Good job man. I love your write ups.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Retrofitting a '13 GT500 carbon fiber driveshaft to an '07-'12 GT500

- Thread starter Tob

- Start date

Brother, I'm doing my best to juggle family, work, moderating, and projects such as this. No different than most I suppose. The weather may get up to 40 within a week so that shouldn't be holding me back for long either.

Hopefully, it'll be done by next weekend. But I've got a big brake kit coming from Bruce at FTBR that'll have me tearing things apart again. Oh well. I simply hope it works well.

Were you interested in a flange?

Hopefully, it'll be done by next weekend. But I've got a big brake kit coming from Bruce at FTBR that'll have me tearing things apart again. Oh well. I simply hope it works well.

Were you interested in a flange?

Brother, I'm doing my best to juggle family, work, moderating, and projects such as this. No different than most I suppose. The weather may get up to 40 within a week so that shouldn't be holding me back for long either.

Hopefully, it'll be done by next weekend. But I've got a big brake kit coming from Bruce at FTBR that'll have me tearing things apart again. Oh well. I simply hope it works well.

Were you interested in a flange?

LOL - Never ends huh?

I'm just interested to see the work and hear your thoughts, by DSS has held up to near 1000 whp, so I'm a "if it ain't broke don't fix it guy"

Never ends is right!

Which DSS shaft are you using?

it was on the car when I got it from sfadchi, but I believe it to be this one:

The Driveshaft Shop | FORD 05-11 Mustang Shelby 6-Speed 1-Piece Aluminum Shaft CV 900HP (no clearance issues) - Ford - Domestic Driveshafts

DSS said:Custom conversion plate (corrosion plated) to change from the stock Ford CV to our 108mm version

I read the entire page but I'm still not clear - is the 108mm 'version' DSS uses a different diameter than the factory CV joint?

DSS said:...with the CV in the rear there is no need to change pinion angle on lowered cars.

I've seen this elsewhere. While it is comforting to hear, I can't help but wonder if durability is still affected by 'substantial' pinion angles. There has to be more friction as misalignment is increased. But again, I do feel better what with a CV joint at each end of the '13 shaft in concert with mention that pinion angle isn't an issue.

Looking back, it's been a long road. A lot of research, planning, and quite a bit of field work. I must have been under the car 25 or 30 times for this one. This is one custom mod that I did not want to fail.

