in the form of bigger numbers and, more importantly, a stout driver.

My question for you is when you say " They don't produce the numbers because the stock case isn't capable of flowing the extra air the larger rotors need" is that primarily because of the inlet restriction that you modified?

The reason I ask is that I have the Magnusun MP112 (Tork Tech) which has a different rear inlet that is much larger than the cobra eaton and I am wondering if I would benefit from this modification (M122 rotors, spacer, snout, port). Either way, carry on my friend and I will keep watching this for updates and thanks for not only doing the work but taking the time to share it (and answer questions) with us all. Cheers!

Last edited:

My hats off to you brother for forging a path that most of us don't have the skills, talent or ability to. I have been following this thread with a lot of interest and hope that it pays off in the form of bigger numbers and, more importantly, a stout driver.

My question for you is when you say " They don't produce the numbers because the stock case isn't capable of flowing the extra air the larger rotors need" is that primarily because of the inlet restriction that you modified?

The reason I ask is that I have the Magnusun MP112 (Tork Tech) which has a different rear inlet that is much larger than the cobra eaton and I am wondering if I would benefit from this modification (M122 rotors, spacer, snout, port). Either way, carry on my friend and I will keep watching this for updates and thanks for not only doing the work but taking the time to share it (and answer questions) with us all. Cheers!

Sorry for the Delay in a response, this week was miserable and stupid busy with work. wasn't home from work before midnight one day this week.

