Hey Guys, so I read a lot about guys switching to teksid blocks and it's always a no brainer post. Swapped blocks lol. I assume it's because most have a shop or builder of sorts do it for them so they're unaware of what all went into the swap. In the process myself and here's what I've noticed so far and would like some feed back how some of it was tackled by those who've done this swap. Got a few pics too for those interested in just looking at the differences.

Black block is my stock 03 Cobra block

Aluminum colored block is the teksid

Front of the two

The teksid

The stock

Rear of two blocks

Rear of the teksid. Notice the shape of the rear plate is different. Make sure you get the rear plate from the teksid

Stock block

Teksid block has these two knock sensor bosses sticking up on top. The lower intake will not fit with them there. From what I gather you can just grind them down with an angle grinder and fix that issue.

The stock block valley area for reference

Nipple behind water pump on block on stock block has two orings and a slip type fit

Teksid had a barbed type fitting which you can see here smashed. I tried knocking it out with a block of wood and a hammer and just crushed it. Going to have to do more delicate surgery to get it out. Probably some heat and cut that mangled end off and possibly even drill it out.

Stock block has this extra bolt hole right by the driver's side motor mount that does not exist on the teksid block. Not a big deal but I had my J&S Vampire attached there. I will need to find a new place on the teksid.

The same view on the teksid for reference

Stock block has two shafts sticking out where the chain tensioners pivot. They are thicker than the threaded holes on the teksid block... assuming these are threaded on and not pressed on. I really don't know right now.

Same view on teksid. I know it's hard to tell in pics but the same holes on this block where those two shafts stick out are much smaller threaded holes.

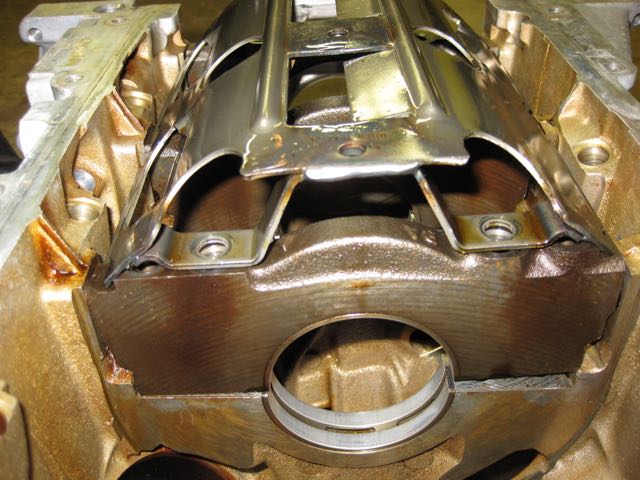

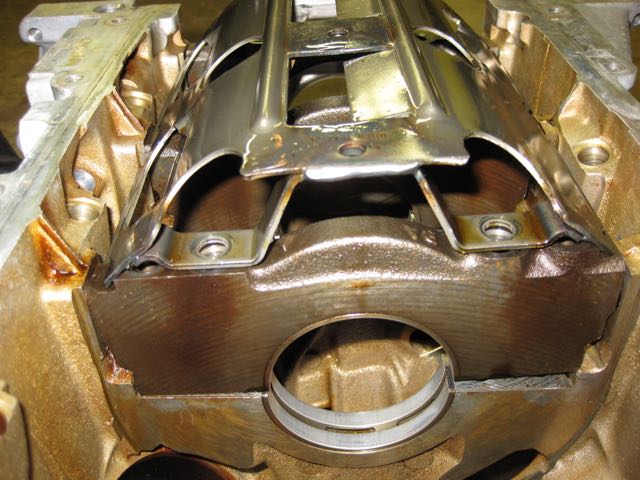

Stock block has 4 bolt mains.

Teksid has 6 bolt mains. So different design. Won't be able to reuse my ARP main studs. Get new ones.

Teksid mains on the left. Stock on the right.

Different side bolts into the mains. Stock on left and teksid on right

Stock mains have this threaded end that you use an allen wrench to back out and pressure against the side of the block.

Teksid mains just have a thread in the side of the caps

Instead the teksid has the threaded pieces built into the block itself.

Back side where you can see the threads.

This timing bolt hole on the teksid block is in a different spot

Same bolt hole on the stock block.

As a result this hole on the timing cover has no where to thread into. Looks like a solid piece of block I can just drill and tap a thread into. Easy fix it seems.

Passenger's side of teksid for reference

Passenger's side of stock block for reference

Due to difference in main caps the stock windage tray no longer fits. It would have to be all cut up to make space for the extra bolts on the teksid

Perhaps some factory teksid blocked cars came with a windage tray and I just need to pick up one of those?

Any feedback on dealing with the differences is greatly appreciated.

Malcolm

Black block is my stock 03 Cobra block

Aluminum colored block is the teksid

Front of the two

The teksid

The stock

Rear of two blocks

Rear of the teksid. Notice the shape of the rear plate is different. Make sure you get the rear plate from the teksid

Stock block

Teksid block has these two knock sensor bosses sticking up on top. The lower intake will not fit with them there. From what I gather you can just grind them down with an angle grinder and fix that issue.

The stock block valley area for reference

Nipple behind water pump on block on stock block has two orings and a slip type fit

Teksid had a barbed type fitting which you can see here smashed. I tried knocking it out with a block of wood and a hammer and just crushed it. Going to have to do more delicate surgery to get it out. Probably some heat and cut that mangled end off and possibly even drill it out.

Stock block has this extra bolt hole right by the driver's side motor mount that does not exist on the teksid block. Not a big deal but I had my J&S Vampire attached there. I will need to find a new place on the teksid.

The same view on the teksid for reference

Stock block has two shafts sticking out where the chain tensioners pivot. They are thicker than the threaded holes on the teksid block... assuming these are threaded on and not pressed on. I really don't know right now.

Same view on teksid. I know it's hard to tell in pics but the same holes on this block where those two shafts stick out are much smaller threaded holes.

Stock block has 4 bolt mains.

Teksid has 6 bolt mains. So different design. Won't be able to reuse my ARP main studs. Get new ones.

Teksid mains on the left. Stock on the right.

Different side bolts into the mains. Stock on left and teksid on right

Stock mains have this threaded end that you use an allen wrench to back out and pressure against the side of the block.

Teksid mains just have a thread in the side of the caps

Instead the teksid has the threaded pieces built into the block itself.

Back side where you can see the threads.

This timing bolt hole on the teksid block is in a different spot

Same bolt hole on the stock block.

As a result this hole on the timing cover has no where to thread into. Looks like a solid piece of block I can just drill and tap a thread into. Easy fix it seems.

Passenger's side of teksid for reference

Passenger's side of stock block for reference

Due to difference in main caps the stock windage tray no longer fits. It would have to be all cut up to make space for the extra bolts on the teksid

Perhaps some factory teksid blocked cars came with a windage tray and I just need to pick up one of those?

Any feedback on dealing with the differences is greatly appreciated.

Malcolm