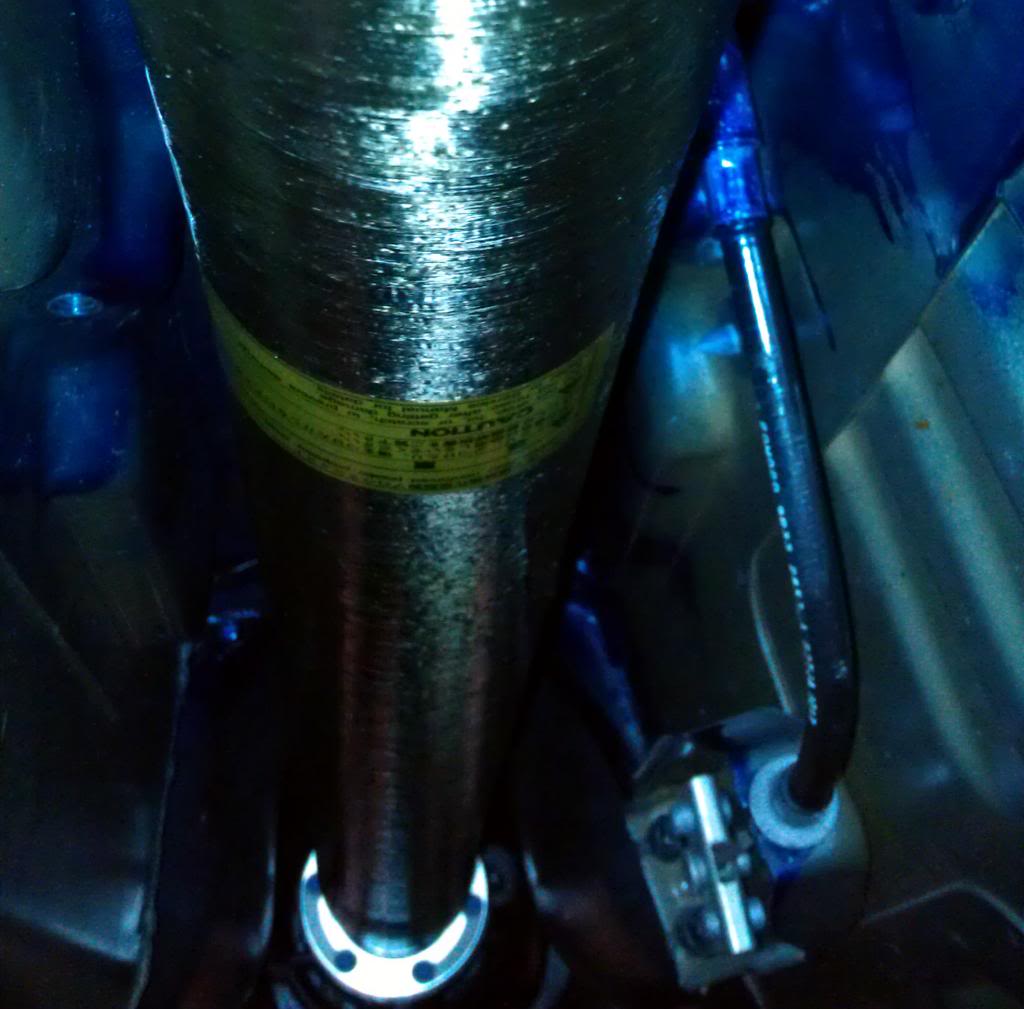

I'm happy to report that with the adapter and flange in place that the factory 2013 GT500 carbon fiber driveshaft fits like a glove. After torquing the new output shaft nut in place I laid a protective layer of cardboard atop the exhaust system and then carefully slipped the shaft into the tunnel, starting from the rear moving forward. I slipped the rear CV joint into the pinion flange at the axle and then put a couple of bolts in so that it couldn't slip out. I then moved to the front joint. It was easy to compress the CV joint enough to allow it to fit into the custom flange up front.

I then torqued the bolts at the front, using the factory 'paired' washers that I pillaged from the original steel driveshaft.

I then torqued all new factory Ford hardware at the rear of the shaft. All of this was done with the axle at simulated ride height. I did not have to lower the axle in order to get the shaft into place. So I moved to checking clearances.