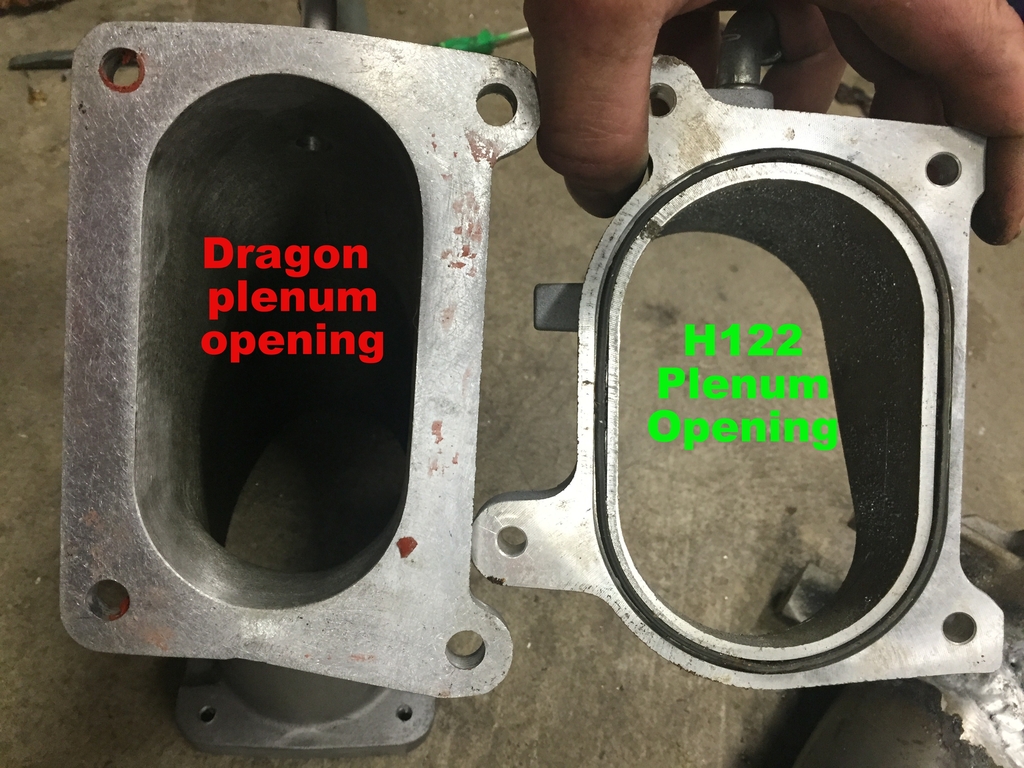

The Hybrid blowers that I've seen only made 540ish. There has only been three over the last couple of years posted here or otherwise. A posi port with 4/2.76 will hit those numbers, so why spend all the time and money to do that hybrid setup? The H122 complete blower from the shelby on our cars make 550ish stock, ported 580-620. That is because the case volume and the inlet is so much larger to Feed the larger rotors. So, this is why I added extra material to my bastard child to make the opening as large as physically possible. Look at the 2.3 TVS VMP. The opening is easily double the size of even the H122 blower, I have a couple VMP plenums I can post pics of size difference.

I'm not familiar with the maggy's, but if you have a large inlet and a large tb/plenum to feed it, then you might very well benefit from the H122 rotors. There a few things you'd have to do to the discharge to make the swap worthwhile. I wouldn't just thrown them in a "stock" or as cast case. you would be taking it from a 1.8L blower to a 2.0L blower.

And thanks, that's my goal is to have a stout driver and maybe a low 10 second street car. lots of other things need done to accomplish that goal as well.

Last edited:

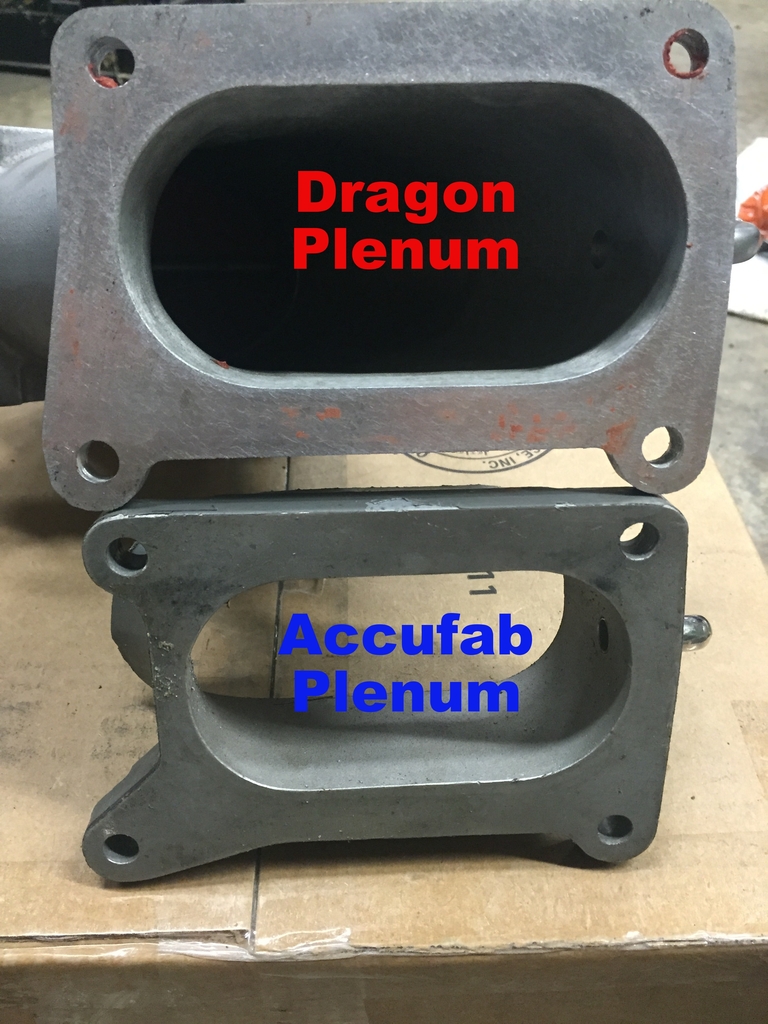

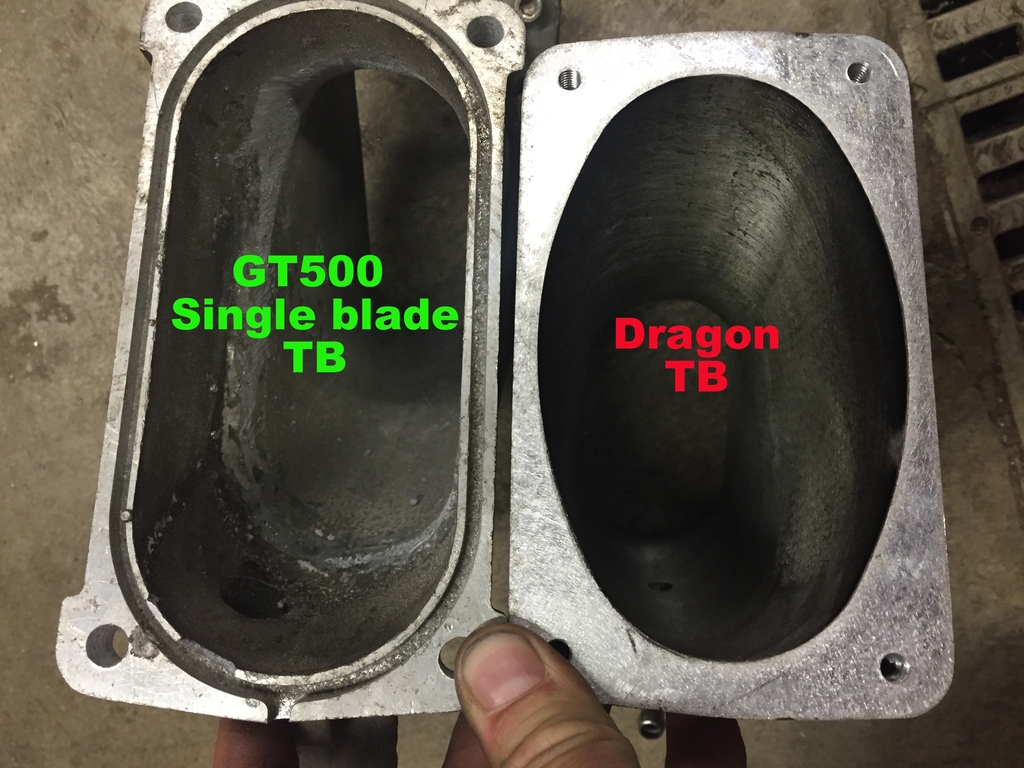

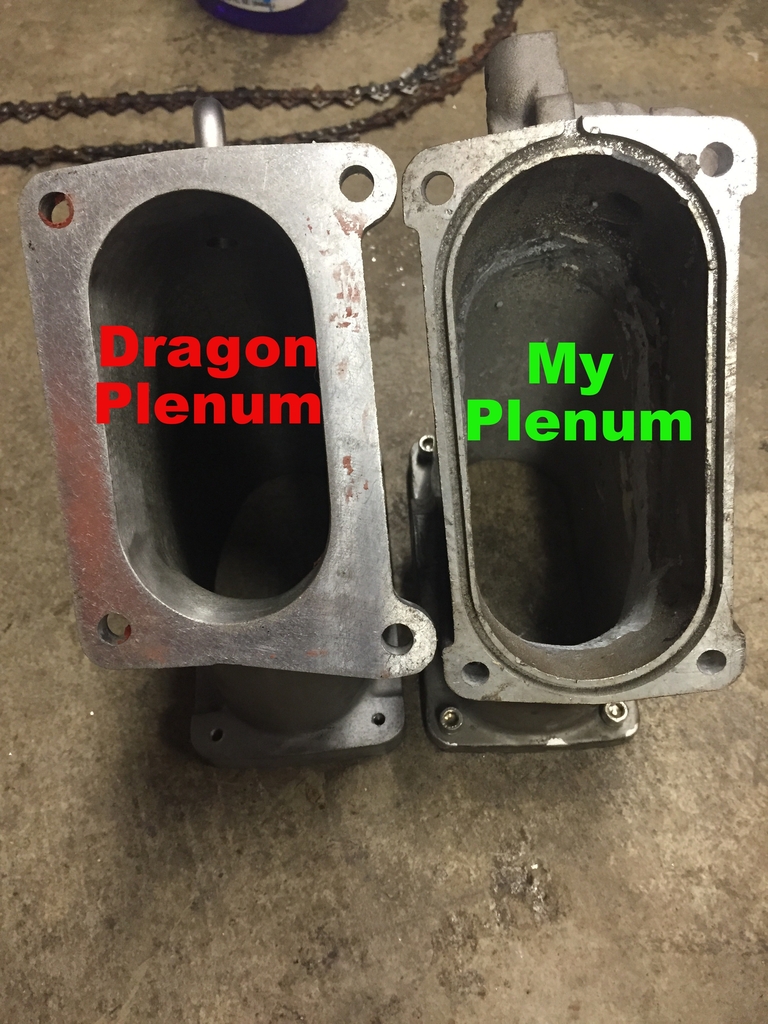

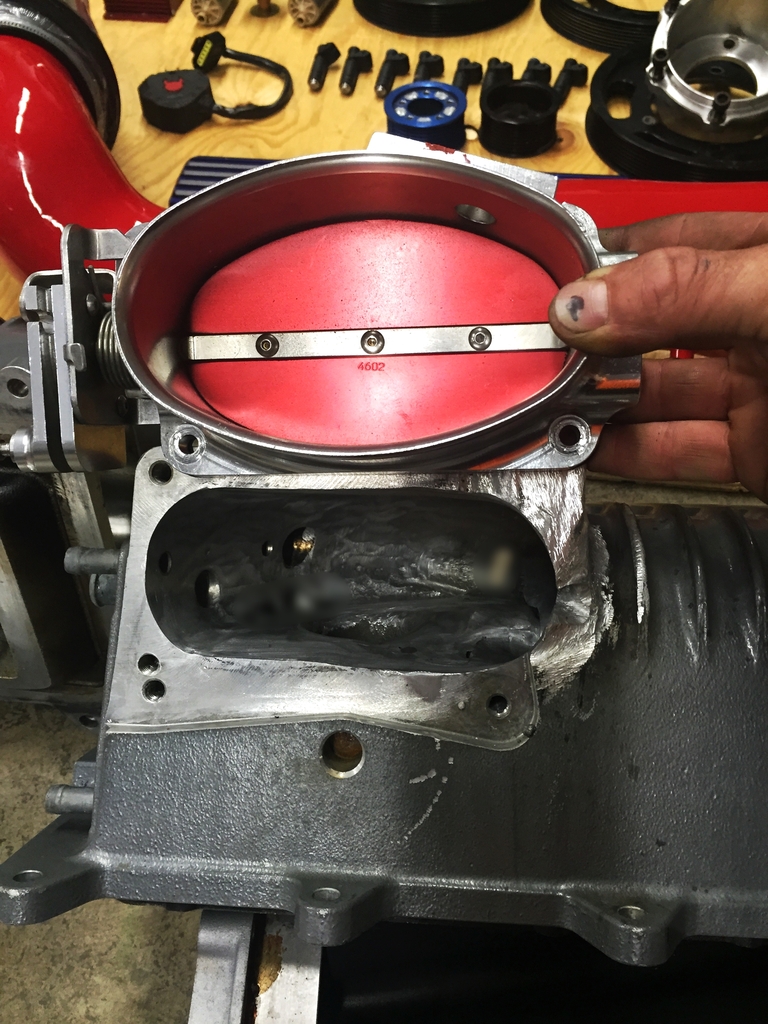

Not much progress this week on welding, with the busy work I had this week. I did get a dragon TB and plenum to add to the mix.