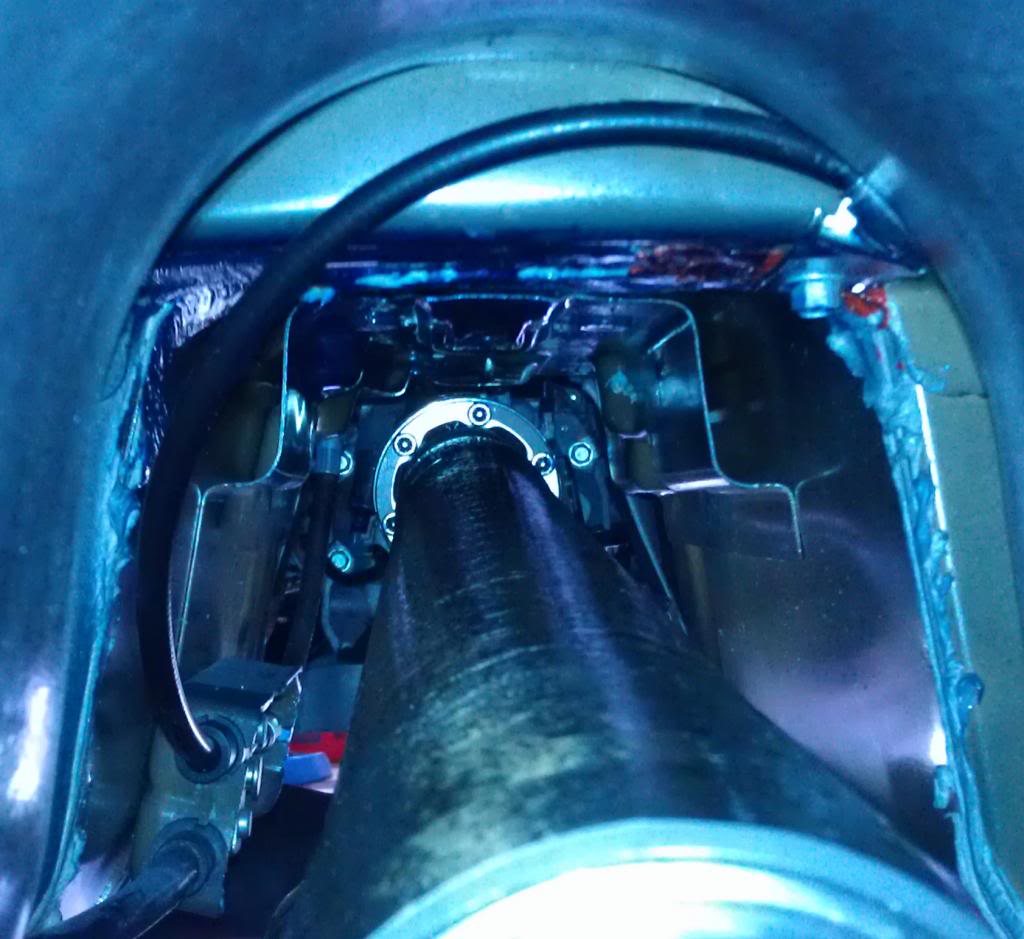

Atop the shaft, from the rear looking forward, at normal ride height...

Below the shaft, from the rear looking forward, at normal ride height...

I was beyond giddy. So I elevated the rear axle, compressing the bumpstops until they started to lift the car off of the jack stands...

Mid-shaft, looking rearward...

Beneath the fixed flange at the transmission, I shifted to the gap between the body/tunnel and the driveshaft on the passenger side, looking rearward...

Same direction, except I shifted over to show the gap on the driver side...

Because I couldn't get my phone or Canon Rebel XT between the top of the shaft and the tunnel, I resorted to my Milwaukee ColonCam to verify clearances, as well as sliding my hand atop the driveshaft from one end to the other...

Nothing less than an inch and a half all the way with the suspension compressed on factory bumpstops. Well, there was one point where I measured about an inch. It was right where the transmission tunnel tapers down aft of the shifter. Not a concern, as it is very near the start (or pivot point) of the shaft. A 1/8" worth of shaft movement at the front yields something like an 1" of clearance at the axle end.

Fits like a glove.

So I'll no longer need:

The bolts at the front U-joint or the bolts/spacers at the carrier...

The heavy ring at the OE flange...

Or this marvel of engineering from FoMoCo...

It will now live out its life atop a shelf at the back of the shop.

I'd be road testing but I don't have any seats in the vehicle right now and have just started my FTBR braking upgrade. But I am very pleased with the results to date.

I'm happy to report that with the adapter and flange in place that the factory 2013 GT500 carbon fiber driveshaft fits like a glove. After torquing the new output shaft nut in place I laid a protective layer of cardboard atop the exhaust system and then carefully slipped the shaft into the tunnel, starting from the rear moving forward. I slipped the rear CV joint into the pinion flange at the axle and then put a couple of bolts in so that it couldn't slip out. I then moved to the front joint. It was easy to compress the CV joint enough to allow it to fit into the custom flange up front.

I then torqued the bolts at the front, using the factory 'paired' washers that I pillaged from the original steel driveshaft.

I then torqued all new factory Ford hardware at the rear of the shaft. All of this was done with the axle at simulated ride height. I did not have to lower the axle in order to get the shaft into place. So I moved to checking clearances.