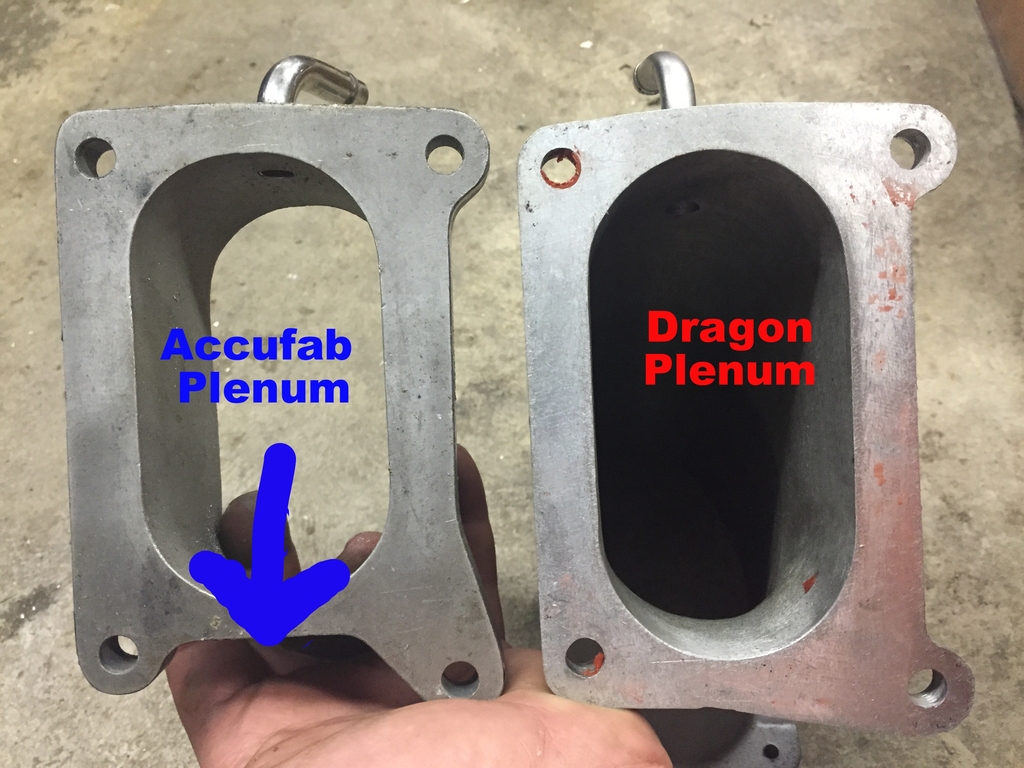

The reason the Dragon TB and plunum make power power is due to the plenum. The accufab stops just at the edge of the opining, where as the dragon goes all the way to the blower case... dragon plenum on top, accufab on bottom