Atop the shaft, from the rear looking forward, at normal ride height...

Below the shaft, from the rear looking forward, at normal ride height...

I was beyond giddy. So I elevated the rear axle, compressing the bumpstops until they started to lift the car off of the jack stands...

Mid-shaft, looking rearward...

Beneath the fixed flange at the transmission, I shifted to the gap between the body/tunnel and the driveshaft on the passenger side, looking rearward...

Same direction, except I shifted over to show the gap on the driver side...

Because I couldn't get my phone or Canon Rebel XT between the top of the shaft and the tunnel, I resorted to my Milwaukee ColonCam to verify clearances, as well as sliding my hand atop the driveshaft from one end to the other...

Nothing less than an inch and a half all the way with the suspension compressed on factory bumpstops. Well, there was one point where I measured about an inch. It was right where the transmission tunnel tapers down aft of the shifter. Not a concern, as it is very near the start (or pivot point) of the shaft. A 1/8" worth of shaft movement at the front yields something like an 1" of clearance at the axle end.

Fits like a glove.

So I'll no longer need:

The bolts at the front U-joint or the bolts/spacers at the carrier...

The heavy ring at the OE flange...

Or this marvel of engineering from FoMoCo...

It will now live out its life atop a shelf at the back of the shop.

I'd be road testing but I don't have any seats in the vehicle right now and have just started my FTBR braking upgrade. But I am very pleased with the results to date.

F'N sweet man. Just as a curiosity, about how much (counting profit) do you think it would cost for your guy to make another flange?

Well, this has never been about turning a profit for me or even the machinist that did these. It was done more out of angst with Ford for not making this one available. Angst (or displeasure) because I knew what I was being told wasn't completely forthcoming. Ford Racing has been very tight lipped about this one but the information I was able to glean proved to be incorrect - in a general sense, anyway. So I moved on to Tremec and spoke with some very knowledgeable people there. I found that the necessary flange in order to make this happen actually existed, a '13 cup with an early spline count.

Problem is, Tremec isn't in the aftermarket business to sell flanges to allow factory driveshaft swapping. And for whatever reason, FRPP has shied away (for now, anyhow). If I can fill that niche because nobody else wants to, I'll do my best. I'll have to talk to Travis about it first. For now, let me road test to further verify the positive results to date. If everything passes the test I'll try to collect a list of names and see what we can do regarding price. That's the best I can do.

Before then, anyone interested may want to check with a Ford Parts vendor, such as Tousley, for the best price on the OEM '13/'14 CF shaft. There are a few companies that sell aftermarket CF shaft kits for less money than if you choose this route. But I think I've made the case as to why this way may be the best.

Problem is, Tremec isn't in the aftermarket business to sell flanges to allow factory driveshaft swapping. And for whatever reason, FRPP has shied away (for now, anyhow). If I can fill that niche because nobody else wants to, I'll do my best. I'll have to talk to Travis about it first. For now, let me road test to further verify the positive results to date. If everything passes the test I'll try to collect a list of names and see what we can do regarding price. That's the best I can do.

Before then, anyone interested may want to check with a Ford Parts vendor, such as Tousley, for the best price on the OEM '13/'14 CF shaft. There are a few companies that sell aftermarket CF shaft kits for less money than if you choose this route. But I think I've made the case as to why this way may be the best.

I agree wholeheartedly that the OEM piece is superior to any aftermarket piece. I get harmonic vibrations out of my stock driveshaft at about 165-170 mph and I'd love to quell them with this driveshaft.

Thanks for the update.

What was the total weight reduction vs. the stocker?

Two+ pounds at the flange an d another 14.4 at the shaft. So the total weight savings is ~17lbs.

Looks good Tob.

Why not just throw your OEM set in to drive it?

Ugh. It isn't moving until the seats are done. It is so much easier to remove/replace them when the car is elevated.

Anytime, Ron.Thanks for the update.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)