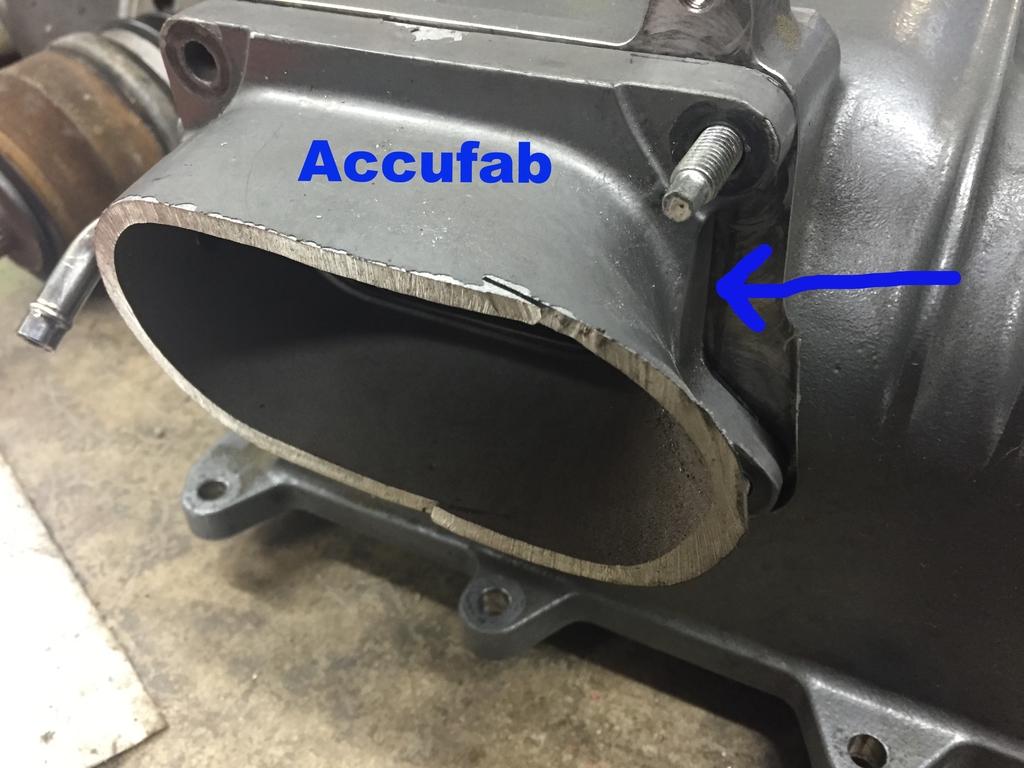

Accufab against the blower case

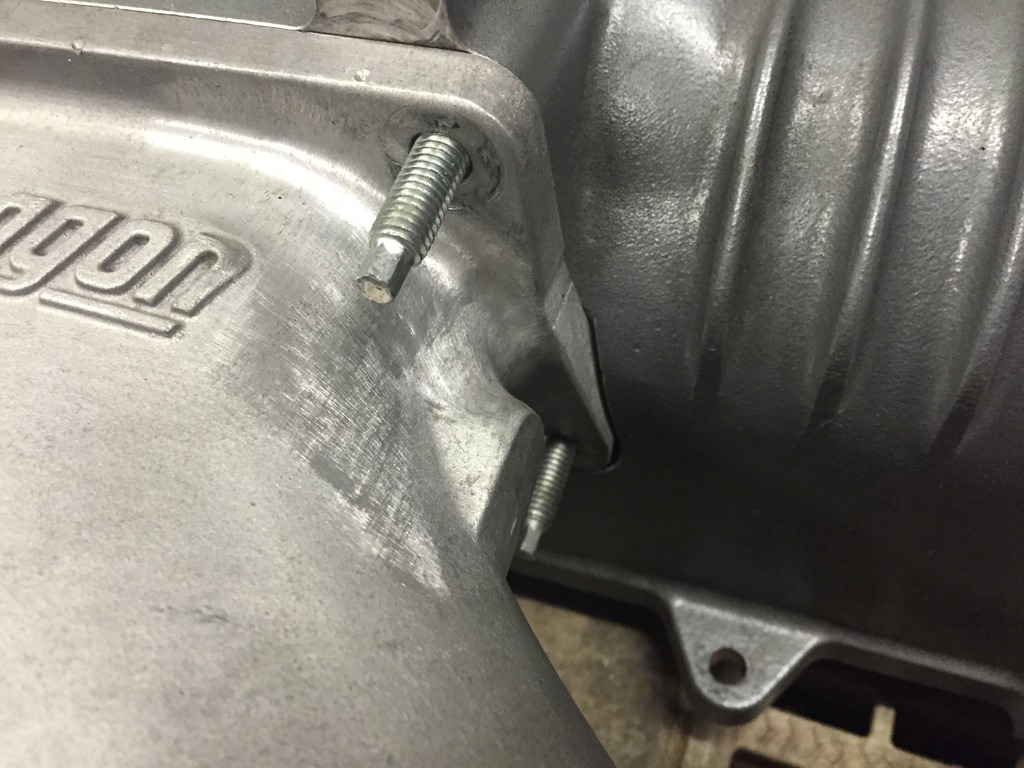

dragon against the blower case

more pics..

And last pic for now, the dragon plenum against my cut case...

The reason the Dragon TB and plunum make power power is due to the plenum. The accufab stops just at the edge of the opining, where as the dragon goes all the way to the blower case... dragon plenum on top, accufab on bottom

Accufab against the blower case

dragon against the blower case

more pics..

And last pic for now, the dragon plenum against my cut case...

I would light my car on fire if I spent $4K on a blower and made 26hp more than a posi race port with an upper and lower on 93. That's another reason for this build. 20 degrees of timing is low. pretty muh standard timing is 23 degrees for an eaton equipped car.

What's your advice if a car makes no more power on 21+* than on 17* timing?

Yeah. This isn't for the weak at heart. It wasn't a cheap venture by anymeans and wouldn't be cost effective for anyone looking to buy this setup.

M112 blower. 250-400 used

H122 blower 250-500 used

Accufab plenum 100-150 used

H122 plenum 50-250 used

Paying someone to make a rotor spacer, 200

Paying someone to port it. 5-700

Paying someone to weld it. ???? 5-1k?

Doin it myself and having a buddy give me a case, another buddy giving me his old Shelby blower...

I'm in it time, welding materials and 40 bucks in aluminum stock..

So for those not doing it themselves expect $3,200 on the high end? Makes bolting on a TS sound pretty tempting.

AWESOME.. Very few have. What was your fuel system. I plan on keeping it return for this year but want to spray a 100-125 on top of it.

If you achieve your hp #'s as hoping, get ready for main cap walking on much less than the amount of N20 you plan on administering.

part of the reason I attempted this years ago because people just went and bought bigger blowers instead of doing some homework and research, also part of keeping the stockish look.

See 2 quotes above regarding price.

I know steg had a conversion setup and cobra engineering had a conversion kit to do this that I know wasn't extremely expensive ($6-700). That would have just left the port work and the tbody/plenum work.

Any the reason it never too off is because even with the lengthened case and extra inlet work the gain for the cost wasn't cost effective.

Hey, don't be such a downer. Let the man cobble his frankenblower together and have his "its alive" moment would ya?

Hey, don't be such a downer. Let the man cobble his frankenblower together and have his "its alive" moment would ya?

I admire his ingenuity, hard work, and hope all his dreams come true. I'm also and Eaton fan. I'm merely pointing out the obvious and trying to wrap my head around the timing comment.

Probably a good idea to put the village on alert and keep the torches handy in case frankenblower turns out to be a monster!

;-)

;-)

Probably a good idea to put the village on alert and keep the torches handy in case frankenblower turns out to be a monster!

;-)

I like the Franken blower comment

The tvs is a deal with all things considered. There's a reason it's so popular and makes huge numbers. As far as the power comment not sure what to say to that. Haven't seen one make the same power on 21* as 17*. I also haven't seen one less than 600 without having an loose converter auto skewing the numbers.

I'm more worried about the stock Pistons on a hundred shot than crank walk. The tune will have to be spot on and room for error.

Looking forward to seeing the final numbers nice work:thumbsup:

Have you considered changing the internal gears like the Stieg Snakebite setup to spin it harder?

Have you considered changing the internal gears like the Stieg Snakebite setup to spin it harder?

Looking forward to seeing the final numbers nice work:thumbsup:

Have you considered changing the internal gears like the Stieg Snakebite setup to spin it harder?

Not really.. I have a 4 and 6 lb lower, as well as a 2.65, 2.80 and 2.93 upper to play with to see what it will like. I imagine it will be quite the screamer. Going to go with the 6lb/2.93 setup to start with

- Status

- Not open for further replies.

Users who are viewing this thread

Total: 8 (members: 0, guests: 8)